Here you will learn:

- Features of potbelly stoves

- Is it possible to line a potbelly stove with bricks?

- How to properly line a stove with bricks

A potbelly stove is one of the simplest stoves. By burning solid fuel in its interior, it provides heat to residential and non-residential premises. These ovens are divided into factory-made and home-made. Thanks to their simple design, they are easy to assemble with your own hands. In the future, it is recommended to cover the potbelly stove with bricks. This step will increase its effectiveness and protect users from burns. Get information about the lining in our review.

Option two - homemade potbelly stove

If you have a welding machine, potbelly stoves, proven and simple designs, can be made in one day. To fire a potbelly stove, you can use thick-walled pipes, barrels and gas cylinders. A rectangular potbelly stove can be welded from a metal corner and steel sheets (3 mm thick).

Important rules for locating a potbelly stove in the garage

In order to avoid fire, you must follow the following fire safety rules when installing a homemade potbelly stove:

- distance to walls and flammable objects - a meter, distance to a brick wall - 0.5 meters;

- the walls and ceiling around the stove are additionally sheathed with sheets of metal;

- a thick metal sheet is placed under the stove - 10 mm or a cement screed is made - thickness 20 cm;

- It is necessary to install ventilation (forced or natural) so that if there is smoke there is no trouble. A 5 cm gap under the garage door or two exhaust vents under the roof will ensure sufficient natural ventilation of the room.

The distance from the stove to the car must be at least two meters. If you come into close contact with the hot walls of the stove, there is a risk of damage to the paint or ignition of the fuel.

An additional protective casing made of brick walls will not only create a convection flow of warm air and increase heat transfer, but also ensure safety.

Note. Only square or rectangular potbelly stoves can be covered with bricks

A furnace in the form of a cylinder requires a special design of the casing, in the form of side metal ribs. A brick casing for the cylinder will reduce heat transfer and lead to rapid burning of the walls.

How to make a simple square potbelly stove

For a standard garage, a heating device 30 x 30, 50 cm high is quite enough. The diameter of the pipe for a potbelly stove is at least 30 cm, the wall thickness is at least 5 mm. For a chimney, a pipe with a diameter of 12–15 cm and a thickness of 3 mm is suitable. To prevent the chimney pipe from quickly becoming frozen, it is wrapped on the outside with a layer of mineral wool.

Work order:

- First, we draw the cutting of the stove parts, determine all the dimensions;

- we cut out the necessary parts from sheet metal to size;

- First, we weld the walls and bottom of the oven together, but only grab them. To be able to set all sides strictly according to level;

- after checking the vertical and horizontal lines, you can weld all connections using a T-weld;

- We install the lower partition into the finished housing. You immediately need to drill holes in it to remove ash (the step between the holes is one and a half centimeters, from the walls - 5 cm);

- the partition is located no lower than 10 cm from the bottom;

- cut out a circle in the back wall to install the chimney pipe;

- firebox and blower doors - distance from the wall - 5 cm;

- when attaching the door curtains, you need to take into account that they will sag due to temperature, so we attach them 2 cm higher;

- The last to be installed are the legs of the potbelly stove - the height is at least 15 cm and the top sheet of the stove is installed.

In order to obtain maximum heat transfer, the stove pipe should not be straight. It is necessary to install pipes with two 30-degree turns and lead them through the wall of the garage. Then the combustion products will give off all the heat not to the street, but to the room.

The video shows how to make a simple potbelly stove from a metal sheet and corners and from an old gas cylinder.

Installation and connection

When installing the stove, you must strictly follow the fire safety rules:

- The distance to walls and surrounding objects must be at least 800 mm. The walls can also be covered with ceramic tiles.

- All parts of the chimney must be tightly connected.

- The room must be equipped with a supply and exhaust ventilation system.

The chimney is installed like this:

- We fix the first piece of pipe above the chimney opening.

- We increase the pipe bends to the ceiling level.

- We make holes in the ceiling with a diameter of 170 mm. We remove a layer of thermal insulation around the hole to prevent fire.

- First, we mount the pass-through glass, then insert the pipe into it.

- Next, we connect the pipes to the external chimney.

- We apply bitumen to the pipe and insulate it.

If you need to heat a large area, you can connect the stove to a heating panel. This will increase the heat flow and allow it to be retained longer.

A DIY brick potbelly stove is a good alternative to a metal stove. Potbelly stoves made of metal are small in size, but have a serious drawback - the high thermal conductivity of the material. The metal heats up quickly, but soon cools down, resulting in the need to regularly maintain the fire, which means high fuel costs. A brick stove or a metal stove lined with brick is a more rational choice - it can retain heat for a long time.

