Without proper care and compliance with operating rules, any knife will quickly become unusable. This kitchen helper must have a sharp blade to cut well. Find out what ways to restore original cutting properties or improve existing ones in the review of budget and specialized sharpening methods.

Knife sharpener: an assistant in sharpening knives.

How to use a knife with wheels

The operating principle of this sharpener is based on the rotation of two rollers. They act like millstones, between which the blade is inserted and sharpened on both sides. The rollers are coated with an abrasive substance - diamond or ceramic coating. When the wheels turn, the blade is ground at a 45° angle. The movements are repeated 4-5 times.

For frequent cutting of meat, fish and hard foods, sharpening is not the best option, since a wheeled sharpener will have to be used before each preparation.

How to use the knife:

- Knife with a wheel.

The blade is inserted into the slot first with a slant to the left and processed, then the right side. - When approaching the tip, you need to slightly lift it by the handle.

There is no need to treat the blade with water before the procedure, but after it is necessary to wash off metal particles.

How else to sharpen knives

Dull knives spoil food, so to avoid spoilage of the dish, they must be sharpened. If you perform this ritual incorrectly, the result will be even worse. Therefore, you should not take risks without being sure of the success of the business, otherwise the instrument will be damaged.

For example, only diamond-coated stones are suitable for ceramic tools. But Damascus steel and bread knives require only professional processing.

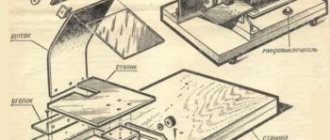

On the grinding machine

Sharpening on a machine.

It is one of the most effective turning methods. The round whetstone rotates at high speed. At this moment, a knife is applied at the desired angle and the blade is drawn along the surface of the stone.

In this case, the pressure exerted by your fingers should be the same throughout the entire process.

With the machine, the quality and speed of sharpening are high. The device is durable, but few people want to spend money on buying a unit. In addition, the speed of rotation is so high that only professionals can sharpen safely with it - the method is very dangerous. Without experience, adjusting the sharpening angle is problematic.

Stone

When hiking, outdoors and in other extreme conditions, you can take an ordinary stone or cobblestone. Run the cutting part along the stone, like on a sharpening machine. The effect will not be achieved so quickly, at least 10 movements. This is only a temporary measure. Returning home, you will need to put the instrument in order using special tools. It is a sharpening stone, which will last a long time, but is not cheap.

In nature, preference should be given to smooth and sea stones. Rough, rough stones will further damage the cutting edge.

On sandpaper

Sandpaper has long been used to scribble various surfaces, including cutting surfaces. Almost every housewife uses this method when sharpening kitchen knives. To do this, 2 pieces of soft and hard sandpaper are glued to the blocks of wood on both sides with adhesive tape/insulating tape. You need to process the surface until it becomes rough on both sides. It is necessary to achieve their disappearance, then we can talk about sharpness.

Knife on knife

The simplest Soviet method is to take 2 knives and rub them against each other. The duration of rubbing is about 10 minutes. The quality of sharpening leaves much to be desired, but instant results are achieved in a short time. In addition, friction causes the metal to crumble. If you do not wash the product, particles will end up on food.

File

Sharpening methods.

Compared to sandpaper, this is a rough sharpening method. Even the softest files are not able to provide a delicate finish to the blade. You need to choose a file on which the size of the notches will be medium, so as not to scratch the blade.

Electric sharpener

Similar to mechanical sharpening, but with an electric drive. Multifunctional tool used for sharpening knives, scissors, etc. The sharpener is efficient and fully automatic. The performance of the device depends on the power of the electric motor.

Damascus steel and professional knives will be damaged by an electric sharpener.

Combination roller knife sharpener TAIDEA

Subscription

- China stores

- CHINABUYE.COM

- For kitchen

Roller sharpeners have proven themselves very well; they do not damage knives and allow you to maintain their sharpness at the proper level for a long time until the sharpening angle “deteriorates” or nicks appear on the knife.

