A vortex pump is a device whose task is to pump water from wells, reservoirs and storage tanks. Equipment of this type is used in conditions where it is necessary to create high pressure of liquid with relatively small volumes. At the same time, the composition of the pumped liquid should not contain chemical impurities.

Vortex pump - device and principle of operation

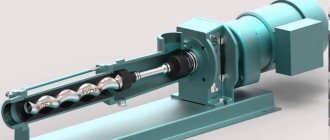

The high-pressure vortex pump has a fairly simple design.

The main part of its device is an impeller equipped with blades. It is located in a durable housing and is fixed on the shaft. There is a gap between the body and the wheel, no more than 0.2 mm wide. The main difference between these pumps and axial units is the method of supplying fluid inside the casing. In vortex devices, liquid is supplied along the line of contact with the impeller. This design of the vortex pump makes it easier to operate and repair.

The operating principle of the device is to rotate the wheel along with the liquid. The sucked water is affected by the centrifugal force of rotation and the suction force that is generated in the grooves. Thanks to centrifugal force, the liquid is directed towards the periphery of the blades. As a result, a vacuum is formed in the grooves, due to which suction force appears. When it suppresses the centrifugal force, the water begins to move towards the wheel.

This procedure is repeated until the impact forces become equal. As a result, a vortex appears on each of the blades, which increases the pressure. Despite the rather complex principle of operation, the design of a vortex pump is extremely simple.

Operating principle

The housing of such a pump usually has a snail-shaped shape. Inside there is a shaft on which an impeller with blades is located. There are two flanges at the edges - suction and pressure. In most cases, the pump unit consists of a hydraulic pump and an electric motor.

Next, we will consider each element separately and describe the functions that they perform:

- Electric motor - this element in the design of a centrifugal pump plays the role of a drive. The driving part of the electric motor, which is located in the pump, is carefully sealed.

- Impeller shaft - its function is to transmit rotational action from the electric motor to the impeller.

- The impeller is located on a shaft and has curved blades.

- Sealing parts – protect parts of the unit from ingress of the pumped liquid.

Basic principles of operation of a centrifugal pump:

- Through the suction flange, the liquid enters the working chamber of the pump and moves due to the blades located on the impeller.

- With the help of centrifugal force, the liquid medium hits the walls of the working chamber and creates excess pressure.

- The excess pressure forces the fluid through the pressure flange.

- The absorption of a new portion of liquid occurs as a result of the formation of excess pressure in the working chamber.

Centrifugal pumps are manufactured as single-stage or multi-stage. The latter are called “sectional centrifugal pumps”. In such units, an increase in the total pressure drop is achieved, which is proportional to the number of sections of the unit. At the same time, the principle of their operation in any design remains the same - the liquid moves under the influence of centrifugal force, which is created by a rotating impeller.

In accordance with the processes listed above, all elements of the centrifugal pump ensure continuous pumping of liquid and guarantee the stability of all necessary pump operating parameters. This principle of pump operation applies not only to the surface type, but also to the deep type.

The centrifugal pump must not be operated if there is no liquid inside the working chamber. If these rules are neglected, the unit will fail. It is advisable to use a pump for pumping large volumes of liquid on an ongoing basis at low pressures.

The most important thing in the operation of the unit is not to encounter such a problem as cavitation. This process occurs as a result of the formation of bubbles in the liquid due to the occurrence of rarefaction zones in it. They end up in a zone with higher pressure. The bubbles collapse and create powerful energy that destroys the insides of the pump. But there are cases when the housing itself is destroyed.

More details about the operation of a centrifugal pump are described in the following video:

Advantages and disadvantages of vortex equipment

Vortex water pumps have several advantages. These include:

- Lower cost compared to other types of equipment;

- Simple design;

- Ability to independently absorb water;

- Possibility of use in liquid-gas mixtures.

Units of this type also have a number of certain disadvantages. Firstly, they have low efficiency - on average it does not exceed 45%. This indicator does not allow vortex pumps to operate at consistently high power. Secondly, the pumps cannot cope with pumping high-viscosity liquids.

Varieties

Vortex type pumping equipment can be divided into two types:

- open-vortex units;

- closed vortex pumps.

Their operating principle is slightly different, since the first type of pumps have:

- extended impeller blades;

- reduced diameter of the impeller in comparison with the clearance of the working channel;

- the annular channel in the device is connected to the pressure hole.

Closed-vortex units have the following structure:

- shortened blades installed at different angles of inclination (tilt forward, bend back, or at a certain angle back or forward);

- the diameter of the impeller is equal to the clearance of the working channel;

- the annular channel has a direct connection with the inlet and outlet.

The principle of operation is different for each variety. During operation of the open-vortex unit, water from the inlet pipe enters the annular channel through the inlet and the working chamber with the impeller. Here, the working vortex process contributes to the formation of a pressure flow. This flow is directed through the outlet into the main pipeline.

In closed-vortex type units, the aqueous medium from the suction pipe penetrates through the inlet into the annular channel. Here a pressure flow is formed and directed through the outlet into the main pipeline.

Classification of units by method of action

Depending on the mode of action, vortex pumps can be of the following types:

- Reciprocating - in such units, fluid circulation is carried out by moving a piston located in the cylinder. On sale you can find reciprocating vortex pumps, both with a piston and with a membrane;

- Rotary - in these devices a piston displaces water. Based on the type of working body, such pumps are divided into roller, screw, vane and gear pumps;

- Dynamic - in these pumps, the movement of liquid is carried out as a result of the transfer of kinetic energy to it.

Each of the listed types of units has found application in specific areas. They differ from each other in design and dimensions.