Which brick to choose?

In order to cover a potbelly stove, ordinary brick will not work. You need to choose between special stove and solid ceramic. Kiln brick will withstand temperatures up to 1000 degrees, while solid ceramic bricks can withstand temperatures up to 800 degrees. Every stove maker will say that laying bricks on edge is strictly prohibited, although you can hear similar advice in order to save material. Heat-resistant bricks are placed in water before laying so that they do not draw moisture out of the mortar and provide maximum adhesion.

Use only heat-resistant bricks

To calculate the consumption of bricks, you need to measure the stove and take into account the 10-15 centimeters of gap between the metal wall and the brick. The potbelly stove is placed on one or two brick rows, and the top is laid as desired. The area of the proposed masonry must be divided by the area of the narrow side of the brick. This is a rough calculation without taking into account seams and air circulation holes in the masonry, but it gives an idea of the maximum amount of material required.

For example: to cover a metal stove “Gnome” you need 83 bricks if you lay it according to the technology and 45 bricks if you lay the brick on its side. This amount will be needed provided there is a foundation in two rows and a lining on top.

There are craftsmen who fill the space between the brick and the stove with sand. But a potbelly stove with sand rarely lives up to expectations - the sand becomes a heat insulator without increasing the useful time of the firebox. The same can be said about gravel, which is used along with sand.

Briefly about the main thing

Building a brick stove in a house or country house is far from the final stage in decorating a room. The stove structure also needs to be coated with paint.

Before decorating the structure with paints and varnishes, you should seal the cracks, treat the joints and clean up the irregularities. If you don’t figure out what paint to paint a brick stove with or don’t carry out additional surface treatment before painting, very soon the brick will begin to crumble.

The stove can be painted with polyurethane or silicone paint; the most budget-friendly method is ordinary lime whitewash.

It is important to follow the painting instructions: first treat hard-to-reach places and depressions with the composition, and only then apply the substance to the main area.

Finishing a potbelly stove with brick: tips and tricks – Working with Brick

The potbelly stove is familiar to all summer residents. It is not profitable to buy expensive heating devices for change houses and country houses, but an old potbelly stove will cope with the task and will not ruin the owner. This stove does not require fuel, has a cooking surface and is small in size. In some cases, you can line the potbelly stove with bricks.

Potbelly stoves come in cast iron and metal. The first ones are, of course, more economical. The problem with all metal stoves is rapid heat transfer. As soon as all the fuel has burned out, the potbelly stove instantly cools down, and with it the heated room.

Fast heat transfer helps when you need to quickly warm up a room, but requires constant loading of fuel. The potbelly stove got its name for such “gluttony” - no matter how much fuel you put in, it’s not enough. To increase the efficiency of a potbelly stove, during the October Revolution the chimney pipe was lengthened.

Burning gases passing through a long pipe heated it, so the length of the chimney could be equal to the perimeter of the room.

An easier way to retain some of the heat is to line the stove with bricks. The heat emanating from the stove heats the brick, and as it cools, it releases the accumulated heat. The brickwork will allow the stove to remain warm for a couple of hours after it has cooled down.

Covering a potbelly stove with bricks in this way not only increases efficiency, but also externally transforms a cheap stove. For greater beauty, you can use special heat-resistant tiles.

So a potbelly stove can become visually very attractive and resemble a Dutch or Swedish stove.

Cover example

How to cover a potbelly stove with bricks at the dacha

To heat a room in a country house or country house, a potbelly stove or fireplace is often used. A cast iron or metal stove is easy to manufacture, easy to maintain and affordable.

The furnace material - metal or cast iron - has both negative and positive properties.

So, while promoting rapid heating of the room, a metal stove, on the other hand, cools down quickly with the same “success”.

You can find a large number of videos on the Internet with instructions for lining a stove or fireplace, but we propose to consider this problem in detail in the article.

To begin with, let us list the main qualities that distinguish a potbelly stove with a lining from the original stove:

- The structure, made from brick with your own hands, allows you to retain heat inside for a long time, distributing it evenly throughout the room.

- After turning off, the stove will maintain a high temperature in the room for a long time, eliminating the need to reheat the cold house after the next turn on.

- The design of a brick-lined potbelly stove or fireplace is safe to use. as it relieves the owner from the possibility of getting burned when in contact with a hot metal body.

