The classical theory of electrical conductivity of metals originated at the beginning of the twentieth century. Its founder was the German physicist Karl Rikke. He experimentally established that the passage of a charge through a metal does not involve the transfer of conductor atoms, unlike liquid electrolytes. However, this discovery did not explain what exactly is the carrier of electrical impulses in the metal structure.

The experiments of scientists Stewart and Tolman, conducted in 1916, allowed us to answer this question. They were able to establish that the smallest charged particles - electrons - are responsible for the transfer of electricity in metals. This discovery formed the basis of the classical electronic theory of electrical conductivity of metals. From this moment on, a new era of research into metal conductors began. Thanks to the results obtained, today we have the opportunity to use household appliances, production equipment, machines and many other devices.

Gold

Gold is a good electrical conductor and does not oxidize like other metals when exposed to air. For example, steel or copper can oxidize (corrode) when exposed to oxygen for long periods of time. Gold is one of the most expensive metals and is only used for certain materials, such as circuit board components or small electrical connectors. Some materials may have gold plating as a conductor.

How does the electrical conductivity of different metals differ?

The electronic theory of electrical conductivity of metals was developed in the research of Paul Drude. He was able to discover such a property as resistance, which is observed when electric current passes through a conductor. In the future, this will make it possible to classify different substances according to their conductivity level. From the results obtained, it is easy to understand which metal is suitable for the manufacture of a particular cable. This is a very important point, since incorrectly selected material can cause a fire as a result of overheating from the passage of excess voltage current.

Silver metal has the highest electrical conductivity. At a temperature of +20 degrees Celsius, it is 63.3 * 104 centimeters-1. But making wiring from silver is very expensive, since it is a rather rare metal, which is used mainly for the production of jewelry and decorative items or bullion coins.

The metal with the highest electrical conductivity among all elements of the base group is copper. Its indicator is 57*104 centimeters-1 at a temperature of +20 degrees Celsius. Copper is one of the most common conductors used for household and industrial purposes. It withstands constant electrical loads well, is durable and reliable. The high melting point allows you to work for a long time in a heated state without problems.

What is an electrical conductor? Definition and types of electrical conductors

Definition: A conductor is a type of metal that allows electric current to pass through it. An electrical conductor is usually made up of metals such as copper, aluminum and their alloys. In an electrical conductor, electrical charges move from atom to atom when a potential difference is applied to them. Electrical conductors are used in the form of wire. The choice of conductor can be taken into account by considering various factors such as tensile strength, fatigue strength, corona loss, local conditions and cost.

The electrical wire that is used to transmit energy is usually multi-stranded. Stranded conductors have greater flexibility and mechanical strength compared to a single wire of the same cross-section. In a stranded wire, usually a central wire is surrounded by successive layers of wires containing 6, 12, 18, 24,... wires.

The size of a conductor is determined by the equivalent cross-sectional area of the copper and the number of strands with the diameter of each strand. The equivalent cross-sectional area of a stranded conductor is the cross-sectional area of a solid conductor of the same material and length as the stranded wire. And also a conductor that has the same resistance at the same temperature.

Types of Electrical Wires

Rigid-drawn copper, hard-drawn aluminum conductors, and steel-core aluminum conductors are most often used in the power generation industry. Some of the important types of conductors are described in detail below.

Rigidly drawn copper conductor

This type of wire provides high tensile strength. It has high electrical conductivity, long service life and high scrap value. It is most suitable for distribution work where the spans and outlets are larger.

Cadmium copper conductor

The tensile strength of copper is increased by about 50 percent by adding 0.7 to 1.0 percent cadmium to it, but their conductivity is reduced by about 15 to 17 percent. The property of higher tensile strength allows the conductor to be erected over longer spans with the same deflection. This conductor has the advantages of easy connection, greater weather resistance, better wear resistance, easy machinability, etc.

The temperature at which copper anneals and softens also increases, and the effect of temperature on stress is less. Changes in sag due to changes in load and temperature are minimized.

Steel Core Copper Conductor (SCC)

In a steel-core copper conductor, one or two layers of copper strands surround the steel-core copper conductors. Steel core increases tensile strength.

Copper welded wire

In this type of conductor, uniform layers of copper are welded to a steel wire. The electrical conductivity of a welded copper conductor varies from 30 to 60 percent compared to a solid copper conductor of the same diameter. These types of wires can be used over longer distances, such as when crossing a river.

