GOST 8509-93

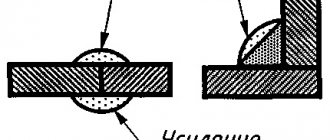

b - shelf width; t—thickness of the flange;

R—radius of internal curvature; r is the radius of curvature of the shelves;

F is the cross-sectional area; i—radius of gyration;

I—moment of inertia; Ixy is the centrifugal moment of inertia;

x0 is the distance from the center of gravity to the outer edge of the shelf.

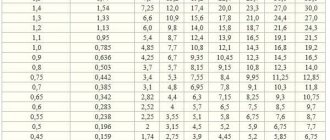

| Angle number | b | t | R | r | F, cm 2 | Reference values for axes | Weight 1 m, kg | |||||||||

| x - x | x 0 — x 0 | y 0 - y0 | Ixy, cm4 | x0, cm | ||||||||||||

| mm | Ix, cm4 | Wx, cm3 | ix, cm | Ixо max, cm4 | ixo max, cm | Iyо min, cm 4 | Wyo, cm 3 | iyо min, cm | ||||||||

| L20x3 | 20 | 3 | 3,5 | 1,2 | 1,13 | 0,4 | 0,28 | 0,59 | 0,63 | 0,75 | 0,17 | 0,2 | 0,39 | 0,23 | 0,6 | 0,89 |

| L20x4 | 4 | 3,5 | 1,2 | 1,46 | 0,5 | 0,37 | 0,58 | 0,78 | 0,73 | 0,22 | 0,24 | 0,38 | 0,28 | 0,64 | 1,15 | |

| L25x3 | 25 | 3 | 3,5 | 1,2 | 1,43 | 0,81 | 0,46 | 0,75 | 1,29 | 0,95 | 0,34 | 0,33 | 0,49 | 0,47 | 0,73 | 1,12 |

| L25x4 | 4 | 3,5 | 1,2 | 1,86 | 1,03 | 0,59 | 0,74 | 1,62 | 0,93 | 0,44 | 0,41 | 0,48 | 0,59 | 0,76 | 1,46 | |

| L28x3 | 28 | 3 | 4 | 1,3 | 1,62 | 1,16 | 0,58 | 0,85 | 1,84 | 1,07 | 0,48 | 0,42 | 0,55 | 0,68 | 0,8 | 1,27 |

| L30x3 | 30 | 3 | 4 | 1,3 | 1,74 | 1,45 | 0,67 | 0,91 | 2,3 | 1,15 | 0,6 | 0,53 | 0,59 | 0,85 | 0,85 | 1,36 |

| L30x4 | 4 | 4 | 1,3 | 2,27 | 1,84 | 0,87 | 0,9 | 2,92 | 1,13 | 0,77 | 0,61 | 0,58 | 1,08 | 0,89 | 1,78 | |

| L32x3 | 32 | 3 | 4,5 | 1,5 | 1,86 | 1,77 | 0,77 | 0,97 | 2,8 | 1,23 | 0,74 | 0,59 | 0,63 | 1,03 | 0,89 | 1,46 |

| L32x4 | 4 | 4,5 | 1,5 | 2,43 | 2,26 | 1 | 0,96 | 3,58 | 1,21 | 0,94 | 0,71 | 0,62 | 1,32 | 0,94 | 1,91 | |

| L35x3 | 35 | 3 | 4,5 | 1,5 | 2,04 | 2,35 | 0,93 | 1,07 | 3,72 | 1,35 | 0,97 | 0,71 | 0,69 | 1,37 | 0,97 | 1,6 |

| L35x4 | 4 | 4,5 | 1,5 | 2,67 | 3,01 | 1,21 | 1,06 | 4,76 | 1,33 | 1,25 | 0,88 | 0,68 | 1,75 | 1,01 | 2,1 | |

| L35x5 | 5 | 4,5 | 1,5 | 3,28 | 3,61 | 1,47 | 1,05 | 5,71 | 1,32 | 1,52 | 1,02 | 0,68 | 2,1 | 1,05 | 2,58 | |

| L40x3 | 40 | 3 | 5 | 1,7 | 2,35 | 3,55 | 1,22 | 1,23 | 5,63 | 1,55 | 1,47 | 0,95 | 0,79 | 2,08 | 1,09 | 1,85 |

| L40x4 | 4 | 5 | 1,7 | 3,08 | 4,58 | 1,6 | 1,22 | 7,26 | 1,53 | 1,9 | 1,19 | 0,78 | 2,68 | 1,13 | 2,42 | |

| L40x5 | 5 | 5 | 1,7 | 3,79 | 5,53 | 1,95 | 1,21 | 8,75 | 1,52 | 2,3 | 1,39 | 0,78 | 3,22 | 1,17 | 2,98 | |