Selection of material and tools

You can cover a potbelly stove with a brick casing with your own hands and on your own. The main problem is the correct selection of the necessary tools and bricks of a certain quality.

For lining a potbelly stove or fireplace, classic bricks, clay stove bricks, are used. characterized by heat resistance qualities.

When exposed to high temperatures, such a brick will not undergo deformation, and, most importantly, will retain its performance properties.

The surface of the brick does not affect the functionality of the final structure. This can be a smooth solid ceramic brick or a brick with a textured surface.

For decorative aesthetic purposes, it is better to use textured brick. which will perfectly complement the interior of any room.

You cannot use brick with voids, as high temperature will lead to its destruction.

The entire arsenal of tools necessary for lining a stove and fireplace with bricks with your own hands includes. trowel, spatula, pick or rubber hammer, grinder, level, angle, plumb line and fishing line for laces.

Conclusion

A potbelly stove lined with brick retains heat longer and allows you to consume less fuel. Masonry significantly increases the aesthetic qualities of a simple stove. If desired, the efficiency of the potbelly stove can be increased by installing a sandwich mesh. It protects the chimney from burning out and accumulates heat. Often the front side and top are left open. This way the stove warms up the room faster, but due to the reduction in brick area, it releases the heat faster. Clay mortar is ideal for stoves, but is demanding on room humidity. If the logs are old, it is better to remove some of them and pour a cement foundation.

People have been wondering how to line a potbelly stove to preserve heat since the time of the revolution. The brick absorbs some of the heat, which is safer to use and reduces the risk of getting burned. You can dry things, fruits and berries on the masonry. A potbelly stove has been helping out in the cold for more than one generation; it never ceases to be in demand and loved by all summer residents. Covering a stove with brick is an affordable and quick way to improve it and keep the house warm. A budget method that does not require special skills.

How to properly fold a potbelly stove?

Even a beginner can correctly assemble a brick stove-stove on his own. To do this, you need to know and follow the simple rules that pechnoy.guru will provide below.

Scheme and drawing

Below we will look at how to build a potbelly stove out of brick with your own hands. The drawing and dimensions can be seen in photo No. 1:

Photo No. 1 - do-it-yourself drawing of a potbelly stove made of brick

The sequential layout of bricks from a potbelly stove is shown in photo No. 2:

Photo No. 2 - sequential layout of bricks (diagram)

We have decided on the materials and design of the furnace, and the solution is ready. This design does not require a foundation. For comfortable and safe operation, heating must be placed in compliance with all fire safety standards. Having chosen a place, lay two layers of waterproofing. On top we make a preparation of sand, 10 mm thick. Let's start laying:

- We lay a brick on top, without mortar (see photo No. 2, first row). We strictly control horizontality using a level.

- We install the door for the blower. We secure it with wire and wrap it with asbestos cord.

- We continue laying (see photo No. 2, row No. 1).

- Next comes fireclay brick (see photo No. 2). Grate bars will be installed above it.

- We place grate bars directly above the ash pit.

- We place the next row on a spoon. We put the wall at the back without mortar (knockout bricks).

- Installing the firebox door. We secure it with wire and bricks.

- On top we place a row on the bed along the contour of the fourth.

- The next one is again on a spoon. We put 2 bricks at the back.

- The row at the top should overlap the combustion door and end 130 mm above it.

- We continue laying, moving the bricks back a little. Before this, we lay an asbestos cord on which we will install the hob.

- Let's start forming the chimney from the next row. The design provides for the installation of a mounted pipe made of tin or corrugated aluminum. The pipe should not be heavy. Otherwise, the center of gravity may shift.

- On the eleventh row we install a valve to regulate the air flow. Don’t forget to seal it with asbestos cord and cover it with clay.

- Next, we place a chimney pipe in the quadrangle, which we connect to the metal one. The pipe must stand strictly vertically and not lean to the side. For greater stability, it should be covered with three rows of bricks.

- We remove the knockout bricks that we placed on the 4th row and clean the chimney of debris.

- Now the stove should be whitened. Any lime will do. Experts recommend adding blue and a little milk. This way the whitewash will not darken and fly off.

- We install a metal sheet in front of the firebox.

- We install the baseboard.

An example of a finished brick stove

Drying

The cause of cracks is excess moisture in the bricks, so the oven must be thoroughly dried. There are two stages of drying: natural and forced.

- Natural drying lasts at least five days. All doors must be fully open. To increase the intensity of the process, place a fan in front of the firebox or stick it into it and turn on a regular electric incandescent lamp (not an energy-saving one). It will not be possible to completely dry the oven using this method, so we move on to the next step.