Rigidly drawn aluminum conductor or all aluminum conductor

The cost of a copper conductor is very high, so it is replaced with aluminum. Processing, transportation and installation of aluminum wires becomes very economical. It is used in distribution lines in urban areas and short power lines with lower voltages.

Aluminum conductor reinforced with steel

All aluminum conductors do not have sufficient mechanical strength for the construction of long-span lines. This lack of strength can be compensated for by adding a steel core to the conductor. This type of conductor is called steel core aluminum conductor (SCA) or steel core reinforced aluminum conductor (ACSR).

ACSR wire has seven steel strands forming a central core, around which are two layers of 30 aluminum strands. The wire strand is defined as 30 Al / 7 St. ACSR conductors have high tensile strength and are lightweight, so they are used for low deflection.

ACSR Plain Wire

This type of conductor is also called compacted ACSR. Conventional ACSR wire is pressed through dies to give the aluminum strands a segmented shape. The interstrand space is filled and the diameter of the conductor is reduced without affecting its electrical and mechanical properties. This conductor can be made with different ratios of aluminum to steel. The figure below shows a conductor with a ratio of 6 Al / 1 St.

.

Advanced ACSR Explorer

To reduce losses due to corona discharge and radio interference at high voltage, fibrous or plastic material is filled between the threads. The diameter of the conductor increases due to the filler, which is why it is called an expanded conductor. These conductors consist of a paper material that separates the inner aluminum conductors from the outer steel ones.

Aluminum alloy conductor

This type of wire is most often used in urban environments. This conductor has a good combination of conductivity and tensile strength. One of the alloys that are used to make such a conductor is Silmalec. This alloy contains 0.5% silicon, 0.5% magnesium and the rest aluminum. These alloys are very expensive because they are heat treated.

ACAR Explorer

Reinforced aluminum conductor

has a central aluminum alloy core surrounded by layers of conductive aluminum. This conductor gives better conductivity at a specific gravity equal to ACSR construction of the same diameter.

Aluminum welded conductor

Aluminum powder is welded to high-strength steel wire. About 75% of the conductor area is covered with aluminum. It is more expensive than silicon core wire. A ground wire was used to make the cores of the SCA wires.

Phosphor bronze conductor

Phosphor bronze is used as a conductive material over very long distances, such as river crossings. It is stronger than copper conductor, but has low conductivity. This conductor is superior to aluminum bronze conductor for environments containing harmful gases such as ammonia.

Galvanized steel conductor

Galvanized steel cable has high tensile strength. They are used in very long spans and in rural areas where the load is light. In such cases, the steel conductors may be replaced with a steel core conductor to cope with the additional load in the future. This conductor has high resistance, inductance and voltage drop. But it has a short lifespan compared to other conductors.

.

Classical conduction model

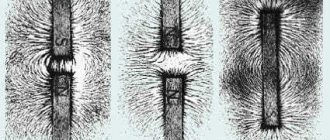

Without an external electric field, electrons undergo thermal chaotic movements, colliding with each other and also colliding with ions of the crystal lattice. As a result of such movement, the average position of the electrons practically does not change (see Fig. 1).

Rice. 1. An example of the trajectory of an electron during its chaotic thermal motion in a metal

Due to quantum effects, and in particular the Pauli exclusion principle, which prevents all electrons from occupying the lowest energy state, the average speed of electrons in metals, associated with their chaotic thermal motion, is greater than the speed of particles in a classical ideal gas. same temperature. It is about 10 m/s.

If an electric voltage U is applied to the ends of a conductor of length L , an electric field with intensity E = U / L

Under the influence of this external field, according to the second law of dynamics, electrons are accelerated: a = F / m ,

where F = e*E is the force with which the electric field acts on an electron with a charge. Thus, the acceleration of the electron is: a = e*E / m .

The accelerated motion of an electron lasts only a fairly short time until it collides with an ion in the crystal lattice. As a result of such a collision, the electron loses almost all of its kinetic energy. However, the slowed down electron does not remain at rest - it is again accelerated under the influence of the electric field, again collides with one of the ions from the crystal lattice, etc. This effect adds to the speed of thermal movements an additional directional average speed u , which, due to the negative charge of the electron, has a direction opposite to the strength of the external electric field. This speed is called the average drift speed (Fig. 2).

Rice. 2. Electron drift under the influence of an external electric field

An electric current with current strength I (see Figure 3).

