The central element of a welder's workplace is the table. What it should be like and how to choose the right one are important issues in organizing a room for welding work. You will find the answers in the article.

- Welding and cleaning

- Siegmund

- Clamps

An integral element of any welding workshop is the table. Without it, doing work will be much more difficult and uncomfortable. It serves as a working platform where metal workpieces are joined, as well as a storage place for a large number of useful items and consumables.

Design

A large selection of welding tables is due to the need for diverse design solutions for specific tasks. But every product has elements that are mandatory and basic:

- tabletop. The working surface is made of durable, non-flammable material. It has many holes and grooves, which are used to secure workpieces during operation;

- frame. A frame to which a tabletop, pull-out shelves and various kinds of organizers are attached;

- adjustable supports. They make it possible to set the tabletop evenly and at the desired height;

- open and closed shelves. The first are used to place electrodes, filler wire and other consumables that should always be at hand. Tools are stored in closed shelves;

- pallet. It is located at the bottom of the table and serves to collect production waste, scale, shavings, etc.;

- brackets. They are located along the contour of the working surface. Hold the welding wire and ground loop;

- suction sleeve. An element of the ventilation system designed to remove exhaust gases and dust.

Tables are the central element of a welder's workspace. They are complemented by other elements for proper organization of space - cabinets, shelves, racks, mobile and stationary tool carts, as well as other equipment.

Final assembly

For final assembly, turn the frame face down and expose the legs of the welding table. You can use a building level, but a simple plumb line will do. They grab the legs and once again check the correct installation, hammer them to the desired position and weld all the joints. For greater reliability of welding, scarves are welded on the inside. They will serve as stiffeners.

Nickels from the strip are welded to the ends of the legs of the welding table. Then the table is turned over and the lower jumpers are welded at a distance of 150-200 mm from the bottom. Mark the places where the shelves are attached and weld the corners. The skeleton of a simple welding table design is ready. All that remains is to clean all the joints with a grinder and check the seams.

Next, all surfaces of the welding table are degreased with a solvent and the first layer of primer is applied. After drying, install the countertop. Before installation, plywood must be treated with impregnation. The top of the plywood is covered with a sheet of metal with curved edges. They grab the metal in several places to the frame.

After drying, if desired, you can paint the table with heat-resistant paint, or you can do without painting. At the last stage, the shelves are installed.

The entire manufacturing process is reviewed in the video.

Peculiarities

The most important parameter of the equipment and accessories that a welder uses in his work is safety. This can be fully discussed in relation to such a harmless object as a welder’s table. It would be more accurate to say - to his workplace, the central element of which is the table. Among the mandatory conditions for arranging a workplace, several basic provisions should be highlighted:

- Forced exhaust over the table. Active ventilation is necessary to quickly remove harmful gases and dust accumulations from the room.

- They pumped in air. They are necessary for the ventilation to work as efficiently as possible, and for the specialist to continue working for as long as desired.

- Work area lighting. It is important to ensure optimal lighting levels. To do this, it is best to combine natural and artificial light sources.

- A place should be provided for storing work equipment.

An important condition for desktop materials is their complete environmental friendliness: they should not emit substances harmful to human health when exposed to strong heat. This leads to another mandatory requirement: the materials from which the table is made must be non-flammable.

What is important to know about welding safety?

When making welding tables yourself, you must take into account all safety requirements.

Self-made workstations for welding work should:

- have well-thought-out ventilation for the welding station, ensuring complete air purification in the area where a person is present;

- be equipped with a network of hoods for efficient operation of the ventilation system;

- have properly installed grounding;

- be made of non-combustible materials.

There are several risk factors when performing welding work:

- electric shock;

- the effect of an electric arc on the visual organs;

- getting foreign objects into the eyes;

- damage to the respiratory system by harmful gases and fumes;

- contact of molten metal with skin areas;

- getting injured when working at height;

- burns from an explosion of a liquefied gas cylinder.

Immediately before starting welding work, several preparatory measures should be carried out:

- checking the quality of the electrical network;

- control of the reliability and stability of a table made of a profile pipe;

- diagnostics of the integrity of the insulation of the supply wiring;

- monitoring the performance of the air exchange system of the welding station;

- checking the serviceability of auxiliary equipment.

In general, safety precautions when working with welding should be followed as diligently as possible.

Drawing of a welding table.

To prevent the risk of injury, the workplace must comply with the following rules:

- All cables must be securely insulated and secured. The use of welding workstations with dangling power wires is not allowed.

