Often the concrete surface has to be drilled and dismantled. This requires effective and safe tools that will not damage the surface and can make a neat hole. A drill is ideal for drilling a concrete surface, but you need to learn how to use it. Let's look at how to properly prepare the tool and surface for repair work.

Impact drill vs hammer drill

Both impact drills and rotary hammers are excellent for drilling into masonry. Although, of course, hammer drills are more powerful tools, and they have a special operating mode when only the surface is chiseled without drilling. They are usually equipped with an SDS cartridge, which copes better with the impact mode.

Of course, you can drill a couple of holes in a concrete wall with an ordinary drill using a masonry drill bit, but if you are faced with the task of making many holes in 50-year-old concrete, then you will probably want to find a more suitable one for yourself. convenient and effective equipment option. From this article you will learn all about the differences between an impact drill and a hammer drill and you will be able to understand which of these construction tools is right for you. We'll also introduce you to the most essential accessories and share some helpful tips on how to get the most out of these great tools.

All impact drills and rotary hammers are equipped with an impact function, which makes them extremely effective when working on masonry. In parallel with the rotation, both tools drive the drill into the surface of the masonry. These two instruments differ from each other in the mechanism that provides the percussion function.

In an impact drill, this mechanism consists of two toothed discs pressed against each other (see Figure A). When one disk, rotating, clings with its teeth to the teeth of the second disk, it then rises and then falls, as a result of which the cartridge produces an oscillatory (shock) movement. If there is no pressure on the chuck (when the drill is not pressed against the surface), the discs disengage and the impact mechanism stops. This prevents premature tool wear. Most impact drills can be used as a regular drill for drilling holes by simply turning off the impact function.

Figure A. Inside an impact drill: Impact is produced by two toothed discs.

In a hammer drill, the impact is achieved by a hammer piston driven by a crank shaft (see Figure B). The impactor piston performs translational and reciprocal movements in the cylinder and, when moving forward, creates air pressure, which activates the impact mechanism. Rotary hammers have much more impact power than impact drills. They are much more durable and are the main tool for professionals for this type of work. Another undoubted advantage is that most hammer drills can operate in three modes: drilling mode, impact-drilling mode and chiselling mode, so in some cases they can even be used as a jackhammer. Of course, they are more expensive than an impact drill, but we will return to this issue a little later.

Figure B: Inside a Hammer: A piston compresses air to produce a blow.

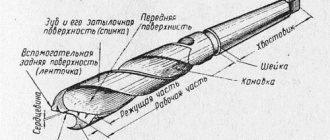

Impact drill bits

Impact drills are ideal for light masonry work.

An impact drill works best for holes in brick, mortar, and concrete blocks. But it can also drill a couple of holes in poured concrete.

You don't necessarily have to spend a fortune on drill bits, but keep in mind that more expensive drill bits tend to be made from high-quality alloys and have tips that are more firmly attached to the shank, greatly reducing the risk of them breaking under heavy use.

Surface preparation

Before drilling, the surface should be carefully prepared. The work site must be free of wires and other elements that could be dangerous if a drill gets into them. Therefore, it is best to use a metal detector to make sure that there are no cables.

After carefully checking the walls and any other concrete surface, you need to select a point where the hole will be drilled. You need to mark it with a marker or pencil, and then carefully drill a small recess. This is important to do so that it will be easier to carry out further work later. At this point, the preparatory stage can be considered complete.

Accessories for rotary hammers

Rotary hammers are designed for heavier construction work

Rotary hammers are excellent at drilling holes in hardened concrete.

They can also be equipped with various useful attachments.

The most popular type of chuck found on hardware store shelves today is the SDS-Plus chuck. SDS-Plus type drills have special grooves on the shank, due to which the drill is securely held in the chuck, but at the same time it can perform translational and reciprocating movements independently of the chuck. These drills are very easy to install and remove - no additional equipment is required. Some heavy-duty rotary hammer models use a similar clamping system, which differs only in its increased size - it is called SDS-Max. In addition, there are several brands that have developed their own clamping systems and corresponding drill bits, so when purchasing accessories, make sure that you buy an attachment that will fit your hammer drill.

A hammer drill operating in chiselling mode can be used to perform many types of repair and construction work, and in order to make this work easier for us, manufacturers have created a huge number of all kinds of attachments.

Possible equipment for the hammer drill includes various attachments for metal processing, chiselling, removing tiles, and even digging hard ground (in the picture on the left is a spade attachment for the SDS-Max chuck). In addition, you can attach a three-jaw chuck to the tool to use traditional drills.

Some of the most popular attachments are shown in the photo above:

- Earth Spade Attachment: Helps break up hard soil.

- Chisel for cold cutting: designed for chipping concrete.

- Tile Remover: Great for removing old ceramic tiles.

- Pointed chisel: This is useful for making pilot holes.

- Chisel: designed to remove rust, concrete deposits and splashes of molten metal.