- Forced drying is carried out by burning dry wood. This type of fire is carried out once every 24 hours. You should only heat with small dry logs. Open the blower door slightly and open the plug halfway.

When the wood burns out, loosely cover the ash pit. Close the top plug, leaving 1-2 cm. When the coals burn out, open all channels. Carry out this fire for a week. On the first day, about 2 kg of wood is burned. Then add 1 kg every day.

Making a firebox door

This element is the most complex in the entire structure. The following table shows the standardized dimensions of oven doors:

| Size | Blower, cleaning doors, mm | Openings for fire doors, mm | |||

| length | 25 | 25 | 25 | 30 | 25 |

| width | 130 | 130 | 250 | 250 | 250 |

| height | 70 | 140 | 210 | 280 | 140 |

We make the door for the firebox according to the drawings shown in photo No. 3:

Photo No. 3 - drawing of the door for the firebox and cleaning chamber

Metal cladding

A brick potbelly stove can be additionally sheathed with metal. We will get a metal potbelly stove with all the advantages, but without the disadvantages (except for weight). This design will protect the stove from cracking and chipping. This will significantly increase service life. This will require sheet metal 4-6 mm thick. The process is not particularly difficult. The metal sheet is marked, the necessary parts are cut out with a grinder or a cutter. Next, the cladding is carried out and connected using welding and a metal corner.

This design is not only durable, but safer. However, it requires additional costs and labor.

Brickwork

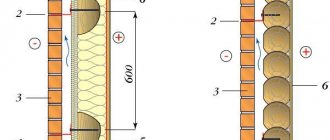

Image 2. Stages of bricklaying.

According to the markings, start laying the brick. Try laying the first row without mortar first, just to check the fit of the bricks and the possibility of somehow fitting them, sawing it if necessary. The entire first row is laid completely, while in the second row small holes should be made - 2 on each of the 4 sides, keeping to the size of half a brick. They will act as ventilation holes, which can be made in the shape of circles or polyhedrons to give your stove a beautiful and original appearance.

During the laying process, do not forget that to ensure better adhesion of the bricks to the mortar, it is recommended to pre-wet them in water. All subsequent rows are laid out without making holes, but with constant checking of the evenness of the masonry. Every 3-4 rows, wipe the bricks with a wet cloth so that it is easy to remove excess mortar. Try to maintain the same thickness of the seams, making it no more than 5 mm.

Diagram of a cast iron stove.

You can make the hole that will need to be made for the potbelly stove door according to your personal desires and fantasies. Even if you are not making a wide opening, in order to organize a lintel over it, you will need to use a metal corner or brackets, under which you will need to make a small hole in the brick. Do not forget that, as with any other construction, brickwork is carried out in half a brick (image 2).

The top of the oven can be laid out however you like, according to your personal wishes, since it will not bear any special load. By applying the most sophisticated design ideas here, you can get a truly unique, beautiful and rich stove for your home.

What special paints are there for brick walls and how to apply them?

example of a painted stove

If you decide to buy paint to paint a stove, it is best to choose paints that are resistant to high temperatures. Such paints will not burst or crack after a short period of time, but, on the contrary, will retain their original appearance for a long time.

You can also paint the stove with oil or enamel paints, which will allow the stove to enhance its thermal conductivity.

When choosing how to paint a brick stove, it is best not to paint it with paints containing aluminum or the like. Since if the stove is built incorrectly and the wall of the hearth of the stove itself does not comply with building codes, then its outer side can heat up from eighty degrees Celsius, and such heating can release from the paint itself such incredibly harmful substances as toxic fumes, which can poison from the inside human body and so on.

It is important to know: the darker the paint color, the more heat the stove will be able to emit. This phenomenon is explained by the laws of physics

Dark objects quickly attract heat, while bright and shiny objects have much worse heat transfer.

Well, paints that were made on the basis of drying oil may darken over time or completely lose their original color.

Today, in construction stores you can find special paints with increased heat resistance. These paints are ideal for frequently used stoves. But, unfortunately, their range of colors will not please a sophisticated painter, and if you could not find the shade you need, you can always paint the stove with a special primer or paint it with paint containing construction latex.

Important to know: before buying paint, it is very important to make sure that it has heat-resistant functions. Perhaps the best option to buy from this segment would be silicon-organic enamel

Since such paint can retain all its properties and qualities even at temperatures above six thousand degrees Celsius. Well, as a solvent for enamel, you can use the familiar turpentine or a special construction solvent six hundred forty-six. In order to get an excellent result, it is best to apply the paint in two or three thick layers.