Rice. 3. Drifting electrons collide with ions of the crystal lattice

Assuming that the electron's motion is uniformly accelerated between collisions with lattice ions, with acceleration a = e*E / m , and assuming that as a result of the collision the electron transfers all its kinetic energy to the crystal lattice, we can calculate the speed that the electron develops in its free movement: v = a*τ . In this formula, τ is the average time interval between subsequent collisions of a drifting electron with ions of the crystal lattice.

Since with uniformly accelerated motion without an initial speed, the average speed is the arithmetic mean of the initial (equal to zero) and final speed, we obtain: u = v / 2 = e*E*τ / 2*m .

From the resulting formula it follows that the drift speed, in addition to the external electric field, is determined by the average time interval between collisions of electrons with lattice ions. This parameter depends on many factors (including temperature, crystalline structure of the metal, defects in the crystalline structure, impurities) and, as it turns out, significantly affects the electrical resistance of the material.

The average drift velocity of electrons is about 10-4 m/s. It is very small compared to the speed of thermal movement, which is about 106 m/s.

The classical theory of conductivity describes the phenomenon of electrical conductivity in metals quite well. However, this theory cannot explain the experimentally observed dependence of electrical resistance on temperature.

The reason for the mentioned failure of the classical theory of conductivity is that it does not take into account the influence of lattice ions on the movement of electrons between collisions. More realistic results are provided by quantum conduction theory, which describes electrons as particles subject to quantum statistics, moving in a periodic electric field created by positive ions in the lattice.

Unit

The SI unit of electrical conductivity σ is: [σ] = 1 S/m (Siemens per meter).

These units are defined by the formula G = σ * S / l. If we solve this formula in accordance with σ, we get σ = G * l / S.

The unit of electrical conductivity G is given as: [G] = 1 / σ = 1 Sm (Siemens, international designation: S).

If we now enter all the units of measurement into the formula, we get:

[σ] = 1 cm * 1 m/m2 = 1 cm/m .

You will also be more likely to use units of cm/cm, m/ohm*mm2 or cm*m/mm2. You can convert individual measured variables like this: cm/cm = cm/10-2 m and like this: m/ohm * mm2 = cm * m/mm2 = cm * m/10-3 m * 10-3 m = 106 cm/ m.

Where does the current come from?

It should be noted that electric current can be generated not only in a metal conductor, but also in other substances. For example, atmospheric energy appears in rain clouds, but it is not possible to use it. Coils of copper generator sets are ideal for generating electricity used for household needs.

Electric current in metals is created by the ordered movement of electrons. The term “Electricity” was first introduced by William Gilbert in the 16th century, but the natural scientist limited himself to producing electrical discharges of static electricity. Two centuries later, Michael Faraday had already created a working model of a dynamo , the birth of which was due precisely to the effect of the formation of electricity in metals.

The scientist improved a previously known physical experiment in which a current in metals was created by the movement of a magnetic field around a static metal object. The first generator was a structure consisting of a rotating permanent magnet and a copper coil. Such a machine made it possible to obtain a relatively small voltage in the conductor. At that time, it was not yet known for certain what particles created current in metals. Only in 1913 did scientists manage to prove the electronic nature of this phenomenon.

Experiments to determine the causes of stress in metals were started by Russian scientists L. I. Mandelstam and N. D. Papaleksi. After 3 years, physicists R. Tolman and B. Stewart significantly improved the technique, which made it possible to carry out quantitative measurements.

To obtain accurate results, scientists had to create special machines, thanks to the use of which they were able to determine the cause of the current. If we briefly summarize the essence of the experiments carried out to prove the electronic nature of the appearance of current, we will get a summary of the following content:

- It is necessary to prepare a coil that can rotate around its axis.

- Place the product on a hard surface, such as the floor.

- Connect the output of the conductors of this electrical machine to a galvanometer.

- Spin the coil (the rotation speed should be significant).

- Brake the device sharply.

As a result of the experiment, an electrical impulse arises, which can be recorded by a measuring device. The appearance of voltage in the circuit could only be caused by the presence of charged particles called electrons. These elements are affected, like any solid body, by the force of inertia, which forces them to “come out” of the conductor after the coil suddenly stops.

