Features of cable condition monitoring

In accordance with the requirements of the governing document RD ROSEK 012-97, regardless of where the steel cable (not rope) is used, it must be checked before the start of each work shift. A detailed assessment of the condition must be carried out at least once every 10 days.

Defects must be detected through the use of flaw detectors. Their purpose:

- exercise control over maintaining the diameter of the metal section specified in the passport;

- detect the presence of external and internal corrosion;

- detect the break of one or more rope elements.

Steel material

Increased requirements are placed on compliance with steel rope rejection standards in the following places:

- where fastenings are made;

- where the rope comes into contact with fixed and moving structural elements;

- at the ends of the cable.

For a full assessment, several different options are used:

- an indirect method in which linear and angular damage to the rope structure is calculated;

- visual assessment. Allows you to determine the safety of visible surfaces;

- flaw detection using magnetic, x-ray and ultrasonic radiation;

- instrumental measurement. Allows you to identify the degree of wire wear, changes in cable diameter, and changes in straightness values.

Rope driving mechanism: basic assessment

Features of the rejection method

When should ropes and slings be inspected: frequency

When rejecting steel ropes, the number of broken wires is counted over a length equal to 30d or 6d (d is the designation of the rope diameter). This is done at the points of contact of the cable with the equalizing blocks, at the end seals and at the points where a break is detected. The permissible quantity, in the presence of which operation can continue, is established by Gosgortekhnadzor and is displayed in the table below:

Table

Note! The letter n denotes the number of supporting wires located in the outer strands, and d is the diameter of the cable. This is all determined by a special machine.

Determination of rope winding pitch

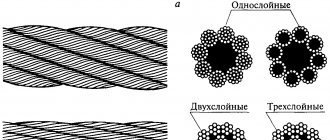

A parameter such as the lay pitch of a cable or rope is very important when considering the issue of rejection. The fact is that the number of breaks in thin fibers is usually calculated over a rope length equal to this pitch.

If there is no experience in carrying out such work, then difficulties may arise. Although in reality everything is quite simple. The pitch will depend on how many strands are in the rope. Next, a mark is made on the surface of one of the strands with a marker or center punch. All that remains is to count the number of strands in the cable one to the right or to the left and put a second mark. The distance between the two marks will be equal to the lay pitch. And it is precisely in this interval that the number of breaks must be counted.

Criteria for assessing the degree of wear of steel cables

Fire hydrants: norms and regulations, brands, sizes, requirements

When determining the safety of rope operation, the following criteria are used:

- the number of cliffs and their nature. Calculations are made on a certain section of the cable;

- are there places where wire breaks are concentrated;

- degree of internal and surface wear;

- the presence of corrosion, both internal and external;

- when one or more wires of the outer layer come out of the lock (applies to ropes of a closed structure);

- breaking of several or even one strand;

Rope mechanism - strength test

- reducing the diameter of the cable in one place;

- the cross-sectional area indicator decreases;

- the presence of basket-shaped and wavy deformation, as well as crushing and extrusion of strands;

- detection of damage resulting from exposure to high temperature or electric arc;

- lay parameters have been changed;

- the intensity of residual elongation changes.

Crane rope rejection

Crane ropes should be rejected if examination shows that the deterioration of the rope has exceeded certain criteria. General rejection criteria require that any one of the factors listed below is sufficiently serious to cause negative consequences. However, the deterioration of the rope and the decision to remove it are almost always the result of the cumulative effect of a combination of these factors: - wire breaks; — reduction in diameter; - deformation; — corrosion.

How to assess the condition of the cable core (its property)

Service life of workwear: standards

Based on the standards for rejecting steel ropes, they can be considered faulty even in the absence of external damage. This happens if flaw detection reveals damage to the core. The rope is considered unsuitable for use if the inspection reveals more than 18% loss of wires of the internal part.

Note! Not every enterprise has such equipment, as well as specialists to service it. And this is normal, because there is no need to constantly check the sealed parameters of the core. These tests are only required for products that must meet very high safety requirements.

In production

What are the ways to detect defects?

The most accessible, simple and cheap way to determine the rejection rate of steel rope slings is the visual method. An external inspection carried out by an experienced specialist using simple auxiliary equipment will allow timely detection of critical damage to the rope strands and take measures to prevent an emergency or accident.

In second place in popularity and effectiveness is the so-called instrumental method of establishing compliance with the standards for rejecting slings made of steel ropes. As research and experimental work have shown, by the nature of straightness and violation of the geometric shape in the cross-section of the cable, one can quite accurately predict its useful life. Not every engineer can do this kind of work. Here you need to have a powerful mathematical apparatus and appropriate instrumental support. Currently, highly specialized software packages have appeared on the market that allow partial automation of routine mathematical calculations. However, the cost of the license is very high, and its acquisition is unlikely to be economically feasible.

