To give the slope evenness and the desired opening angle, a slope grinder is used, which plays a significant role in its formation. This is relevant during the next renovation, which involves replacing windows and doors, or during renovations in a new building.

A small tool is a device that allows you to determine and fix an angle and transfer it to the desired workpiece. It is convenient to work with it when installing window sills, installing door or window slopes, and when performing other construction, plumbing and other work.

Malka can be metal or wood. It consists of two elements:

- The block is a wider part with a slot inside where the second element, the feather, is “hidden.”

- The pen (ruler) is attached to the block with a screw; it is movable and is designed to mark and fold into the groove.

Almost everything happens according to the scheme - measuring the angle - fixing it with a clamping bolt - transferring the size to the workpiece. Today the market offers an amazing selection of tools and all kinds of devices. And malka is no exception - you can buy it to suit your taste and budget.

But it is quite possible to make the simplest wooden clapper for slopes yourself.

Do-it-yourself small goniometer

A goniometer is a fairly affordable tool that can be bought at almost any hardware store, but the master does not always have time for this, and the device may be needed urgently. In this case, you can do it yourself. To do this you will need:

- A block of wood from which the block will be made. A small piece of up to 30 mm will do.

- A piece of plywood, the thickness of which should be more than 3 mm. It is better not to take plywood thicker than 5 mm. The moving part of the device is made from this material.

- A bolt and nut can be used as fasteners.

- Using a drill, you need to drill a hole for the bolt.

You need to start assembling the goniometer from the block. To do this, measure 10 cm on the workpiece and saw off the required length. After this, you can proceed to making a slot for the feather, which will require cutting the block from the end.

The feather of the instrument is made of plywood, and if it is not available, then you can use a material of similar size - for example, a sheet of plastic. Marks of 20-40 mm are made on the sheet: these will be the dimensions of the pen itself. They can be changed at your discretion. If you did everything correctly, the feather and the cut in the block will form an acute angle when folded. The parts are bolted together at an angle of 90 degrees; the pen must be able to move. The excess needs to be cut off and cleaned.

How to make it yourself

If you don’t have a tool at hand and you need it urgently, you can make it yourself.

The feather can also be made from plastic if plywood is not at hand. Marks are made at a distance of 20-40 mm. They will match the size of the pen.

You will need to make a cut in the block; if the feather is folded correctly, it should form an acute angle. The bolt will help hold the parts together. The result will be an angle of 90 degrees.

There is no need to tighten it too much; the pen should move freely.

Using powder for plastering

With this small tool you can easily and efficiently perform not only plaster, but also putty.

First of all, you need to form the same “dawn angle” for all slopes. We install the block on the edge of the window frame, for example, and use a pen to determine the angle along the edge of the slope adjacent to the wall. We secure the resulting result with a screw.

Now you need to check the entire slope around the perimeter of the small wall. The result should be the same everywhere. If there are deviations somewhere, then we remove the excess and check again. You may have to change the angle on the fry a little if there are large errors. The malka we made using a simplified scheme works in a similar way.

The next stage is preparatory work and plastering, puttying the slopes. The entire sequence is described in detail in the article plastering slopes. Here's a device for you - it seems like a very simple tool, but when used, the slopes are formed quickly and efficiently with a given opening angle, symmetrical and even.

I offer a short video where the small one is a very simple template made with your own hands.

Malka protractor. The Builder's Essential Protractor

Finishing slopes always causes some difficulties even for experienced craftsmen, not to mention amateurs who have undertaken to do home repairs on their own. It is quite possible to achieve perfectly smooth slopes with the same angles if you know some professional tricks. In order to determine angles other than 90 degrees, a special device is used called a goniometer . It will significantly speed up and facilitate your work, helping you achieve excellent results without extra effort. Using it, you may not have to think about how to measure the angle and how to transfer it to the workpiece.

How to use malka?

If we are talking about a pure transfer of an angle to a workpiece, then there is nothing to describe here: set the angle specified by a template or sample, or a drawing (possibly scaled), fix the relative position of the pen and the block and transfer it where necessary. In this case, it is absolutely indifferent to us what the magnitude of this angle is in degrees, radians or segments of any size. But, if you need to calculate the angle of conjugation of two connected elements, when it is different from a straight line, or a pair or three of others present on some miter box, then, perhaps, you cannot do without a small tool. Let's look at an advertising image of one of the digital cards.