Electrical conductivity of wood

The ability to conduct electric current characterizes the electrical resistance of wood. In general, the total resistance of a wood sample placed between two electrodes is determined as the result of two resistances: volumetric and surface. Volume resistance numerically characterizes the obstacle to the passage of current through the thickness of the sample, and surface resistance determines the obstacle to the passage of current along the surface of the sample. Indicators of electrical resistance are volumetric and surface resistivity. The first of these indicators has the dimension ohm per centimeter (ohm x cm) and is numerically equal to the resistance when current passes through two opposite faces of a cube measuring 1X1X1 cm made of a given material (wood). The second indicator is measured in ohms and is numerically equal to the resistance of a square of any size on the surface of a wood sample when current is supplied to the electrodes delimiting two opposite sides of this square. Electrical conductivity depends on the type of wood and the direction of current movement. As an illustration of the order of magnitude of volumetric and surface resistance in Table. 22 shows some data.

Table 22. Comparative data on the specific volumetric and surface resistance of wood.

| Breed and direction | Humidity, % | Specific volume resistivity, ohm x cm | Specific surface resistance, ohm |

| Birch, along the grain | 8,2 | 4.2 x 1010 | 4.0 x 1011 |

| Birch, across the grain | 8,0 | 8.6 x 1011 | 2.8 x 1012 |

| Beech, along the grain | 9,2 | 1.7 x 109 | 9.4 x 1010 |

| Beech, across the grain | 8,3 | 1.4 x 1010 | 7.9 x 1010 |

To characterize electrical conductivity, volumetric resistivity is of greatest importance. Resistance is highly dependent on the moisture content of the wood. As the moisture content of wood increases, the resistance decreases. A particularly sharp decrease in resistance is observed with an increase in the content of bound moisture from an absolutely dry state to the hygroscopic limit. In this case, the volumetric resistivity decreases by millions of times. A further increase in humidity causes a drop in resistance only tenfold. This is illustrated by the data in Table. 24.

Table 23. Specific volumetric resistivity of wood in an absolutely dry state.

| Breed | Specific volume resistivity, ohm x cm | |

| across the grain | along the grain | |

| Pine | 2.3 x 1015 | 1.8 x 1015 |

| Spruce | 7.6 x 1016 | 3.8 x 1016 |

| Ash | 3.3 x 1016 | 3.8 x 1015 |

| Hornbeam | 8.0 x 1016 | 1.3 x 1015 |

| Maple | 6.6 x 1017 | 3.3 x 1017 |

| Birch | 5.1 x 1016 | 2.3 x 1016 |

| Alder | 1.0 x 1017 | 9.6 x 1015 |

| Linden | 1.5 x 1016 | 6.4 x 1015 |

| Aspen | 1.7 x 1016 | 8.0 x 1015 |

Table 24. Effect of humidity on the electrical resistance of wood.

| Breed | Specific volume resistivity (ohm x cm) across the grain at wood moisture content (%) | ||

| 22 | 100 | ||

| Cedar | 2.5 x 1014 | 2.7 x 106 | 1.8 x 105 |

| Larch | 8.6 x 1013 | 6.6 x 106 | 2.0 x 105 |

The surface resistance of wood also decreases significantly with increasing humidity. An increase in temperature leads to a decrease in the volumetric resistance of wood. Thus, the resistance of false sugi wood decreases by 2.5 times when the temperature rises from 22-23° to 44-45° C (about half), and the resistance of beech wood decreases by 3 times when the temperature rises from 20-21° to 50° C. At negative temperatures, the volumetric resistance of wood increases. The specific volumetric resistance along the fibers of birch samples with a humidity of 76% at a temperature of 0°C was 1.2 x 107 ohm cm, and when cooled to a temperature of -24°C it turned out to be equal to 1.02 x 108 ohm cm. Impregnation of wood with mineral antiseptics (for example , zinc chloride) reduces the resistivity, while impregnation with creosote has little effect on the electrical conductivity. The electrical conductivity of wood is of practical importance when it is used for communication poles, masts of high-voltage transmission lines, handles of power tools, etc. In addition, the design of electric moisture meters is based on the dependence of electrical conductivity on the moisture content of wood.

What is electrical conductivity? (with picture)

Electrical conductivity (EC) is a property used to describe how well materials allow electrons to flow. It is determined through experiments and mathematical equations. Electrical conductivity is inversely proportional to resistivity, that is, the higher the conductivity, the lower the resistivity. A conductor is a material with high electrical conductivity, and an insulator is a material with high electrical resistivity. Both properties depend on the temperature and purity of the materials.

Power lines are made of conductive materials.

The temperature dependence of electrical conductivity is of a general nature. Metal is a conductor and it has lower conductivity at higher temperatures. Glass is an insulator and shows higher conductivity at higher temperatures.