| L45x3 | 45 | 3 | 5 | 1,7 | 2,65 | 5,13 | 1,56 | 1,39 | 8,13 | 1,75 | 2,12 | 1,24 | 0,89 | 3 | 1,21 | 2,08 |

| L45x4 | 4 | 5 | 1,7 | 3,48 | 6,63 | 2,04 | 1,38 | 10,52 | 1,74 | 2,74 | 1,54 | 0,89 | 3,89 | 1,26 | 2,73 | |

| L45x5 | 5 | 5 | 1,7 | 4,29 | 8,03 | 2,51 | 1,37 | 12,74 | 1,72 | 3,33 | 1,81 | 0,88 | 4,71 | 1,3 | 3,37 | |

SEE OTHER SIZES OF CORNERS HERE

L20 - L45, L50 - L75, L80 - L110, L125 - L180, L200 - L250

DOWNLOAD THE FULL VERSION OF THE DOCUMENT:

DOWNLOAD FILE TO YANDEX.DISK

DOWNLOAD FILE TO GOOGLE.DISK

VIEW FULL RANGE

Equal angles have a very wide range of applications. Of these, you can combine different sections (Tee, cross-section, channel, I-beam). Corners are used as racks, braces, and belts. Sometimes corners are used as stiffeners for various floorings. It is not recommended to use corners as the main load-bearing beams in metal frames, because excessive consumption of steel will be unjustified.

Corners are used for various auxiliary structures (Support tables on columns for installing beams, support tables on beams and trusses, for installing purlins. Corners are widely used for the manufacture of seasonal structures, such as canopies, tents, greenhouses, greenhouses and much more.

When using the assortment, it should be taken into account that some items are popular and can be purchased at almost any metal stock, while some items are rare and difficult to obtain, especially in the regions. You should also take into account the price range, because... sometimes it is more profitable to lay cheaper beams, which pays off even despite some overconsumption of metal.

The table shows prices at the beginning of 2022.

For isosceles angles, it is necessary to calculate the centrifugal moment relative to the central axes У1Z1:

.

Angle b is measured from the U1 axis to the Z1 axis. In the case of clockwise movement, angle b is considered negative.

In our case b = – 45°.

For unequal angles, angle b is selected from the tables.

| Fig.3. Channel |

| Rice. 4. Rectangular section |

It is recommended to present all initial data in the form of a table, which will be convenient to work with on a computer.

| Item number | 1 – corner | 2 – channel | 3 – rectangle |

| Area F | 9.03 | 31.84 | 36.00 |

| Coordinate | 4.22 | 11.00 | 23.00 |

| Coordinate | 4.22 | 8.10 | 15.00 |

| Moment of inertia J | 29.60 | 157.80 | 972.00 |

| Moment of inertia J | 29.60 | 2393.90 | 12.00 |

| Moment of inertia | -17.20 | 0.00 | 0.00 |

Equal angle corner GOST 8509

| TK STEEL-INTEX TRADE, LLC | EVRAZ METAL INPROM, OJSC | OMEGA METAL, GK | DIPOS, GC | METALLO-KOMPLEKT-M, JSC | ARIEL METAL, JSC | A GROUP, LLC | METAGOR, LLC | ATON-STEEL, LLC | AMG, LLC | SPECSTAL-SERVICE, LLC |

| 20x20x4.0 mm | ||||||||||

| 25x25x3.0 mm | 43 080 | 46 000 | 47 500 | 48 490 | 44 700 | 46 600 | 47 490 | 42 990 | 44 900 | |

| 25x25x4.0 mm | 43 080 | 45 400 | 45 500 | 45 800 | 45 490 | 45 900 | 46 000 | 47 490 | 43 490 | |

| 32x32x3.0mm | 43 880 | 46 600 | 45 800 | 48 490 | 46 600 | 46 490 | 44 490 | 44 900 | ||

| 32x32x4.0 mm | 43 380 | 44 800 | 46 000 | 47 500 | 44 990 | 45 700 | 46 000 | 46 490 | 43 490 | |

| 35x35x3.0 mm | 41 580 | 46 000 | 46 000 | 44 490 | 43 990 | |||||

| 35x35x4.0 mm | 45 400 | 46 000 | 43 900 | 44 990 | 46 000 | 44 490 | ||||

| 35×35x5.0 mm | 33 490 | |||||||||

| 40x40x3.0 mm | 45 580 | 46 000 | 46 600 | 47 990 | ||||||

| 40x40x4.0 mm | 43 880 | 44 400 | 44 700 | 44 700 | 43 990 | 44 700 | 44 700 | 45 490 | 44 490 | |