The tool showed the wall bevel angle down to tenths, but did not bring us even 1/10 closer to a practical solution to the problem of accurately joining the plinth sections in such a strongly “wrong” angle. It is clear that by dividing 135.4° by 2, we get the angle at which the skirting boards should be cut, but marking them accurately and then cutting them is not an easy task. With the help of malka, these issues can be solved as easily as possible:

- Place the bait in the corner, pressing the block and feather tightly against both walls, and fix the turn of the corner.

- Transfer the resulting angle to a sheet of paper, drawing it with a pencil or pen.

- You cut out the resulting corner, although you can simply bend the sheet along the marked lines.

- Bend the resulting segment in half from the corner.

- You align the plinth by aligning its back part with one of the sides, and the end with the top of the corner.

- Combine the cutting tool with the second ray of the angle and make a cut. If you have doubts about the verticality of the cut, place a block with an exact right angle behind it and cut along its edge.

The video shows a slightly more complex way of transferring an angle taken from a scale drawing.

But its relative difficulty lies in maintaining extreme accuracy, because even minor deviations in the overall length of the structure can result in decent linear deviations in size. What can we say about such metal-plastic window systems, which are shown in the photo. If memory serves, their dimensions are: 5000 x 4000 x 3500 or so.

Can you imagine the consequences of an error in cutting the welding corners of the upper bevel of the structure? But everything was marked with impeccable accuracy using a small marker. A rectangle of 5000 ? was drawn on a flat floor in the workshop. 3500 with checking the diagonals, then one of the sides is extended to 4 meters and this point is connected to the second upper corner. Next - everything is as described in the example with the plinth, only the necessary values for welding are added to the nominal dimensions. For some types of work, special baits are created - double ones. They are used to transfer the angles of rotation of the bay window and similar tasks.

There is confidence that after what has been described above, there is no particular need to explain in detail how such a tool works. It is only necessary to emphasize that the grooves in the unit, which replaces the block common to both feathers, allow the fry to be moved apart in width, increasing its functionality. It is also obvious that this is a homemade small machine, and its design is significantly simplified, even in comparison with the simplest commercially produced one. But it does its job no worse than the factory one; you just need to be more careful when handling such not very durable structures. But making even a more structurally complex piece of work is not a problem for a person who knows how to use simple carpentry tools.

Small fry design

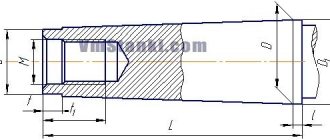

The tool consists of only three parts:

Scope of use of the tool

This is a very useful tool that accurately performs tasks in a matter of seconds that would take much longer and more difficult to do with a regular ruler and protractor. Using a small tool, angles are transferred and copied from workpieces and other surfaces.

It is used:

Malka is an almost irreplaceable tool that allows you to accurately and quickly form the desired angles. For example, using a hammer you can trim laminate, tile, and parquet. Its use ensures that the ends of the floor covering will be located along the wall with the same gap, even if the joining is not at a right angle.

How to use malka

To use the tool, you need to loosen the wing nut and apply the tool to the corner. As a result, its feather and block should press against its legs. The nut is then tightened. The template formed by the tool is transferred for marking to copy the angle. Using a regular small scale does not allow you to determine the size of the angle in degrees, but only copy it.

The angle fixed with a small pencil is applied to the paper or workpiece and outlined with a pencil. After this, a cut is made according to the marking. It will completely repeat the desired angle.

When using a pulley, it is important to tighten the wing nut firmly to prevent the angle from changing when carried. Otherwise, it will move a couple of degrees, so the part prepared using this template will not meet the required parameters.

Manufacturing materials

Malka is a marking tool that usually does not bear a heavy load, so with careful handling it can serve for a long time, regardless of the material it is made of. However, when choosing, you need to take into account its strength and compliance with operating conditions.

Malki are made from the following materials:

Steel bars are strong and durable. They are more expensive than similar tools made from other materials, so they are used to a greater extent in cases where the tool is exposed to adverse effects. They are used on construction sites, when performing finishing repairs and in locksmith shops.

Wooden claws are a tool for indoor use, as they are resistant to moisture. It is primarily used by carpenters. The wing nut screw of the wooden tool is made of steel, so the mount itself is quite secure. It’s nice to hold such a small thing in your hands, it’s warm to the touch.