- Before making a table, the master must thoroughly think through the grounding. The following tools must be grounded in the workplace: power supply housings, auxiliary electrical equipment and the equipment box.

- The cross-section of network wires laid to the work site must be at least 25 mm2.

- The equipment used must be of industrial production.

- The gas line is fully operational and has no leaks.

- Connection, disconnection and repair of welding equipment must be carried out exclusively by a regular electrician.

- Lighting devices used for welding must be powered from a 12-volt network.

- The electrode holder of welding equipment must be insulated. This precaution will help avoid electric shock when touching live parts of the electrode holder.

- The electrode holder of the welding installation must have good mechanical characteristics and provide at least 8,000 electrode clamping cycles.

The welding machine operator must be dressed in special clothing that provides reliable personal protection:

- protective bandages, respirators and, in rare cases, gas masks are optimal for workplaces where it is not possible to install high-quality ventilation;

- overalls and protective masks to prevent droplets of molten metal from contacting the skin;

- a helmet or goggles to protect your eyes from sparks and flying hot drops.

Application area

The table is used in the process of working on individual orders, which are characterized by a unique design, and for mass production. It should provide maximum comfort and at the same time promote work efficiency. It is not suitable for mounting large-sized products, but it is quite comfortable to assemble individual components of a large structure on a table.

An important advantage of the welding table is the ability to use guides with mobile stops. Additionally, they can be fixed with clamps and other clamps. For example, often the position of the workpiece is fixed using a standard ruler provided on the working surface.

Varieties: collapsible, modular and others

Depending on the design features of the parts being welded, production conditions and other technological factors, the tables have certain differences, which makes it possible to distinguish their main types.

Modular. The principles of the modular design of welding tables allow you to change their working surface for each specific part being processed. Moreover, the workspace is brought into the desired position quite quickly.

Video

Universal. Such welding tables allow you to solve various production problems at a single workplace. The design of the base base allows you to install a wide variety of equipment for fastening parts of various shapes, including three-dimensional products. Then you can carry out welding work, stripping products, machining and other technological operations.

The rotary round table Slot-Table of the PST series is used for assembly, welding, stripping and other positioning of workpieces. Photos Tehnoveld

Collapsible. The design allows you to disassemble the equipment into small components and then assemble it again without any problems. This makes it much easier to transport the table over long distances.

With a coordinate grid . The presence of scratches in the form of a coordinate grid on the working surface facilitates the installation of assembly equipment and parts to be welded . Any of the marks can serve as a base for installation, which reduces the time for using additional stops.

Five-sided 3D table TEMPUS SSTW 75-105/35M nitrided, with a coordinate grid. Photo MOSSklad

Mobile. Production conditions often require welding to be carried out in a strictly defined location. Mobile tables provide this opportunity. of special wheels on the supports makes it easy to move the table to the desired location.

Mobile table SibarWelding. Photo by BelSvaMo

On the rail track. When producing long steel structures, welding equipment can be used on rail tracks. The rails are leveled and installed as basic equipment elements for the production of cars, bridges, railings and other similar objects . The welding tables mounted on them move one after another and are fixed in the right place using special stops.

Welding table on a rail track. Photos Tehnoveld

Rotary. The use of a rotary table allows the welder to process even large workpieces without changing his position at the workplace. This makes it possible to best position the auxiliary equipment for constant and comfortable use. Rotary tables allow you to mechanize welding work using automatic and semi-automatic machines.

Rotary welding and assembly table with an inclined plate. Photos Tehnoveld

With rotating work plate. It is convenient to weld large fences and rectangular frames on equipment with a rotating working base. If you do not create rotation for such workpieces, then it will be very difficult for the welder to reach some places. In such cases, it is necessary to reinstall the workpiece, which significantly complicates the welding process.

With hydraulic drive. The hydraulic drive is used to raise/lower welding plates with massive workpieces. This allows the welder to work at different height levels, leaving the fasteners in the same position.

With hood . Local suction is the most effective option for cleaning the welding work area from harmful substances. With minimal air flow, maximum toxic welding gases are removed. Structurally, on welding tables, local exhaust is made in the form of umbrellas or a suction pipe with filter elements made of material that stretches and bends for better installation in the welding zone. It is important that the exhaust device does not interfere with the welder while working.

Type overview

Today there are a large number of different models of welding tables. They can be divided into three groups:

- traditional workbench;

- Rotary table;

- universal tables with a set of additional features.

To understand in more detail the functionality of each group of tables, you need to take a closer look at their structure and features.