Separation of pumps according to the type of arteries and wheels

Depending on the location of the waterway, the following types of vortex pumps can be found on sale:

- Units with open artery:

- Pumps with a closed water artery.

According to the types of impellers, pumps are divided into:

- Open wheel equipment;

- Devices with a closed wheel.

Closed-type pumps are equipped with short blades. Liquid suction is carried out through a special pipe. Such units have a low cavitation rate. Due to the joining of the longitudinal vortex and the liquid substance, the rate of movement of the water at the inlet slows down slightly. In order to increase the cavitation properties, a centrifugal stage is connected in front of the vortex wheel. Such equipment is called centrifugal-vortex. These units have a slightly higher efficiency than vortex pumps, about 48%. Devices of this kind are widely used for water supply systems and boiler power supply.

Units with an open wheel differ from devices of the previous type by the longer blades. Due to this, their cavitation rates are an order of magnitude higher, which allows them to be used for pumping wastewater in industry and utilities.

Nowadays, many manufacturers combine the properties and advantages of several types of equipment in pumps. Thanks to this, on the modern market you can find vacuum, air and thermal vortex pumps. The main difference between these devices lies in the technical characteristics and areas of application. Units of the first type are successfully used in the chemical industry for working with gaseous substances. Thermal devices have found application in providing liquid to various steam power plants. Air vortex pumps are used to maintain the operation of deep industrial water wells.

Membrane devices

A diaphragm pump is a relatively new type of equipment for pumping liquids and other substances. This type of equipment is capable of working with a gaseous medium and does this through a special membrane or diaphragm. It performs reciprocating movements and changes the volume of the working chamber with a given cyclicity.

The device design includes:

- membrane;

- working chamber;

- rod for connecting the diaphragm to the drive shaft;

- crank mechanism;

- valves to protect against backflow of substances;

- inlet and outlet pipe.

The work is carried out as follows: when starting, the rod bends the membrane, which increases the volume of the chamber and creates a vacuum effect in it. This phenomenon ensures the suction of the pumped medium. After filling the chamber, the rod returns the membrane to its place, the volume decreases sharply, and the substance is pushed out through the outlet pipe. At the same time, in order to prevent liquid or gas from getting back during the return movement, the inlet is automatically closed with a special valve.

There are models with two valves located parallel to each other. Here the process is carried out in a similar way, only there are two working chambers, and with each movement, water leaves one and enters the other. Such devices are considered more efficient.

Advantages of diaphragm pumps:

- can work with any environment;

- small size;

- quiet operation;

- no vibration;

- simplicity and reliability of design;

- energy efficiency;

- maintaining high purity of the pumped substance;

- low price;

- long service life;

- do not require special or frequent care, they do not need lubrication;

- a person without special education can replace damaged parts;

- have high versatility.

With such an abundance of advantages, no significant disadvantages were identified.

The diaphragm pump is widely used in medicine and pharmaceuticals, on farms (in milking machines). They are used for food production and in the nuclear sector. With their help, dosing pumps are made for use in the production of varnishes and paints; they are used in printing and in various places where there is a need to work with toxic and dangerous substances. It is safe to work with the latter, since diaphragm pumps have high tightness.

Areas of application of vortex pumps

It is quite difficult to imagine modern industry without pumping equipment. Vortex pumps were no exception. Today they are used in the following industries:

- To maintain the operation of boiler stations;

- For pumping liquids containing gaseous components;

- To supply water to rural water stations;

- For the operation of automobile service stations;

- As elements of compressor units;

- For the purpose of pumping alkalis and acids.

Smooth operation in all these industries requires pumps to withstand mechanical damage, aggressive chemicals and wear.

Vortex or centrifugal pump - which is better?

In order to understand which is better - a centrifugal or vortex pump, you should decide on several factors - areas of application and characteristics of the units. Centrifugal pumps can be used to pump clean water or water containing small impurities from ponds no more than 9 meters deep. During operation, such devices create a small pressure, consume a significant amount of electricity and have quite large dimensions.

The main difference between a vortex pump and a centrifugal pump is that units of the first type create greater pressure while having the same power. They are smaller in size and consume much less electricity. In addition, vortex pumps can pump liquids containing gases.

For comparison, it is also important to note the disadvantages of vortex pumps, which centrifugal devices do not have. The main one is the instability of vortex units to frequent mechanical damage. In contrast, centrifugal pumps are made of cast iron, which can withstand shock easily.

When comparing units of both types, it is quite difficult to determine the best one.

We can only note that if the buyer does not need high pressure and wants to pump out dirty water, then you can purchase a durable centrifugal pump, which, moreover, will operate much quieter. If you need to achieve maximum pressure, then it is better to purchase a vortex unit - it produces more noise, but costs an order of magnitude cheaper. We should also not forget that manufacturers constantly combine the properties of different types of pumps. Today it is very easy to purchase a centrifugal vortex pump that will have all the properties and advantages of the units we are comparing.

Operating rules

The described unit is installed on a hard surface strictly horizontally and, if possible, closer to the source of water intake. In case of vibrations, it is also advisable to secure the structure with a metal frame or bolted frames. The pump is connected to the network through the RCD fuse block. Grounding can be provided with a steel wire about 6 mm thick. In this case, one end of it is attached to the body, and the other to a ground electrode in the form of a metal pipe from a well or any structure leading into the ground.

Next, you can begin direct operation of the vortex pump, checking its tightness and the correctness of the connections made. First, the suction pipe and pump part are filled with liquid. To do this, you can use a funnel and a filler outlet in the structure. When the pumping part is completely filled, you can put the equipment into operation.