Author of the article:

Bolts are among the most common and popular fastening elements in various fields of activity, ranging from mechanical engineering and construction to minor home repairs. The bolt appears as a threaded rod of metal with a head shaped to provide a secure grip for the tool to provide torque. The most common versions of such hardware have hex heads - a turnkey size of the appropriate size.

Marking of high strength bolts

There are many classifications that use different designations for high-strength bolts. But the most significant characteristic by which they are distinguished and divided into groups is the strength of the bolts in relation to physical pressure. Resistance to such effects characterizes the functional potential of the hardware and its service life. It also covers the ability of a fastener to withstand changes in temperature and other artificial and natural phenomena.

Here are some of the notations used:

| Strength class | Material of manufacture | Main sizes |

| Bolts of strength class 8.8 | 40X | M30-M64 |

| 40ХН2МА | M30-M64 | |

| 40ХН | M30-M64 | |

| Bolts of strength class 10.9 | 40X | M12-M36 |

| 40ХН2МА | M24-M48 | |

| Bolts of strength class 12.9 | 40X | M12-M30 |

| 40ХН2МА | M24-M36 |

Hardware with strength class 8.8 is made from hardened steel and is suitable for most construction and installation work. Bolts of a higher strength class are designed not only for constant load, but also for variable pressure, therefore they are used in structures of increased complexity, as well as where regular installation and dismantling of individual elements is planned.

DIN standards

The emergence of the procedure for developing new regulatory documents at the interstate, international level led to the emergence of standards designated by a special combination of letters, for example, DIN EN, DIN EN ISO, etc. All of them have a certain status.

- DIN is a document of national importance. It precedes work on the creation of an international standard. However, there is a difference in the designation depending on the stage of its preparation. The draft version is E DIN. The preliminary standard is designated as follows: DIN V.

- DIN EN is the German edition of a normative document, adopted without even minor amendments by all full members of the committees CEN (Committee of Europe for Standardization) and CENELEC (Electrotechnical Committee of Europe for Standardization).

- DIN EN ISO – standards that are the result of joint work of specialists from the CEN committee and the ISO organization.

- DIN ISO is a regulatory document developed by ISO and adopted at the national level without making any adjustments.

- DIN IEC is a standard developed by the International Electrotechnical Commission, which was adopted in Germany without amendments as a national-level document.

All DIN standards are registered under their own identification number and have a unique name. For example, the technical characteristics of nuts with six edges and metric threads from M5 to M64, made with precision meeting the requirements of class “C” and with strength class 5, are specified in the DIN 555 standard “Sechskantmutter mit metrischem Gewinde von M5 bis M64, Genauigkeitsklasse C , Festigkeitsklasse 5".

Operation of High Strength Bolts (Spheres, Areas and Examples)

The use of high-strength bolts is often found in such areas as construction, road equipment manufacturing, instrument and mechanical engineering, as well as other production-related areas. The high demand for them is due to the fact that such hardware has practically no restrictions on use and is used in toxic aggressive environments and at low temperatures (down to −60C).

High-strength fasteners can withstand both constant and variable loads, with a moving center of gravity, and even strong vibrations. Therefore, with the help of these hardware, buildings are built, industrial equipment, heavy equipment (including military) and special purpose vehicles (cranes, loaders, etc.) are manufactured.

How DIN standards are developed

Work on the text of the new regulatory document involves the participation of representatives of the production and consumption sectors, trade organizations, research institutes, government agencies and, of course, regulatory authorities. The most qualified experts from all these institutions are involved in the work of regulatory committees, which are divided by industry. The responsibilities of DIN staff include coordinating the process of creating/developing a standard and providing project management. During work:

- experts solve the problem of developing a unified approach to resolving issues on all relevant aspects, taking into account the put forward requirements of a technical and economic nature;

- then the draft regulatory document is submitted for open discussion;

- the standard is approved and published only after reaching consensus on all controversial issues.

Additional difficulties arise due to the rapid development of technology. This phenomenon necessitates constant improvement of the technology for developing new regulatory documents. However, in certain areas, for example, in IT technologies, the need for standards that have undergone a full approval procedure does not always arise. Here problems are often solved by a small number of interested firms.

This prompted DIN management to expand the organization's scope of activities. Thus, along with the development of documents that de jure have the status of standards, this institute began to publish other documentation, which is commonly called a publicly available specification. Work in this direction is also being carried out at the request of foreign, and not just German, companies.