Crafting table

The simplest option for a mounting surface made of metal. Both the frame and the tabletop are made of metal, which ensures high structural strength. Additionally, the table is equipped with accessories - clamps, angles, clamps, bench vices and other accessories.

Rotary

The next class of equipment in terms of complexity. It has an electric drive, which provides the ability to position the surface according to the angle of inclination or move it along any axis. Such tables are in demand in the production of complex shaped structures. A slot table is a type of rotary structure designed for assembling, stripping and welding workpieces.

Universal

In addition to the functionality of rotary tables, such tables have additional equipment designed to optimize welding, grinding and other operations. The workplace is designed for intensive use, therefore it is equipped with hoods to remove dust and gases from the room.

Welding and assembly tables.

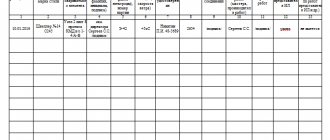

Welding and assembly tables (SSM series) are designed for welding and assembly work, with the ability to fix parts, assemblies and assemblies in grooves on cast iron or aluminum-copper beams with special devices that allow assembly and welding of structures of any complex configuration.

The ability to dismantle and move beams to a convenient position, equipped with additional slats and support stands makes the design of the SSM welding table universal. Features of SSM welding and assembly tables:

The use of solid solid beams on welding and assembly tables of the SSM series provides a stepless surface with a non-flatness of no more than 0.5 mm in width , which is very difficult to achieve with the butt version. The use of continuous solid beams ensures better and more accurate assembly of the product (assemblies and subassemblies).

The use of aluminum-copper alloy beams is justified by such a property as the high current conductivity of the material, which improves the quality of welds when welding parts made of non-ferrous metals and stainless steel, and also eliminates the adhesion of metal splashes. Also, the relatively high tensile strength of the beam material, combined with low surface hardness, allows it to withstand large, evenly distributed loads and does not cause damage to the polished surfaces of stainless steel parts.

The use of beams made of gray cast iron is justified by the high resistance of the material to high temperatures during welding work, and also eliminates the adhesion of metal splashes.

In welding and assembly tables of the SSM series, adjacent beams form T-shaped grooves, and the maximum permissible load on 1 beam is up to 1500 kg.

| Basic series | Modular | Mobile | Rotary | With PVU |

| With rotating work plate | Universal | On the rail track | With hydraulic drive | With coordinate grid |

| With T-slots and ø 28 mm holes | Collapsible | Accessories for welding and assembly tables |

Types of tables for welders and assemblers

The range of equipment sold is varied: from simple and compact ones, which are suitable for amateurs and home craftsmen, to serious installations with mechanized functionality. Some of the most common types are described below.

Welding and cleaning

The tables are equipped with a fan or a full exhaust system to remove dust and exhaust gases. The tabletop is made from high-strength structural steel that is wear-resistant. It has holes or is made in the form of a lattice.

Universal assembly and welding machines

Before starting welding work, the workpieces are attached to the surface using various devices. If necessary, the tabletop can be dismantled and moved to a position that best suits the task at hand. At the buyer's request, the tables are equipped with additional supports, which make the solution universal.

Transformers

The height, width, and length of the table can vary to suit the dimensions of the structure with which the welder has to work.

Stationary and mobile

There are models of tables that are firmly attached to the base and remain motionless all the time. These are stationary versions. Mobile ones are often equipped with wheels. They are installed on legs and easily rotate around the axis of the fastener. The wheels themselves are made of polyurethane and are equipped with a brake mechanism.

Simple and professional

The first group of welding tables is designed to perform simple operations and simple work on assembling structural components. Professional models are universal in use and have many options for fixing workpieces. They are equipped with an effective exhaust system and allow the installation of additional equipment - grinding, drilling and others.

With ventilation

During welding of metals, a lot of gases - combustion products - are released into the surrounding space. If the welder’s workplace is equipped indoors, then an effective system for removing exhaust gases and dust is needed. Local ventilation is most often used. The suction and removal of combustion products can be performed in the form of autonomous ventilation, or can be connected to a general exhaust hood.

3D

Such models are designed for precise positioning of workpieces in two planes: vertically and horizontally. The devices allow you to weld any parts with a three-dimensional configuration.

Folding, folding, folding

In order to save space indoors, transformable structures are installed. They take up little space and are folded until welding of workpieces or any structure is required.

Nitrided

Characterized by the fact that the surface is nitrided. This gives it special strength and resistance to wear. Scale and molten metal do not stick to the working surface.

