Copper pipe products are used in a variety of industries. Pipelines made from it transport gas, oil products, water and other media. To install highways, solder is used to weld copper pipes.

The conditions in which such pipelines are operated can be different - they influence the choice of the type of solder for connecting structural elements.

What is soldering and soldering?

Solder is an alloy or metal that is used to join individual metal parts to create a single system. The technology of joining two parts into a solid structure is usually called soldering.

Since solders are used in many industries, they are produced in a variety of forms - it can be wire, rods, foil, etc. The chemical composition of solder for soldering copper pipes directly depends on the melting temperature, the type of elements used, their parameters and other nuances.

The basis of solder are the following chemical elements:

Solder should have a melting temperature lower than that of the metals from which the joined parts are made, which are slightly heated during the soldering process and cannot be deformed. Soldering is considered a more advantageous connection method compared to welding.

There are several types of solders depending on their melting point:

- Low-melting - from 150 to 450 degrees.

- Medium melting - no higher than 1100 degrees.

- High-melting - up to 1850 degrees.

The first type of solder is used for soft soldering, and the second and third - for hard soldering.

What is needed to solder copper pipes? When joining products, in addition to solder, flux is required. It is necessary to protect the bonded surfaces from the oxidation process. To make a strong connection, you need to choose the right solder and flux. The purpose of using solders is to obtain a reliable weld. It is often impossible to do without it when joining pipes for different purposes, including copper products.

Copper-phosphorus and silver solders

Copper-phosphorus solders

Three-component copper-phosphorus solders with a silver content of up to 15% are intended for high-temperature soldering in the refrigeration industry.

Peculiarities.

Copper-phosphorus solders have a relatively low melting point and have good fluidity when soldering copper and some of its alloys. Due to the presence of phosphorus in the solder, no flux is required. Brazed seams are characterized by significant strength and satisfactory corrosion resistance.

Solders of this class are widely used in the installation of refrigeration equipment for connections experiencing minor vibration and shock loads, and with increasing silver content, ductility increases. When soldering fittings with non-heat-resistant elements (thermal expansion valves, valves, sight glasses), the latter must be cooled to prevent unacceptable overheating.

During the soldering process, dry nitrogen purging is recommended to protect against scale formation. Copper-phosphorus solders are not used for soldering steels due to the formation of a brittle film of phosphites along the weld boundary, which can lead to a violation of the tightness of the joint.

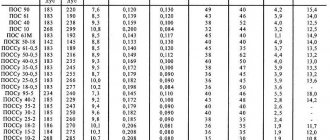

Table 2. Main characteristics of copper-phosphorus solders

Solder 102.

Three-component copper-phosphorus solder with a silver content of 2%.

Economical, has average spreading. It is recommended to use when installing refrigeration systems for soldering copper and its alloys in connections that do not experience high vibration and shock loads.

Solder 105.

Three-component copper-phosphorus solder with a silver content of 5%.

It is plastic, has slow spreading, and therefore is able to fill large gaps. The soldered seam can withstand light vibration and shock loads. Recommended for soldering copper and its alloys in refrigeration products.

Solder 115.

Three-component copper-phosphorus solder with a silver content of 15%. The most ductile due to the high silver content and low phosphorus content. Recommended for soldering connections of copper and its alloys. The soldered joint can withstand moderate vibration and shock loads during thermal cycles. Most common when soldering refrigeration units.

Silver solders

Four-component solders with a silver content of up to 55% are intended for high-temperature soldering in the refrigeration and food industries.

Peculiarities.

Silver solders have a low melting point and wet the surfaces being joined well. They perfectly fill joint gaps and produce strong vacuum-tight seams with high strength and ductility, capable of withstanding significant vibration and shock loads over a wide range of operating temperatures.

Solders of this class are widely used in the manufacture and installation of refrigeration equipment, especially when soldering joints that experience significant vibration loads (for example, soldering pipelines to a compressor).

The lower spreading temperature compared to copper-phosphorus solders makes them preferable for soldering fittings (expansion valves, sight glasses, valves). In addition, the likelihood of scale formation is reduced. Use with "Superflux" or similar flux.

Only cadmium-free solders are allowed to be used in food industry products.

Table 3. Main characteristics of silver solders

Solder 1530.

Four-component solder with 30% silver content.

Economical. Has medium spread. Fills large gaps well without overheating the connection. Solder is used in all products with the exception of food industry products due to the cadmium it contains.

Attention! Soldering should be done in a well-ventilated area, taking all safety precautions.

Solder 530 Sn.

Four-component solder with 30% silver content.

Has a higher melting point than 1530 solder and has average flow. Forms a soldered seam well in any spatial position.

Solder 538 Sn.

Four-component solder with 38% silver content.

It has rapid spreading, which makes it possible to obtain vacuum-tight seams with significant installation gaps.

Solder 540 Sn.

Four-component solder with 40% silver content.

It has a large melting range and has good spreading properties. Recommended for soldering copper and steel in any combination for connections subject to significant vibration and shock loads.

Solder 545 Sn.

Four-component solder with 45% silver content.

It has very fast spreading and has a low melting point, therefore it is recommended for soldering automation elements that are afraid of overheating (thermal expansion valves, solenoids, valves).

Solder 555 Sn.

Four-component solder with 55% silver content.

It is characterized by the highest turnover. Brazed seams have maximum strength, corrosion resistance, as well as high ductility and are able to withstand significant vibration loads over a wide temperature range. Recommended for soldering fittings containing non-heat-resistant elements.

For soldering, heaters (burners) operating on a mixture of gases are used: propane-butane-air, propane-butane-oxygen, acetylene-air, acetylene-oxygen (Fig. 2).

Read also: Turning a cone on a lathe

Rice. 2. Heaters for soldering pipes: a - propane-air; b - propane-oxygen; in — electric

Resistive electric heaters are also used.

Correct selection of the heater and correct installation of the flame avoid overheating of the material. The burner flame should be smooth, with a clear blue glow at the core. In the first heating phase, the distance between the burner tip and the heated surface should be equal to the length of the flame cone. The burner is kept in this position until the pipe temperature reaches about 650 °C (red color). Then the distance from the torch tip to the soldering point is approximately doubled.

To reduce heat loss, especially when using a propane burner, reflectors are used (Fig. 3, b).

Rice. 3. Warming up the pipe before soldering: a - propane-oxygen burner; b - propane burner

When soldering, it is necessary to create a neutral gas environment inside the pipe, which will prevent the formation of scale inside the pipe. When the refrigeration machine is operating, copper oxide, flux, and solder residues can clog the capillary tubes and four-way valve. Most often, dry nitrogen is used as an inert gas.

Rice. 4. Soldering copper pipes in an inert gas environment: 1 - reducer with gas flow regulator; 2 — seal with a rubber hose; 3 - soldering point

Using a rubber hose, connect the freon line and the nitrogen cylinder. A rotameter or gas flow regulator is installed between the pipeline and the nitrogen cylinder (Table 4).

Table 4 Technical characteristics of gas flow regulators

The nitrogen cylinder reducer is set to the minimum possible nitrogen pressure (no more than 0.2 bar). Using a rotameter, set the gas speed in the pipe to 5 m/min (flow rate 0.05 m3/h). After soldering is completed, it is necessary to pass nitrogen through the pipe until it cools (to a temperature of 35–45 ° C).