At very high temperatures, conductors behave like insulators, and insulators behave like conductors. This behavior of dielectrics and conductors is explained by the free electron model. In this model, conductors clearly demonstrate the ability to release electrons, and when current or electrical force is applied, the force can easily push the extra electrons through.

Soil is a mixture of minerals, salts and organic materials. It has a special electrical conductivity called soil conductivity, which measures the amount of salt in a soil sample, called soil salinity. This process can also measure other soil properties where salinity is low enough. These properties are related to the effect of cleanliness on EU data.

Data

ECs for a soil sample can determine the amount of impurities in the soil. Soil impurities - water, air and minerals. Each impurity affects the data differently, but an experienced soil scientist can determine this information from the data collected. Generally, more impurities lower the EC, with the exception of minerals, which increase the EC. Impurities may also explain the use of pure copper in electrical wiring.

Metals are often composed of alloys made of two or more elements. It is not useful for conducting electricity. The metals in alloys are not the same elements, and electrons cannot easily move between different elements. Pure metals such as copper wire have high electrical conductivity. This only applies to hard metals because air pockets can reduce the electrical conductivity of the materials.

Materials that are not metals are generally good insulators. The best insulators are materials that naturally have air pockets, such as rubber. Air pockets are like impurities and disrupt the flow of electrons. The best natural insulators are gases, such as air. Modern chemistry has mastered insulators, creating materials with a resistivity thousands of times greater than air.

.

Rikke's Experience

Why did we decide that current in metals is created by the movement of free electrons? Positive ions of the crystal lattice also experience the action of an external electric field. Maybe they also move inside a metal conductor and participate in the creation of current?

The ordered movement of ions would mean a gradual transfer of matter along the direction of the electric current. Therefore, you just need to pass current through the conductor for a very long time and see what happens in the end. This kind of experiment was carried out by E. Rikke in 1901.

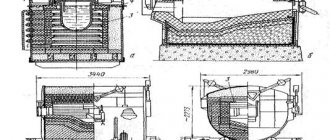

Three cylinders pressed against each other were included in the electrical circuit: two copper cylinders at the edges and one aluminum cylinder between them (Fig. 2). Electric current was passed through this circuit for a year.

Rice. 2. Rikke's experience

Over the course of a year, a charge of more than three million coulombs passed through the cylinders. Let us assume that each metal atom loses one valence electron, so that the charge of the ion is equal to the elementary charge Cl. If the current is created by the movement of positive ions, then it is easy to calculate (do it yourself!) that this amount of charge passed through the circuit corresponds to the transfer of about 2 kg of copper along the chain.

However, after separating the cylinders, only a slight penetration of the metals into each other was discovered, due to the natural diffusion of their atoms (and nothing more). Electric current in metals is not accompanied by the transfer of matter, so positive ions of the metal do not take part in creating the current.

Why do metals conduct heat and electricity so well?

Metal structure

The structures of pure metals are easy to describe because the atoms that form these metals can be considered as identical perfect spheres. More specifically, the metallic structure consists of "aligned positive ions" (cations) in a "sea" of delocalized electrons. This means that electrons can move freely through the structure and give rise to properties such as conductivity.

What types of bonds are there?

Covalent bonds

A covalent bond is a bond that forms when two atoms share electrons. Examples of compounds with covalent bonds are water, sugar and carbon dioxide.

Ionic bonds

Ionic bonding is the complete transfer of valence electrons between a metal and a non-metal. The result is two oppositely charged ions that attract each other. In ionic bonds, a metal loses electrons to become a positively charged cation, while a nonmetal gains these electrons to become a negatively charged anion. An example of an ionic bond would be a salt (NaCl).

Metal bonds

Metallic bonding is the result of an electrostatic force of attraction that occurs between conduction electrons (in the form of an electron cloud of delocalized electrons) and positively charged metal ions. It can be described as the distribution of free electrons between a lattice of positively charged ions (cations). Metallic bonding determines many of the physical properties of metals, such as strength, ductility, thermal and electrical resistance and conductivity, opacity and luster.

Delocalized moving electrons in metals -

It is the free movement of electrons in metals that gives them conductivity.

Electrical conductivity

Metals contain freely moving, delocalized electrons. When an electrical voltage is applied, the electric field within the metal causes the electrons to move, causing them to move from one end of the conductor to the other. The electrons will move in a positive direction.

| Electrons flow to the positive terminal |

Thermal conductivity

Metal is a good conductor of heat. Conduction occurs when a substance is heated, the particles gain more energy and vibrate more. These molecules then collide with neighboring particles and transfer some of their energy to them. This then continues and transfers energy from the hot end to the cooler end of the substance.