Cast iron

Manufacturers offer table models with cast iron surfaces. Cast iron cooks very poorly. Therefore, the advantage of a cast iron surface is that the melt does not stick to it.

Welding table design

There are several types of designs. The most common:

- amateur, for occasional welding work, small structures by a home craftsman;

- semi-professional assembly and welding, for performing complex operations

For a table made from a profile pipe, made by yourself, the following dimensions are recommended:

- height of the working surface from the floor 70-85 cm;

- working surface dimensions of at least 80×100 cm;

- The height of the protective box is at least 140 cm from the floor.

Simple table for welding work

This design is durable, easy to manufacture, and convenient to use for small amounts of welding. It consists of a rigidly welded metal frame made of 60*60 profile. Four racks are attached to it. 20 cm from the floor they are connected by 20*20 corners. Tabletop elements are installed on top of the frame, forming a reliable support for the workpieces to be connected and equipped with grooves for their fastening.

Example of a mobile table

Hooks for wires from the welding machine are welded to the frame, and a shallow tray for scale and dust is placed under the working surface.

On one side of the welding table, a cabinet made of thin metal sheet is installed for storing small tools. Here I weld a stand for the water tank.

Semi-professional welding table

It is a welding and assembly station designed to improve the convenience of welding work. Allows you not only to cook, but also to carry out related mechanical processing.

This table includes:

- rotary working platforms;

- installation of drilling or milling equipment;

- quick-release bench vice;

- rotary attachments for attaching the welding machine;

- exhaust ventilation;

- flexible illumination of the working area;

- anchorage to concrete floor.

The purpose of all these improvements is to enable the welder to work from a comfortable, non-tiring position and to save time on the operation of removing and installing the product. Pays off for large volumes of work

Optimal sizes

The size of the working area is one of the key points that is very important for welders and affects the ability to perform certain jobs. It is this indicator that determines the size of the workpieces that the welder can subsequently work with. The dimensions of the table surface vary over a wide range of values: from small (approximately 70x70cm) to large (298x148cm). in height it should not exceed 1.4 meters.

Tables with a small workspace are used for working with small workpieces or assemblies. Tabletops of impressive dimensions provide more opportunities. You can place a corresponding structure or several nodes on them. Here you can leave the most frequently used equipment, which is easier to keep at hand.

Scope of application: for the manufacture of railings, for welding doors and more

The welding table facilitates the work of the performer both when performing individual individual work and when welding serial parts . In the first case, a large amount of various equipment is required, in the other case, they are limited to standard equipment. Welding is used in almost all metalworking industries.

Most large-sized structures , such as fences and frames, are assembled from separately welded assemblies on tables. Such equipment has its own specifics. Each individually welded unit must be mounted into the overall structure with minimal adjustments. Therefore, welding tables contain guides with movable stops and clamps, which are installed in the required position using rulers on their surfaces. If it is necessary to install railing supports at an angle, the design contains rotating substrates with an angular scale. This ensures the necessary manufacturing precision.

Five-sided 3D table TEMPUS SSTW 75-105/35M nitrided. Photo MOSSklad

In addition, the basic structure of the table rotates freely around a horizontal axis for ease of assembly and welding of elements of railings (fences) and frames . The design contains braking devices to fix the product in a certain position. For more reliable fastening, in addition to mechanical braking, compressed air braking is used. The operation of welding tables for the manufacture of railings is shown in more detail in the following video

The operation of tables for welding rectangular frames is also presented:

In mass production, mechanical welding equipment can form a technological chain with other types of technological devices.

Top brands

It is possible to weld metal workpieces without a special table, but it is very convenient. As a result, the specialist’s labor productivity decreases and the quality of the welded joint suffers. Therefore, a working surface is definitely needed. Today the market offers a large selection of such equipment from famous and unknown manufacturers. Of the total number of brands presented, several of the most popular ones should be highlighted.

Siegmund

The company supplies the market with products that fully comply with generally accepted requirements for welding tables. The manufacturer has equipped the working surface with quick-clamping devices, which helps to increase the welder’s productivity.

Forster

A company from Germany specializes in the production of modular options. The countertops are made of ferrite or cast iron and can be easily removed if necessary. This allows you to change the shape of the table in order to adapt it as much as possible to a specific workpiece. The brand supplies rotating, lifting and rotating type products.

Demmeler

The brand belongs to a German manufacturer specializing in the manufacture of welding tables and additional equipment for them. The main advantage of the products is the versatility of the solutions.

"WTO Plant"

The Ulyanovsk company produces a fairly large range of non-standard equipment and accessories. Prefabricated welding tables are practical and come with additional accessories to increase productivity and improve working conditions.