There are plastic fryers on sale. For the most part, this instrument combines other materials; usually its feather is made of steel. Plastic is not afraid of corrosion and moisture, so in this regard it is very wear-resistant, although it has low mechanical strength, which in most cases is not required. Plastic fry are inexpensive and quite durable.

Popular malok designs

The high demand for tools by people of different professions forces manufacturers to improve and modify the basic designs of the small tool. They are presented in various designs, differing in size, materials of manufacture, functionality and ease of use for specific tasks.

Digital protractor

This tool is the most functional. This is a mini with a protractor option. The device consists of 2 steel pens with metric markings, like on a ruler. Their connection unit is equipped with an electronic part capable of displaying the angle formed by the tool’s arms. That is, using such a protractor, you can measure angles in degrees and use it to transfer dimensions to workpieces.

This is the most expensive type of malka. However, most users do not need such a tool, since they do not need to actually measure the angle value. Electronic goniometers are used by masons for laying non-standard corners according to the project, mechanics, and sometimes carpenters. For craftsmen engaged in finishing work, a simple piece of wood is sufficient, which can be used as a template.

Electronic small scales are mainly produced with ruler lengths of 200 or 300 mm. They are powered by a battery. The devices support the function of switching units of measurement from degrees to minutes. Also on sale you can find an electronic grinder with a protractor function in a classic folding design. It is more compact, has a beveled end of the pen, cut at 45 degrees. This allows it to be used for quick angle control as well as drawing. This tool is very popular. As a rule, pins of this design create a stronger fixation of the feather, which precisely eliminates its movement relative to the block.

Wooden spoon without block

This is a very simple design, which is an adjustable template in the form of two wooden rulers connected at the ends with a screw. They fit together for compact storage and portability. Such a device can have different lengths of 300, 500 mm or more. Its feathers are completely identical to each other. This is very convenient when doing drawings. Due to the elasticity of the rulers, it is more difficult to use such a tool in weight than analogues with a thicker block, especially in the extended version.

Folding wooden with block

This fry completely copies the design of a folding knife. Its feather can be inserted into the groove of the block. This makes the tool very compact. It is convenient to put it in a portable tool box, and even carry it in the pocket of your overalls. This compactness also has a drawback: the device has a small coverage. They can be used to mark small elements or remove corners with straight legs. This makes the tool unsuitable for checking wide door and window slopes and setting plaster beacons. This tool is best used for carpentry work only.

Folding retractable

This instrument can be found in various designs. Usually its pen is made in the form of a metal ruler with markings, and the column is made of wood or plastic, less often aluminum. The device is very similar to a regular folding small. It differs in that its feather is longer than the last. It itself has a longitudinal cutout that allows you to move the ruler and change its length. The device can be moved to a T-position. This is required when performing complex markings. In the storage and carrying mode, the part of the pen beveled at 45 degrees is wrapped in the last. As a result, the malka becomes safe, since the tip cannot prick or cut.

Tool selection

When selecting a fry for purchase, it is worth evaluating the tool according to some nuances:

For most cases, the material of the fry is not particularly important. However, if the tool will be used directly on a construction site, where contact with cement mortar, tile adhesive and high moisture is possible, then it is important that it is resistant to such exposure. In this case, metal baits will perform best, as well as those with a plastic block and a steel feather. For carpentry work, you can use a completely plastic device or a wooden one. If the rest of the carpentry tools in the workshop have unpainted wooden handles, then the small tool will fit very well into the set.

One of the main parameters when choosing a fry is the reliability of the fastening. Some tools use a steel screw with a high-quality M10 wing nut, while others use a thin M6 thread with a thread that is very easy to strip even by hand. It is important to be able to tighten the halves of the line tightly so that they are guaranteed not to move when carrying angle measurements. If possible, before purchasing, you should tighten the nut and try to fold the device. It should not move or move apart until the nut is loosened.

It is very convenient if the pen has a ruler scale. Little things like this save time, since many marking tasks can be completed without changing the tool. The presence of a scale does not make the malka more expensive. When choosing between a tool with and without a ruler, it is better to choose the first option.

Many small fish are equipped with a bubble level. It should be noted that this is a useless option. The tool block is too short to obtain a real vertical or horizontal indicator by applying it to the surface. A real building level must be used for this purpose. Even if the flask with the bubble is fixed level, the malka will still not be able to give an accurate deviation indicator.