A traditional ceramic roller sharpener cannot do anything about this - it can only straighten the knife. This sharpener can also handle real knife sharpening. You can sharpen everything except ceramics and serrated parts. So, here it is. Its essence is three sharpening rollers, two of which are steel “diamond” ones, and the third is ceramic, like Fiskars. It is these diamond rollers that allow you to do without this tedious procedure, which my servant does once every couple of months, correcting approximately these notches and adjusting the angle of sharpening - the roller simply no longer touches the cutting edge, but shuffles along the sides of the blade. Roller sharpener, unlike longitudinal ones , does not leave grooves parallel to the RK (which contributes to the rapid chipping of the sharpened edge), it cuts them at an angle of 45 degrees, which for the blade is exactly the same as perpendicular. This is what the grooves look like after sanding on the roughest roller (the knife is cheap) And this is what the RC of the Arcos knife looks like. As you can see, it’s a microserrator. Then it should be straightened with a medium roller, and then sanded with a ceramic one. In theory, such a microserrator does not need to be removed for some applications - for example, cutting bread with such a knife is awesome. This is what a knife looks like after ceramics. Cuts a grape almost without squeezing out the juice. Very good, we talked about the results, now I’ll describe the gadget itself. Large, heavy, very neat and, in general, solid. Weighs about half a kilo. Made of hard plastic, with a decorative metal body on top. Everything is neat and convenient. The rollers rotate easily and do not creak. Due to its large size, the sharpener is very comfortable to hold - the grip is human (Fiskars constantly tries to slip out), and the bottom is equipped with a stable platform with rubber feet. The sharpener is supplied in a beautiful box, which the Chinabike packers carefully covered with tape. Three years warranty! Unexpectedly - competent Russian language. The sharpener itself was still sealed in a thick film hermetically - even throw it into water. Thanks to its design, even a child can use the sharpener. Summary: a very useful thing, well made, works great. It also looks good and is easy to use. Provided to me free of charge. Thank you for attention! Planning to buy +127 Add to favorites Review liked +43 +120 mysku.ru

Kitchen knife sharpening angle

Knife sharpening angle.

Kitchen knives come in different types, so each one needs to be sharpened differently. Thus, filleting and boning tools are processed at an angle of 25°, cutting tools - 25-30°, shredding tools - 35°.

For hunting knife

A sharpening angle of 30-35° is suitable for hunting knives. You need to restore your cutting ability with the help of professional tools, since the blade is wide and thick.

Hunting and camping knives

The main difference between hunting and camping knives and kitchen knives is the metal used. It is much stronger, withstands bending better, and is also thicker. In addition, the handle of the knives is more comfortable and allows you to more securely fix the knife in your hand.

In addition, the method of sharpening such knives is also different. It is quite possible to sharpen a knife with a stone, but with hard metal it is a rather long task that can take 2-3 hours before an average result is achieved.

When sharpening hunting knives, one whetstone will not be enough; it is advisable to have a leather belt or a wide leather strip designed specifically for grinding the edges of knives.

It can be purchased at a specialty store, the cost is quite high. Its task is to grind the edges of knives after several stages of sharpening; it is thanks to it that it is possible to achieve the highest possible sharpness on a specific type of metal.

It is recommended to watch a video with a detailed analysis and overview of the nuances of turning hunting knives, as well as familiarize yourself with safety precautions when carrying out such work, especially when using machines.

Sharpening knives on a knife blade

Specialized knife care devices include knife blades. With their help, sharpening occurs quickly, but with frequent use the blade becomes dull. They can be mechanical or electric on rollers.

At what angle

It depends on the functional purpose of the blade. The sharpening angle of the razors is 12°. Fillet knives become sharp at 15°. For kitchens, 20° is suitable. But even so, each leading tool has areas that require different sharpening.

Manual sharpening procedure

It would seem that sharpening a knife yourself is a simple matter. However, without knowing certain rules, the work will go down the drain:

- Place a sanding block on the table. It is advisable to secure it.

- Choose a sharpening angle and do not stray from it in the process.

- Movements should be smooth and uniform, without strong pressure, “from yourself.”

- The knife must go completely; Having reached the tip, continue movements in the opposite direction.

- Sharpen until burrs appear on both sides of the blade.

- Change the block with increasingly finer abrasive until the cutting part becomes mirror-like.

What to pay attention to

When purchasing kitchen knives, you need to pay attention to the type of metal that was used to create the blades. The optimal sharpening method depends on this type. Many people are accustomed to sharpening knives with a whetstone; this is actually a universal option, but the whetstone should also be selected carefully.

There are more varieties of sharpening stones. They are all divided into 3 types:

- For rough sharpening. Allows you to straighten the blade after notches and give the edge the correct shape.

- For medium sharpening. Grinds the blade and edge so that it can be sharpened efficiently.

