A universal chipping tool with a rotary impact mechanism, also known as a hammer drill, is used by construction crews, electricians and repairmen. They also use it in the home workshop.

Like other electrical appliances, a rotary hammer sometimes breaks down. Take it to a service center and leave a certain amount there, or take advice and repair the instrument yourself - everyone decides for themselves. If the decision to repair a rotary hammer at home has been made, you should first study the features of its design and the advice of experts on diagnostics and repair.

Disassembly and assembly procedure

Having cleared and freed a place in the workshop for repair work on electrical equipment, and prepared the necessary set of tools, the hammer drill begins to be sequentially disassembled to determine the malfunction, carefully inspecting each component and part. The tool is disassembled according to the following scheme.

How to disassemble an electric motor

To inspect the moving part, the first thing the master does is separate it from the impact mechanism and gearbox. To do this, unscrew the holding bolts (there are four of them), then:

- The rotor (or rotor armature) is removed from the gear drive sleeve.

- The separated motor is removed from the housing.

- The rotor and stator windings are diagnosed separately.

- The rotor armature is checked for the integrity of the windings and the absence of bridging and twisting turns. The technician will also pay attention to the bearings - if their integrity is compromised, they are removed and replaced.

- Having unscrewed the holding screws, the technician removes the stator by slightly shaking or tapping it.

- The rotor and stator windings are examined with a multimeter, measuring the resistance on the lamellas.

Important. If the stator winding is broken, the technician can twist it in a workshop, but if the fault is in the rotor armature, it will most likely have to be replaced.

The brushes sparkle

When the brushes sparkle, the first thing it is recommended to do is clean the tool from dust. If the effect of sparks does not stop, the device is disassembled and the integrity of the brushes themselves is checked. If necessary, one or both brushes are replaced to avoid shorting.

Disassembly algorithm

Do not forget that repair of a rotary hammer is only possible in de-energized mode! Due to the similarity in the internal composition of the main part of the hammer drills, the tool disassembly scheme is approximately the same. If no external faults are observed, you should start disassembling the device from the cartridge.

Next, the following parts are removed sequentially:

- rubber boot;

- retaining ring (using a screwdriver);

- plastic boot;

- washer;

- plate;

- spring;

- small metal ball.

When the last four parts wear out, the barrel cannot stay in the cartridge and begins to fall out. To fix this, you need to replace the broken part, and clean and lubricate the remaining parts.

The next part in the parsing algorithm is the body . The first thing to do is remove the switch. To do this, it must be transferred to the “Strike” state, indicated by a drawn hammer. Then, hold the button on this mechanism and turn it until it clicks.

To complete removal, take a screwdriver and use it to pry up the switch and remove it. In order to get to the electrical fault, it is worth removing the plastic housing.

This is not difficult; it is usually held on with screws around the perimeter. If there is a problem in the gearbox, it must be dismantled and damaged bearings replaced.

Read also: Accessories for electric sharpeners

Replacement of main components

If during diagnostics the technician determines that one of the main components has become unusable, he will replace it to avoid damage to other parts of the device.

How to remove the mode switch

To diagnose internal components, it is necessary to remove the hammer housing and clean the surface of the components from dust. The analysis begins with the compartment of the operating mode regulator.

It is moved all the way - as a rule, this is the extreme right position (below the rebound mode icon), after which, using a flat screwdriver, the regulator is removed from its socket.

Mechanical failures

If you hear the sound of the engine rotating, but the device does not perform functions, this means that problems are observed in the operation of the mechanical “stuffing” of the instrument:

- the impact does not transfer to the cartridge or the nozzle, i.e. stopped hitting and the blow disappeared;

- the rotation of the axis is stopped;

- hammers, but does not twist;

- works only in one position;

- the nozzle slips in the chuck clamps or, conversely, gets jammed after use.

Lost impact on the hammer drill?

Reference. The listed mechanical problems indicate malfunctions in the chuck mechanism. If grinding and extraneous sounds come from inside the case, in order to identify and eliminate the malfunction, you will have to disassemble the entire instrument and inspect the transmission units.