Why do metals conduct heat so well?

The electrons in a metal are delocalized electrons and free moving electrons, so when they gain energy (heat) they vibrate faster and can move, meaning they can transfer energy faster.

Which metals conduct best?

Top: Electron shells Gold (au), Silver (Ag), Copper (Cu) and Zinc (Zn). Logically one would think that Gold is the best conductor having a single s orbital electron in the last shell (diagram above)... so why are Silver and Copper actually better (see table below).

| Electrical conductivity of metals | >S/m |

| Silver | 6,30 × 10 7 |

| Copper | 5,96 × 10 7 |

| Gold | 4.10 × 10 7 |

| Aluminum | 3,50 × 10 7 |

| zinc | 1,69 × 10 7 |

Silver has a larger atomic radius (160 microns) than gold (135 microns), despite the fact that gold has more electrons than silver! See the comment below for the reason for this.

Note: Silver is a better conductor than gold, but gold is more desirable because it does not corrode. (Copper is the most common because it is the most economical) The answer is a bit complicated and we are posting here one of the best answers we have seen for those familiar with the material.

“Silver is in the middle of the transition metals, about 1/2 the way between the noble gases and the alkali metals. In column 11 of the periodic table, all of these elements (copper, silver and gold) have a single s orbital electron, an outer shell electron (platinum also, in column 10).The orbital structure of the electrons of these elements has no special affinity to gain or lose an electron relative to the heavier or lighter noble gases because they are halfway between them. In general, this means that it doesn't take much energy to temporarily knock down an electron or add one. Specific electron affinities and ionization potentials vary, and with respect to conductivity, the presence of relatively low energies for these two criteria is somewhat important.

If these were the only criteria, gold would be a better conductor than silver, but gold has an additional 14 f orbital electrons under 10 d orbital electrons and a single s orbital electron. 14 f electrons are associated with additional atoms in the actinide series. With 14 extra electrons that seem to push the d and s electrons out, you'd think the s electron was just "ripe" to conduct (it took almost no energy to push it away), but NOPE. The electrons in the f orbit are packed in such a way that it causes the atomic radius of gold to actually be SMALLER than the atomic radius of silver - not by much, but it is smaller. A smaller radius means a greater force from the nucleus on the outer electrons, so silver wins the conductivity “competition.” Remember, the strength of an electric charge is inversely proportional to the square of the distance. The closer 2 charges are together, the higher the force between them.

Both copper and platinum have an even smaller diameter; hence more attraction from the nucleus, hence more energy to knock down that lone s electron, hence less conductivity.

Other elements with a single s-orbital electron sitting there, "ripe for a conductivity picker to emerge," also have smaller atomic radii (molybdenum, niobium, chromium, ruthenium, rhodium) than silver.

So, exactly where it is is where "Mother Nature" placed silver on the periodic table, which determines its superior conductivity."

Source from pound101 Yahoo

SELECTION OF SOURCES AND READERS -

Structure and physical properties of metals

Why do some metals conduct heat better than others?

How is heat transferred?

Thermal conductivity of metals

.

Stewart–Tolman experiment

Direct experimental proof that electric current in metals is created by the movement of free electrons was given in the experiment of T. Stewart and R. Tolman (1916).

The Stewart–Tolman experiment was preceded by qualitative observations made four years earlier by Russian physicists L.I. Mandelstam and N.D. Papaleksi. They drew attention to the so-called electroinertial effect: if you sharply brake a moving conductor, a short-term current pulse appears in it. The effect is explained by the fact that for a short time after the conductor is decelerated, its free charges continue to move by inertia.

However, Mandelstam and Papaleksi did not obtain any quantitative results, and their observations were not published. The honor of calling the experiment by its name belongs to Stewart and Tolman, who not only observed the indicated electroinertial effect, but also made the necessary measurements and calculations.

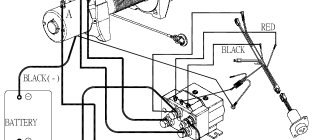

The Stewart and Tolman setup is shown in Fig. 3.

Rice. 3. Stewart–Tolman experiment

The coil was driven into rapid rotation around its axis by a large number of turns of metal wire. The ends of the winding were connected using sliding contacts to a special device - a ballistic galvanometer, which allows you to measure the charge passing through it.

