Plastic products are durable and do not require special maintenance conditions. To make them, liquid plastic is used for pouring, which is purchased in a store or made independently at home. Before starting work, you must familiarize yourself with the cooking technology and observe safety precautions.

Where should you start?

The first thing you need to do before organizing production is to choose which groups of goods you will produce.

A lot depends on your specific capabilities. For example, if it is possible to agree on the supply of containers for packaging semi-finished products, you should start with it. This will give a good start to the production process. Later, if necessary, it will be possible to expand and engage in the production of other product groups. If there are no developments, then you should start with consumer products:

- buckets;

- flower pots;

- containers for seedlings;

- packaging.

Gift to school

The traditional task of a labor teacher to prepare some little thing at home usually becomes a headache for parents. Making plastic crafts for school can free yourself from unnecessary work and at the same time keep your child busy with something useful.

A win-win option would be to make an original flowerpot. There is always a place for such a thing in the interior of the classroom - teachers are always interested in a large number of living plants in the school.

Selecting the appropriate room

Plastic injection molding does not impose strict requirements on production conditions. But, despite this, the premises should be located away from residential areas, it is best if it is located in an industrial area. In this case, a number of conditions and fire safety requirements must also be met. At the same time, from 50 to 200 square meters will need to be allocated for the production workshop itself. m. Also about 80 sq. m will go under the warehouse. Plastic products, although lightweight, are quite bulky.

Decorating the walls of the cottage

A mosaic panel applied to the wall of a country house looks very impressive. How to make a plastic craft for the wall so that it does not lose its attractiveness for a long time?

There are several important points to consider here:

- It is best to attach the caps with thin nails to plywood or a wooden board;

- It is better to nail the mosaic with the caps facing up, otherwise the panel will quickly become dirty and lose its appearance;

- It is necessary to make a drawing in advance, according to which the picture will be assembled.

In a similar way, you can create an elegant fence for a balcony.

Main types of raw materials for plastic injection

For plastic injection molding, polymers in granules are used. The use of one or another of them depends on its physicochemical properties. Based on temperature resistance, all solid polymers are divided into the following groups:

- Thermoplastic. Under the influence of temperature, they have the ability to easily transition from a solid to a plastic state and back. They are very easy to recycle.

- Thermosetting. They have high strength and heat resistance. They are based on various synthetic resins. To impart certain properties, special additives and fillers are introduced into their composition.

- Foam plastics. They are characterized by excellent heat and sound insulation. They are made from synthetic polymers, the role of a filler in them is played by a gaseous medium.

You can buy plastic for casting from companies specializing in the sale of polymers. Usually you can purchase raw materials from them not only domestically produced, but also imported. The average price for high-density polyethylene at the moment is about 35 rubles. per kilogram, polypropylene from 40 rubles. and higher.

Where else can liquid plastic be used?

The homemade composition is great for filling up gaps on windows - they often remain after installing a new double-glazed window. As it dries, an elastic, sealed film will appear.

Plastic will protect metal surfaces from corrosion, so it can be used to treat any metal against rust. After drying, the base will be moisture-resistant, resistant to ultraviolet radiation, aggressive chemicals and mechanical damage. In addition, it will become beautiful, acquire a pleasant shine and interesting texture.

Basic casting technologies

There are three main plastic injection technologies:

- Extrusion or injection molding. One of the most common technologies. Among its disadvantages, it is worth noting the high cost of injection molding machines; also, competent organization of the technological process requires special education.

- Blown. Used for making hollow products. For example, plastic bottles and other containers. The essence of this technology is that the polymer is first heated to a certain temperature and then blown onto a cooled mold.

- Thermoforming. This technology involves the use of compressed air or pressing. Most often, disposable tableware and food packaging are made using this method.

Working together with children

Many teachers and psychologists believe that crafts done by children with their own hands develop the following necessary qualities in the child:

- attentiveness;

- accuracy;

- patience;

- perseverance.

Parents also need to remember this fact - children who do handicrafts develop faster mentally and are ahead of their peers.

Crafts made from plastic glasses are also good because the material costs a penny, and you can make very original things out of them.

You can make appliqués from cups; to do this, you just need to cut out a figure from one glass, paint it and stick it on another vessel.

It's not that difficult to make a beautiful New Year's garland. You need to paint several cups, pierce the bottom and insert LED bulbs into the hole. This children's plastic craft will undoubtedly decorate the New Year's holiday in kindergarten or school.