VTM

The Russian brand specializes in the production of standard welding equipment and custom-made metal structures. The main focus is the production of D16 and D28 systems, as well as the execution of individual orders. The parameters of the finished product exactly correspond to the customer's requirements. For the production of welding tables, only high-quality certified materials and components are used.

Evidence

The main direction of the company is the production of welding and installation equipment. The main advantage is the wide range of models offered, which allows you to find the option that best suits your needs.

ESAB

Perhaps the most recognizable brand on the domestic market. The Swedish brand supplies high-quality welding equipment, including tables. In addition, its assortment includes a large selection of other equipment, consumables and accessories.

Sovplym

A joint venture created by businessmen from Russia and Sweden. Production facilities are located in St. Petersburg and supply ventilation systems to the consumer market. One of the company’s areas of work is the production of filter and ventilation devices for welding tables.

TEMPUS

The German manufacturer supplies 3D tables to the domestic market. They are excellent for solving problems of welding and installation of frames, fences and a whole range of other products.

Table-Table

The Russian company specializes in the production of welding tables, the table tops of which consist of stacked plates. The typesetting elements themselves are made of cast iron and aluminum, to which molten splashes do not stick. The plates are easily removable, which allows you to transform the working surface to suit specific workpieces or structures. Production processes can be simplified. For this purpose, the table can be equipped with various hydraulic and electromechanical drives.

SIBAR

A young domestic company is creating its own range of products. takes into account the needs of customers as much as possible.

Do-it-yourself: assembly kit, drawing, etc.

Making a table for a home craftsman who, among other things, also does welding work, will not be particularly difficult . It is better to make a table that will take into account all the wishes of the master according to the drawing . This engineering approach will make it possible to prepare the required set of materials and quickly process the structure in the absence of any standard size material.

It is better to cut workpieces on a saw, instead of using a traditional grinder. They will be exactly the size of the drawing. In addition to the welding machine, you must have a set of plumbing tools, especially marking tools. Thus, to make a welding table with your own hands you will not need a wide range of equipment.

How to choose?

Choosing the most suitable table for specific tasks is not so easy. After all, many factors have to be taken into account and it is possible that new circumstances may arise in the process of work. That is, if possible, it is necessary to provide for the maximum possible number of working moments.

Those who prefer comfortable working conditions and put them at the forefront should pay attention to round models of welding tables. They are usually rotating. Therefore, the entire range of problems (or most of them) can be solved without changing your location. Such equipment is mounted on a prepared concrete platform. If you plan to produce complex structures, you should choose a work surface with a set of additional equipment that would make it easier to complete the tasks.

Fortunately, manufacturers produce a wide range of welding tables and there really is plenty to choose from. Structures are often equipped with special equipment and equipment designed to perform highly specialized operations. And if you need universal equipment, then finding it will not take much time.

When choosing a welding table, experienced specialists advise paying attention to the following recommendations:

- The first step is to determine the optimal dimensions of the structure. They must meet production requirements and at the same time be comfortable for a specialist. If you lose sight of this point, welding work can become an unpleasant and even dangerous process.

- It is important that the work area is fenced. This is a kind of protective screen. It must be made of fire-resistant materials.

- The table should have a decent weight. At least 180-200 kilograms. Thanks to this, it will be rigid and quite stable.

- It is necessary to abandon energy-saving lamps. Their light creates glare, which is a source of discomfort while doing work.

- A big plus is the presence of a rotating platform. It is advisable to purchase just such models.

Sometimes the table lacks integrated ventilation. Then you definitely need to purchase it separately. As an option - a small exhaust device with magnets.

If it was not possible to choose something appropriate from the presented models, then you can order the manufacture of the structure according to individual drawings. Thanks to this approach, the owner will receive a welding table that will best meet his requirements. At the same time, you will not have to overpay for unnecessary functions or devices.

Comfortable working conditions cannot be created without the appropriate tools. You should pay special attention to his choice. It is important that fastening devices and clamps securely hold the workpieces in the desired position and make it possible to quickly change the position of the workpieces being connected.

When buying a table for a home workshop or small business, universal models are best suited. They are suitable for more than just welding work. On such surfaces you can fix a part for grinding, sharpening, drilling or performing any other technological operations.

Design, components, features

The rotary round table Slot-Table of the PST series is used for assembly, welding, stripping and other positioning of workpieces. Photos Tehnoveld

The variety of types of welding work determines the design features of the tables . For both simple and professional ones, common components .