| 40x40x5.0 mm | 46 990 | 43 990 | ||||||||

| 45x45x3.0 mm | 45 000 | 45 000 | ||||||||

| 45x45x4.0 mm | 43 480 | 41 900 | 44 700 | 42 200 | 41 490 | 43 800 | 44 700 | 42 990 | 41 790 | |

| 45x45x5.0 mm | 42 480 | 42 600 | 38 200 | 41 990 | 45 700 | 45 000 | 43 490 | 42 990 | ||

| 50x50x4.0 mm | 41 580 | 41 500 | 42 000 | 44 200 | 42 490 | 42 000 | 42 990 | 41 790 | ||

| 50x50x5.0 mm | 41 580 | 41 900 | 42 500 | 42 000 | 42 700 | 42 490 | 46 000 | 42 000 | 42 990 | 41 490 |

| 63x63x4.0 mm | 43 380 | 42 490 | 45 000 | 43 490 | ||||||

| 63x63x5.0 mm | 43 480 | 41 900 | 42 000 | 42 000 | 42 500 | 42 490 | 44 000 | 42 000 | 43 790 | 42 990 |

| 63x63x6.0 mm | 43 480 | 42 000 | 42 700 | 42 000 | 43 500 | 42 000 | 42 990 | 42 990 | ||

| 70x70x5.0 mm | 42 780 | 42 300 | 45 000 | 45 500 | 44 490 | 45 000 | 46 490 | 44 490 | ||

| 70x70x6.0 mm | 42780 | 44900 | 44490 | 45100 | 45990 | 43490 | ||||

| 70x70x7.0 mm | 45490 | 42490 | ||||||||

| 75x75x5.0 mm | 42680 | 42300 | 42600 | 45200 | 44490 | 44700 | 42600 | 45490 | 42790 | |

| 75x75x6.0 mm | 42680 | 42300 | 42500 | 42300 | 44700 | 44490 | 44300 | 42300 | 44990 | 42790 |

| 75x75x7.0 mm | 42680 | 45000 | 44490 | 45000 | 46990 | 43990 | ||||

| 75x75x8.0 mm | 42680 | 44150 | 44900 | 43990 | 44900 | 44150 | 45990 | 43490 | ||

| 80x80x6.0 mm | 43880 | 42300 | 45600 | 44900 | 45490 | 46000 | 45600 | 45990 | 43490 | |

| 80x80x7.0 mm | 43880 | 45600 | 45600 | 45990 | 42490 | |||||

| 80x80x8.0 mm | 43880 | 45600 | 45200 | 45600 | 44490 | |||||

| 90x90x6.0 mm | 43380 | 42300 | 42300 | 44900 | 44490 | 44200 | 42300 | 42990 | ||

| 90x90x7.0 mm | 42780 | 42300 | 44000 | 42300 | 43500 | 43490 | 45700 | 42300 | 45490 | 42290 |

| 90x90x8.0 mm | 42900 | 45900 | 45490 | 46300 | 45900 | 46490 | 43490 | |||

| 90x90x9.0 mm | 45600 | 42790 | 45600 | |||||||

| 100×100x6.5 mm | 45680 | |||||||||

| 100x100x7.0 mm | 43480 | 42800 | 43500 | 42900 | 47900 | 43990 | 43900 | 42900 | 37990 | |

| 100x100x8.0 mm | 43480 | 42800 | 43500 | 42000 | 44700 | 44990 | 47800 | 42900 | 37990 | |

| 100x100x10.0 mm | 43480 | 42800 | 47700 | 48900 | 48490 | 48900 | 47700 | 44990 | ||

| 100x100x12.0 mm | 38990 | |||||||||

| 110x110x7.0 mm | 43580 | 49500 | 45700 | 49500 | 45990 | |||||

| 110x110x8.0 mm | 43080 | 42900 | 50500 | 49500 | 43990 | |||||

| 125x125x8.0 mm | 43080 | 45300 | 39200 | 49500 | 49500 | 51490 | 45700 | 49500 | 44990 | |

| 125x125x9.0 mm | 43080 | 45300 | 49500 | 48400 | 46000 | 49500 | 44490 | |||

| 125x125x10.0 mm | 43080 | 45300 | 49500 | 48500 | 48990 | 45700 | 49500 | 37990 | ||

| 125x125x12.0 mm | 46990 | 37990 | ||||||||

| 140x140x9.0 mm | 54180 | 53600 | 55000 | 55500 | 54950 | 55000 | 55950 | |||

| 140x140x10.0 mm | 54180 | 53600 | 55000 | 54950 | 55000 | 55950 | ||||

| 140x140x12.0 mm | 55000 | 55000 | ||||||||

| 160x160x10.0 mm | 54180 | 54800 | 55000 | 55500 | 54950 | 55000 | 55950 | 57200 | ||