After a sharp braking of the coil, a current pulse appeared in the circuit. The direction of the current indicated that it was caused by the movement of negative charges. By measuring the total charge passing through the circuit with a ballistic galvanometer, Stewart and Tolman calculated the ratio of the charge of one particle to its mass. It turned out to be equal to the ratio for the electron, which was already well known at that time.

Thus, it was finally found out that the carriers of free charges in metals are free electrons. As you can see, this fact, which has long been well known to you, was established relatively late - given that metal conductors by that time had already been actively used for more than a century in a wide variety of experiments in electromagnetism (compare, for example, with the date of discovery of Ohm's law - 1826. Case, however, is that the electron itself was discovered only in 1897).

Basics of Electrical Conductivity | mho siemens

Electrical conductivity and its formulas are often used in electrical and electronics engineering in Siemens or mhos units.

Resistance Tutorial Includes:

What is Resistance Ohm's Law Resistivity Table of Resistivity for Common Materials Temperature Coefficient of Resistance Electrical Conductivity Series and Parallel Resistors Parallel Resistor Table Parallel Resistor Calculator

Unlike resistance, which measures resistance to the flow of electric current, electrical conductivity or electrical conductivity is a measure of how electric current moves within a substance.

The higher the electrical conductivity of the material, the higher the current density for a given applied potential difference.

Thus, it can be seen that electrical conductivity or electrical conductivity of a substance is a measure of its ability to conduct electricity.

Electrical conductivity, or electrical conductivity, of a material is important because some substances need to conduct electricity as well as possible. Conductors must allow current to pass as easily as possible. Other materials may be required to limit the passage of current, as in the case of a resistor, and other materials must not conduct electricity, as in the case of insulators.

Basics of Electrical Conductivity

Electrical conductivity is the ratio of current density to electric field strength. The higher the conductivity value, the less resistance it provides to the passage of electric current.

The value of electrical conductivity depends on the ability of electrons or other charge carriers such as holes to move within the lattice of the material.

Highly conductive materials such as copper allow electrons to move freely within their molecular lattice. There are free electrons inside the lattice.

Materials with low levels of conductivity or conductivity contain very few free electrons in their structure. Electrons are held tightly within the molecular structure and require significant levels of energy to get them out.

Conductivity units: siemens and mho

The units of electrical conductivity are siemens per meter, S⋅m -1.

Siemens was also formerly called mho, which is the reciprocal of ohm and is derived by writing ohm backwards.

Electrical conductivity is the reciprocal of resistance, and one siemens is equal to one reciprocal of resistance.

The name siemens for the unit of conductivity was adopted by the 14th General Conference on Weights and Measures as a derived SI unit in 1971. It was named after Ernst Werner von Siemens.

As with any SI name that is derived from the name of a proper person, the first letter of its symbol is capital, i.e. in this case the letter "S" denotes the value in Siemens, 10S. When the full name of the SI unit is written in English, it must always begin with a lowercase letter, which in this case is siemens. The exception is when any word is capitalized, as in the case of the beginning of a sentence, etc.

The most commonly used symbol is the lowercase Greek letter sigma, σ, although kappa, & kappa, gamma, and gamma are also sometimes used.

Although the SI units of conductivity are the most widely used, conductivity values are often expressed as a percentage of IACS. IACS, the International Standard for Annealed Copper, was established by the International Electrochemical Commission in 1913.

The electrical conductivity of annealed copper (5.8001 x 107S/m) is determined to be 100% IACS at 20°C.

All other conductivity values are related to this conductivity value. This means that iron with a conductivity value of 1.04 x 107 S/m has a conductivity of approximately 18% of that of annealed copper, which is 18% IACS.

As metal processing techniques have improved since the standard's introduction, some modern copper products now often have IACS conductivity values above 100% IACS because more impurities can now be removed from the metal.

Electrical conductivity formulas

Resistivity and conductivity are interrelated. Electrical conductivity is inversely proportional to resistivity. Accordingly, one is easy to express through the other.

Where: σ is the resistivity of the material in siemens per meter, cm -1 ρ is the resistivity of the material in Ohm-meters, Ohm m

This can then be plugged into the resistivity formula to obtain the following relationship.

Where: σ is the conductivity of the material in siemens per meter, S⋅m -1 E is the magnitude of the electric field in volts per meter, V⋅m -1 J is the current density in amperes per square meter, A⋅m -2

It is often necessary to relate conductivity to a specific length of material with a constant cross-sectional area.