Injection molding technology

Plastic injection molding technology includes the following production processes:

- Loading raw materials into a vacuum loader. In this case, the raw materials used can be in the form of granules, powders or tablets.

- Supply of raw materials to the hopper of the injection molding machine.

- Heat. The heated surface of the screw located in the hopper melts the polymers and, if necessary, mixes them with fillers.

- Pour the plastic into the mold. Under the influence of axial force, the molten polymers are extruded into the mold.

The advantages of this type of casting include the following:

- High quality products.

- High performance indicators.

- The casting process can be fully automated.

How to use ready-made material

Homemade plastic adheres well to metal surfaces, so it can be used to cover the handles of steel tools. After hardening, holding them will be much more convenient and comfortable.

To apply the plastic “paint” you will need a small brush. The composition is applied to the surface of the handles in a thick layer, and then allowed to dry completely in fresh air until the xylene evaporates. The finished coating will be monolithic and very durable.

Applying the composition to tool handles

Important! When working, it is necessary to observe safety measures, work in an open space and use a protective mask, because solvent vapors are harmful to humans.

The following must be done:

- wear special safety glasses that will prevent eye burns in case of accidental contact with the material;

- Avoid being near sources of open fire and heating devices (xylene is a highly flammable liquid), and do not smoke under any circumstances;

- Do not pour any remaining plastic or solvent down the drain;

- work only with gloves.

Types of plastic molding

The production of plastic products by injection molding can be carried out in several ways:

- Injection. One of the most common casting methods. It is characterized by a short-term injection of molten polymer. During this process, a certain pressure is created in the working chamber of the casting machine, after which the plasticized polymer is injected.

- Injection-press. This method is used in the production of products with a large surface area. It requires special molds with moving components.

- Injection-gas. During such casting, the force of compressed gas is additionally used, which compresses the plastic in the mold.

- Intrusive. The simplest casting option. Used for casting the simplest goods with a minimum number of surfaces.

Read also: Solder resistivity pos 61

In addition to the above methods, there are more complex types of casting:

- Sandwich. During it, two types of plastics are used. This method makes it possible to produce products with an external coating.

- Co-injection. Used for the manufacture of multilayer products. To do this, you will need to install a complex nozzle design on the injection molding machine. This method makes it possible to produce products with mixed colors.

- Casting into multi-component molds. This method allows the production of products with clear color differentiation. Among its features, it should be noted that it is possible to produce products with adjacent parts of different densities.

- Casting in rotary molds. Using this method, two-component products can be produced. During it, the main blank is first cast, which is then moved to another mold, where a second layer of polymer is applied. This method is the least productive of all of the above.

Plastic products

Environmentalists all over the world are sounding the alarm - plastic does not decompose in natural conditions for half a thousand years and is increasingly polluting the world's oceans and land! So imagine what kind of “eternal” thing can be made from an ordinary bottle!

No one can say exactly how many different things can be made from plastic bottles. Let's note the most common ones:

- lamps;

- various decorations for the garden and home;

- costume jewelry;

- toys;

- piggy banks;

- decorative vases and glasses;

- piggy banks, coasters, etc.

But for the American Garth Britsman, his carport, which took more than a thousand bottles to make, brought him worldwide fame and a place in the top 50 most unusual structures in the world!

Selecting the necessary equipment

After deciding on the organizational issues and choosing the premises, you can begin to select and purchase equipment. It is represented by models of both domestic and imported production. The only advantage of the former is most often the price. Although imported equipment is much more expensive, it is of much higher quality and reliable.

When organizing production, you will need the following equipment for plastic injection:

Injection molding machine

It is an injection molding machine designed for the manufacture of piece goods. Injection molding machines or extruders are the most used type of equipment; they produce more than 2/3 of all plastic products in the world. Regardless of the model, each plastic injection machine necessarily consists of the following structural units:

- Injection. It melts and feeds plastic.

- Closings. It is responsible for closing and opening the mold during the casting process.

- The drive responsible for the operation of all moving units.

All currently existing extruders can be classified into the following types based on the type of mechanism that creates pressure:

- One-worm. Their main advantage is the simplicity of design and the small size of the material chamber.

- Two-worm. They feature better polymer mixing and improved production characteristics.

- Worm-piston.

- Piston.