If flux is used in soldering, the solder is heated and the flux is applied to the heated end of the solder rod by immersing it in the flux. Soldering with copper-phosphorus solder is performed without flux.

When soldering closely spaced joints, it is necessary to follow a certain soldering sequence so as not to melt the previous seam. In Fig. Figure 5 shows the sequence of soldering a tee depending on its position in space. When soldering elements of different thicknesses, heating begins with the thicker part. The pipeline joint is heated, a solder rod is introduced into the soldering zone and soldering is performed. After cooling the brazed pipeline to ambient temperature, turn off the nitrogen supply to the pipeline and wipe the seam area with a damp rag. If necessary, clean with a wire brush. The surface of the soldered seam should be smooth, without solder sagging or shrinkage cavities.

Rice. 5. Tee soldering sequence

Soldering with an electric resistive heater (Fig. 2, c) is carried out by passing an electric current through the junction. The junction point is clamped by carbon electrodes and when an electric current passes through the coal-copper-coal structure, a large voltage drops, due to which the copper heats up.

The advantage of this method is the possibility of smoothly increasing the current, and, consequently, the temperature. However, you need to increase the current very slowly, otherwise you can burn the pipe.

Features of physical and chemical processes

When soldering, the solder first heats up and softens, and then becomes liquid. This temperature range is called the melting zone. When soldering, the parts to be joined are heated, but not brought to a liquid consistency. The stage of fusion of liquid solder occurs when the degree of its heating exceeds the melting temperature, called the working temperature.

The solder, being in a molten state, wets the metal being joined and spreads, thereby eliminating the gaps between the joined sections of pipes.

The period during which the joint is heated, and then the solder crystallizes, acquiring a solid state, is usually 4-5 minutes. In this case, the soldering iron must generate so much heat that within two minutes of heating the liquid solder has time to react with the mating surfaces. Only if these conditions are met, the flux and parts will not have time to overheat.

When soldering is performed, the solder and the areas being joined interact. It should be noted that the nature of the processes occurring during soldering has not been thoroughly studied. Diffuse, solution-diffuse and various chemical processes occur on the joining surfaces associated with the interaction that occurs between liquid solder and copper products. After filling all the cracks, a super-strong connection of the elements is formed.

Safety precautions

- First of all, you need to remember that copper conducts heat strongly, and you should not solder a part shorter than 30 cm by simply holding it in your hands, this can lead to burns !

- When soldering, copper becomes very hot and acquires very unpleasant properties, causing very severe burns in a split second when touched! For example, many can pick up a coal from a fire and throw it from hand to hand without harming themselves, but with copper such a trick will not work, a burn is guaranteed!

- During soldering, flux may drip onto exposed parts of the body; rinse off immediately with water, otherwise there may be a chemical burn!

- While working, you should not be wearing synthetic clothing; do not forget that you are working with fire, hot metal, and flux containing acid! Synthetics tend to ignite and melt easily!

- Do not put flux in your eyes, nostrils, mouth, ears or genitals!

- When soldering, open the window, do not breathe in large amounts of smoke from the burnt Flux!

Soldering copper pipes

Due to the fact that copper is slightly susceptible to corrosion processes, it can be easily soldered. Tin, silver, and other alloys and metals come into best contact with it during the joining process.

To connect copper products, capillary soldering is used. It is based on the ability of a liquid to move through narrow channels due to adhesion, including against the direction of gravity. Due to the phenomenon of capillarity, solder is able to fill gaps evenly, regardless of how the pipes are positioned.

The soldering process can take place using light, medium and high melting point solders. Due to the first type, low-temperature soldering is performed, and the other two - high-temperature soldering. The choice of solder is based on the conditions in which the finished pipeline will be operated.

The low-melting type, also called soft solder for soldering copper pipes, includes tin and alloys with it: tin-copper, tin-silver, tin-copper-silver. The same type includes solders, the main component of which is lead, but they are toxic and for this reason they cannot be used when laying pipelines for drinking water supply.

Silver based

Silver-based high-temperature soldering agents have very good properties. They are suitable for almost all metal products. The only drawback is that the price of the noble metal limits the possibilities of frequent use.

There are alloys (PSr-15) with a low concentration of silver. They cost less than concentrated compositions and can be used more often.

Compositions (PSr-45) containing silver - 45%, copper - 30%, zinc - 25% have very good properties: viscosity, fluidity, malleability, resistance to oxidation and mechanical stress. These alloys are used as needed, subject to financial availability.

By varying the ratio of these components, you can change the maximum temperature values that the future seam will withstand. Even better qualities are demonstrated by the high-temperature composition with a silver content of 65%, but it is very expensive.

How to choose solder

Despite the fact that soft solders are considered not strong enough, using capillary welding you can obtain a high-quality plumbing structure. Low-melting solders are used for joining copper pipe products with a diameter of 6–180 millimeters. They are preferred because they operate at low temperatures. The fact is that copper can lose strength at high temperatures.

All solders belonging to the medium and high melting point are of the hard type. For high-temperature soldering of copper products, solders based on copper, silver and other metals are used. Thanks to their use, a seam is obtained that is durable and resistant to high pressure and high temperatures.

The most popular among them are:

- copper-phosphorus;

- copper-silver-phosphorus;

- silver

In the latter case, not only solder is required, but also flux paste for soldering copper pipes.

What properties does copper-phosphorus solder have, where is it used.

The basis of copper-phosphorus solder is copper, to which phosphorus is added as an additive. This solder perfectly connects copper parts without requiring a very high heating temperature of the product, since it melts at a temperature of 700–850 degrees. The exact melting point depends on the specific solder formula. For example, a compound containing copper and phosphorus in a ratio of 91%: 9% melts at a temperature of 800 degrees. And if the solder composition, in addition to copper and phosphorus, also includes tin and a small zinc content (ratio 89.5 (copper) : 6 (phosphorus) : 4 (tin) : 0.5 (zinc)%), then melting begins at a temperature of 690 degrees C.

The most common brands of copper-phosphorus solder are PMF-7, PMF-9 and PMFOTsr-6-4-0.03. In the labeling of a compound, the number following the abbreviation indicating the composition indicates the percentage of phosphorus. PMFOTsr brand solder also includes tin and zirconium, which is indicated in its name with the letters O and Tsr, as well as numbers that indicate the amount of these additives (4 and 0.03%).

The main characteristics of solder joints of this type, in addition to not too high a melting point, are:

- significant fluidity;

- good corrosion resistance;

- immunity to aggressive environments.

As a result of using such solder, fairly strong seams are obtained. True, they have one drawback: their elasticity decreases significantly at low air temperatures.

Copper-phosphorus solders are used to join parts made of pure copper or its alloys: bronze, cupronickel or brass. They can also be used in situations where it is necessary to solder parts of a product to each other, one of which consists of copper, and the second of steel (regular or stainless).

