It is known about the hammer drill that it is a highly specialized tool that is designed to perform percussion work. To do this, a corresponding nozzle is attached to the tool chuck, which has a special shape of the tail section. If you need to use the impact tool in question, but there is no drill in the package, then only an adapter for a hammer drill for a drill, into which you can install any type of cylindrical attachments, will save you. More details about the design of this device are described in the material.

Device for securing a drill in a hammer drill

There is no better tool for drilling concrete and reinforced concrete than a hammer drill. The tool differs from the drill not only visually, but also in the design of the chuck mechanisms. If the drill design uses chucks with a collet mechanism, then rotary hammers use special devices of the SDS design. The installation of working attachments is carried out using a special clamp, which is presented in the form of slots for centering and balls for fastening. This is done so that the nozzles in the cartridge of the impact devices have some play. This play is needed so that the drill and other types of attachments make reciprocating movements when drilling concrete materials.

Often there is a need not only to drill concrete, but also to drill holes in wood, metal and other materials. For such purposes, you can use a hammer drill, but only in drilling mode. In addition, you must insert an attachment into the tool chuck - a drill for metal or wood. It is irrational to buy such drills for a hammer drill, especially if drills of the required diameter are available for a drill. To combine the tool with a regular drill bit, you will need to buy an adapter. This device is also called an adapter for a hammer drill, which is popular.

This is interesting! Having a special adapter, you can drill holes in durable materials with ordinary drill bits for concrete. This will allow you to save on the purchase of drills, which, unlike concrete drills for a drill, are somewhat more expensive.

While a drill with a special shank design can be installed in the collet chuck of a drill, it is impossible to secure a cylindrical drill in a hammer drill without a special device (connector). However, it is not recommended to use drills and other types of attachments in the chuck of a drill or screwdriver, since the collet mechanism does not allow the attachment to be centered. As a result, it turns out that when working with a drill with a drill from a hammer drill, the load on the tool increases due to the low straightness of the nozzle.

So, knowing why you need to insert drills with cylindrical shanks into powerful power tools, let’s figure out what the device for such attachments is.

Types of drills for hammer drills

It should be immediately noted that a drill is an accessory for a drill, and a drill is used in rotary hammers. The difference is explained by the fact that the hammer drill makes holes, but does it with simultaneous chiselling, that is, drilling is obtained.

Tips come in the following types:

- chisel;

- drill;

- lance or chisel lance;

- channel drill;

- crown.

A drill, similar to an ordinary twist drill, is used to make round holes, usually for a dowel or dowel-nail. In construction stores it is often defined as a drill bit for a hammer drill.

The chisel is designed for removing plaster, tiles, tiles or any other worn-out coating. It is convenient for them to carry out dismantling by simply prying up the material to be removed.

The lance is convenient to use when scoring or punching holes in concrete or other hard surfaces. The tool has a noticeably larger diameter than a drill and is characterized by increased “bounceability”. This tip is used when it is necessary to make larger holes, which can be achieved using a drill.

A channel drill is indispensable when you need to make grooves for wiring or installing interior items: guides for plasterboard structures, fastening sliding or false walls.

The crown is used to make holes for placing switches and sockets. Modern drills for rotary hammers are available in any size, among other things, for installing these electrical devices.

Drills are made from steel grades:

- alloyed;

- high-speed;

- carbonaceous.

For processing hard materials, drills are equipped with heavy-duty soldering.

Even particularly strong metal drills for rotary hammers are ineffective when processing thick material. Their scope of application is limited to thin sheet metal.

Based on the type of working tip, drills are classified into the following types:

- Screw type, designed for making deep holes. Thanks to the spiral design and significant torque, crumbs and dust are removed, the load on the hammer is reduced, and the work time is reduced.

- Drill with a slight slope of working chutes. Used for work that requires little force, for example for making many shallow holes in relatively soft materials.

- A drill with a significant inclination of grooves, characterized by high drilling speed. The load on the hammer drill from such drills is higher than when using auger drills. Designed for making deep holes.

- Drills with one or more spiral grooves or grooves of a special shape. This tip ensures high drill stability, balanced rotation, and reduced vibration load on the hammer drill.

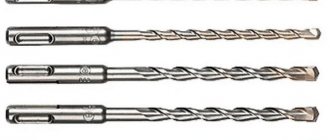

No less important is the shape of the rear part of the drill, clamped in the chuck - the shank.

The most commonly used:

- SDSplus. Used for low and medium power hammer drills. The depth into the cartridge is 4 mm, the size of the “tail” is 10 mm.

- SDS is a special guide system. The drill is held in the chuck by clamps. The diameter of the tail part is 10 mm.

- SDSmax. Format used in a powerful professional tool. The diameter of the shank is not 10, but 18 mm, the recess into the chuck is 9 mm.

- SDStop. Used primarily in BOSH rotary hammers. The tail size is 14 mm.

- SDSquick. It is also a development and is used in instruments of this brand only.

For a certain type of cartridge, only use drill bits of the same type. Otherwise, the “tail” is not fixed and wobbles under load, which can cause injury.