- The main distinguishing feature is the stove (countertop). The presence of structural elements such as holes and grooves on it ensures fastening of equipment for precise positioning of the parts to be welded.

- A durable frame serves as a supporting frame on which the slab (table top) is attached.

- Adjustable supports allow you to set the surface in a horizontal position and provide a comfortable height for the welder to work.

- The table can be equipped with both closed and open shelves. Closed shelves contain working and measuring tools, while open shelves contain temporary equipment and other devices used on a one-time basis.

- The tables are equipped with a tray for collecting welding dust and other process waste.

- Along the contour there are brackets used for fastening the welding wire and connecting to the ground loop.

- A suction hose from the ventilation system is supplied directly to the welding zone.

Equipment

To speed up welding work as much as possible, you need to take care of purchasing special equipment and devices. Basic requirements for auxiliary equipment:

- must ensure the desired location of the joined workpieces. In this case, you will not have to additionally adjust the parts;

- during welding, the edges must be at a certain equal distance in relation to each other. This is easy to achieve with the right tools;

- auxiliary equipment should be placed on the work table and not interfere with the performance of various technological operations.

It is difficult to weld parts without fixing them in a certain position. Various types of clamps, clamps, clamps and clamps cope well with this task. There are several types of fixing devices, which are divided into groups according to the type of drive:

- mechanical;

- hydraulic;

- pneumatic.

Hydraulic and pneumatic clamps are equipped with strong links, which provide the ability to brake parts automatically. This design prevents unauthorized loosening of fasteners. It is important to ensure clear joining and fixed fixation of the elements before welding them. Otherwise, the seam may turn out to be of poor quality. It is noteworthy that the preparatory work very often takes more effort and time than the welding process itself.

In addition to the clamps supplied with the tables, other devices for fixing workpieces can be used.

Clamps

A separate subtype of clamps that holds workpieces at a given angle. There are many options for devices that differ in both shape and size. The design includes a pin on which there are clamps.

Prisms

Fixing devices designed to hold bulky workpieces. To keep the part stationary, it is fixed using prisms at an angle. The main disadvantage of this type of holder is the fact that marks of fixation often remain on the surface of the workpiece.

Cast iron plates

In budget models of welding tables, cast iron plates replace the tabletop. The main advantage of this solution is that if one of the plates fails, it can be easily replaced. Another plus that you should pay attention to is the low thermal conductivity of cast iron. Even with prolonged operation of the welding machine, it does not heat up to high temperatures. In addition, the metal is characterized by high resistance to static loads.

Vise

Mechanical unit for holding workpieces. They are used in the welding process, as well as subsequent (or preliminary) processing of workpieces. The main feature of the vice is the fact that the specialist has both hands free and it is easier for him to perform the necessary manipulations. There are several types of vices.

Plate

In fact, it is the same tabletop, but with a perfectly flat surface due to its thickness. The choice of plate size is determined depending on the size of the workpieces that will have to be worked with in the future. The advantages of the plate include markings for placing parts on the surface. The metal sheet has several holes that can be used to secure workpieces using other equipment.

Suction sleeve

A lot of welding work is now done indoors. It is important that they have active ventilation, which will remove combustion products and dust outside. A forced ventilation system is sometimes used as a primary or additional workpiece holding system. The suction pipe is located under the table and the air flow, passing through small holes in the table, presses the part to its surface.

DIY welding table

Cooking on the floor or ground is for one-time work in the field. Regular welding processes require a special welding table. It can be very simple, or it can be professional. Let's consider the requirements for such devices, types of tables for welders, step-by-step instructions on how to make it yourself.

In this article:

A welding table is needed to place workpieces and weld, which improves work convenience and productivity. The work area should be well lit, but whether the light is mounted on the desk itself or on the wall above it is a personal choice.

Exhaust supply is required. It can be in the form of a rigid channel or flexible. But it is not fixed to the table. The hood ensures the removal of hazardous gases emitted by molten metal by coating the electrodes.

The welder's table must be able to withstand the workpieces placed on it, therefore it is made only from a metal profile or angle (frame). Wooden structures are not permitted. Since the tabletop is subject to regular heating, its cross-section is chosen from 5 mm and above. When welding at high currents of 300-400 A, a 10 mm plate is required, otherwise the surface will bend.

To fix the product and carry out assembly without outside help, the welder’s table is equipped with through holes for inserting tie rods, clamps, and a vice. If other people are working nearby, there must be a fence. A vertical screen is placed on the far side with a height of 50-100 cm.