How to line an iron stove with bricks?

Finishing the stove in the bathhouse is not at all difficult. Let's divide the process into four stages, you need to:

- Select materials.

- Pour the foundation.

- Cladding a metal stove.

- Perform decorative work.

Let's look at each point in more detail.

Selection of materials for work

What kind of brick is best to line a stove? It is necessary to take into account that the facing brick will be constantly exposed to high temperatures and must withstand all loads. Therefore, it is better to line the stove with a refractory solid material that copes with the assigned tasks and retains its properties for many years. In addition, you can line the bathhouse with both smooth and textured bricks.

For brick lining of the furnace, you need to use refractory material

In addition, for lining the furnace you will need:

- sheet asbestos;

- bonding solution;

- grout;

- tools.

Pouring the foundation

First of all, you will need to mix the solution. A traditional mixture of clay and sand is perfect for this purpose. In addition to it, cement-based solutions with various impurities are used. They may seem like they are more reliable (because they are more expensive), but in reality their durability differs little.

Scheme of pouring the foundation for the furnace

Once you have decided on the facing mortar, you can begin pouring the foundation. If the plane used does not inspire confidence, then you will have to pour a foundation under it. Additionally, you can reinforce the floor with boards or metal guides. In other cases, the process is simpler.

The foundation is poured in the following way:

- Determine the size of the base.

- Place the formwork.

- Prepare the solution.

- Fill it up.

- Wait until it dries.

Brick laying

When the foundation has completely set, you can begin laying. Before starting this stage, in order to properly line the stove, mark the location of the brick.

First of all, calculate the required space from the stove to the walls. Too large a space will interfere with high-quality heating and heat transfer, too small will significantly reduce the service life of the brick. The optimal space is 3-5 centimeters.

Place an iron sheet along the edges of the markings. Such a sheet will protect the material from overheating. Place asbestos cardboard on it. This refractory material will additionally protect the brick from wear and tear.

Scheme of brick lining of a metal stove

Upon completion of all these preparatory work, you can line the bathhouse. To get the desired result, follow these instructions:

- Soak the brick in water. Don't forget to soak it before styling.

- Shake it, the first row should be laid solid.

- You can use reinforcement to strengthen the masonry.

- Tie wire around the corners of the mesh.

- Start laying the second row in a staggered pattern.

- Apply the mortar into the space between the bricks.

- Reinforce the top edge of the hole with a metal corner. This is done to construct the firebox opening. Please note that the opening should be comfortable, the firebox should open without touching the walls.

- To ensure air circulation, special holes are made in the penultimate row. To do this, one row is laid across the previous one and four holes are made on each side.

- Laying the finishing row does not require anything specific - you can do it the way you want. You can make it decorative, cover it with tiles or simply pour stones.

As for the laying technology, keep the seams within 3-5 centimeters, do not forget to bandage the brick.

Decorative works

Before starting decorative work, clean off any remaining traces of mortar. If you don’t want to additionally finish the brick, you can make a so-called “fur coat”. To do this, sand it with a brush dipped in soapy water.

Most often, a sauna stove is decorated with:

- smooth multi-colored brick;

- textured brick.

You can also tile or paint it, or decorate it with some kind of decoration.

In conclusion, we would like to say that the first firebox must be done very carefully. Do not heat the oven too much; allow the solution to completely harden. After covering the stove, wait three days. If you do everything right, your bathhouse will serve you for many years.

Modernization methods

The design features of the stove do not allow for major changes, of course, unless you decide to make a small home nuclear reactor out of it, but all the proposed improvements are aimed at only one thing - heat preservation. During operation, the stove easily loses heat through the pipe; the thinness of the walls quickly transfers it, but does not allow it to be stored for a long time. The direct-flow furnace consumes a large amount of fuel, and its properties are aimed at consuming charcoal raw materials.

To modernize and increase efficiency, it is to obtain the greatest amount of heat with the same fuel combustion.

There are four main and simple methods for upgrading a potbelly stove, the use of which will significantly reduce heat loss:

- Attaching 2 tanks welded together from a washing machine.

- Making an ash pit.

- Grid with stones.

- Increasing the number of pipe bends

Let's take a closer look at them.