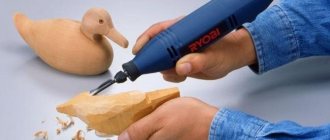

How a regular drill is inserted into a chuck

If there is a need to make a hole in metal or wood, but the drill is not working, then there is a way out - take a tool, a drill and an adapter. Of course, many will think that it is easier to buy the appropriate SDS metal drill for a hammer drill, but that was not the case. Even if you manage to find such a drill of the appropriate diameter, it will cost at least 1.5 times more than a regular drill.

This is interesting!

Manufacturers produce sds plus , which are designed for drilling metal and wooden structures.

However, due to the special design of the shank, the cost of such devices differs from the price of drills with ordinary cylindrical shanks. As a result, it turns out that it is much more profitable to buy an adapter for a hammer drill for a drill, and use a nozzle of the appropriate diameter, than to buy a drill with a special shank shape. Many people don’t even know what an adapter or adapter for a drill to a hammer drill is, so let’s look at the design of the device.

Structurally, the adapter consists of two parts:

- The shank is the part that is inserted into the chuck of the unit. The tail part has a similar design as drills and other sds plus type attachments

- Threaded part - a collet chuck from a drill and screwdriver is screwed onto it. At the end of such an adapter there is a screwdriver bolt for fixing the devices. When choosing adapters, you need to take into account the size of the thread onto which the chuck from the drill and screwdriver is screwed.

The thread on the tip of the adapter is not right-handed, but left-handed, that is, in order to secure the cartridge to the adapter, you will need to rotate it to the left. The chuck from the drill is installed on the adapter for the hammer drill, and after that all that remains is to insert the corresponding drill into it and use it on the hammer drill.

This is interesting!

If you plan to install a concrete drill into the collet chuck structure and work with it in a hammer drill, then it is not recommended to do this for a long time.

The impact actions performed by the unit mechanism are quite strong, so collet keys and quick-release chucks can quickly fail. The adapters are made of tool steel, so they can withstand heavy loads. The cost of such an adapter does not exceed 150-200 rubles, while for that amount you can buy only one attachment. An adapter for a hammer drill is a universal device that significantly expands the capabilities of the tool. Moreover, in a collet chuck from a drill, which is fixed in the power tool chuck through an adapter, you can fix not only drills, but also crowns, mixer attachments for mixing mixtures, as well as polishing and other types of working attachments.

Collet type chucks

Not all rotary hammers belong to the modern SDS system. Today you can find tools with collet-type clamps, among which it should be noted:

- Key type cartridges. Such a fixing part allows the installation of a shank with a cylindrical rear part. Special slotted keys drive the cams, which ensures reliable fixation of the nozzle. Among the disadvantages, it should be noted the complexity and time consumption of installing and removing the working part.

- Among the collet-type models, quick-release chucks are also known. The principle of operation and design of such a part are similar to the clamps on screwdrivers.

Both types of cartridges should not be used in impact hammer drills, since the parts will quickly fail.

Why is it better to drill metal with a hammer drill?

Not only drilling concrete, but also drilling metal or wood is best done with a powerful power tool, which is a hammer drill. This tool copes with any complex tasks, which is associated with the use of more powerful electric motors. Power ratings range from 700 W and above, while drills use electric motors with a power of 300 W or more.

In addition, the unit has great torque, so there are no difficulties with mixing dry mixtures. If you have a hammer drill, then you don’t need to buy a specially low-speed drill or mixer, because this power tool will cope with the task of mixing the solution.

The reasons why it is better to choose a rotary hammer for drilling than a drill are as follows:

- Greater power, which will allow you to achieve positive results faster than using drills

- Great torque force - this indicator is very important when using power tools for mixing dry mixtures and drilling wood with a large diameter drill

- High rotation speed - for this purpose, special regulators are used in the design of straight or pistol units. When the chuck rotation speed decreases, the torque increases, and when it decreases, on the contrary, the torque decreases, but at the same time the number of revolutions of rotation of the actuator increases

Now that you know why it is necessary to buy and use drill adapters for hammer drills, you should immediately order them or purchase them at your nearest tool store.

This is interesting!

Manufacturers also produce special collet chucks for rotary hammers, however, this option is irrational to purchase, since the time for replacing devices takes at least 15 minutes, while installing the adapter is done in a matter of seconds.

What type of shank is on the hammer drill adapter?

A pertinent question is what type of shank has an adapter for drills for mounting in a hammer drill chuck. Manufacturers produce exclusively one type of adapters, which can only be installed in units with sds plus type cartridges. Manufacturers do not produce such adapters for units with sds max type cartridges, and the reasons for this are the following factors:

- Rotary hammers with sds-max chucks do not have a drilling option, so you cannot use ordinary metal or wood drills in such tools

- Tools with sds max chucks are quite powerful (from 1.5-2 kW and above), so using fragile drill bits in them is simply irrational. They will quickly heat up, wear out and break.