The table should be heavy so that it cannot be moved by leaning on your foot. The height of the tabletop is chosen based on the height of the welder. It is generally accepted 80-100 cm from the floor. But for tall welders, we recommend focusing on the location of the table at waist level.

Types of welding tables

Welding tables are either stationary or collapsible. The first ones are more massive and are assembled by welding. They are designed for permanent use. Collapsible tables can be large or small, but are assembled using bolted joints. Most often, the legs can be separated from the tabletop. This makes moving easier and is suitable for rented premises (workshop, garage), so that if necessary, you can transport a huge table with a small pickup truck, van, or minibus.

Depending on the upcoming welding tasks, the dimensions and configuration of the welding table are selected. Here are some popular options used in garages, workshops and factories.

Simple table

Professional table

A simple welding table consists of a solid rectangular plate and four legs. This is enough to apply neat seams with argon devices on small parts. Suitable for welding welding of pipes and small containers.

The configuration of semi-professional tables is more varied and offers several options that determine the functionality of the workbench. The most common option is a tabletop with numerous round holes for tension systems. Its analogue is a tabletop made from a channel or profile welded parallel to each other at intervals of 20-50 mm. This allows you to install not only a threaded axle, but also an entire clamp.

If the welder regularly assembles large structures with protruding parts, a frame table without a tabletop will be required. This is relevant for assembling gates, entrance doors, and agricultural equipment.

For easy access to the outside and back of products, such as heated towel rails, rotary welding jigs are used. This is a frame on an axle, connected through bearings to two conical posts. Thanks to this, the frame can rotate vertically. The frame has threaded clamps that secure the product. This makes it easier to quickly turn the structure over to weld the seams on the reverse side.

Horizontal rotary tables are made round. They are fixed on the axis and connected to the gearbox and electric motor. Most often, such devices are small and are needed for welding pipes to flanges. Thanks to rotation, the seam is continuous and even. The welder selects the appropriate rotation speed on the gearbox through a reduction gear. They cook at such tables, as a rule, with semi-automatic MIG/MAG.

Making a welding table with your own hands

To make a welding table, you need to stock up on tools and accessories.

This will reduce work time and simplify assembly. Prepare the materials so you don’t throw everything away later, rushing to the store to get the missing corner. Necessary tools and equipment

- grinder with cutting/grinding wheels for cutting material;

- square for setting even corners;

- roulette;

- welding chalks or welding markers for marking;

- clamps;

- bubble level

If you plan to make a table from 10 mm thick metal, cutting with a grinder will be inconvenient. Then purchase a plasma cutting machine to prepare all the parts. Subsequently, it will be useful in the production of products, saving cutting wheels.

Materials for welding table

- Tabletop. This can be a solid sheet of metal 5-10 mm thick with drilled holes or a stacked tabletop made of a 100x40 mm profile flat pipe, welded parallel to each other with a distance of 20-50 mm. In the second case, you will need supports made of a 60x40 mm profile, welded around the perimeter, and additional stiffening ribs in the center under the tabletop. It is possible to manufacture it from cut metal strips, but with a thickness of 5-6 mm it will take a lot of time.

- Support legs. They are made from a corner with a 75 mm shelf or a profile pipe 80x80 mm with a wall thickness of 3 mm.

- Gussets 8 pcs for strengthening racks with a thickness of 3 mm and above.

- Profile pipe 60x40 mm for tying the legs to strengthen the structure.

- Sheets of metal for shelves, protective screen (if necessary).

Dimensional drawings for welding tables

We offer several options for drawings of tables for welders, so that everything can be done exactly to size. In other cases, you can take the model as a basis, and determine the length, width and height of the structure yourself according to your garage and height.

Step-by-step instruction

Since holes for fixing workpieces are necessary in most processes, we will consider the option of assembling a table from a profile pipe with the given dimensions of 100x40 mm.

- Preparation and cutting

- Making a countertop

- Making table legs

- Welding table stiffening belt

- Protective screen

- Tool shelf

- Painting the table

Mark and cut a 60x40 mm profile to fit the tabletop frame. With a surface size of 200x100 cm, you will need 4 profiles 2 m long and 2 profiles 1 m long. Assemble a rectangle on a flat surface, welding the corners. Join into a joint, pressing the ends of the long profile to the side walls of the short one. Check the diagonal to ensure that there is an error of no more than 3 mm. Weld the corners and check the diagonal again. After this, place 2 more profiles inside the frame and weld them parallel to each other at an equal distance. The result was a base for the table top.