High Strength Bolt Table (Standards)

| Standards | Standard sizes | Notes |

| Bolts GOST 7795-70 | M6-M48 | Instead of bolts GOST 7795-62. Hexagonal reduced head, guide support, accuracy class B. |

| Bolts GOST 7796-70 | M8-M48 | Instead of bolts GOST 7796-62. Hexagonal reduced head, accuracy class B. |

| Bolts GOST 7798-70 | M6-M48 | Instead of bolts GOST 7798-62. Hexagonal head, accuracy class B. |

| Bolts GOST 7805-70 | M2-M48 | Instead of bolts GOST 7805-62. Hexagonal head, accuracy class A. |

| Bolts GOST 7808-70 | M8-M48 | Instead of bolts GOST 7808-62. Hexagonal reduced head, accuracy class A. |

| Bolts GOST 7811-70 | M6-M48 | Instead of bolts GOST 7811-62. Hexagonal reduced head, guide support, accuracy class A. |

| Bolts GOST 7817-80 | M6-M48 | Instead of bolts GOST 7817-72. Hexagonal reduced head, accuracy class A, for reamer holes. |

| Bolts GOST 10602-94 | M52-M150 | Instead of bolts GOST 10602-72. Hexagonal head, accuracy class B, thread diameter more than 48 mm. |

| Bolts GOST 15589-70 | M6-M48 | GOST was introduced for the first time. Hexagonal head, accuracy class C. |

| Bolts GOST 15590-70 | M6-M48 | GOST was introduced for the first time. Hexagonal reduced head, guide support, accuracy class C. |

| Bolts GOST 15591-70 | M6-M48 | GOST was introduced for the first time. Hexagonal reduced head, accuracy class C. |

| Bolts GOST 18125-72 | M52-M160 | Instead of bolts GOST 10603-63, GOST 10604-63. Hexagonal reduced head, accuracy class A and B, thread diameter more than 48 mm. |

| Bolts GOST 22353-77 | M16-M48 | GOST was introduced for the first time. Hexagonal head, accuracy class B. |

| Bolts GOST R 52644-2006 | M16-M48 | GOST was introduced for the first time. Hexagonal head, increased wrench size, for metal structures. |

| Bolts OST 26-2037-96 | M16-M48 | Instead of bolts OST 26-2037-77, OST 26-01-566-72. Hexagonal head, for flange connections. |

| Bolts OST 37.001.123-96 | M6-M16 | Hexagonal reduced head. |

There are not many manufacturers of high-strength bolts, since the production of these hardware requires high-quality raw materials, and the production technologies are complex. The steel of high-strength bolts must meet a long list of requirements and limitations. Most factories producing such fasteners have their own design departments for the development of non-standard individual orders, especially for strength class 12.9. In addition, such enterprises are usually equipped with quality control laboratories for careful handling of raw materials and testing of finished products.

Differences between DIN and GOST

Often on the Internet there is a phrase that, they say, such and such a GOST is an analogue of such and such a DIN standard. They are indeed similar in many ways, but sometimes there are significant discrepancies in individual positions. The table shows examples of differences between German and domestic regulations that establish the technical characteristics of the most popular fasteners.

| Name of fastening element | DIN standard | GOST standard |

| Screws | ||

| Ball head screws | 7985 | 17473-80 |

| The height and diameter of the head of a product made according to GOST requirements is less than that manufactured according to DIN provisions. According to the German standard, the slot can only be straight or cross-shaped. The domestic regulatory document also allows for the production of a Torx-type slot. | ||

| Bolts | ||

| Hinged bolt | 444 | 3033-79 |

| According to the norms of the German standard, one version of the product is possible, and according to the provisions of the domestic standard, three versions are possible. Accordingly, the sizes differ. | ||

| Eye bolt | 580 | 4751-73 |

| There are no significant differences between DIN and GOST. | ||

| Plowshare bolt | 608 | 7786-81 |

| The differences lie in the fact that the height of the head together with the head, the side of the square head and the diameter of the countersunk head, established by GOST, are slightly less than the values of these parameters prescribed in DIN. | ||

| Washers | ||

| Locking multi-claw | 5406 | 11872-80 |

| These standards differ in terms of the location and number of legs. According to DIN, such a part can have only 8 of them, and these tabs must be located evenly over the entire surface of the fastener. According to GOST standards, only large washers of the type in question have 8 legs; small samples have no more than six, and the legs should be located in groups of 4 (3) pieces, also evenly over the entire surface of the washer. | ||

| Flat | 125 | 11371-78 |

| The DIN standard normalizes the production of these hardware with increased precision (class “A”). GOST applies to flat washers made with precision that meets the requirements of two classes “C” and “A”. Taking this into account, the dimensions of the parts may vary slightly. | ||

| Grover | 127 | 6402-70 |

| According to DIN, 2 versions of growers are allowed. The domestic standard establishes the same number of designs, but each of which, in turn, comes in four types. Accordingly, depending on the manufacturing option, the weight and dimensional characteristics of these hardware differ. | ||

Rules for installing high-strength bolts

Before starting work, a preliminary analysis of the technical operating conditions of the future structure is always carried out. The selection of the required hardware will be influenced by the following factors:

- Characteristics of additional accessories.