When using a screed for installing beacons and for plastering work, it is important that its feather and block are long enough. If the tool is used for metalworking and carpentry tasks with smooth, straight workpieces, then even a length of 200 mm is sufficient.

Source

The main tasks of this tool

The main purpose of the grinder is to measure the existing angle and then transfer it to the workpiece or a more accurate measuring device. They are extremely popular when installing window sills. Using this tool, the angle of repose is measured, after which it is transferred directly to the workpiece, which allows you to cut the required size as accurately as possible.

The adjustable bevel is also used to determine the “dawn angle” during the installation of window slopes.

Malki are also called protractors, which today come in various types, shapes and sizes. Protractor meters with a size of 300 mm are popular, which allows you to measure different lengths of angles. Protractors are also made of wood, plastic or metal. You can measure angles using a protractor, but this is very inconvenient and time consuming. Recently, an electronic protractor has appeared that allows you to measure angle accuracy up to 1 mm.

Malka do-it-yourself protractor

Sometimes there is a need to use a protractor, but it is not at hand. It can and even needs to be purchased, but if a one-time job is being performed, then it is quite possible to make the tool in question yourself. For manufacturing you will need the following materials:

- A wooden block, which will serve as a block or a fixed ruler. If plywood or plastic is used, then use the thin part of the tool.

- A piece of plywood or plastic, but it is best to use old wood; their thickness should not exceed 3 mm. These materials will play the role of a moving element.

- To connect these two materials, you will need to drill holes in them, and then connect them together using a bolted connection with a “lamb.”

Marks of 20-40 mm are made on a sheet of plywood or plastic. If you use a ruler, then there are already markings on it. After this, you will need to combine the prepared materials, resulting in a homemade protractor. The video below shows how to make malka with your own hands in the simplest way.

How to use malka: step-by-step diagram

Not many craftsmen know that you can use malka in your work. In this context, there is not just a transfer of an indirect angle to the workpiece, but a direct calculation of the conjugation of the two elements being connected. Let's consider the features of using the tool in question using the example of window slopes.

Using a hammer, you can perform proper plastering based on standards. A step-by-step diagram of the correct use of the tool is as follows:

- The “dawn angle” is selected. We decide on the bevel under which the plastering will be carried out.

- A. To do this, we pick up a protractor, after which we proceed to measurements. The fixed part of the tool is applied to the edge of the window frame, and the movable part determines the angle from the edge of the window opening from the wall side. To fix the obtained value, you need to screw the “lamb” on the tool. From the wall side, we fix the result obtained directly at the top and bottom points.

- Slope leveling. To make the angles for the slopes ideal, you simply need to install a rail or strip to the wall around the perimeter of the window. The goniometer determines the location of the edge of the rail, after which we fix it with self-tapping screws. The rail must be checked using a building level, since it must be strictly vertical.

- Applying mortar and sealing slopes. The solution is applied to the slopes with a reserve, and the excess is removed using the rule. In order for the slope to receive the direction of the angle, you need to set the rule with the edge towards the window frame, and then draw it along the slope from bottom to top. The rule will remove excess mortar and also level the surface.

- Finishing is the addition of a final layer of plaster mortar (if needed) to complete the leveling of the slope. It is not advisable to seal slopes with large layers of plaster, since it will simply “float” without having time to dry. Finishing also involves the use of a protractor, with which the check is carried out.

Using the example of window slopes, the use of a protractor was considered

It doesn’t matter what kind of small tool you used to level the slope angles. The main thing is that the master uses a small tool to perform these actions, and also knows how to use it correctly

Instructions for using the goniometer grinder

Often, when a simple tool falls into the hands of a specialist, the question arises of how to use it correctly. One of these tools is a grinder, which is better known as a protractor or surface planer. The material describes the process of measuring slopes using the instrument in question. But what else can you use such a simple and uncomplicated tool for, which you can make easily and quickly with your own hands.

What a malka is and why a protractor is needed is explained in detail in the material. It remains to understand the potential of the tool and find out what actions this device is capable of. Without exaggeration, the possibilities of the tool can be called limitless, since with the help of the device you can measure any angle and find out its exact values. This can be not only a window slope, but also an arch or greenhouse structure, the manufacture of which is carried out by a specialist.