| 160x160x11.0 mm | ||||||||||

| 160x160x12.0 mm | 52580 | 55000 | 54950 | 55000 | 58200 | 57200 | ||||

| 160x160x14.0 mm | 58200 | |||||||||

| 160x160x16.0 mm | 53580 | 54800 | 54950 | 58200 | 57200 | |||||

| 160x160x20.0 mm | ||||||||||

| 180x180x11.0 mm | 56800 | 57500 | 57200 | 57200 | 57500 | 58200 | ||||

| 180x180x12.0 mm | 57500 | 57500 | 58200 | |||||||

| 180×180x14.0 mm | ||||||||||

| 200x200x12.0 mm | 53580 | 55000 | 54950 | 55000 | 55950 | 54950 | ||||

| 200x200x14.0 mm | 51180 | 54000 | 55000 | 55000 | 55950 | 54950 | ||||

| 200x200x16.0 mm | 51180 | 54000 | 54950 | 55950 | 54950 | |||||

| 200x200x20.0 mm | 55950 | 54950 |

Assortment of unequal hot-rolled angles GOST 8510-86

Source: https://sbk.ltd.ua/ru/sortament-ves-metalloprokata/137-sortament-ugolka-neravnopolochnogo-gorjachekatanogo-gost-8510-86.html

| The range of steel angles is divided into equal and unequal angle steel. The range of equal angle angles is 2-3 times wider than the range of channels and beams. Hot-rolled steel angles, unequal, are a solid metal profile with an L-shaped section. The range of angle steel is produced in accordance with GOST 8510-86 both from ordinary quality carbon steel (GOST 380-94) grades: steel St0-St6, steel 09g2s, steel 3sp5, etc., and from low-alloy steel of high strength (GOST 19281-89) grades 08G2S, 12GS, 16GS. The full range of corners contains: - geometric characteristics of the angle according to GOST 8510-86; - axial moments of inertia of the hot-rolled unequal angle; - radius of inertia relative to the main central axes; - weight per linear meter; — cross-sectional area; Unequal-flange angles (the dimensions of shelves A and B are different in contrast to equal-flange angles) are usually used in the manufacture of metal structures that have a bend (for example, arched structures, roof trusses). Metal corner unequal. Dimensions and weightThe list of rolled angles indicating geometric characteristics, flange dimensions, weight of one linear meter (specific gravity), tolerances and delivery conditions is called a metal angle assortment. A variety of types of hot-rolled profiles, including unequal angles in the range, as well as a fairly frequent gradation of angle sizes, ensure the economical production of metal structures with the possibility of creating a variety of structural forms of metal products. The gradation coefficient (the ratio of the cross-sectional area Fn to the cross-sectional area of the nearest smaller Fn-1) in the assortment of hot-rolled angles has a variable value. In the size range of the most commonly used hot-rolled steel, the gradation coefficient is smaller. Corner rental, variety of GOST 8510-86 is made of carbon steel: ST0, ST3KP, ST3SC/PS, ST4KP, ST4PS, ST4SP, ST5PS, ST6PS, ST6SP, from steel of low-alloy brands: 08G2C, 12GS, 16GS, 14G2, 17GS, 09G2C2C2C2C, 09G2C2C2C2C, 09G2S , 14HGS, 15HSND, 10KHNDP, 17G1S, 10G2S1, 10G2BD, 10HSND, 15G2SFD, 14G2AF, 16G2AF, 15G2AFDps, 18G2AFps. It should be remembered that the range of angle steel, unequal angles are used for the manufacture and installation of building frames, strengthening of load-bearing structures, the manufacture of supports and columns, various machine parts and mechanisms. The characteristics of the angle (strength and geometric) can be downloaded in the “Assortment of unequal steel angles”, and the properties of steel in the “Assortment of metals and alloys”. Metal strength is an important strength characteristic that can change during cold hardening (hardening the surface of the metal of a corner as a result of plastic deformation is called cold hardening or cold hardening). Such properties of steel angles must be taken into account during pressing work, especially when straightening rolled steel with a flange thickness of 3 mm, 4 mm, 5 mm (see. Assortment of angle steel), where increasing the pressing force of the punch instead of improving the tightness of the fit, when testing on a plate, often leads to completely opposite results, due to warping of the angle metal under the influence of work hardening. In places where work hardening is possible, cracking of the metal surface is possible, which is sometimes observed in a defective corner (characteristics do not meet the requirements of GOST), which was rolled on a mill in a cold state, because cold rolling creates high hardness and elasticity of the metal. When choosing an angle from the assortment of rolled angles, you must clearly know what kind of environment will be in the structures in which rolled metal will be used. For example, if the environment is aggressive, with high humidity, then you should choose angle bars made of galvanized steel in accordance with GOST. Equal and unequal angles made of galvanized steel are widely used in galvanized power line supports. |