- For soft sharpening. It is used at the final stage, when the blade needs to be given maximum sharpness.

The best option is diamond bars, they have an excellent price/quality ratio, and they also have a long service life.

How to test the sharpness

Checking the sharpness of the blade is carried out in several proven ways:

- paper - hold the sheet with one hand and strip the paper with the other. With sufficient sharpness, cutting will go like clockwork;

- tomato - place the vegetable on the table and cut horizontally;

- on hairs - carefully press the blade to the skin of your hand and lightly run through the hair on it. If the “epilation” is successful, then the blade is sharp.

Checking knives on tomatoes.

Sharpening tools

There are many ways to sharpen, as well as devices used for this process. Let's look at the most popular ones. Among them the following are popular:

Sharpening stone

Natural whetstones are popular among professional sharpeners; when used correctly, they achieve the highest cutting quality of the tool being sharpened. Arkansas novaculite stone and Japanese water stone are favorites of natural stones. The price of such bars is high, although they are produced artificially in an industrial way. The wear of the stone is high, which is suitable for lens-shaped sharpening of blades. A beginner will need patience and perseverance, high qualifications to work with such stones:

- Diamond stones are a popular and very affordable material for turning any tool. They produce fine and coarse grains of different shapes and sizes. They are an excellent choice for a beginner. The price is budget-friendly, allowing you to have a set of stones in your arsenal for any need. The wear of the diamond stone is very low, the abrasive effect is strong, so control of the sharpened edge of the blade should be increased as much as possible. Used in most cases for initial processing of the cutting part and setting the sharpening angle.

- Ceramic whetstones are modern sharpening stones that combine the advantages of natural and diamond materials used by sharpeners. The main application is final finishing after working with a knife on a diamond abrasive. They have little wear and allow to achieve high quality cuts, just like natural stones.

- abrasive artificial stones. The main representatives are carbides and electrocorundum. They have minimal cost, availability, and high wear. They are used, like diamond stones, for the initial preparation of the blade to be sharpened.

7 Helpful Tips for Cleaning Pots Without Scratching

Mechanical sharpener

A mechanical sharpener is a device for sharpening knives that requires physical effort and has the following capabilities:

- choosing the right grinding stone in terms of grain size and hardness;

- securing, holding the blade in the position required for proper processing;

- setting a suitable angle of the abrasive relative to the cutting edge of the blade being processed;

- availability of instructions for proper use of the device;

- obtaining a consistently positive result after correctly performed actions.

Electric sharpener

It is used for straightening and sharpening all types of cutting tools, even with a ceramic blade, does not require a professional approach, just read the instructions. The working element is replaceable (mostly a diamond roller is used). It is possible to sharpen knives with single-sided and double-sided sharpening. Powered by electric current.

Musat

This is a type of mechanical sharpener that requires the application of physical force and maintaining the sharpening angle. Used for straightening a properly sharpened blade. The external shape of such a device resembles a file with a round or oval cross-section. It has a working part, a handle with stops for safe sharpening, and protects your hand from the knife slipping.

The working part of the musat is made from:

- magnetized steel;

- aluminum coated with a thin layer of oxide of this metal (leucosapphire);

- metal rod with ceramic coating;

- solid ceramics.

Musats are not used for sharpening, only for straightening the blade of a cutting tool with a hardness of the material from which they are made up to 60 HRC units. To straighten the razor, use a razor belt.

Sharpening and grinding machines

This is a category of electrical devices in which, to perform a given job, an electric motor and replaceable abrasive materials attached to its shaft are used. They can be discs, sanding tapes.

Types of machines:

- household, universal. They are used for sharpening all types of cutting tools. The sharpening angle of the blades is selected visually. The pressing force on the rotating abrasive is self-maintained;

- special purpose. Initially they were created for a specific tool (scissors, drills, chainsaw chains, electric saws), with a choice of sharpening angle and limited clamping force.

Lansky sharpener

This is a sharpening device for forming the desired angle on the cutting edge of the blade. It is used after processing the blank of the future knife on an emery machine, when it is necessary to set the desired sharpening angle of the blade. To do this, the blade is fixed in an aluminum clamp, the guide with the stone holder is inserted into the marked hole on the holder, corresponding to the desired sharpening angle. Next, the desired cutting angle of the blade is formed. This device also works well for straightening the blade and sharpening angle on a finished cutting tool of any configuration.