Repair instructions - replacing and connecting a hammer drill button using the example of Makita 2450

Most MAKITA rotary hammers (models HR2020, 2432, 2440, 2440F, 2450, 2455, 2475 and 2641) use a standard TG813TLB-1 series switch.

To inspect and/or replace it, you need to prepare the following tools:

- Phillips screwdriver;

- an awl or a knitting needle.

The procedure for repairing/replacing the power button on a Makita 2450 rotary hammer is as follows:

- Let's disassemble the electrical part of the tool. To do this, use a Phillips screwdriver to unscrew the three mounting screws on the back of the handle and remove the plastic cover.

- Next, you need to fold back the brushes and remove the TG813TLB-1 switch itself.

- To disconnect the switch, you must remove all wires from it. The network wires (brown and blue) are secured with a screw clamp and there are no problems with them - to remove the two wires, you just need to loosen two screws. The remaining wires are attached to self-clamping connectors, and to remove the wire you will need a knitting needle or an awl, which is inserted into a special hole and opens the clamp. In a similar manner, all wires are removed sequentially. To carry out repairs, it will not be superfluous to have a connection diagram for the hammer drill button on hand, so we strongly recommend that before removing the wires, sketch out a schematic diagram or take photos on your smartphone so that no questions arise when connecting the new button.

- Connecting a new button. The wires are simply inserted into the automatic clamps until they stop; the network wires are secured with screws.

- Next, you need to install the button in the mounting hole, return the brushes to their place, install and secure the back cover of the handle with three screws.

VIDEO INSTRUCTIONS» alt=»»>

Useful tips

Often even professional equipment quickly breaks down. This occurs due to the operation of the tool with significant overload of the electric motor. The power unit must not be allowed to overheat; technological breaks must be taken periodically. Sometimes serious damage to a hammer drill is a consequence of careless handling of the tool during operation or during storage.

After each use, it is necessary to thoroughly clean the rotary hammer from dust. Use a soft cloth or napkin to wipe not only the body of the power tool, but also the ventilation slots.

Carbon brushes, which are an important part of the electrical circuit, should be regularly inspected - they conduct current to the commutator and during operation gradually wear out and require replacement.

You should not buy non-original components of questionable quality, which can lead to more significant breakdowns.

List of sources

- pro-instrument.com

- shtyknozh.ru

- neknopka.ru

- domremstroyka.ru

- stroy-podskazka.ru

- www.novaso.ru

Everything a home mechanic needs to know about rotary hammer repair

A universal chipping tool with a rotary impact mechanism, also known as a hammer drill, is used by construction crews, electricians and repairmen. They also use it in the home workshop.

Like other electrical appliances, a rotary hammer sometimes breaks down. Take it to a service center and leave a certain amount there, or take advice and repair the instrument yourself - everyone decides for themselves. If the decision to repair a rotary hammer at home has been made, you should first study the features of its design and the advice of experts on diagnostics and repair.

- The structure of the tool and its mechanism

- Troubleshooting

- Mechanical failures

- Electrical faults

- Disassembly and assembly procedure

- Removing the cartridge

- How to remove the mode switch

- How to check the start button and brushes

- How to disassemble an electric motor

- How to disassemble and check other elements

- Possible faults

- Doesn't hit - reasons

- Doesn't spin or drill

- The drill does not stay in the chuck and flies out

- The brushes sparkle

- The tool gets very hot

- Doesn't hold a cartridge

- Replacement of main components

- Bearings

- Start button

- Brushes

- Cartridge

- How to repair a barrel tool?

- Daily care and storage

How to fix a rotary hammer with your own hands

The repair procedure at home is the optimal solution and will cost less than the services of service centers. Instrument repair is expensive and it is not a fact that you will find a conscientious repairman. Before you think about how to make a hammer drill, you should acquire the necessary tools and stock up on theoretical knowledge on how to disassemble and assemble a hammer drill. After completing the repair, run it in gentle mode.

READ How Drill Works Video

Barrel hammer drill repair

This procedure is no different from repairing a conventional hammer drill. Honor states that the engine and shaft are located vertically.