Also, depending on the location of the press part, the following types of injection molding machines are distinguished:

- horizontal;

- corner with vertical press;

- vertical;

- corner with horizontal press.

The price for such units ranges from 200 thousand rubles for used ones to 1-2 million rubles. for new ones.

Press forms

Molds for plastic injection are the main type of equipment for injection molding machines. For the production of each product, its own individual mold is made. The principle of its operation is very simple. An injection molding machine injects molten plastic into a mold. After it cools, she opens the mold and pushes the finished product out of it. Plastic injection molds can be made from various grades of steel. This affects the number of their production cycles. It can range from 100,000 to 1 million.

Vacuum raw material loader

Vacuum autoloaders of polymer raw materials are a type of peripheral equipment that can significantly speed up and facilitate the process of feeding polymer materials into the loading hoppers of injection molding machines. According to their design features, they can be divided into vertical and separate models. The first ones perform standard functions, the second ones are used when transporting polymers over long distances.

Refrigeration unit

Refrigeration units, or chillers in other words, are used to cool water in the production of plastics under pressure. They can significantly reduce the production cycle time.

All of the above equipment is used for casting in mass production conditions. But what if you don't need thousands of identical products? The way out of this situation is small-scale plastic molding at home.

Bottle caps

Among crafts made from plastic bottles, a special place is occupied by things made from the caps of vessels. The most common type of decoration made from this material is the design of garden paths. True, it will take a very long time to collect material for the mosaic. You can’t do this without the help of friends and acquaintances.

One important point to take into account is that laying out mosaics is painstaking and monotonous work that requires patience and perseverance. This type of activity is unlikely to be suitable for people who do not have the necessary qualities.

As a rule, covers are laid on a garden path or a small area near a flower bed. There are small nuances in the design of these two types of areas. When forming a path, the covers are laid directly on the cement mortar before it hardens.

The area in front of the flower bed is laid out with lids that are simply pressed into the ground. This is necessary so that air can penetrate underground.

Homemade plastic molding

Do-it-yourself home plastic molding is a type of industrial version of the manufacture of plastic products. It allows you to produce any not very large products. For example, such as:

- various caps and lids;

- housings;

- toys;

- cubes;

- dishes;

- souvenirs.

Equipment for small-scale casting

Small-scale casting does not require the purchase of expensive equipment. For a small workshop it will be enough to purchase the following:

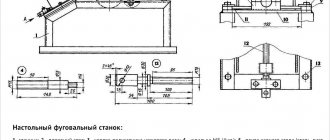

- Tabletop manual machine for plastic injection.

- Form-forming part of the mold.

- Silicone for molds.

- Two-component plastic.

A tabletop casting machine is a type of foundry equipment used for small-scale production. He can carry out his work using both single and multi-place forms. To install such a machine, an ordinary desktop of a small area is quite enough, the main thing is that it is stable.

Currently, there are modifications of machines with electromechanical drives. They are more reliable and easier to maintain. Some of the advanced models of such units are even equipped with an automatic clamping unit. A manual casting machine allows you to produce an average of 10 to 15 products per hour.

Making your own silicone molds

You can make molds for plastic injection at home yourself. To do this, you will first have to prepare a sample model. Its production can be ordered from the owner of the 3D printer.

Next we proceed as follows:

- Using a wide brush, carefully coat the sample with a thin layer of silicone.

- We place it in a pre-prepared formwork.

- We fill the entire volume of the formwork with silicone.

- We wait 7-8 hours until the silicone completely hardens.

- We make a cut shape.

Your first mold is ready, now you can start hand casting.

Main types of silicones for making molds

There are quite a lot of silicones for making molds, the most common of them are discussed below:

- Mold Star 15,16,30. This series of silicones hardens well at room temperature. Can be used to produce molds with very good detail. Chemically sensitive to latex and sulfur. The number in the classification means the hardness indicator. They have a two-component base, which is mixed immediately before pouring.

- Rebound 25, 40. Used to create shapes using the “spread” method. Silicone is simply applied to the sample with a brush. Can be used in combination with various plasticizers and modifiers. They are two-component formulations.

- Sorta Clear 18, 37, 40. Translucent silicones, well suited for creating cut shapes. They can also be used together with various additives and hardening accelerators.