Preparation of the solution

Let's start by preparing the solution. For masonry work we use a special ready-made mixture. Sold in construction stores. It is a yellow-gray powder in 25 kg bags. All that remains is to dilute it with water in the correct ratio and mix. Detailed instructions are always indicated on the packaging; you need to follow them step by step. This solution is the best choice. It has only one drawback - its high price.

You can prepare the mortar for masonry yourself. For this we need clay and sand. First, let's determine the quality of the available clay and the content of impurities in it. We follow the following instructions:

- Roll the clay into a rope. Thickness - 10-15 mm, length - 150-200 cm.

- Take a rolling pin with a diameter of 50 mm and wrap a rope around it.

- The tourniquet should stretch smoothly and break, stretching by about 15-20%.

Expert opinion

Pavel Kruglov

Stove maker with 25 years of experience

If the rope stretches more, the clay is “fat”; if it breaks earlier, the clay is “skinny.” In the first option, the solution will shrink greatly under the influence of temperature, in the second it will crumble.

The next step is to prepare the sand. First, sift it through a fine sieve. The cell should not exceed 1.5x1.5 mm. Next we follow the instructions:

- using a handle and burlap, we arrange some kind of net;

- pour sand into it and begin to rinse it under running water;

- Rinse until the draining water runs clear.

Thus, we have rid the sand of impurities.

We do the same with clay. Now it should be soaked. To do this, pour the clay into a previously prepared container. Pour water so that the entire surface of the clay is covered. After 24 hours, mix thoroughly. We repeat the process until the clay has a consistency similar to toothpaste.

There is no universal proportion for a solution. Everything is installed by trial and error, depending on the characteristics of the materials used. The main thing is that the solution is convenient to work with.

To increase strength, experts recommend adding a little cement or salt.

Expert opinion

Pavel Kruglov

Stove maker with 25 years of experience

Here is a basic recipe for masonry mortar:

Take 2 parts of clay. Add one piece of sand to it. Using a construction mixer, mix until smooth and thick. We will need approximately 40 liters of solution.

Additional materials

In addition to the brick you will need:

- metal sheet 0.5mm;

- asbestos cardboard, 1 sheet 10mm;

- sand;

- clay;

- pure water.

Sand and clay can be replaced with a ready-made refractory mixture. The amount of mortar depends on the area of the masonry. The water must be purified - it is impossible to get rid of water stains, and mineral impurities weaken the solution. Clay can be either white or red - only its fat content is important. The sand is sifted and washed on stretched burlap.

Plating sequence

Diagram of an iron stove lined with bricks.

Before covering the stove with bricks. you need to make sure that the floor can withstand such a load. Without a foundation, stoves weighing up to 800 kg can be installed on a wooden floor. Of course, this is provided that the beams and joists are in good condition. A sheet of steel is placed on the floor, a layer of brick is placed on it, and then a stove is installed. If the floor is wooden, then a sheet of asbestos must also be placed under the metal. The steel sheet lining should protrude 30-40 cm in front of the front wall of the stove to prevent hot coals from falling onto the unprotected floor. Metal sheets with an asbestos cement backing also need to be attached to the walls of the room located next to the stove. It is necessary to take into account that a gap must be left between the stove lining and the wall of the room.

There must be a gap of 30-50 mm between the metal wall of the stove and the masonry. This must be done because metal and brick have different temperature coefficients of linear expansion. When heated, metal expands much more than brick, so if you place a potbelly stove closely, without a gap, the stove may collapse. Free space between the metal wall and the brick is also necessary for air convection.

As a rule, they line the stove with 1/2 brick. It makes no sense to make the wall thicker, since it will take too much time and fuel to warm up thick brickwork. Before you start covering the potbelly stove, you need to make markings, taking into account the gap. Mark the outer contour of the furnace. The first row is made continuous. You should try to make the thickness of the mortar between the bricks no more than 0.5 cm. In the second row, 1-2 holes are made on each side of the stove, depending on the size of the stove. The length of the holes is 1/2 of a brick. All subsequent rows are continuous, like the first row.

The front wall of the stove on the firebox side must be lined with ease of use in mind - the door must open and close freely. Here you can show your imagination and perform figured masonry. At the top of the opening above the door you need to lay a metal corner on which the top rows of bricks are laid. The upper part of the stove can be covered at your discretion, since technically it does not play a significant role, performing mainly a decorative function. The top of the oven can be made in the form of a vault or made flat.

After the lining is completed, the mortar in the joints should dry. This will take 1-2 days. After this, the surface of the masonry must be cleaned from excess mortar using a drill with a brush attachment. Then the masonry is washed with a soapy solution and a brush with stiff bristles.