Oil is leaking from the drill

Leakage is a direct indicator of wear and tear on certain parts inside the mechanism. Spin the model and make diagnostics, change the lubricant if necessary.

Rotary hammer design, assembly diagram and spare parts list

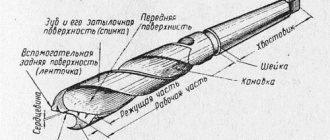

The tool consists of a single-phase motor and rotor. A gear located on the armature shaft is responsible for rotational movements. Between them there are bearings, one of which is “drunk”, it is this that transmits movement to the working parts.

The hammer drill does not rotate under load

Most likely, the load does not correspond to the permitted norm, resulting in this defect.

Why does the hammer drill heat up?

Most often, the reason for this is the length of operating time and heavy loads on the tool. The engine interacts with working units, which may result in overheating. When it appears, turn off the tool, give it time to cool - at least half an hour.

If the rotary hammer hammers but does not drill

- The conical spring holds the clutch, if it becomes loose, a problem may arise;

- The locking roller no longer locks the large shaft gear;

- stops working .

In this case, it is enough to replace or tighten up the problematic parts and start in a gentle mode.

How to repair a hammer drill if it stops working. We find out the causes of tool failures

The construction industry is developing and adding new tools every day. For several years now, the hammer drill . Essentially, this is a regular drill that is equipped with an impact effect. Every second worker encounters malfunctions.

The splines of the clutch, pos. 67, mounted on the intermediate shaft, were cut off

The malfunction can be eliminated by repairing the clutch or completely replacing it. When making repairs, the worn teeth on the clutch are filed down. To correct this defect, a round needle file and a drill are used. The coupling is clamped in the hand, and the tooth profiles are straightened using a drill with an appropriate file. The splines on the intermediate shaft are modified in the same way.

Restoring the teeth of the intermediate shaft clutch

The rolling bearing race has fallen apart (drunk bearing)

If the drunk bearing pos. 830 is destroyed, the rotational movement of the intermediate shaft cannot be converted into the translational movement of the cylinder in the impact mechanism.

Eliminated by completely replacing the rolling bearing.

Friction bearing

The hammer drill does not rotate under load

If the hammer drill has stopped hammering , the feasibility of repairs should be assessed. There is no point in restoring imitations of popular brands, cheap modifications - they are not designed for a long service life, the cost of repair is approaching the purchase of a new power tool. Models of famous brands last longer; their replacement is often caused by the appearance of modifications with additional capabilities and obsolescence.

Lack of preventive maintenance after 100-80 hours of operation will inevitably lead to failure of the hammer drill.

Mechanical malfunctions of the Bosch rotary hammer

When mechanical malfunctions occur in the operation of the tool, an extraneous unpleasant sound appears, sparking intensifies in the collector area, a burning smell appears, the tool heats up excessively, its power drops depending on the duration of operation and the impact on the material.

We will look at all the faults in the diagram of the Bosch 2-26 rotary hammer. Other models, such as Bosch 2-20, 2-24, differ in the design of the intermediate shaft and the installation of various bearings.

Let's consider options in which the hammer drill does not hammer, but drills

Wear of rubber rings on the striker, striker, piston.

This reason appears gradually as the rubber rings wear out. At first the blow weakens, then disappears altogether.

The malfunction is eliminated by replacing the indicated rubber rings with new ones.

For any repair of rotary hammers or their components, all rubber products must be replaced.

Repair kit for rubber sealing rings for a Bosch 2-26 rotary hammer

The mechanism for fixing the tool in the drill barrel does not hold the drill

Bosch rotary hammers use two types of chucks: SDS-plus and SDS-max. The difference is in the design of the locking mechanism.

The reason is the wear of the antennae of the chuck raster bushing, which makes it impossible to transmit the shock pulse to the working tool of the hammer drill.

Tool shanks for hammer drill chucks Bosch 2-26

"Drunk" bearing

It is mounted on the shaft at an angle and drives the piston. If there is wear or damage, the bearing must be replaced.