Read also: How to glue plastic glasses

Main characteristics of two-component plastics

Liquid two-component plastics are quite widely used in small-scale casting. There are quite a few brands of such polymers. Their main difference is the density and hardness of the finished product. Also, depending on the additives, they can have different texture and color. After mixing the components that make up the polymer, an accelerated process of hardening or polymerization begins, which usually lasts no more than 10 minutes.

The use of liquid plastics makes it possible to implement a variety of design solutions. Also, such polymers are very often used to create prototypes and models during design development.

Products made from liquid plastic are in no way inferior to industrially produced analogues. They are just as strong, beautiful and durable. In addition, the market for liquid polymers is constantly expanding and improving, which makes it possible to purchase more and more advanced samples.

Silicone molding technology

For silicone molds, you will also need to purchase a special liquid plastic for casting. It does not require preheating and hardens perfectly at room temperature. Molding plastic into silicone molds looks like this:

- The casting mold is thoroughly cleaned of dust and other contaminants.

- Both halves of the form are firmly secured using rubber bands, tape or any other available materials.

- Two-component plastic for casting is diluted in a container. Both of its components should be mixed very thoroughly. In this case, you need to act as quickly as possible. After just a few minutes, the plastic begins to set. At this stage, dye is added to the composition to give a certain color.

- The thoroughly mixed mixture is poured into the mold in a thin stream. It must even fill the casting channel. After the degassing process, the volume of the material will decrease slightly.

- Wait for the product to cure. Usually this takes no more than 10-15 minutes.

Injection plastic allows you to create a small amount of original designer products with your own hands.

Manual casting technology

Casting methods using a manual machine are somewhat similar to industrial ones. The process itself looks like this:

- Installation of injection molding nozzle on the machine.

- Applying a layer of silicone to the surface of the mold.

- Installing the mold on the unit.

- Loading raw materials into the bunker.

- Stirring and heating polymers using a screw.

- Casting.

- Cooling.

- Disassembling the mold and removing the finished product.

The tabletop injection molding press is ideal for small production environments. It is highly versatile. He can cast products from almost any type of polymer. To increase productivity, a plastic injection press should be equipped with several similar molds at once. This allows for a virtually uninterrupted production process.

Additionally, finished products can be fastened together using a special welding extruder. This allows us to significantly expand the injection molding business by producing more complex products.

The largest independent platform for discussing the production and processing of plastics and elastomers in various ways. Recommendations from leading experts.

- Unanswered topics

- Active topics

- Search

- our team

- PlastExpertForum about polymersQuestions about production organizingTechnical equipment/Molds and dies

- Search

Preparation of material for casting

At home you can create lids, toys, souvenirs, household utensils and other solid objects. For the procedure you need to prepare a number of materials:

- plastic for casting;

- melting container;

- master model;

- mold;

- lubricant

And other means.

For casting, plastic scrap can be used, which is crushed and melted. However, the melting point of all types of plastics differs, and only one specific type is used to create the blank. If this rule is not followed, the plastic melts unevenly and the parts created from it turn out to be inhomogeneous and bubbly.

At home, it is easier to use ready-made mixtures, such as liquid plastic or epoxy resin. The material does not require melting, it cooks and sets quickly, and products made from it are not inferior in quality to analogues. As an alternative, AKP-7 powder is also suitable, requiring mixing with a solvent. It takes longer to prepare plastic from it, but the result is pleasing.

However, if you still decide to melt scrap, for example, old boxes, buckets, dishes, you should follow safety precautions and carry out casting in ventilated, non-residential areas, since plastic fumes are toxic and dangerous to humans.

Make your own mold

Make your own mold

#1 Post by Mikhail Ivanovich » April 29, 2013, 3:16 pm

Re: Making a mold with your own hands

#2 Post by Mikhail Ivanovich » April 29, 2013, 3:19 pm

While nothing has been changed, as past comrades promptly did, I am copying the entire article here.

“Most often, clients who want to organize the production of plastic products are concerned with one single question: how to make a mold? In fact, you can create this device with your own hands – we’ll talk about this below.

So, you decided to create a mold yourself. To do this, first of all, you need to have a complete understanding of what kind of product you will be making with its help. It is necessary to draw up a drawing of the product that could be used when designing the mold.

Further. As you know, for injection molding, the mold must be made of durable metal - for example, steel. Based on this, to create a mold of proper strength, you will need steel. Moreover, it is necessary to use 2 steel plates or bars - one will play the role of a punch (moving part), the other will become a matrix.