Note! Steel or cast iron workpieces should not be soldered using these compounds, since phosphorus forms phosphites upon contact with iron. Because of this, the solder seam becomes brittle and unable to withstand mechanical stress. Such a connection will simply collapse upon impact or bending of the product, and it will also not withstand vibration influences. The only way to avoid this is to coat the steel or cast iron product with a layer of copper before soldering.

Read also: Vbus what is it on pinout

Another area of application for copper-phosphorus soldering compounds is jewelry repair. Typically, silver solders are used for these purposes. But a PMF brand connection can cope with such a task no worse, and such repairs will cost less.

Pros and cons of different types of solders

An important advantage that hard solders have is directly related to the strength of the resulting seams and their resistance to high temperatures. Using high-temperature soldering, copper pipes with a diameter of 6 to 159 millimeters are joined. When laying water supply lines, the cross-section of pipe products connected by this type of soldering cannot be less than 28 millimeters.

As practice shows, among the soft solders for joining copper pipes, the most popular is tin-copper, and among hard solders, copper-phosphorus ones are often used. Different companies have different manufacturing technology and percentage composition of components.

Before you start creating a copper pipeline, you should make sure that there are no defects on the surface, which can often be found when cutting pipes. The reliability of seams largely depends on the cleanliness of the products used in the work process. For products with a diameter of 6-108 millimeters, the width of the joint can be 7-50 millimeters.

Read also: DIY smokehouse grates

The use of copper pipes allows you to create an efficient and durable heating or water supply system. The simplest and most common way to connect such products is soldering technology. It involves the presence of solder - a thermoplastic substance that seals the joint by melting and flowing under the influence of high temperature. After cooling, it hardens and fixes the connection.

Soldering of copper pipes is carried out with different types of solder

How to use solder

To ensure that the seam after soldering is strong and airtight, you must:

- Prepare the pipes thoroughly before soldering. To do this, the ends of the pipes are cleaned of oxides and other types of contaminants with a metal brush, and burrs formed after cutting the pipes are removed using a special device - a chamfer;

Preparing a copper pipe for soldering

- widen the end of one pipe by a few millimeters so that the pipes can be easily joined together. If soldering is done using fittings (special elements designed for assembling pipelines of various configurations), then the diameter of the fitting increases, not the pipe;

Increasing pipe diameter

- treat pipe soldering areas with flux;

Treating the pipe with flux before soldering

- prepare a gas burner (equipment designed for soldering pipes made of copper) and slightly heat the areas to be soldered;

- carefully apply solder along the entire perimeter of the pipe, which, during the heating process, will gradually transform from solid to liquid, thereby filling all the empty space;

Read also: In what position should the circulation pump be installed?

Soldering with solder

- Allow the solder to cool completely while still. Depending on the type of solder, it takes an average of 3-5 minutes to cool completely.

The process of soldering copper pipes using solder is presented in the video.

When choosing solder and flux, it is necessary to take into account all the basic characteristics of the substances, that is, if high-temperature solder is used for soldering, then the flux should also be designed for high-temperature soldering. Properly selected and matching materials contribute to obtaining not only a tight seam, but also the most durable connection.

Copper is a material that is best soldered, especially for thin pipes used for heating or gas, as well as in other activities. That is why it is worth making the right choice in favor of suitable solder. Copper is perfectly soldered, especially when using the material in its pure form. The metal retains its structure and properties.

Preparing copper pipes

These products are strong, durable, can withstand high pressure and temperature, and are not afraid of ultraviolet radiation.

To solder copper pipes you will need a pipe cutter, an expander, a hammer, a tape measure and a chamfer. The choice of pipe cutter is determined by the diameter of the products used. It allows you to get an even cut that is perpendicular to the axis of the pipe. Chamfer removers are used to remove burrs and chamfers from the edges of products. Removing burrs from the outer and inner edges of the pipes makes it easier to fit them into each other. Chamfer removers come in a round body (with a pipe diameter limit of 3.6 cm) or in the form of a pencil.

If the connection of copper pipes does not involve the use of fittings, then a pipe expander is used.

Important! The copper product to be expanded must be either soft or annealed.

There should be no flammable or combustible substances in the copper pipe soldering room. It is also necessary to ensure good ventilation and ventilation.

For a quality connection, an even cut is important, so the pipe must be cut with a special device - a pipe cutter

Soldering copper pipes

Solders designed for soldering copper pipes work well with pure copper, as well as with other additional alloys. Using flux, you can quickly and easily remove oxidation, so the process is greatly simplified. Other metals form oxides that fluxes are practically unable to dissolve, so it is worth taking care to solve this problem. When soldering copper pipes, it is necessary to use the overlapping option so that the structure is as strong as possible and has a long service life. To make the connection high-quality and durable, it is necessary to make an overlap of at least 5 mm. The seams here are made of any thickness, and the quality of the joints does not depend on this. During soldering, small gaps are left so that the solder is drawn evenly into the hole and becomes airtight.

Types of solders for copper pipes

- 1S is a soft type solder. It contains silver. It is perfect not only for copper pipes, but also for bronze and brass workpieces, which are often used for water supply. This solder does not contain flux, so it must be purchased additionally.

- Rosol 3 solder is a soft type of material; when using it, you must purchase flux. It melts at a temperature of 240 degrees Celsius. That is why it is excellent for soldering thin products. After soldering, it holds up remarkably well at low and high temperatures.

- Rolot 94 solder is hard solder. This material of the highest quality is used to work with copper products, red bronze and brass. It is usually used for soldering pipes using the capillary method. Its melting temperature reaches 730 degrees Celsius, so it is not recommended to use it for working with products with thin walls.

- Rolot 2 solder is a non-standardized hard-type solder. It contains some silver content, so the material is excellent for soldering standard type products.

Read also: Is it possible to fill the compressor with engine oil?

It is necessary to separately note the solders for soldering food-grade copper. They must be completely harmless to human health. Such solders also have several types:

- Tin-copper solder includes zinc and silver. This solder is used for soldering copper pipes at high temperatures, which is capable of providing a ductile and high-quality connection that is resistant to corrosion and has a long service life;

- Silver-copper solder is a low-temperature material, melts very quickly and forms a strong connection that is resistant to corrosion;

- Copper-phosphorus solder is a high-temperature material; when using it, there is no need to purchase additional flux. The seam is elastic and of high quality;

- Copper-silver solder is a high temperature solder. The seams are very durable and flexible. When using it, it is necessary to purchase additional flux. Its cost is quite high, so it is not suitable for everyone.

Materials required for work

You can solder copper pipes yourself. To work you will need:

- solder;

- steel brush;

- flux;

- brush;

- soldering iron or gas torch.

Solder has the form of a wire with a melting point lower than that of copper. This allows products to be joined by heating. Using a steel brush during preparatory work, the inner surface of the fitting and the outer part of the pipe are cleaned.

Solder can be high-temperature, which is a thin wire made of copper with the addition of up to 6% phosphorus and has a melting point of 600-800 °C, and low-temperature - made of tin, melting at 300-400 °C.

Liquid flux is applied to the coupling and pipe before assembling the connecting unit, solid flux is melted in the soldering zone. Flux in the form of a paste is a thickened mixture that can be applied both before and after the joining process. Flux cleans the surface of the pipe from oxides, protects the soldering site from oxygen, promotes the spreading of solder and improves the adhesion of the parts being connected.