As a result, it turns out that adapters for hammer drills for installing drills are used only in household and semi-professional power tools. Such units have the following options:

- Chuck rotation speed regulator, which allows the tool to be used not only for drilling metal and wood, but also for mixing solutions

- Mode switch that allows you to turn on the drilling mode. It is in this mode that you can use drill bits from a drill in a hammer drill, installed through a special adapter

- Reverse is another useful option that allows you to free a jammed drill in a metal base or mix the solution in two directions

This is interesting!

If you have a barrel perforator or a straight one, but without a drilling mode, then buying an adapter for drills does not make sense, since using it in such tools is not only impossible, but also impossible.

How to combine a hammer drill with a regular drill

In drills, torque comes from the electric motor shaft to the chuck that secures the drill, and only the direction or speed of rotation changes.

The shaft and drill rotate together. The clamp is a collet device that secures the shank. Rotary hammers use a universal chuck, which is used both for drilling and when chiselling is necessary. In it, torque is transformed into reciprocating movements or rotation. For this reason, hammer drill chucks must be able to withstand both axle load and torque.

Under certain operating modes, these loads can act simultaneously, therefore the use of simple collet clamps, like a drill, is unacceptable.

The device of the adapter chuck for the drill

The drill shank, inserted into the clamp, has a cylindrical or conical shape. It has two pairs of grooves running along its entire length - two open and two closed.

The typical design of the cartridge is as follows:

- a splined bushing mounted on the motor shaft;

- sleeve ring;

- a cone-shaped spring supporting the ring;

- retaining balls placed between the sleeve and the ring;

- a casing that covers the entire assembly.

The drill is secured when the shank enters the sleeve. In this case, the open grooves coincide with the splines, and the balls supporting the ring fit into hidden holes. As a result, the drill is prevented from falling out of the clamp; torque is transmitted from the shaft through splines. The heel of the shank receives impulses from the hammer hammer.

Adapter from sds max to sds plus

I know everything about the difference between sds max and sds plus cartridges. Situations often arise when your tool arsenal includes a hammer drill with an sds max chuck type. These are good and powerful units that are designed to perform serious work. For such units, corresponding attachments are produced, which cost 2 times more than drills, shovels, etc. for tools with sds plus chucks.

That is why, in order to save budget, manufacturers produce special adapters that allow you to install nozzles with sds plus type shanks in the sds max hammer drill chuck. This is not only profitable, but also very convenient, since it is very difficult to find a small-diameter sds max drill. The video shows in detail what the adapter from sds max to sds plus is and how the corresponding attachments are attached to it.

It is only worth noting one factor: the cost of such adapters, compared to those that allow you to attach a drill bit to a hammer drill chuck, is quite high. Their price starts from 1000 rubles and above, which depends on the quality of the steel used in their manufacture.

This is interesting!

attachments for SDS plus SDS max tools , it is necessary to take into account that they can quickly not only wear out, but also break under the influence of high impact force.

It is contraindicated to use drill bits for drills in the design of powerful units with sds max cartridges, using two types of adapters. The reasons for such contraindications are indicated above.

How to choose the right adapter for a hammer drill for a drill

When choosing an adapter, no difficulties arise at all, since manufacturers produce only models that have sds plus shanks for a hammer drill. Shanks of this type have a diameter of 10 mm, as do the nozzles. It is not necessary to buy a drill chuck, since it can be removed from the power tool. Moreover, you can use cartridges not only from drills, but also from screwdrivers.

It is worth considering that it is much safer to use key-type clamps, since they firmly fix the nozzle, unlike quick-clamping ones. It is impossible to make the transition from sds plus to sds max, and there is no need to. After all, the most popular are rotary hammers with sds plus type cartridges. When purchasing, you need to take into account the diameter of the hole on the collet chuck. They are different, so first you need to clarify the diameter of the hole, and then order the appropriate adapter for the hammer drill for the drill.

This is interesting!

SDS this name from a German developer. The full decryption looks like this: “steck -dreh -sitzt ”.

Translated from German it means insert, turn and seat. In addition, there are also adapters for bits that allow you to install appropriate attachments in the hammer drill chuck for unscrewing or screwing fasteners. If there is an adapter for switching to a collet mechanism, then it is not necessary to buy such a device. What the device is is shown in detail in the video.

Knowing all the advantages and disadvantages of the considered device in the material, one can draw an appropriate conclusion about the rationality of their use. In a household where you have both a hammer drill and a hammer drill, the adapter will play an important role, so it is recommended to buy it before you need it. And be sure to consider the size of the thread the chuck is screwed onto, as they come in different sizes and buying at random "should fit" always comes down to the need to replace the device.

How to insert a drill

To install the drill in the chuck, lightly press on the casing: the spring will compress and the slots in the shank will fit into the slots.

When the casing is released, the spring moves the ring, the locking balls enter the closed slot of the tail section. In the case of quick-release chucks, you can insert drills into hammer drills without any difficulty. But a screwdriver attachment or ordinary drill bits for drills cannot be installed in fasteners of this type.

To use a tool with smooth round shanks, you need to purchase an additional element - a collet chuck with a special holder with grooves.

The element is placed on a hammer drill, after which it is possible to use conventional drills.

What kind of hammer drill do you use? Is it possible to use a regular drill with a round shank in your model? Please share your experience in the comments.