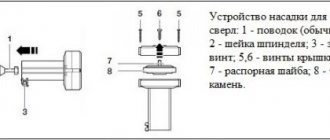

If you already have a hammer drill and are looking to buy a powerful drill for drilling large holes, for example in wood, then we would recommend that you consider purchasing an SDS-Plus chuck adapter (shown in the photo below). This adapter will allow you to use cylindrical drill bits, hole saws and paddle mixers. The only thing is, do not forget to switch the hammer drill to drilling mode, otherwise the chuck may break.

Adapter for SDS-Plus socket. This adapter allows you to use your rotary hammer with cylindrical drills, hole saws and paddle mixers. Attention! When performing such work, the device must be in drilling mode, otherwise you will simply break the chuck.

Choosing a suitable drill

Some drills will even drill through rebar. If you need to drill a hole in a reinforced concrete surface, do not skimp and buy a special drill designed for drilling concrete even through metal mesh and reinforcement bars.

For about $50 you can buy an impact drill that can drill shallow holes in most types of masonry, but by spending a little more on a hammer drill you will get two benefits in return: the ability to drill deep holes and, just as importantly, faster drilling speeds. which is especially important when you have to drill many holes at once.

The impact power of a drill is measured by BPM (blows per minute). But this is far from the only important indicator of the performance of an impact drill: much more important are the amperage of its motor and how conveniently this tool lies in your hands. All metal cartridges are more durable than cartridges with plastic parts. Quick-release chucks are undoubtedly more convenient for everyday work, but they are not well suited for drilling masonry, as they lack the holding force of the drill.

How to drill through a concrete wall with a regular drill?

The diameter of the chuck often determines the maximum recommended hole size that can be drilled with a particular drill.

The impact force of a hammer drill is measured in Joules. When choosing a hammer drill, remember that the more powerful the model, the better, but the force of its impact is even more important. Rotary hammers are classified by the maximum hole size they can drill according to the manufacturer's recommendations, but this does not mean that this tool is not capable of drilling a larger hole from time to time.

If you only need a drill to make couple-centimeter holes and nothing more, then buy a more powerful model so that it does not have to “puff” at maximum power all the time.

Work with large diameters

At the beginning of the work, the area where the hole should be formed is outlined. It is important to observe dimensions here. When the hole diameter is 100 mm, then the circle needs to be drawn at approximately 20 mm. This is typical for situations where the drill deviates from the working circle. Even a small shift can damage the surface if this is not taken into account from the very beginning. You need to make sure that the drill goes through the walls. Only in such a situation can you be sure that the hole will be made correctly.

Secrets of mastery

- Clear Debris

The grooves on the drill bit are designed to remove debris from the hole as you drill, but to keep the hole as clean as possible, simply remove the drill bit from time to time as you work. This simple technique will help reduce friction, as a result of which the drilling process will proceed more smoothly, the drills will not get stuck, and they will last longer this way. - Know how to stop in time

Most impact drills and rotary hammers are sold complete with a side handle and a drilling depth limiter. Don't be lazy to use them! You should not drill holes deeper than you need, and thereby “kill” both your time and the drills. And it’s not always necessary to make a through hole: for example, some plastic anchors must be installed in a concrete block with a stop, otherwise they may simply fall out on the other side of the through hole. - Do not press too hard

When drilling, it is important to grasp the optimal ratio of drilling speed and pressure on your part, at which the drill begins to work in the fastest possible mode. But you are unlikely to achieve this if you press the drill with all your might. The fact is that too much pressure will, on the contrary, slow down the drilling process and lead to premature wear of the tool motor. In addition, in the process of such rough operation you risk breaking all your expensive drills. - Start with a small hole

If you need to drill several holes that will be larger in diameter than the maximum recommended by your drill manufacturer, make a smaller hole first. This will significantly reduce the load on the drill. In addition, smaller drills do not glide across the surface as much as larger ones, which means this advice will definitely come in handy in a situation where you need to drill a hole in a precise location.

Some useful tips

Before starting work, you should stock up on attachments for drilling not only concrete, but also metal, because... During work, drilling of reinforcement may be required. During operation, it is necessary to monitor the degree of heating of the device. Overheating must not be allowed. You need to take a break every 15 seconds to let the device cool down. Drills made of relatively soft material require periodic sharpening.

If it is necessary to make a hole for further installation of a plastic dowel, you should take a longer drill. This will prevent the dowel from being placed incorrectly due to dust accumulating inside. You should start working at low speeds. This will make it easier to control the drill.

As it deepens, you can increase the number of revolutions. You should periodically check how securely the nozzle is held. If it becomes loose, it should be replaced.

If you need to drill through a concrete wall without damaging the decorative ceramic coating, you should not use the impact mode, because this will damage the tiles. In this case, you need to use a special nozzle for ceramics. This will help make a clean hole and avoid damaging the tile.