A gas torch is required to heat the metal and solder.

There are gas burners with a stationary cylinder or a disposable one. There is a separate type of burners - acetylene-oxygen, which differ in their design. The power of the soldering machine is selected based on the melting temperature of the solder. Professional tools are used to solder copper pipes with hard solder, and semi-professional tools are used to solder copper pipes with hard and soft solder.

What tools will you need?

To properly connect the highway, you must immediately prepare the following tools:

- Pipe cutter Without it, it will not be possible to cut the highway elements evenly. Using a pipe cutter you can make a perfect cut.

- Bevel remover. This tool is necessary for rounding and cleaning the edge of the cut pipe in order to ensure high-quality joining of parts.

- Pipe expander. If you plan to use couplings and fittings during the work, then thanks to this tool you can quickly expand a part of the pipe to the desired size.

- Brushes and brushes. After soldering, the pipes must be cleaned of oxide formations.

- Reflector. It is attached to the burner nozzle in order to direct the flame to a specific area. If you do not install the reflector, there is a risk of damaging surrounding objects.

- Gas-burner. With its help, copper-phosphorus solder is heated.

It’s worth talking about the last working tool in a little more detail.

Features of solders and fluxes

There are a large number of hard and soft solders that can provide high-quality soldering of copper pipes. Low-temperature solders produce a seam with slightly worse mechanical parameters, but allow work to be performed at a temperature that does not have a strong effect on the strength of the pipe metal. About 95-97% of such solders are tin, the rest are other elements.

The best technological properties are found in compounds containing silver. There are three-component solders, which include tin, silver, and copper. Fluxes used for low-temperature soldering often contain zinc chloride.

Sufficient joint strength when soldering with soft solder is achieved by a large contact area of the elements. For gas pipelines, only high-temperature soldering is used, ensuring the best strength and reliability.

Low temperature solder is made of tin and has the appearance of a wire.

The permissible pressure in pipelines when using different types of soldering is given in the table.

Table 1

Soldering type

| Temperature of the medium being transported, °C | Pressure, atm | |

| Low temperature | 30 | 16 |

| 65 | 10 | |

| 110 | 6 | |

| High temperature | 30 | 40 |

| 65 | 25 | |

| 110 | 16 |

For high-temperature soldering, copper-phosphorus solders are usually used. They are produced in the form of rods.

Note! Copper-phosphorus solder cannot be used when soldering cast iron, steel, and non-ferrous metals that contain more than 10% nickel.

It is recommended to use flux and solder from the same manufacturer for both low- and high-temperature soldering.

Soldering copper

Unlike steel, in most cases it is more expedient to solder copper than to weld it. Especially when it comes to thin-walled copper pipes used for various systems - plumbing, heating, refrigeration, gas. This feasibility is due to a number of features. Firstly, copper and its alloys are much easier to solder than to weld. Even a beginner can cope with soldering copper with some effort, while welding it without thorough preparation is unlikely to be possible. Soldering does not change the structure of the metal and does not require expensive equipment, as welding requires. And finally, solder joints, if the technology is followed and suitable materials are used, are strong enough and heat-resistant to withstand the mechanical and thermal load intended for them. Most often, at home, there is a need to solder copper pipes when installing water pipes or heating systems. Copper is a good material for water pipes. It does not corrode, has a smooth surface that ensures good water flow, does not become overgrown with deposits, and not only does not contain harmful substances, but even has bactericidal properties. Copper plumbing can last a very long time, 50 years or more.

Soldering copper pipes

A little theory

The prevailing opinion about the good solderability of copper and its alloys is true only when it comes to copper itself and its alloys with zinc, tin, lead, phosphorus, antimony, iron, nickel, and manganese.

These metals actually have oxides that are relatively easy to remove with fluxes. But copper alloys alloyed with chromium, aluminum, silicon, titanium and some other elements have oxides on their surface that are difficult to dissolve with fluxes. Fortunately, more often you have to deal not with them, but with commercially pure copper or those alloys that form easily removable oxides. So the statement that soldering copper does not cause much trouble can be considered true in most cases. When soldering in general and copper tubes in particular, lap joints are usually used. They make it possible to ensure sufficient structural strength even if soft solders with relatively low strength are used. It is believed that to ensure satisfactory solder joint strength, the overlap should be at least 5 mm. In practice, much higher values are usually used, which provides a good margin of safety.

Mutual overlap of elements in the pipeline is ensured through the use of fittings or pipe expansion and flanging operations. Parts of pipes and fittings are inserted into each other. In this case, between the elements being connected, just such a gap is provided (0.1-0.2 mm) that is necessary for the action of capillary forces, which are a prerequisite for most types of soldering. Under their action, the molten solder is spontaneously drawn into the gap, distributed evenly over the entire contact surface and tightly seals the connection. Capillary forces allow solder to be fed from below.

Soldering copper pipes

Copper pipes

The chemical composition of the metal used for the production of copper pipes is regulated in Russia by GOST 859-2001.

According to it, in all grades of copper the Cu (+Ag) content is more than 99%. Small impurities of iron, tin, lead, antimony and other elements are acceptable. Copper pipes come in annealed (soft) and unannealed (hard) varieties. The first are obtained as a result of annealing - heating to 600-700°C with gradual cooling. This operation returns copper to its natural ductility, lost during machining (stamping or rolling) during manufacturing.

Annealed pipe has some technological advantages over unannealed pipe. While inferior to it in strength, it is much superior to it in ductility. The value of its elongation at break can reach 40-60%. This means that the annealed pipe can be bent if necessary without fear of rupture. Observing, of course, certain relationships between the diameter of the pipe and the bending radius (R = 3d-8d, depending on the bending method). Annealed copper pipes can prevent a water pipe from bursting when it accidentally freezes - thanks to the plastic deformation of the metal, which prevents the pipe from rupturing. Anyone who has at least once encountered the replacement of steel “frozen” pipes is able to fully appreciate this advantage.

Annealed pipes are supplied in coils of 50 and 25 m, unannealed pipes are supplied in the form of measured pieces (rods) 3 and 5 m long.

Unannealed and annealed copper pipes

Pipe connection methods

The most convenient way to connect copper pipes is with fittings, of which there are many available.

With all the abundance of types of these parts, there are only three main forms used most often: tees (provide branches from the pipe), corners (change the direction of the pipeline by 90°) and couplings (connect two pipes). Copper solder fittings

If you wish, you can do without fittings at all, or, in any case, with a minimal amount of them. True, for this you need to have a special, expensive tool that allows you to perform certain operations with pipes, namely bending, expanding and flanging. Using bending, you can do without corner fittings. Expansion (increasing the diameter of the pipe end) allows you to do without couplings when soldering pipes. By using flanging, you can avoid purchasing tees (or corners, if you cut the pipe and install a plug at its end). You just need to keep in mind that when using flanging, the outlet pipe must be smaller in diameter than the main one.

To perform all these operations with pipes, you must have manual or electric tools: a pipe bender, a beading machine and an expander.

When using pipe benders

The bending radius must be no less than 3.5d (d is the diameter of the pipe) for a diameter of up to 15 mm, and 4d for a diameter of 18 mm.