Cut a 100x40 mm profile 1 m long. For a 2 m table you will need 13 pieces with a gap of 50 mm. Sand the edges with a sanding wheel to remove any burrs. Place the wide profile on the frame in 50 mm increments. Grab each element from the side in 4 places. Turn the frame over and weld the profile on each jumper with longitudinal seams. Alternate the seams so that the structure does not move.

Cut legs 80-100 cm long from a 60x40 mm profile pipe. On an inverted tabletop, insert the legs into the inner corners. Check the position with a square, tack with welding, and weld with vertical seams. Strengthen the legs with scarves with a side length of 10-15 cm.

From the 60x40 profile, cut out the jumpers for the lower tier, connecting the legs. Weld them with continuous seams at a distance of 20 cm from the floor. This will hold the structure together and serve as a support for your feet while working.

If other people are working in the workshop, create a protective screen. Weld a vertical profile pipe 50 cm high to the far corners of the tabletop. Attach a thin sheet of metal 0.8-1.0 mm to it with tacks.

To keep a hammer, slag separator, or grinder at hand, organize a shelf. Weld two additional 20x30 mm profiles to the legs under the tabletop, parallel to the horizontal surface. You can move 20-30 cm away from the tabletop, which depends on the dimensions of the tools placed on the shelf. You can put a thin sheet of metal or steel mesh on the profile. Tack it by welding.

To prevent the welding table from rusting, it is primed and painted. You can work with a brush or spray. Paint the counters, shelf, frame and lower part of the table top. The top is not painted, since it is exposed to high temperatures and the coating will burn (it will still smell strongly).

Helpful tips when working at a welding table

To operate manual arc welding machines, provide a small bucket on the side of the table to throw away electrode stubs. Then they will not stick to the sole, lying around under your feet.

A hook can be welded on the side for hanging the welding helmet. Then the protective glass will remain unscratched longer, and hot scale will not stick to the plastic.

It is better to make a shelf under the table at least 30 cm in height to accommodate large spools of wire if you plan to work semi-automatically.

For the electric holder or welding torch, it is better to create a hook on the right side (for right-handed people) so as not to throw it on the table or floor. For good ground contact of the grounding terminal, provide a place on the lower strapping contour that has been cleared of paint.

It is convenient to store welding electrodes in a special quiver attached to the tabletop.

You can build a welding table for a garage or workshop in 4-6 hours, if you have the necessary materials and tools. But subsequently it will be much more convenient to work, and productivity will increase.

Video source: weldmaniac

Answers to questions: how to make a welding table with your own hands?

How to prevent the welding table from wobbling? HideMore details

The easiest way is to place a plate of metal, tiles, or a block of wood under the sagging leg. A more reliable and durable option is to weld thick nuts with screws and rubberized coins into the legs. They will allow you to adjust the evenness of the table and even slightly the height.

How high should a welder's chair be? HideMore details

If there is a lot of welding work to be done with small parts, it is more convenient to do it while sitting at a table. The height of the chair depends on the height of the table and the height of the welder. Ideally, your knees should be bent just below the tabletop. Then you will be able to rest your elbows on them so that your hand does not tremble. Therefore, the legs of the chair should be high, like bar furniture.

Is it possible to make a tabletop from 2 mm sheet? HideMore details

Theoretically it is possible. But even when welding thin metals, deformation is possible at currents of 120-160 A, the sheet or strips will begin to warp. After a while, the tabletop will be covered in waves and it will be impossible to spread anything out to create a flat surface. It’s better to immediately buy 5 mm thick metal or a profile that will hold its shape due to the rigidity of the closed structure.

How to extend the welding table? HideMore details

If there is a need to increase the table area, weld a rectangular frame from two legs and two jumpers. Connect it at the top to the main frame of the table. Extend the surface of the tabletop using similar elements. Strengthen two new legs with scarves and tie them along the second contour to the others.

If the increased size of the table is needed only periodically, and the rest of the time a huge table will only get in the way, provide a folding surface on hinges with a support leg.

How to disassemble a welded moving table? HideMore details

If you need to transport a large welding table, which is made using welding (there are no bolted connections), you will have to use a grinder and a cutting wheel. Carefully cut the welds connecting the legs and the table top. Cut the seams of the reinforcing bottom contour. Use a hammer to knock off parts of the structure. Sign them first with a marker so that you can assemble them in the same order later. Before assembly, all protruding parts of the old seams will have to be sanded so that they do not spoil the plane.

There are still questions

Leave your contact details and we will contact you shortly

Feedback

Return to list