WHY DO YOU BUY SHARPENERS?

A practitioner who has perfectly mastered sharpening with a set of water stones or a compact belt grinder will most likely look at a household sharpener with disdain. And there is a reason for this. The high level of professional skills required to operate such a tool makes us perceive household sharpeners as controversial, primitive and functionally limited devices.

Not every professional chef is willing to take an intensive course from a professional sharpener to keep their knives sharp and invest in a professional tool to restore sharpness. What can we say about a simple cooking enthusiast whose knives solve much more modest tasks. Professional services in the field of sharpening high-quality knives are now rare and expensive. Therefore, in an ordinary kitchen, simple devices for restoring sharpness have been used, are being used, and will be used for quite a long time, despite their shortcomings.

The main advantage of household sharpening devices is the ability to quickly return the knife to working condition on your own, without developed sharpening skills and the use of expensive sharpening tools. Of course, even the simplest sharpener will require some skill when using it. But developing it will not require a course of lectures and hundreds of hours of practice. You can master a household sharpener yourself in half an hour. It is this simplicity and intuitiveness of use at low cost and, in general, a result that satisfies the average consumer that has earned hand-held kitchen knives enormous popularity in home kitchens.

No other tool embodies the “two out of three” concept as clearly as the household knife sharpener. We are naively looking for a tool that will provide the required result quickly, efficiently and cheaply. But in practice, at least one of these properties has to be sacrificed in favor of the other two. Let's illustrate this with an example.

Ceramic grinder HD-1230C Hatamoto with abrasive ceramic rod 203 mm long.

The most popular tool for quickly restoring sharpness is musat. In recent years, modified versions of this tool, proven by generations of chefs, using ceramics and wear-resistant coatings make it possible not only to sharpen and straighten blades, but even to slightly repair them. It would seem that all three properties are met: an affordable price, a good result and the speed of achieving it. But no.

The knife and musat, floating in the hands of the chef in a paired dance of acquiring sharpness, is the result of a skill developed by long practice. To acquire which you will have to spend more than one hour of training. The second unpleasant point is the minimal contact patch between the cutting edge and the round musat. That is why, even to easily straighten the blade, the cook has to make one and a half to two dozen movements. The musats are made elliptical to increase the contact area, but this does not greatly help speed up the process. The size of the contact spot between the flat side of the water stone and the blade being sharpened is still very, very far away. And, therefore, productive work on sharpening and minor repairs is too tough for the musat. This is a tool with the narrow task of straightening cutting edges and combating slight dullness.

ON STEEL LEVERS.

The most complex and demanding sharpener skills are lever sharpeners. From a mechanical point of view, they are radically different from other designs in that the knife itself is fixed motionless on a support, and sharpening is performed by manipulating abrasive elements of various grain sizes along certain trajectories set using a system of rods, rods and levers.

Lever sharpener with a set of sharpening elements for various tasks.

Such sharpeners do a good job of solving the problem of setting different sharpening angles and performing various operations (repairing, sharpening, straightening, finishing) by varying abrasive materials of different grain sizes and properties. The wide contact zone reduces the time required to complete the work; the cutting edge is formed quickly and efficiently. Even high-quality knives made from high-tech steels can be trusted with such a sharpener.

One of the most sophisticated lever sharpeners with instructions on how to use it.

The main disadvantages include the rather cumbersome design. “Straighten an edge in no time” is not about a lever sharpener, on which even simple work turns into a Ritual: assemble the sharpener, attach the knife to the support, select the correct abrasive element for the task, secure it in the holder, process one side, turn it over to the other side, process the other... In general, even the most ardent apologist of this type of sharpener would be embarrassed to call the whole described process fast. That is, while getting a good result for affordable money, we are again forced to sacrifice speed.

Tips for sharpening knives quickly

There are times in life when, finding yourself in nature, you need to sharpen a dull knife, but there is no opportunity to use a sharpening tool. Some tips that can help in this situation:

- For editing, cobblestone is suitable as an abrasive stone. By choosing the right angle and having experience in editing the blade, you can achieve a decent result with it;

- you can use the second knife as a grinder;

- glass and ceramic products (back side of the plate) can act as a sharpening stone;

- A tightened leather belt can be a substitute for musat; you won’t be able to achieve much sharpness, but the blade will polish “excellent.”

Choose good knives and take care of them. In return, they will “thank you” with high-quality and long-term work.