When using a bending spring

- no less than 6d.

Manual pipe bender

Springs for bending copper pipes

Branded pipe benders are not cheap, so information about homemade pipe benders may be useful.

An excessively small radius may cause the pipe to rupture or collapse. Annealed pipes can be bent to a smaller radius, but a tight bend (less than 3d) is unfavorable from a flow point of view. Annealed pipes can also be carefully bent by hand. In this case, to avoid flattening, the bending radius must be no less than 8d.

Poorly executed bends, in which the pipe has flattened and the cross-section has lost its round shape or the inner surface of the bend has gathered like an accordion, cause turbulent flows in the pipe bend, which leads to erosion-corrosion damage.

Unannealed (solid) pipe, up to a diameter of 18 mm, can be cold bent with a pipe bender. Larger diameter pipes should be softened at a temperature of 500-600°C before bending.

Expander operation

is based on the radial expansion of segments of a cam mechanism inserted inside the pipe. The expandable copper pipe must be annealed (soft). Thanks to the lever system, pressing on the tool handles creates the necessary force required for plastic deformation of the metal. Everything is very simple - insert the cam tip into the pipe, squeeze the handles and get a socket into which you can insert a pipe of the same diameter. You can make a coupling from a piece of pipe by expanding both ends of the workpiece. If necessary, the end of the unannealed (solid) pipe can be annealed yourself.

Pipe expander

Flanging operation

The expansion operation is somewhat more complicated. It consists of two stages: drilling a hole with a special calibration drill and the flanging itself. After the hole is drilled, it is necessary to insert into it a mandrel with sliding antennae lubricated with grease, and attach the outer part of the device to it, which serves as a stop when drawing. After that, a power tool is connected to the outer part. Rotation of the spindle pulls the mandrel out of the hole. In this case, by spreading the antennae, flanging is carried out - bending the edge of the drilled hole outward.

Pipe flanging

Pipe flanging

Pipe flanging

Now you can insert a bend into the pipe, which is a piece of pipe with a smaller diameter. To prevent it from protruding too much from the inside and preventing the movement of water, two protrusions are formed on its walls using a special tool. The latter rest against the socket, ensuring that the outlet is immersed in the hole to a strictly defined depth.

Pipe flanging

The described beading method involves the use of power tools, but there are also manual models.

Manual beader

Solders and fluxes

Copper and its alloys can be soldered using both low-temperature and high-temperature soldering.

There are a sufficient number of soft and hard solders that provide good quality pipe soldering. The use of low-temperature solders allows soldering to be performed at a temperature that has little effect on the strength of copper, but they produce a seam with worse mechanical characteristics. Solders for high-temperature soldering provide greater strength to the seam and allow high operating temperatures of the system, but in this case the copper is annealed and more skill is required, since it is easy to burn out the metal.

Low-temperature soldering is most in demand in water supply and heating. There are many low temperature lead-free solders that provide fairly good quality copper soldering. These are alloys of tin with antimony, copper, silver, bismuth, and selenium. The main part (up to 95-97%) of them is tin, the rest is other elements. Silver-containing solders, for example, S-Sn97Ag3, containing 97% tin and 3% silver, have the best technological properties. Copper-containing solders, in particular S-Sn97Cu3 (97% tin and 3% copper), have somewhat worse, but quite good qualities. There are three-part solders containing tin, silver and copper (for example, a composition with 95.5% tin, 3.8% silver and 0.7% copper). The most versatile and widely used is tin-copper solder. The disadvantage of tin-silver alloys is their higher cost compared to tin-copper alloys.

Solder S-Sn97Ag3 containing 97% tin and 3% silver

Solder S-Sn97Cu3 containing 97% tin and 3% copper

These solder compositions provide good seam quality and meet all the requirements for strength, durability and reliability of water supply and heating systems. Solders of other compositions are practically not used.

In fact, lead-tin solders are also suitable for low-temperature soldering of copper, but if a pipeline for drinking water is being soldered, they must be abandoned due to the harmfulness of lead.

Compositions containing zinc chloride are mainly used as fluxes for low-temperature soldering. However, it is hardly worth paying special attention to its composition when purchasing flux. There are many effective fluxes for soldering copper; you just need to purchase any composition designed for this. For example, F-SW 21 or rosin-vaseline paste, consisting of rosin, zinc chloride and technical petroleum jelly. The paste form is the most convenient for applying to parts.

Flux F-SW 21

Taking into account the large contact area of pipeline elements, low-temperature solders provide sufficient strength of the connections. It makes sense to resort to high-temperature solders only in cases where there is a special need for it. For example, if the brazed pipeline is expected to operate at high temperatures (above 110°C) - in heating systems using high-pressure steam or other cases. For soldering gas pipelines made of copper pipes, only high-temperature soldering is used, as a connection with the greatest strength and reliability; low-temperature soldering is not used in gas supply.

The following table contains the values of permissible pressures in pipelines made of copper pipes with a diameter of 6-28 mm, soldered with low-temperature (soft) and high-temperature (hard) solders.

| Solder type | Temperature of the transported medium, °C | Allowable pressure, atm.* |

| Soft | 30 65 110 | 16 10 6 |

| Solid | 30 65 110 | 40 25 16 |

* - for copper pipes with a diameter of 6-28 mm.

For high-temperature soldering of copper, copper-phosphorus solder of the composition Cu-94%, P-6% (L-CuP6 and similar ones - PMF 7, PMF 9, etc.) is most widely used. The introduction of a 6% phosphorus additive very sharply reduces the melting point of copper (to 710-750°C), which makes it possible to use this composition as solder.

Copper-phosphorus solder L-CuP6 containing 94% copper and 6% phosphorus

Copper-phosphorus solders in the case of copper-to-copper soldering do not require the mandatory use of fluxes. Another advantage of this solder is that the thermal expansion coefficients of the solder and copper of the soldered parts are almost identical. Self-fluxing solder with the composition: 92% Cu, 6% P, 2% Ag (copper-phosphorus with silver - L-Ag2P) has also become widespread. All hard solders are produced in the form of solid rods.

Due to the brittleness of the connection resulting from the chemical reaction of phosphorus with some metals, copper-phosphorus solders cannot be used for soldering non-ferrous metals with a nickel content higher than 10%. These solders are also not recommended for soldering aluminum bronze. They cannot be used when soldering steel and cast iron.

When joining elements from different copper alloys with copper-phosphorus solders: copper with bronze or copper with brass or bronze with brass, it is always necessary to use flux for high-temperature soldering.

Flux for brazing

For low-temperature and high-temperature soldering, it is preferable to use matched solder and flux for a particular type of soldering from the same manufacturer.

Soldering copper pipes

The process of soldering copper pipes consists of sequentially performing the following operations: cutting the pipe, chamfering, cleaning the joined parts from oxides, coating them with flux, assembling the joint, heating it and applying solder.

cutting

. The most convenient way to cut pipes is with a pipe cutter. Many types of this tool are produced, but they all have a similar design and consist of a body, support rollers, a cutting knife in the form of a disk, and a screw that presses the knife to the pipe. The main difference between the models is the shape of the body, which determines the required rotational force when cutting. The longer the lever that the pipe cutter turns, the easier it is to cut. To cut pipes located close to enclosing structures, compact pipe cutters with a minimum size are used. They require more force than regular sized pipe cutters.