Features of the rejection method

A rope may be rejected even if it appears completely normal under the following conditions:

- there was a decrease in diameter by 7% (surface wear or corrosion);

- it was revealed that the diameter of the rope decreased by 10% or more (wear of the internal part, ruptures or bends);

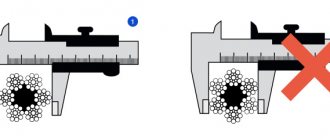

- The rope is considered defective if the original diameter of the outer wires has become smaller by 40% or more. It does not matter whether this was due to corrosion or wear. To take measurements, it is recommended to use a micrometer or its equivalent, which allows for accurate measurements.

The rope cannot be used if the following defects are found in it:

- one or more strands are torn;

- there is a basket-shaped deformation;

- the core is extruded onto the outer surface;

- a place with a reduced or increased diameter has been identified;

- creases, crushed areas, twisting, and bends were found.

If blocks are used to operate the channel, the stream of which is lined with synthetic materials, or made entirely of them, then the destruction of the rope from the inside is considered characteristic when the outer layer is intact. In this case, flaw detection of the entire length of the cable is performed. If losses exceeding 17.5% are detected, the rope is removed from service.

Checking for damage

Special rejection standards

If a metal rope is used to propel vehicles with people or to transport potentially dangerous and dangerous goods (acids, straightened metal, etc.), then the safety requirements, of course, become stricter, and the rejection rate is reduced exactly by half. That is, if a rope with forty fiber breaks per step length is usually considered defective, then in this case a rope with 20 breaks is already removed from service.

Special techniques are also used when deciding on the rejection of ropes twisted from thick wire. The fact is that domestic enterprises for the production of steel ropes produce two types of products: from thin wire and from thicker ones. It is clear that breaks in thick and thin rolled products cannot be equivalent. Therefore, when calculating the number of breaks in a thick wire per length of twist pitch, one break in a thick wire is equivalent to 1.7 breaks in a thin wire. The total number of defects should not exceed 40.

Norms for rejecting slings

When producing slings, they are guided by standard 25573-82 and RF-10-33-93. In this case, each of the three stages of inspection is performed:

- interior;

- instrumental;

- outer.

When conducting an audit, special attention is paid to the following aspects:

- there are no discrepancies between the data specified in the product passport and its actual condition;

- presence and serviceability of loops at the ends of the rope;

- the presence of damage or defects on the surface of the cable;

- what condition are the internal strands and core in?

The rejection and inspection of slings is carried out by engineering and technical workers who are authorized to check the serviceability of the equipment and are responsible for the safety of the work. To record the results of the inspection, a special journal is created, designed in accordance with the requirements. It is registered with Gostekhnadzor. Its pages reflect the facts of detection of defects and the facts of their elimination, and also contain rules for storing synthetic ropes and slings.

Steel slings at the enterprise

Checking textile slings

Checking the suitability of textile slings consists of visual inspection

, during which the markings comply with the passport, the serviceability of loops and seams, connecting elements, and grips is checked.

After this, instrumental control

. Slings are not allowed for use if the following defects are detected:

- lack of markings or tags;

- the presence of knots or transverse breaks on the load-bearing tapes of the slings, regardless of their size;

- longitudinal cuts or tears exceeding 50 mm, and their total length is more than 10% of the length of the sling branch;

- local delamination of the tapes, except for the places where their edges are sealed, exceeds 0.5 m and has a gap of three or more lines on one extreme or two internal seams;

- local delamination on the sealing of the edges exceeds 0.2 m on one extreme or two internal seams, as well as peeling of the edge or stitching of the tapes at the loop, the length of which exceeds 10% of the length of the sealing of their ends;

- surface breaks of the belt threads resulting from the mechanical impact of the load, exceeding 10% of the belt width;

- damage from chemicals (alkalies, acids, solvents, petroleum products, etc.) exceeding 10% of the total length and width of the sling;

- bulging of threads or through holes from sharp objects or burns, the diameter of which exceeds 10% of the width of the tape;

- contamination with soil, cement, paints, petroleum products, etc., exceeding 50% of the sling length.

All of the above applies to textile tape slings. Rejection standards for round-strand slings also include: rupture of the cover, breakage of more than 6 wires, breaks of threads in stitching nodes exceeding 10% of its length, holes in the cover.