Mode switch

Mechanism parts may come out of the guide grooves. This may be a consequence of deformation, wear, or frequent use of the tool with the mode not fully engaged. The malfunction is eliminated by installing the parts in their places or replacing them with new ones.

How to choose a lubricant for a hammer drill?

One of the most popular products is diesel engine oil. Graphite lubricant is also quite good and is often used for open worm gears. Litol 24 is also popular, but this lubricant also causes braking and additional heating. Yes, and it works for a relatively short time, unlike branded lubricant for hammer drills and for cordless tools, it is extremely undesirable.

The brushes sparkle

Sparking brushes is a fairly common phenomenon when working with tools in dusty conditions. As a rule, sparking is a consequence of the deterioration of the material of the brushes themselves. Replacing the latter with new ones will help correct the situation; sparks will no longer fly out.

READ How to Disassemble a Bosch 2 24 Rotary Hammer

If not, the reason must be sought in the stator or rotor windings. It is possible that the large amount of dust entering the motor has caused the protective varnish covering the copper conductors to wear away. And this entails a short circuit. The presence of an interturn short circuit is checked using electrical instruments (multimeter).

Preventative maintenance of the tool: replacing brushes, lubrication of the rotor shaft bearings and additional varnishing of the windings on the coils will reduce the likelihood of breakdowns.

In addition, it should be taken into account that dust may adhere to the lubricant of the bearing located next to the commutator. To prevent this, the collector is degreased using a swab soaked in alcohol or solvent.

Hammer doesn't work

- A short circuit that led to the combustion of the rotor or stator;

- Complete wear of carbon electric brushes;

- The brush holders are loose and do not hold them;

- The lamellas on the collector are burnt out;

- The winding on the rotor or stator has broken;

- Battery failure;

- The power cord is kinked.

Winding can be done at home. If you decide to replace brushes, buy two at once, regardless of whether one or both are damaged. If a short circuit occurs, replace the burnt parts with serviceable ones. If the problem is in the wire or battery, buy new ones and install them in place of the old ones.

Hammer hammer impact mechanism

Most modern rotary hammers have an electro-pneumatic impact mechanism. “Electric” means that the mechanics are driven by an electric motor, and “pneumatic” means that the striker hitting the drill shank is driven by air.

- Engine rotation transmission gear

- "Drunk" bearing

- Piston

- Drummer (“flying piston”)

- Trunk

- Striker

- SDS cartridge

When you press the button, the engine transmits rotation to a shaft with a “drunk” bearing, which in turn drives the piston inside the barrel. As the piston moves forward, air pressure increases between it and the striker. The striker moves towards the striker and hits it. The striker transfers the impact energy to the drill. Then the piston moves in the opposite direction, creating a vacuum area in the barrel. Due to this, the striker returns to its original position, after which the entire cycle is repeated.

Most rotary hammers have two or three operating modes:

- combined mode: impact and rotation of the drill;

- Rotation lock mode: only the impact mechanism works;

- impact blocking mode: the hammer drill can be used as a drill or a mixer for preparing building mixtures.

How to repair a hammer drill / 2-24 / How to change the impact bolt / Drunk bearing / Maintenance / Repair

Happy upcoming everyone!))))) The hammer drill stopped

beat. Replacement: Grease, worn bearing, rubber band, ring for.

The device does not turn on.

This may be due to a broken wire. Very often the cord breaks near the handle itself.

Replace the entire cable or shorten part of it in the place where the break occurred. If the break occurs somewhere in the middle, strip it of insulation, connect the parts, and carefully insulate the cord.

Poor contact of trigger elements.

Such a breakdown can occur due to oxidation or burnout of contacts.

Clean the elements or replace with new ones.

Damage mechanism failure.

Under heavy load, parts of this mechanism simply burn out.

Replace burnt parts. If there are none, then you can connect the motor directly , but it should be noted that with this method of troubleshooting, the wear of the motor increases several times. It is best to use it only in extreme cases.

AUD burnout. There are no options - you need to change the mechanism.