Cutting a copper pipe with a pipe cutter

The cutting sequence is as follows. The pipe cutter is installed on the pipe so that the edge of the cutting roller coincides with the cutting line. The screw is clamped, pressing the roller to the pipe, and cutting is carried out by turning the tool around the axis of the pipe. After every 1-2 revolutions, you need to rotate the screw to press the roller towards the pipe.

The pipe can be cut with a regular metal saw or jigsaw. You just need to try to make the cut perpendicular to the axis. To do this, it is better to buy or make a template - a miter box.

The use of pipe cutters gives a straight edge to the pipe, but can lead to a slight reduction in the diameter of the pipe; in this case, scoring occurs only inside the pipe. Using a hacksaw avoids pipe deformation, but produces a lot of burrs.

Chamfering

. After cutting, it is necessary to remove the internal and external chamfers. The pipe cutter slightly bends the edge of the pipe inward; if this bend is not removed, it will create turbulence and resistance to the flow of water or gas. The outer chamfer can be removed to facilitate assembly. There are special sickle-shaped knives for chamfering. Sometimes they are built into pipe cutters, sometimes they are a separate tool. Chamfering tools are also produced in the form of bushings (the internal chamfer is removed with one side, and the external chamfer with the other). As a last resort, you can use a mounting knife or any other knife.

Deburring

Chamfer remover

Stripping

. After chamfering, you need to clean the mating parts of the parts from oxides. External surfaces are cleaned with fine abrasive sandpaper (P600 grit), stainless steel wire mesh, or a special tool with a hole framed with a wire brush. For internal surfaces, brushes, sandpaper or mesh are used, screwed onto some kind of pin or, in extreme cases, your own finger. The surface is cleaned to a shine. If abrasive sandpaper was used, after cleaning it is necessary to remove any remaining abrasive from the parts. The presence of foreign substances on the surface reduces the quality of any soldering, including copper soldering.

Mechanical cleaning of copper pipe from oxides

Mechanical cleaning of copper pipe from oxides

Flux treatment

. Coating with flux must be done immediately after stripping, since after just a few minutes the cleaned surface will be again covered with oxides that prevent wetting with solder. Paste-like flux is applied with a brush to the outer surface of parts inserted inside others. Apply an amount sufficient to completely cover the mating surfaces, but without excess.

Flux application

When the flux is applied, it is recommended to immediately connect the parts - this will prevent foreign particles from getting onto the surface treated with flux.

Assembly

. When assembling, you need to slightly rotate the parts relative to each other so that the flux is well distributed over the surface and make sure that the pipe reaches the stop. Then you should remove excess flux with a dry cotton cloth and secure the parts in the desired position or place them on fire-resistant materials on which heating can be carried out without the risk of fire.

Assembling parts and removing excess flux

When installing a copper pipeline using a gas torch, a fireproof screen should be used.

Fireproof screen

Heating and soldering

. Before heating pipes containing rubber or plastic components, the latter must be removed to prevent damage during heating. For soldered taps, the valve should be unscrewed to prevent damage to the gaskets. If you are soldering copper pipes in an already installed pipeline, you need to open the valves of the shut-off devices so that increased pressure does not create in the pipe when heated.

The temperature for soldering pipes with soft solders is 250-300°C, with hard solders - 700-900°C. Most often, gas burners are used for heating. For low-temperature soldering of pipes, construction hair dryers are convenient, having an outlet air temperature at full power of up to 650°C. They can be equipped with special nozzle attachments that provide heating of the pipe from different sides.

Soldering copper pipes with a hair dryer

If a gas burner is used, the flame should be normal - without excess or lack of oxygen. In a balanced gas mixture, the flame only heats the metal and has no other effect. In the case of a balanced gas mixture, the burner flame is bright blue and small in size. A flame supersaturated with oxygen oxidizes the metal surface. A sign of this phenomenon is a black oxide coating on the metal. The torch of the burner flame, saturated with oxygen, is pale blue and small.

You need to warm up the entire connection, moving the flame back and forth from different sides of the pipe, while from time to time touching the joint gap with solder. The desired temperature is reached when the solder begins to melt when touching the pipe. There is no need to create excess heat. Usually, with practice, the sufficiency of heating is determined by the color of the metal surface and the appearance of flux smoke. Some fluxes, when heated enough for soldering, emit smoke or change color. The manufacturer usually indicates such features of its flux.

Soldering a copper pipe

We should not forget about the need to move the flame so as not to overheat any particular section of the connection.

When soldering branched connections, such as a tee, you should follow the order of filling the gaps with solder - from bottom to top. In this case, the rising heat does not interfere with the cooling and crystallization of the solder.

The required amount of solder wire with a diameter of 2.5-3 mm per joint is approximately a section whose length is equal to the diameter of the pipe being soldered. To control the consumption of solder, you need to measure the required length on the wire for one joint and bend it with the letter “L”.

Marking the required amount of solder

After heating the joint to soldering temperature, the torch flame must be moved away from the joint (but not from the joint) and melt the required amount of solder into the joint. In this case, one should not forget about the movement of the flame along the connection.

Soldering a copper pipe

Soldering a copper pipe

The solder should melt not from the flame of the burner, but from the heat of the heated connection.

There is no need to try to distribute the solder along the entire perimeter of the joint. Under the action of capillary forces, the solder itself is drawn into the gap and distributed over the mating surfaces. You just need to try to introduce exactly the amount that is required, without shortage or excess. This process proceeds well if the metal surface is clean, the optimal gap between the metal surfaces is maintained, and the connection is sufficiently heated (molten solder flows towards the heat source).

If you heat the entire joint evenly, the solder melts under the influence of its heat and flows evenly into the gap.

To improve soldering, preheat the solder rod with a torch flame.

An important point in soldering is the quick execution of this operation. The heating cycle should be short and overheating should be avoided.

With regard to dosing solder and the whole soldering process in general, fittings with ready-made solder are very convenient. However, they have not become widespread in our market. They have a molded bead in which the required amount of solder is placed. The technology for soldering pipes with such fittings is simpler compared to conventional ones. There is no need to supply solder to the joint and control its consumption. You just need to assemble the structure and heat the connection with a torch. The solder in the bead melts and fills all the gaps. Its quantity exactly corresponds to that required for a given connection.

Solder fitting

The connection must be cooled naturally, allowing the pipe to cool on its own, without water or any other method of rapid cooling. During the natural cooling of the connection, during crystallization of the solder, the elements of the connection must be absolutely motionless.

After a short time has passed after soldering, any remaining flux should be removed with a damp cloth.

Removing flux residues

In plumbing, after installing the pipeline, a mandatory technological flushing of the system is carried out to remove flux residues and other contaminants that have gotten inside the pipes. In addition, sometimes complete cleaning and polishing of the entire pipeline system is used for aesthetic purposes or as an element of room design.