Purpose of the grinder and surface planer

If you don’t know how to use a protractor correctly, then it’s time to look into this issue in detail. To learn how to work with a small spoon, you need to follow an example. So, recently the issue of insulating the walls of a house with polystyrene foam or expanded polystyrene has become relevant. Why might you need a protractor when working with polystyrene foam? Everything is banally simple. If you need to stick foam plastic on the wall of a house that has a triangular or uneven shape, then in this case you will need to use a small tool. This is not necessary, but it will greatly simplify the work.

- To avoid having to measure the angle of inclination of the wall, you need to take a small piece of wood and apply it with one part to a straight angle, and the other to an indirect one.

- After this, you need to fix the moving part in the installed position by screwing the thumb in the central part of the tool

- Attach the protractor in a fixed form to the foam sheet and make a mark with a pencil or marker

- The radius of the corner is known, so all that remains is to use a rule or level to apply it to the resulting mark and draw it to the edge of the foam sheet

- Pick up a cutting tool for cutting foam plastic, which can be not only a construction knife, but also a metal blade. Few people know, but you can also cut polystyrene foam or polystyrene foam with the attachment of a hair dryer. How to cut a sheet of foam plastic if its thickness is greater than the length of the blade of a construction knife. To do this, you can take a special attachment on a hair dryer and make a cut along the mark

- Now the foam plastic in which the corner is cut can be applied to the wall and make sure that the procedure is performed correctly and with maximum accuracy

This is an example of the use of a screed, but the construction sector is not limited to the use of a screed. The device is also used in furniture making, when an irregularly shaped tabletop is made to order.

Often such a tool must be used when carrying out welding work, for example, when it is necessary to make metal posts for an arch or greenhouse with the same deflection angle. Whenever there is a need to cut an angle of the corresponding degree, you will need to pick up a protractor.

It is always convenient to work with this simple and uncomplicated device. Moreover, you don’t need to buy it, because it’s easy to make it yourself. If you set out to buy a small one, then you don’t need to go to hardware stores for this. For this, there are online stores where you can choose a suitable tool of good quality and at a low price. If you don’t yet know how to use a malka, then it’s time to learn, especially since it’s easy and simple.

As a result, it is important to emphasize such a factor as the effectiveness of the goniometer. Without such a tool, making an accurate measurement of an indirect angle would be very difficult. This would require a protractor, which would calculate the angle and then transfer it to the projected plane or workpiece. The video provides a detailed report on making malka with your own hands.

We make slopes without problems

Most often, a goniometer is used when constructing window and door slopes. Using this tool, you can achieve not only even corners, but also properly plaster the surface.

It is important that the corners have the correct angle of dawn and are symmetrical relative to each other. It is almost impossible to achieve this by eye: the difference between the slopes is immediately noticeable

How to get even slope angles? First of all, you need to prepare the walls for work. To do this, they are plastered, removing all visible irregularities. Areas of future slopes are cleaned of dirt and dust and primed. If there are traces of polyurethane foam on the window, its protruding parts are cut off.

Then you need to choose the right sunrise angle. To do this, you need to decide at what angle the plaster will be applied. This can be done using a goniometer. Its block must be placed on the edge of the window frame. The angle is determined using a pen; this is done from the side of the walls. After this, the result is recorded, and the remaining angles are checked with a small tool. If there is a discrepancy, another indicator is selected on the device, or excess plaster is knocked out.

In order for the slopes to become identical, their angles need to be aligned. Plasterers usually don't level the plaster near windows and it looks ragged. Before starting work, it is necessary to align these corners. To do this, you can install a leveled rail on the wall. Then the desired angle is set and the solution is applied at this angle.

Before plaster is applied to the slopes, it is necessary to secure the slats to the walls. This can be done using nails or self-tapping screws, depending on what material the walls are made of. After the slats are removed, the holes formed by the fastenings can be filled with putty.

The mixture must be applied in excess to the slope. To ensure that the plaster does not fall off and lies flat, it is applied at an angle; you need to act from the center to the corner. A goniometer will be needed to remove excess plaster from the slopes. Using the same tool, the corner is given the desired direction: to do this, the block must be moved to the window frame. You need to run the block along the frame, directing it from top to bottom. Using a pen, the goniometer leveles the surface and removes excess plaster from it. Sometimes pits appear during the work process. Getting rid of them is not difficult: just put more mixture on the recess. Excess amount can also be removed with malt.