- Twist factor.

- Correspondence of the technical and mechanical properties of the hardware to the environment in which it will work.

- Resistance to various external influences.

- Properties of the steel from which it is made.

- Thread pitch and type.

The conditions for the correct choice are also influenced by the size, shape of the bolt head, the presence of heat treatment and protective coating. Always start from the purposes for which you need hardware. The further procedure is as follows:

- The holes in the connected elements are aligned and the elements are rigidly secured using assembly plugs. Usually a tenth of the holes are secured with plugs - this is quite enough for reliable fixation.

- High-strength bolts are inserted into the holes free of plugs and tensioned in accordance with the rules and with the force specified in the technical documents.

- Then remove the assembly plugs, install the remaining bolts and tighten all the parts to the design strength. After this, the working surface can be primed.

Use a calibration wrench that allows you to control and adjust the tension of the bolts.

Dimensions/markings of inch (SAE and USS) bolts

- G - strength class marking

- L - length (in inches)

- T - thread pitch (number of threads per inch)

- D - nominal diameter (in inches)

Dimensions and markings of the strength class of metric bolts

- P - strength class

- L - length (in mm)

- T - thread pitch (distance between adjacent turns in mm)

- D - nominal diameter (in mm)

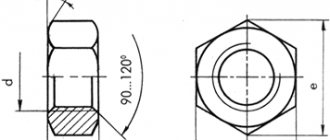

Also, standard nuts can be distinguished from metric ones by strength class marks. To identify the strength of standard nuts, dot marks are used that are stamped on one of the end surfaces of the nut, while metric nuts are marked using numbers. The greater the number of points, or the higher the digital code value, the higher the permissible tightening force of the nut (strength class).

High Strength Bolts

In most cases, conventional connecting elements are used, in the manufacture of which carbon steel is used. However, if necessary, you can purchase high-strength bolts that can be used to create high-strength connections. Marking of high-strength bolts is carried out according to general standards. The production of high-strength bolts is carried out taking into account the information below:

- In manufacturing, special alloys are used, which are characterized by high strength and hardness. They are more expensive than carbon steel, but still the use of the resulting products is advisable in a wide variety of cases.

- Heat treatment is carried out to increase strength and hardness. It involves changing the chemical composition of the metal and the structure of the resulting material.

High Strength Bolts

High-strength bolts may require their own regulatory documentation. In addition, the classification is carried out as follows:

- Fasteners with the letter “U” in the marking are used for operation at temperatures below -40 degrees Celsius. However, the letter in question is not indicated in all cases of marking.

- Offers with HL design can be operated in more severe operating conditions, for example, at temperatures from -40 to -65 degrees Celsius. When marking in this case, the accuracy class is indicated.

High-strength bolts and nuts are quite common today. This is due to high performance qualities, which allow you to expand the scope of the product.

Connecting bolts using threads

Thread classification:

- metric;

- inch;

- cylindrical pipe;

- conical;

- rectangular;

- trapezoidal;

- persistent;

- standardized round.

Metric thread is the main type of threaded connection. Its parameters are the nominal diameter and thread pitch in millimeters, established by GOST 8724-81.

Connecting bolts using threads is reliable and technologically advanced.

Advantages:

- reliability;

- multifunctionality;

- manufacturability;

- the ability to adjust the compression force;

- availability of a wide range of products.

Disadvantage: tendency to self-unscrew.

Types of bolt fastening

Threaded connections are structurally different from each other.

Bolted

A bolt is a part equipped with a head and threads at different ends. The thread is necessary to screw on the nut. The head is picked up from the outside with a wrench.

To install hardware, holes of larger diameter are drilled on the surfaces to be joined. The end side is chamfered.

The bolted fastening is easy to replace if broken.

The disadvantage of the connection is that it requires a lot of space, which leads to an increase in the size and weight of the structure.

Advantage: easy replacement if broken.

Screw

The screw is screwed into the housing using a special end tool. The head comes in different shapes, including 6-sided. The main difference is the small installation area.

Negative point: during installation, the thread is often damaged, and it is difficult to remove part of the fastener. Therefore, screw connections are not used for repeated installation/disassembly.

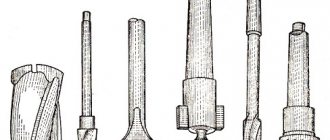

Using studs

A stud is a cylindrical fastener without a head, the ends of which have threads of the same diameter. There is a tight cut on one side. The other end is needed to install the nut.

Fastening with studs is required for frequent assembly of the structure.

The element is in demand for frequent assembly/disassembly of the structure and installation in hard-to-reach places. The stud may bend and lose strength. The thread often breaks due to heavy loads.