In conclusion, a piece of advice that is not directly related to soldering. Like all materials, copper pipes expand when heated. When heated to 60°C, 1m of pipeline lengthens by 1mm. To prevent stress from occurring in the pipes during operation, care must be taken to compensate for thermal expansion. This is usually done using C- and L-shaped compensators and movable methods of fastening pipes, allowing them to move freely relative to the brackets in which they are fixed.

Soldering quality control

To control the quality of soldering, you can use the methods that are used to control the quality of welding.

The simplest are the permeability control methods described here. When using the content of this site, you need to put active links to this site, visible to users and search robots.

Literature

Soft soldering

Low-temperature soldering is used when installing water supply and heating networks with coolant temperatures up to 130 °C and pipe diameters up to 10 cm.

Soldering at low temperatures is suitable for installing water pipes

The technology for connecting copper products with soft solder involves preliminary cleaning of the surfaces, applying flux paste with a brush and inserting the elements into each other. Next, the joint is heated with a gas burner to 200-250 degrees. Solder is applied to the edge of the joint.

When soldering, it is important to remember that the temperature of the burner flame can reach 1 thousand degrees, so 15-20 seconds are enough to heat up the elements. To ensure uniform heating, the flame must be constantly moved. The degree of heating is controlled by the color of the flux. After it darkens, you need to take solder.

After introducing soft solder into the soldering zone, in contact with a heated copper pipe, the tin wire begins to melt and slide along the flux into the seam. Gradually the heated mass fills the space between the socket and the pipe.

Brazing

Do-it-yourself soldering of copper pipes using hard solder is carried out if you plan to operate the system at temperatures above 110 °C. The connection requires a temperature above 700 degrees, so soldering is performed using a gas-flame method.

Copper-phosphorus solder is produced in the form of rods and is used for high-temperature soldering

Note! Brazing technology involves annealing the metal, which softens the copper.

The use of copper-phosphorus solder does not require flux. If you properly ensure uniform heating of the ends of the products, it will fill the gap. The readiness of the connection is checked with a solder bar - it should melt.

The soldering steps are as follows:

- The docking unit is assembled and warmed up.

- Solder is introduced into the connection point between the socket and the pipe, which is softened by a burner.

- After the first coupling, the pipe is rotated and the softened solder is wound onto the next section of the joint.

The advantages of brazing copper pipes technology are:

- good seam strength;

- possibility of reducing the connection width;

- applicability in systems operating at high temperatures.

Since proper soldering of copper pipes with hard solder should prevent overheating of the products, which leads to ruptures, it is better to entrust the work to specialists.

Read also: Homemade chip extractor for carpentry

Brazed pipes are used in heating systems

Useful information about copper

The soft metal alloy began to be used in ancient times for minting coins. Today this material has become a little less popular, but heating and plumbing systems made from copper pipes are still the most durable, reliable and durable.

Installation of such lines is carried out using soldering. During the work process, metal elements are connected to solder - a specially selected material, the melting point of which should be lower than that of the workpiece.

The soldering process itself is simple. The main thing is to choose the right connecting material. In our case, this is copper-phosphorus solder. It is also worth deciding on the soldering method. There are several of them.

Basic mistakes when soldering yourself

Before soldering copper pipes, you need to make sure that there are no defects on their surface, which often appear when cutting products. The reliability of the seam largely depends on the purity of the materials used in the work. For pipes with a diameter of 6-108 mm, the width of the resulting connection can be 7-50 mm.

Important! If the copper pipe or solder is not heated sufficiently, the tin or copper wire of the latter will not stick to the flux and will not soften. This will cause leakage at the joint.

Sometimes, when applying flux, some sections of the pipe are missed, which results in poor adhesion of the solder to the product. A similar result is caused by overheating the pipe, which causes the flux to burn.

During soldering, it is important to comply with safety requirements, since the work involves the use of open flames and chemically active substances. Before soldering copper pipes, you need to take care of personal protective equipment: gloves, goggles, etc.

Properly organized and performed work on connecting copper pipes will ensure a long service life of the pipeline.

Copper pipes are parts for global or local communication systems transporting gas, water, petroleum products, coolants and other important resources. To combine individual fragments into a single network, copper solder is used. It is selected depending on the conditions under which the system is operated.

A properly designed connection ensures the tightness of the entire complex and prevents leakage of the supplied composition into the environment. And their incorrect connection can result in a lot of problems in the future.

Let's try to understand the types of solder and which one is better to give preference in a particular situation.

What is solder?

Solder is a pure metal or thermoplastic alloy made from several components. Designed to connect copper parts into a common integrated network.

The technology of joining two fragments, carried out according to this principle, is called soldering.

Among the main advantages of the technique it is worth highlighting:

- connection without deformation;

- preservation of the original shape of the processed parts;

- absence of any internal tension;

- excellent strength and high level of tightness of the created seam;

- resistance of the bonded area to different temperature conditions, including intense heating;

- simple separation of seam sections in case of need to change the system format.

Soldering is carried out with special equipment - a soldering iron, a gas torch or a blowtorch. Immediately before work, the area is thoroughly cleaned of surface defects and technical oils, and only then work begins.

The process of connecting pipe fragments is easy and quick, but requires mandatory compliance with basic safety rules. To avoid problems and injuries, you should wear thick work gloves on your hands, cover your face and eyes with special goggles or a mask, and protect your clothes with a thick apron. This will protect the technician from potential accidents.

Classification of solders for copper pipes

Solders for high-quality and reliable soldering of copper pipes are made from different components. Products differ from each other in shape and chemical composition.

The type and parameters of the connecting elements are determined by the area of subsequent operation of the pipe system made of copper parts.

Melting point differences

Based on the level of temperature treatment, solders are divided into three types:

- low temperature;

- medium temperature;

- high temperature.

Low temperature options melt in the range from 150 to 450 °C. They do not change the original physical parameters of the parts. In the connection area, a neat but not too strong seam is created. Intended for use in heating and water supply networks that are not subject to heavy loads.

Ensure the tightness and integrity of pipes with a diameter of up to 10 cm installed in communication systems transporting coolant with temperatures up to 130 °C.

Medium and high temperature materials soften at temperatures ranging from 450 to 1100/1850 °C. They guarantee the most durable, strong connection, not sensitive to external influences.

The area connected by medium-temperature or high-temperature solder exhibits resistance to mechanical damage and calmly tolerates active thermal loads.

Separation by chemical composition

According to the chemical composition, modern, practical solders are divided into soft, fusible and hard, refractory.

The first category includes the following items:

- lead - contain only pure lead and melt at temperatures from 180 to 230 °C;

- tin - consist of tin and melt at 220 °C, creating a durable and ductile seam;

- lead-tin - can contain from 15 to 90% tin. The melting temperature of such elements is 183-280 °C;

- tin-copper - 97% consist of high-quality tin and 3% copper. They are among the most popular and are sold at a reasonable price. Form a strong connection with good corrosion resistance;

- copper and silver - 95% copper and 5% silver. They are characterized by high strength characteristics and provide reliable adhesion between fragments.

Soft, low-melting components are used to combine pipes with a diameter of 6 to 108 mm into a single complex. In the joint area, a neat seam with a width of 7 to 50 mm is formed.