After selecting the material and the blanks themselves, you can proceed directly to creating the mold. Using product drawings and a lathe, you can cut the required holes and recesses in the steel plates. Be sure to take care to firmly connect the two plates and fix them in this position. The gating system must be especially carefully adjusted. For some relief details you will need a milling machine, or manual work using a file.

The fully processed mold is tested in operation by casting test parts. This will allow you to verify the quality of the gating system, as well as the compliance of the manufactured products with the desired result.

Such specific equipment as a mold finds its application in the mass production of various products. The use of molds is particularly relevant in the technology of production of plastic products. A high-quality mold allows you to effectively create various polymer structures.

It’s easy to guess that it’s acceptable to make a mold with your own hands only when you need plastic parts of a simple design. As for complex products, and even more so those with internal cavities and bends (when a mold consisting of three parts is required), it is very difficult for them to correctly produce both the drawing and the structure itself (without the appropriate capabilities and skills). In this case, you really can’t do without professional help.”

Read also: Designation of an electricity meter on the diagram

Nowadays, plastic products have become indispensable not only in everyday life, but also in production.

Tabletop mini injection molding machine

The production technology has aroused increased interest, since this is one of the most common methods of producing various products in demand on the farm.

Making your own mold

The production of plastic products without a molding container is impossible. You can make it yourself, and silicone is best suited for these purposes. It can be coated or filled, both options are suitable. The main thing is that the elongation coefficient is at least 200%. It is worth paying attention to the viscosity level. The smaller it is, the more detailed the mold will be.

To make a blank, you need to have a master model - a sample for future products. It can be created from plaster, wood, plasticine, printed on a 3D printer, or used from an existing part.

Stages of making a casting mold:

- Coat the master model with a thin layer of lubricant, for example lithol.

- Place in prepared formwork and fill with silicone.

- Or coat it with a brush if coating silicone is chosen.

- Wait about 8 hours until the material hardens.

- Remove the form from the formwork and make a hole for filling.

- Cut into 2 equal parts and remove the model.

In this way, a collapsible mold is obtained, which is suitable for casting symmetrical plastic products. But you can also make a one-piece mold for blanks that are simple in design. It is made from paraffin, which is filled with plaster. After hardening, the paraffin is melted out of the mold by slowly boiling it.

Other options

Plastic corks are used to make decorative curtains, stands for frying pans or pots. By gluing the lids bottom down to the plywood, you can make a massage mat.

How to make a mold

Mini-TPA does not require a full-fledged mold for casting plastic parts.

It is enough to make a form-building part that is part of any mold.

The form may consist of one, two, three, and so on parts. The main thing is that they must be tightly connected and kept assembled at the moment of plastic injection. Then, after injection, the mold should be easily disassembled into its components, and the part itself should be easily removed after casting.

Making a mold will be shown using the example of the task of casting a cord clip . This example is for a machine with an automatic clamping unit; modifications for a manual machine are also described below.

1. Draw the product.

2. Since the part is small, several such parts can be cast at a time. It was decided to cast 2 pieces at a time, since a small number of products are required.

A computer model of half the mold containing 2 parts is drawn. The injection is planned in the middle between the products. Since the requirements for the product are not high, it is customary to make the casting channels wide for easier casting.

There are threaded holes in the corners.

You can download a zip archive with files of this plate in stp and iges format from this link.

3. The front plate (the second half of the mold) is a smooth surface with a hole in the middle for the MiniTPA nozzle and also four threaded holes for fastening.

4. For ourselves, we have developed a set of frames for attaching various-sized forms with many through holes and with large holes in the corners for mounting on guides.

Subsequently, we abandoned the frames in their original form, leaving only vertical parts with bronze bushings.

Forms are attached to the holes; the hole dimensions for our case are indicated on the “Drawings” page. You have the right to choose them and arrange them as your detail requires.

5. We assemble the entire structure on the machine and make a test casting. All is ready.

6. In our case, we modified the mold, equipping it with pushers for automatic operation.

An example of work is shown in the video below:

Manual casting mold on the desktop

A mold for manual casting will have a minimum of differences: there is no need to make a hole in a flat plate - injection will occur along the line of closure of two plates (half-molds).

The form will need to be pinned to your desktop. The top lever will keep the mold from opening, the second will move the entire work table towards the injection nozzle.

We hope this information will be useful to you when designing and making your mold.