Broken winding. It is unlikely that you will be able to fix such a breakdown yourself. Need a rewind.

Sparks are visible inside.

Malfunction of the drilling mode in the hammer drill

The list of the most common malfunctions of power tools invariably mentions the situation when a BlackDecker, Bosch, DeWALT or any other brand hammer drill does not work in drilling mode, but is actively chiseling the material being processed.

READ Trimmer Doesn't Work Without Choke

Effective impact is an important advantage of a hammer drill, but without rotation of the drill it will be almost completely neutralized. In this case, the functionality of the tool will be limited to short-term operations with a chisel, lance, etc. – long-term operation in the “chiseling without drilling” mode will quickly lead to breakdown of the mechanism.

Usually the simplest answer to the question is why, when switching to drilling, the hammer hammer hits as if in impact mode. Most likely, this is caused by a breakdown of the mode switch - a rather vulnerable component of many types of power tools. Replacing or repairing a switch can be done quickly and does not require large financial outlays.

You can preliminarily determine why a Makita, Metabo, Interskol, etc. hammer drill beats but does not drill by sound: if you can clearly hear the hum of the engine, but there are no rotational movements, then obviously the problem lies in a jammed gearbox. Sometimes gear teeth break off - broken fragments prevent them from turning.

Also among the most common reasons why hammer drills from Elitech, Hammer, Hitachi, STANLEY, RYOBI, Skil and other brands stopped drilling, service specialists name:

- wear of the teeth of the protective coupling - a characteristic “ratcheting” sound will be heard;

- abrasion of gear teeth between the engine shaft and the intermediate shaft;

- weakening of the conical spring holding the coupling;

- lack of fixation of the large shaft gear.

In any case, diagnostics will require disassembling the body and mechanical part of the instrument.

The masters of the “Udachnaya Tekhnika Service” center can easily cope with this work, select the necessary spare parts from the company’s own warehouse, and perform cleaning, lubrication, preventive checks and adjustments of other components. And all this - quickly, at a competitive price and with a guarantee of quality services!

Striker and striker

These parts are made of high-strength steel. The firing pin rarely fails, but the bushing in which it moves absorbs some of the impact energy and breaks down over time. The fragments jam the firing pin and the hammer stops hitting.

The firing pin (“flying piston”) has a compression ring. When it wears out, part of the air passes into the gap between the cylinder in the barrel and the firing pin. The more wear, the weaker the impact. The problem is solved by replacing the ring with a new one.

Sometimes the striking part of the “flying piston” breaks on the firing pin. This is usually the result of pressure on the hammer when drilling holes. The drilling speed does not increase, but the load on the mechanism increases, which accelerates wear. Repair consists of chamfering on an emery machine or replacing a part.

How to disassemble and check other elements

Having dealt with the electrics, the technician will begin to examine the mechanical components:

- Separate the plastic casing from the gear drive. In this case, it is recommended to run a magnet along the casing so that individual parts, for example, ball bearings, do not roll out.

- The axial shaft will be removed from the “drunk” or floating bearing; it is its “swinging” that transmits the shock impulse to the cartridge.

- Remove the drive gears (with crooked and straight teeth) by removing the retaining rings, after which the bearing will also be separated.

- Separate the retaining ring from the raster bushing and unscrew the impact bolt, after which he will check the integrity of the impactor, made of durable metals.

- After examining the components and, if necessary, replacing damaged elements, the structure is assembled in successive blocks. Craftsmen recommend lubricating every part and assembly during assembly.

Important! Two needle bearings are installed in the “drunk” bearing ring and on the raster bushing. The first of them experiences extreme loads during operation and often needs to be replaced.

Pros and cons of Hitachi rotary hammers

Advantages of Hitachi rotary hammers:

Wealth of choice

Hitachi currently offers the widest range of rotary hammers weighing from 2 to 18 kilograms, with various configurations and functionality. Low price with optimal quality distinguishes all Hitachi products. When choosing a hammer drill from this company, you should pay attention to the individual advantages of models of various classes. DH30PC2 is the most compact in its class yet has the fastest drilling and chiseling speeds

Assembly - Japanese. The three-mode DH28PC is equipped with a shock blocking mechanism. Assembly - China. Availability of parts for repair and the ability to repair rotary hammers in private offices. Original Japanese spare parts are an order of magnitude more expensive, but also an order of magnitude better quality.