Lead is considered an element harmful to human health. The use of lead-containing solders is strictly prohibited in networks supplying water to apartment or private buildings, enterprises or public institutions. This prohibition does not apply to other types of communications.

Hard, refractory materials are suitable for high-temperature processing:

- copper in combination with silver and zinc - contains 30% copper, 44% silver and 26% zinc. The adhesion area has good strength, retains ductility, effectively resists corrosion and demonstrates increased thermal conductivity;

- copper with phosphorus - an alloy of 94% copper and 6% phosphorus. The soldering process does not require the use of flux. Makes a strong and reliable connection, but partially loses its elasticity at low ambient temperatures;

- silver – during soldering requires the mandatory use of flux. Creates a strong, reliable seam with good ductility and high corrosion resistance. It is much more expensive than analogues made of simple metals and is not widely used. It is used where there is economic feasibility and increased demands are placed on the quality of the pipe connection.

Using refractory solders, complexes of pipes with a diameter of 12 to 159 mm are installed, including gas communication networks, heating lines and water mains with a diameter of 28 mm.

Read also: Husqvarna 142 chainsaw starts and stalls

The use of classic copper-phosphorus or any other elements is allowed when creating overlap joints. This coupling option ensures maximum structural strength and increases the operating life of the pipeline.

Soft solders are usually made in the form of coils for ease of use. Solid elements are supplied in the form of wires of different lengths.

Types of solders for copper

The following materials are suitable for processing pipes made of this material:

- 102. This three-component copper and phosphorus solder contains no more than 2% silver. Due to reduced plasticity, the composition spreads slowly. Suitable for soldering elements that do not experience strong shock or vibration loads.

- 105. Copper-phosphorus solder with silver (5%) also spreads quite slowly, but has higher ductility. The seam obtained with its help can withstand minor loads from vibrations.

- 115. Another three-component solder, which in addition to copper and phosphorus contains 15% silver. This is a fairly plastic material with which you can create seams on highways that experience fairly heavy loads.

Having selected all the necessary components, all that remains is to get to work.

Flux - features and purpose

Flux is a specific technical material for soldering copper pipes. Protects the surface of parts from oxidation and slag. Prevents contact of the welded seam with oxygen. Improves the overall quality of the joint and gives it good strength and optimal ductility.

Fluxes for soldering copper pipes are available in different consistencies.

Among the most sought after and popular:

The substance in the form of a paste for soldering copper pipes is more expensive than other materials, but fully justifies its high price. Suitable for use immediately after purchase and does not require the technician to add anything to the composition to improve its performance.

The paste is purchased for critical soldering, which requires the most precise and high-quality sealing of the joint areas. The substance easily lies on the copper surface, adheres well to it and is well distributed over the treatment area during heating.

The finished seam looks neat and ensures the integrity of the adhesion of all fragments of the system. Residues of the substance are easily removed after completion of work.

Powder products are sold at a lower price and are well stored in special containers. Maximum efficiency is demonstrated in conjunction with reinforced, refractory solders. They are considered less convenient due to the difficulty of uniform application to the treatment area.

Liquid substances are sold in closed bottles. They have normal contact with soft solders and adhere easily to the copper surface, providing high bonding strength. To ensure a high-quality connection, liquid flux and solder are always used simultaneously and not separately.

Regardless of consistency, flux must be applied immediately after stripping the copper fragment. If this moment is ignored, the metal surface will again be covered with oxides and it will not be possible to process it evenly.

After flux treatment, parts should be soldered immediately. This will eliminate the chance of foreign particles penetrating the work surface.

When connecting parts, care and attention must be exercised. Contact of flux on the skin provokes not only thermal, but also chemical burns.

If this does happen, you should immediately stop soldering and wash the substance off your skin with plenty of soapy water.

Requirements for the quality of fluxes

There are some requirements for fluxes for individual and industrial use.

The substance must meet the following criteria:

- lower structure density and viscosity indicators than solder (for correct replacement);

- ability to distribute evenly over the working surface;

- dissolution of the oxide film;

- prevention of re-oxidation of copper elements;

- resistance to aggressive high temperatures;

- the ability to carry out soldering on both horizontal and vertical sections of the communication system;

- creating a neat, aesthetic seam.

When using good quality fluxes, dust and dirt formed as a result of soldering are removed easily and quickly, without leaving any traces on the pipe element that spoil the appearance. The connection is reliable and maintains structural integrity for many years.

Popular types of material

There is a wide range of fluxes for soldering copper pipes on the market.

The most popular substances are:

- with high anti-corrosion ability;

- with noble materials in the composition;

- based on rosin.

Anti-corrosion flux consists of several complex elements, solvents and phosphorus. During the heating process, they dissolve in the liquid, react and form organic components.

Protect the seam area from oxidation and premature corrosion. Promote the drainage of excess moisture from the soldering zone.

In the second type of flux, the main active ingredient is salicylic acid. During use, it dissolves in a composition of ethanol, gold-containing substances and industrial petroleum jelly.

Creates a perfectly smooth, neat and aesthetic connecting seam that does not require additional complex processing. Does not damage the material of the pipe adjacent to the treatment area

Classic active flux contains rosin and a certain amount of sodium salt. The substance has pronounced protective characteristics and effectively protects the pipeline from corrosion. Rosin covers the seam with a thin and durable protective film, and sodium salt inhibits oxidative processes.

This flux is sold for a reasonable price and provides a strong, reliable connection. However, the finished weld remains highly visible and is immediately noticeable on the outer portions of copper piping.

Regardless of the type and basic composition, the flux must be applied as evenly as possible, avoiding even a millimeter gap. If any part of the metal does not have this coating, the pipe will begin to rust over time and will need to be replaced.

How to choose the right solder?

Correctly selected solder will help you organize a communication system of any complexity without much effort. If we are talking about working at home, it is worth using a material that melts at low temperatures.

The use of high-temperature hard-melting elements in everyday life is problematic, since it requires heating the working alloy to 600-900 degrees. Achieving this without special equipment is quite difficult.

The use of metals and their derivatives that melt at high temperatures involves some risk. During processing, they can damage or even burn through thin-walled copper pipes.

To prevent this from happening, it makes sense to take strong but low-melting soft solder, and leave the hard option for thick-walled copper communications.

To connect copper pipes in gas networks, you should choose silver-containing solders. They provide maximum seam strength, vibration neutrality and high resistance to external and internal influences.

You will have to pay a little more for silver, but the safety, reliability and durability of the system will pay off all financial costs over time.

Solder Connection Capabilities

In gas, water, and coolant supply systems, pipes with thin walls are often installed. Such pipelines are easier to solder than to weld.

True, the process is relatively easy when working with pure copper or its alloys containing zinc, tin, lead, and other chemical elements resistant to oxidation. Even if oxides form, they are easily removed.

If the alloys contain titanium, aluminum, silicon, chromium, then the products formed as a result of oxidation are difficult to remove. In most cases, alloys of the first type are used for the production of pipes.

Read also: Surface area of the corner 50x50x5

Copper pipes can be joined and repaired by soldering using hard or soft solders. Each method has its own characteristics. Brazing of copper is carried out at high temperatures. In this case, a burner is used.

A person with experience in such work can perform soldering well without burning the metal.