Using this diagram, you can relate conductivity to the resistance, length, and cross-sectional area of the sample in the conductivity formula below.

Where: R is the electrical resistance of a homogeneous sample of material, measured in ohms, l is the length of a piece of material, measured in meters, m A is the cross-sectional area of the sample, measured in square meters, m 2

Using these electrical conductivity formulas, electrical conductivity can be calculated by knowing the resistance, length, and cross-sectional area of a block of material.

Additional basic concepts:

Voltage current Resistance Capacitance Power Transformers RF noise Decibel, dB Q, quality factor

Return to the “Basic Concepts” menu...

.

How to be safe with electricity?

Electrical safety tips for children

- Never insert your fingers or other objects into an outlet.

- Keep metal objects away from toasters.

- Never use anything with a cord or plug near water.

- Never pull the plug by the cord.

- Stay away from substations and power lines.

- Don't climb the poles.

- Never fly kites near power lines.

What explains thermal conductivity?

So, the thermal conductivity of different substances is different. ... This is explained by the fact that thermal conductivity is the transfer of energy from one part of the body to another, which occurs during the interaction of molecules or other particles. In a space where there are no particles, thermal conduction cannot occur.

Interesting materials:

How many sites are there at Baikonur? How many planes pass through different triples of four points that do not belong to the same plane? How long does the history exam take? How long does it take to deep-fry nuggets? How many subscribers does Milana Nekrasova have in Like 2022? How many subscribers does Rahim have? How many trains are there in the metro? How much salt should I put in for salting lard? How much does a loader get paid at a fixed price? How much does a consultant earn at Sberbank in Moscow?

What substances conduct electric current?

What are their features and what are their distinctive properties? How dangerous can their compounds be to human health? What is the operating principle of fire retardant coatings? The most popular is the hot galvanizing method. Home Density of metals and alloys Hardness of metals Melting point of metals Specific conductivity of metals. What are the most effective ways to protect metals from corrosion today?

Different substances conduct electric current at different times. Of the metals, the best conductors of electricity are silver, copper, and aluminum. Even in a regular one.

What is metal?

Metal is a light body that can be forged. We find only six such bodies: gold, silver, copper, tin, iron and lead.

Interesting materials:

How much sleep should an orderly sleep? How long was Operation Barbarossa supposed to last? How long should red caviar drain? How many running tracks should there be at any international competition? How much should be in an essay? How many Dungans are there in Kyrgyzstan? How long does it take to get from Krasnodar to Simferopol? How long does it take to get from Boryspil airport to the railway station? How many elements were included in the first published version of Mendeleev's periodic table? How much Elo do you need for lvl 4?

Recycling after use

Despite the long service life of the cables (from 15 to 30 years), they all need to be replaced after this period has expired. After this, the cables must be disposed of and recycled. Searching for wires and delivering them to scrap metal collection points allows us to partially solve the problem of obtaining primary raw materials. Collection points accept scrap:

- household;

- control;

- power;

- special cables.

The price per kilogram of scrap is determined:

- The quality of supplied raw materials.

- The percentage of a particular metal.

- Purity – the amount of contaminants and oxides.

- The integrity of the sheath, as well as the complexity of further processing of cable scrap.

- Volume of recyclable materials - the more cable scrap is handed over, the higher the price per kilogram.

Who is guilty?

In most cases, the power supply or operating organization itself bears responsibility for the condition of the power line. Since its employees constantly monitor branches overhanging power lines or their location in close proximity to them. After all, each line has a power line security zone protruding in both directions from the wires at a distance of 2 to 55 m, depending on the voltage level in it.

Figure 3: overhead line security zone

The power supply organization carries out constant inspections of the line to identify such threats, and if any are identified, they are obliged to remove the emergency tree or branches that threaten the wires.

If old trees are on the balance sheet of any organization, enterprise and electricity supplier simply did not have access or permission to cut them down, then the blame falls on this organization. The same can be said about urban electric transport, when the fall occurred on tram or trolleybus wires.

In addition, the circle of culprits may also include ordinary citizens who decided to cut down in the local area, carried out cutting in public places or along a line for the purpose of collecting firewood. This also includes private entrepreneurs and other legal entities who organized work without the appropriate permits and their actions led to the fall of a tree with subsequent breakage of a high-voltage wire or an interphase short circuit.