Nowadays there is a large selection of metal stoves of various designs and price categories on sale. Metal stoves are used for heating private houses, temporary structures, at construction sites for heating workers, security guards and other purposes. The use of metal stoves in home baths and saunas is also increasingly gaining popularity, although in this case a brick stove is considered more traditional, but it cannot always be used for a number of reasons. The main advantages of metal stoves are their compactness (since not every room can install a brick oven), ease of installation, fast heating. The main disadvantage is that after stopping the fire, it cools down quite quickly. This drawback can be eliminated by lining a metal stove with bricks. This will greatly extend the heat transfer without increasing the size of the stove too much. If you made a metal stove yourself, then by lining such a stove with brick, you will give your stove a decorative look.

Having basic construction skills, you will be able to line an iron stove with bricks yourself; for this you will need the following materials and tools.

Preliminary preparation

Before laying bricks, you need to make sure the floor is in good condition. Thus, a reinforced concrete floor can withstand no more than 800 kg of weight per m2; the load on any other floor is usually calculated as 150 kg per m2. Before you cover the potbelly stove with brick, it needs to be installed on a kind of foundation made of a sheet of metal, asbestos cardboard and brick in this order: cardboard is placed on the floor, a steel sheet on top, then the brick is laid in two rows, as close to each other as possible.

If the potbelly stove has already been installed, it must be disconnected from the chimney pipe and moved away from the site of future masonry. When the floor is old and the weight of the structure cannot withstand, the logs are cut out and a cement foundation is poured, provided that the stove is installed on the first floor of the house. The stove should not stand only on the finished floor. To reduce the load on the joists, it is allowed to lay only 1 row of bricks on a sheet of metal and asbestos cardboard. The steel sheet should protrude 30 cm in front of the firebox door.

Facing

Before you line a metal stove in a bathhouse with bricks, you need to prepare for work.

Preparatory activities

You can start laying only after the concrete and brick base has dried. A metal stove is installed on it, and future cladding is marked around it.

But first you need to install a fireproof shield made of any fire-resistant materials on the wooden walls around the fireplace.

Insulation of wooden walls and floors with mineralite

If you decide to prepare masonry mortar from clay, then you need to fill it with water for several days and carefully sift the sand. Since it is difficult to cover an iron stove with bricks and not stain its body with mortar, before starting laying it should be protected with paper, cardboard or film, securing them to the walls with tape.

To prevent water from the solution from being absorbed into the brick, it is soaked in water about half an hour before starting work.

Soaking the brick

Masonry

When deciding how to brick a cast-iron stove, it is better to choose half-brick masonry. A thicker screen will take longer to heat up, and a thinner screen will cool down faster.

The laying of the first row begins from the far corner, laying a whole brick

It is very important to lay it out evenly and neatly, since all subsequent rows will be aligned with it. They are laid out alternately, with an offset of half a brick. Don't jump over the row, first raising the corners and then filling the space between them.

Laying is done offset

- The permissible thickness of the horizontal seam is 8-10 mm, vertical 3-5 mm.

- The seams are filled completely with the solution, its excess is immediately removed from the surface with a trowel.

Bricks that go beyond the plane are knocked down with a hammer or mallet

During the laying process, you need to constantly monitor the verticality of the walls and corners using a plumb line or building level.

A cord stretched along the upper edge of the row will help to keep the row strictly horizontal.

Auxiliary vertical stands will make work easier

To strengthen the masonry, reinforcing mesh can be placed in the seams every two or three rows.

The photo shows the reinforcement of the masonry with metal mesh

Also, every two or three rows you should unstitch the seams until the mortar loses its elasticity, and wipe the surface from any remaining mortar with a wet rag.

Joining seams

When laying out the walls, it is necessary to leave ventilation holes in them: at least two at the top and two at the bottom. Cold air will flow into the lower ones, protecting the oven from overheating, and heated air will come out through the upper ones.

Furnace ventilation diagram

- As an option, you can line the stove with bricks laid in a checkerboard pattern with holes between all adjacent elements.

- Around the doors of the firebox and ash pit, masonry should be carried out taking into account their full opening.

The brick will have to be cut if it prevents the doors from opening

Where to finish the masonry is up to you. If you have a stove with a stove or heater, it is only brought to the top of the body. You can raise it to the ceiling. Or you can make figured masonry with a vault and chimney lining, turning an ordinary potbelly stove into something like a fireplace.