Disadvantages of Hitachi rotary hammers:

- Inexpensive Chinese-made devices heat up quickly - you can work with such a tool continuously for no more than 30 minutes. During use, a specific smell of heated plastic often arises.

- Consumables quickly break down - plugs, cables, rubber bands on the strikers, regulators.

- A large number of Chinese counterfeits are sold in stores and resellers, which have nothing to do with original Japanese technologies or with the Hitachi company itself.

Mechanical malfunctions of the Bosch rotary hammer

When mechanical malfunctions occur in the operation of the tool, an extraneous unpleasant sound appears, sparking intensifies in the collector area, a burning smell appears, the tool heats up excessively, its power drops depending on the duration of operation and the impact on the material.

We will look at all the faults in the diagram of the Bosch 2-26 rotary hammer. Other models, such as Bosch 2-20, 2-24, differ in the design of the intermediate shaft and the installation of various bearings.

Hammer drill motor does not work

The reasons for a non-working electric motor may be:

- short circuit in the rotor, stator;

- destruction of carbon electric brushes;

- loosening of the brush holders;

- burnout of lamellas on the rotor commutator;

- breakage of the rotor or stator windings.

The listed malfunctions are eliminated by repair (manually rewinding the windings, replacing the commutator and desoldering the winding leads) or replacing the rotor, stator, and carbon electric brushes with new ones. The majority of malfunctions in the electrical part of the Bosch 2-26 rotary hammer are confirmed by increasing sparking in the collector area.

How to repair a hammer drill / 2-24 / How to change the impact bolt / Drunk bearing / Maintenance / Repair

The length of serviceable electric brushes cannot be less than 8 mm. When replacing one brush, the second should change automatically.

The rotor or stator windings can be rewound yourself at home.

Burnt rotor manifold of a Bosch rotary hammer

The hammer drill has stopped drilling, but is chiseling

The main reasons why a rotary hammer hammers but does not drill are:

- the force of the conical spring pressing the clutch has weakened;

- the locking roller does not fix the large barrel shaft gear;

- does not hold the tool locking mechanism in the barrel;

- The hammer drill does not chisel or drill.

The main reasons why a hammer drill does not chisel or drill are:

- sheared teeth on the small rotor gear or on the large intermediate shaft gear;

- The rotary hammer electric motor does not work;

- there is no power to the hammer drill motor.

The brushes sparkle

When the brushes sparkle, the first thing it is recommended to do is clean the tool from dust. If the effect of sparks does not stop, the device is disassembled and the integrity of the brushes themselves is checked. If necessary, one or both brushes are replaced to avoid shorting.

Doesn't spin or drill

Failure to rotate the drive shaft occurs either due to a breakdown in the gearbox, or if something has gone wrong in the engine itself. This can be determined by ear.

When the motor is running and you can hear its humming, it means that the gearbox is not transmitting rotation to the chuck. If, after starting the tool, the motor does not hum, the power supply is interrupted. Perhaps the circuit is broken somewhere or the turns on the coils are shorted.

READ How to Remove the Anchor from a Makita Hammer Drill

What to do if it doesn’t turn under load:

Replacing motor brushes

The main sign that it is time to change the brushes is the formation of increased sparking in the area of the electric motor commutator, rapid heating of the brush holders, and a burning smell. When the brushes are not worn out, the spark can only be seen under them. Otherwise, the spark is visible throughout the entire circle of the collector.

The presence of a spark around the commutator circle with unworn brushes is a sign of bearing wear, rotor or stator insulation failure, commutator plate burnout, stator or rotor burnout.

Another sign that the stator has burned out is the presence of sparks under only one electrode. If you have a tester, you can use it to check the stator and rotor: measure the resistance on the rotor and stator one by one. If it is the same on both windings, then everything is fine with the stator. If you notice clear signs of problems with the rotor or stator in your hammer drill, you will have to take the device to a service center for repair. As for the brushes, you can change them yourself.