The final stage of slope removal is finishing. For slopes, the normal thickness of the plaster layer is 5 mm. If an inexperienced master worked, the layer may be much thicker. In this situation, you usually want to immediately level the slope, but there is no need to rush into this, since the plaster solution has a large mass and falls off if handled carelessly. In order to avoid having to do all the work again and correct mistakes, it is better to give the plaster the opportunity to set a little in the form that it already exists.

You should wait about a day. After the plaster has set, you will need to use a special grater to clean it. This tool will allow you to remove all the crumbs and depressions that appeared on the slopes while working with them.

If desired, the surface can be made perfectly flat, but you need to work with caution: some craftsmen remove too much layer of plaster and make deep depressions that have to be repaired

The manual sanding method is quite dusty, so it is better to use a protective bandage. Using this method, the master will not have to resort to using additional tools or materials, and the angles of dawn will be the same.

Malka is a convenient carpentry tool. The small scale is used to measure and move any angles.

It is convenient to use when laying laminate, parquet, partially tiles, etc. The mould consists of two elements connected to each other with a bolt and nut. The bolt and nut are tightened a little so that the small can folds and unfolds while remaining in the desired position.

Protractor protractor

This is one of the popular DIY tool methods that can be found online. Even a child can do it. A minimum of materials will be required.

Necessary materials

For manufacturing you will need the following materials:

- Stationery protractor (in the shape of a semicircle, preferably made of transparent plastic);

- Laser pointer;

- Strong thread (can be replaced with thick fishing line);

- Fishing sinker with an eye (you can use a nut);

- Superglue and baking soda;

- Matches or lighter, needle.

The cost of such a protractor is literally 50 rubles. And this is taking into account the cost of the laser pointer and batteries required for operation.

Important! Matches and a needle are needed to make a small hole in the protractor. This can be done more accurately using a Dremel type grinder and a thin drill.

Manufacturing instructions

So, a protractor is made according to the following scheme:

- A small hole is made exactly in the center at the bottom of the protractor. The point will be on a line drawn perpendicular to the base from a mark of 90°. The hole can either be drilled or made using a hot needle. The latter is only needed for plastic devices - this is what it is advisable to use.

- A fishing sinker is tied to the thread. She will be like a pendulum. The recommended weight of the weight is 5 grams or more.

- The thread is threaded through the hole in the protractor. A knot is made at the threaded end so that the resulting thickening allows the thread not to slip out of the hole. You can fix the pendulum using superglue, but you don’t have to wait until it hardens - just add a pinch of baking soda and this mixture will instantly harden.

- A laser pointer is attached to the bottom edge of the protractor. You can also fix it with superglue and baking soda. If there are any irregularities on the pointer body, it is better to remove them or completely rub them with a file.

If possible, you should check the accuracy of the protractor using a building level (you need one that has a spirit level).

Usage

If everything is done strictly according to the instructions, then such a homemade protractor will have a maximum error of only 1-2 degrees, no more. To measure the angle you will need:

- Stand on a flat surface;

- Raise the structure to chest level, turn on the laser pointer;

- Point the laser point at the plane from which the angle is measured (preferably it should be a flat plane perpendicular to the ground);

- Fix the position of the protractor and thread;

- Look at the mark on the protractor that the pendulum thread points to.

Please note that you will need to subtract 90° from the indicated mark on the protractor. Naturally, such a homemade product will not replace a full-fledged building level, but in critical cases it will be enough to take measurements.

Tool structure

Most often, a goniometer is used in carpentry, but it can also be found in other areas of repair and interior decoration. Externally, the device is similar to, however, the small sample has a moving part, thanks to which you can conveniently take readings.

The tool in question has the following components:

- Block with slot. This is the main part of the protractor, which allows you to find out the inclination of the angle.

- Movable pen. It is threaded through a groove in the block: this saves space and makes the device more convenient to use.

- A wing that serves to secure the tool.

You can find both metal and wooden devices on sale. The wooden version is safer for surfaces and does not leave scratches.

Malka is a goniometer that can do a lot

Let's immediately look at the tasks for which this measuring device is intended. As a rule, the main purpose of such a device is to measure the degrees of an existing angle and subsequently transfer it to a workpiece or a precision measuring device. It is especially convenient and useful when installing window sills: having measured the exact angle of the slope, you can easily transfer the markings to the workpiece and quite accurately cut the corners, and carry out further installation.