Metal stove for a bath, lined with bricks up to the pipe

Option with full height masonry and pipe lining

The brick portal turned an ordinary stove into a real fireplace. Now you need to let the solution dry for at least a day. It is desirable for this to happen in natural conditions, so it is better not to heat the stove for now.

Laying bricks around a metal body

The work is carried out in this order:

- We lay the first row so that all the bricks are on the same level. To begin with - dry.

- We prepare the mortar and begin laying, using leveling pads if necessary. The first row should be close to the metal.

- The next rows are 50-70 millimeters away from the metal. We set the direction of the wall, maintaining the required gap, for which we lay pieces of brick close to the metal, providing the required gap.

- The brick can be laid either end-on or flat. However, in the latter case, you will need twice as much material.

- On the third row, you need to provide a hole for the circulation of air flows along the gap between the metal and the bricks.

Do not forget about the level and plumb line, which we use to check the verticality and horizontality of the rows. If you want the masonry to have an aesthetic appearance, you can use jointing. However, this must be done before the solution has dried. You can also use slats. Two rows before the end of the masonry (that is, in the penultimate row), it is necessary to provide gaps between the bricks to supply warm air into the room due to convection.

If you have the material and brick laying pattern, building a brick potbelly stove does not seem to be a difficult task. Success is guaranteed if you don’t rush and carefully follow the instructions, since if the evenness of the masonry is disrupted, a significant part of the work will have to be redone.

Required Tools

To organize your work you need the simplest tools. If there is no electricity on the site, you can do without mixing with a drill and do everything by hand. To work you will need:

- Trowel for laying bricks and cleaning off excess mortar.

- Pickaxe for dividing bricks (if necessary).

- Plumb to maintain even vertical masonry.

- Water level for horizontal leveling.

- Container for solution.

- A shovel or drill with an attachment for mixing the solution.

- Joining, if desired, make neat seams.

- Sieve for sifting sand 1.5*1.5mm. Burlap is used for washing.

- An abrasive attachment for a drill for cleaning finished masonry from excess mortar.

Why cover with bricks?

Potbelly stoves come in cast iron and metal. The first ones are, of course, more economical. The problem with all metal stoves is rapid heat transfer. As soon as all the fuel has burned out, the potbelly stove instantly cools down, and with it the heated room. Fast heat transfer helps when you need to quickly warm up a room, but requires constant loading of fuel. The potbelly stove got its name for such “gluttony” - no matter how much fuel you put in, it’s not enough. To increase the efficiency of a potbelly stove, during the October Revolution the chimney pipe was lengthened. Burning gases passing through a long pipe heated it, so the length of the chimney could be equal to the perimeter of the room.

An easier way to retain some of the heat is to line the stove with bricks. The heat emanating from the stove heats the brick, and as it cools, it releases the accumulated heat. The brickwork will allow the stove to remain warm for a couple of hours after it has cooled down. Covering a potbelly stove with bricks in this way not only increases efficiency, but also externally transforms a cheap stove. For greater beauty, you can use special heat-resistant tiles. So a potbelly stove can become visually very attractive and resemble a Dutch or Swedish stove.

Cover example

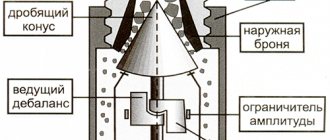

Increasing the number of pipe bends

Increasing the bends of the potbelly stove chimney

The tank at the outlet of washing machines will retain a certain amount of heat, but it will not be able to retain all the heat. A large amount of heat will continue to escape into the chimney.

Therefore, one of the improvements that provides additional heat retention is to increase the length of the outlet pipe. A long pipe running through the room, but with good exhaust, ensures the transfer of heat from its surface, which was previously lost.

Materials and tools

- several elbows that can be easily placed in the room after the potbelly stove,

- brackets for fastening pipe elbows,

- welding machine and metal processing tools.

Instructions

First you need to mark the location of the pipe. It can pass with a large number of bends and zigzags, thereby ensuring maximum heat retention, without forgetting about the loss of exhaust draft. After marking the pipe laying location, it is necessary to install pipe mounting brackets

Particular attention should be paid to the joints of pipe elbows and corners. Brackets must be made of heat-resistant materials. Lay the pipes to ensure a tight, hermetically sealed connection, and, if necessary, modify the elbows to ensure the pipe is laid along the marked route. Firmly secure the elbows in the brackets, check the working draft (burn newspaper in front of the pipe), check the tightness of the connections, connect the inlet elbow to the stove.