To get to the place where the brushes are installed, you will need to disassemble the housing in which the motor is installed, or simply remove the back cover. Opening the lid, you will see brushes secured in special holders. The photo below shows what these parts look like.

Brushes that are installed on rotary hammer motors come in 3 types.

- Graphite ones are durable, but since they are very hard, their rubbing into the collector is not ideal, which negatively affects the latter.

- Carbon - easily rubs into the commutator, providing good contact, but wears out quickly.

- Carbon-graphite is an ideal option, since they are a mixture of 2 components that complement each other.

It is very important not to wait until the engine sparks and then change the brushes. Replacement is needed after they are worn to 1/3 of the nominal value (8 mm). Even if one brush is worn less than the other, both still need to be replaced.

READ How to properly use a hammer drill on concrete

Pay attention to the condition of the spring in new brushes and the fastening of the contact. If the spring falls off while the engine is running, it will suffer significant damage. Also, if the spring is weak, then it will not be able to provide good contact.

Before changing the brushes, be sure to thoroughly clean the rotor and stator from any remaining graphite or coal dust. These parts can be cleaned using technical or medical alcohol.

Next, you should secure the electrodes in the holders and rub them into the collector. To do this, place a piece of fine-grained sandpaper on the commutator and grind the electrode in with rotational movements in different directions. The grinding continues until the contact area of the electrode is slightly rounded. This will ensure a better fit to the collector plates and, accordingly, better contact.

Rotary hammer malfunctions

After a tool stops working, many users try to fix the problem themselves to save time. This is strictly not recommended, since the industry produces several types of rotary hammers:

- electromagnetic - the peak beats in them due to the reciprocating movement of the core inside the coils;

- electro-pneumatic - the clutch assembly transmits the shock through the air cushion to the flying piston through the impact piston.

The impact energy in the second case is five times greater, reaching 1.5 kW. In broken shanks of parts, fatigue damage begins over time, therefore, despite the air cushion, the pistons require periodic replacement. Rice. 1

There are straight, L-shaped tool bodies. The first are intended for limited spaces (niches, narrow cracks), the second - for the destruction of materials in the immediate vicinity of the working body. The cooling of engines of L-shaped models is much more efficient, so their service life is one and a half times longer than direct modifications. Professional rotary hammers are equipped with powerful electric motors, often have an L-shaped body, and are much heavier than their household counterparts. They are equipped with compensators that reduce vibrations on the tool body, electronic overheating protection systems, speed adjustments (for drilling mode), improved ventilation systems, and button locks.

Causes of hammer drill failure

The operating principle of the percussion mechanism of a rotary hammer.

If the hammer drill stops working , the reasons may be as follows:

- malfunction of the crank mechanism;

- development of the intermediate shaft;

- lack of lubrication;

- wear of the clamping unit;

- mechanical damage to impact elements (striker or clutch).

The hammer drill must be periodically lubricated by applying a special material instead of traditional Litol. Saving on equipment leads to intense wear of the barrel in which the bit/drill shank is located. Rice. 2

The hammer drill does not hit after a significant amount of lubricant leaks out of the gearbox due to wear of the seals and rings. Rubber parts operate in aggressive environments and extreme conditions. With a significant accumulation of dust and crumbs on their surface, the material loses its elasticity, bursts, and cracks under stress.

Diagram of the components of a hammer drill.

Violation of operating modes is dangerous for the hammer drill:

- inexperienced users put undue pressure on the body in the hammer mode, forgetting that the bit works due to the force of the internal mechanism, the amplitude of the striker stroke decreases, leading to its breakage;

- a change in the trajectory of the bit with some penetration of the working body into the material being destroyed leads to wear of the piston, striker, bearings, and crank assembly;

- Overheating of the tool during prolonged use in difficult conditions can result in shearing of gear teeth.

A hammer drill is often used for chipping ceilings, which increases the amount of dust in the spindle. External anthers are not able to protect internal components from abrasive penetration. Tools from two or three manufacturers are equipped with internal boots (for example, the Kress PK450HM model), so periodic inspection and cleaning of the clamping unit is required.

Strong noise in the gearbox indicates wear of the gears or broken teeth; excessive heating of this unit warns of either a lack of oil or damage to the bearings.

The power tool can operate in drilling mode without a hammer, but not vice versa. If the rotation unit is damaged, chiseling becomes impossible because the internal mechanisms become jammed. In this case, urgent repairs will cost ½ – ¾ of the cost of a new tool, which is economically unprofitable for the user.

What to do if the hammer drill stops hammering uninterruptedly

If the hammer drill has stopped hammering , the feasibility of repairs should be assessed. There is no point in restoring imitations of popular brands, cheap modifications - they are not designed for a long service life, the cost of repair is approaching the purchase of a new power tool. Models of famous brands last longer; their replacement is often caused by the appearance of modifications with additional capabilities and obsolescence.

Lack of preventive maintenance after 100-80 hours of operation will inevitably lead to failure of the hammer drill.

Preventive measures

It is better to prevent breakdown, so it is better to adhere to the following recommendations.

- Change the lubricant twice a year.

- Every six months, preventive inspection of brushes.

- Thorough cleaning every time after work.

- Before work, lubricate the back of the drill or chisel to reduce the load on the striker.

If the hammer drill stops working normally or breaks down, read the instructions and inspect it carefully. Before you start making repairs yourself, really evaluate your capabilities. If you are sure, try to fix it yourself, otherwise, if in doubt, it is better to contact a specialist. And remember that already repaired mechanisms are not subject to warranty and service centers are reluctant to accept them for repairs.

Troubleshooting Methods

Self-repair of a rotary hammer is extremely difficult due to its complex design. Even disassembling the case is often an impossible task for a home craftsman.

In addition to appropriate education, specialists from service centers of leading brands have regular work experience, the necessary tools, and equipment.

In addition, a diagnosis of a power tool is made during the initial inspection, which allows you to plan your budget: invest in an existing tool without guarantees of long-term operation, or spend money on a new power tool with a long service life and a manufacturer’s warranty.

Disassembling the rotary hammer gearbox: 1 – special ring, 2 – releasing sleeve, 3 – ring, 4 – ball, 5 – spring 8 – casing, 22 – closing spring, 28a – switch, 29 – ring, 30 – spring, 31 – latch.

The hammer drill is used in different modes, which significantly reduces the life of the working parts. In addition, specialized companies more often use either slotting (concrete, stone work, restoration of buildings, foundations) or drilling (installation of household and industrial equipment). If in the second case, following the manufacturer’s recommendations on drilling modes, you can extend the service life of the power tool, then in the first option it is very difficult to calculate the load. For example, with a specified maximum concrete drilling of 24 mm, it is recommended to use drills in the range of 18-16 mm. Peaks for breaking concrete, stone, and brick are standard, so the tool experiences different loads.

If the power tool stops hitting, you can limit yourself to disassembling the spindle assembly in the following sequence:

- dismantling the mode switch lever - the parts are usually made of polymers and therefore are quite fragile;

- detachment of the boot - the rubber corrugation must be periodically replaced, since it often comes into contact with destructible materials, wears out, and cracks;

- with a dismountable cartridge, the brushes are first removed; screws are loosened and unscrewed;

- the body is divided into two halves.

Visual inspection in 90% of cases allows you to identify a malfunction and replace the damaged/worn part. Before assembly, lubricant must be added and replaced.

Sources:

https://pro-instrument.com/ruchnoj/remont-perforatora-svoimi-rukami.html https://crast.ru/instrumenty/perforator-ne-krutit-pod-nagruzkoj https://slavasozidatelyam.ru/strojka- i-remont/pochemu-perforator-ne-bet/ https://slavasozidatelyam.ru/strojka-i-remont/ne-dolbit-perforator/ https://moiinstrumenty.ru/elektro/perforator-perestal-dolbit.html