Also used to calculate the “dawn angle” when installing window slopes. Initially, the device was used for working with wood, but later migrated to other areas of construction work. Visually, this tool is very similar to a regular bench square with a right angle. But by its specificity, the malka is a protractor, and in order to be able to measure angles, the instrument has a moving part, which directly determines the given angle, both acute and unfolded.

- The block is the basis of the entire tool. On a regular square, this is its lower part; on both tools, the block performs the same role. Only on the small block the block has a slot into which the other part of the tool is hidden.

- The pen is the moving part of the instrument. The groove in the block allows the tool to be folded, so it takes up very little space and is convenient for the master to use.

- The fastening element is usually made in the form of a wing nut. Allows you to fix the moving part and make precise dimensions.

It is worth noting that this measuring device can be made in either a wooden or metal version. A wooden clapper is usually used where there is a fear of damaging the surface; the wood does not leave scratches during measurements.

Types of goniometers by method of application

Goniometers were invented quite a long time ago, but now this measuring tool continues to be popular. For different areas of use, appropriate measuring instruments are produced. Let’s find out in detail what they are and how they differ.

- Construction is the most common type of measuring tool that every craftsman must have. The device is intended for monitoring walls, foundations, ceilings, etc. The main feature of this meter is that its parts are at least 50 cm long, which ensures high accuracy of readings

- Carpenter's - used by carpenters in the manufacture of woodworking structures. A carpenter's goniometer is also called a small goniometer, and it is approximate, as it has low measurement accuracy. The main distinguishing feature of a small scale from a protractor is that one part has a graduated scale, and the second is a support leg

- Metalworking - compared to carpentry, it is distinguished by high measurement accuracy. In plumbing, high precision is important, so protractors have a sensitive adjustment mechanism that provides measurements down to the smallest fraction of degrees

- Mountain - in design it has little in common with previous options, but is also intended for measuring angles. It is used to visually determine vertical and horizontal angles in mountainous areas. Such instruments are used today only by amateurs, as they have been replaced by more accurate instruments

- Medical - few people know that medicine also uses a measuring device such as a protractor. The medical meter is used in medicine to determine the operating angles of large, medium and small joints. It looks like a circle with a graduated scale on which the amplitude of movements is analyzed

- Astronomical - has nothing in common in design with all the presented types of inclinometers. This type of instrument is the most accurate, and it is intended directly to calculate the trajectory of the stars in the sky, as well as their speed and size. Typically used in conjunction with telescopes

- Seaworthy - has an individual design, and is intended to identify the geographical coordinates of the vessel’s location. Today, such devices are not used by sailors, as they have been replaced by modern satellite devices. Only every ship must have such a device, which can be used in case of failure of electronic systems

- Artillery or military - serves to install an artillery gun, as well as adjust salvo fire. Today, devices are also practically not used

- Protractor for tightening bolts - a special device that allows you to ensure that bolts are screwed to the required angle of rotation

These are the main, but not the only types of protractors found on the planet. If construction work is being carried out around the house, then the craftsman will definitely need to buy a special protractor. What they are based on the method of measurement is described in detail below.

Application

As already noted, goniometer devices have found their application in almost all sectors, industry, and transport.

In the construction industry, goniometers are used when performing installation work, marking and design work. With its help, they control the installation of building structures that are located at a certain angle relative to each other. Moreover, measurements can be carried out in three planes. In addition to the goniometer, plumb lines and levels are used in construction.

In addition, goniometric tools are used in carpentry, carpentry, and geodesy. Even in medicine, this instrument is used to control joints, spine, etc.

What is an analog micrometer and how does it measure?

An analog micrometer is also called a mechanical micrometer, as it has a simple operating principle and design. Based on the simplicity of the design, the device is durable, which is why even today you can often find devices produced back in Soviet times. A mechanical micrometer is resistant to physical impact, and to all the advantages, you can add a relatively low cost, which ranges from 400-500 rubles, depending on the model.

This is interesting!

On all types of micrometers, the clamps are different, and are presented in the form of a lever switch or a moving washer. Both clamping options are reliable, but the main disadvantage of washer devices is that they are not visible when the clamp is engaged.

Making malka yourself

We cut a blank from the board up to 20 cm in width, and calculate the length - a value equal to the depth of the slope plus up to 15 cm, so that it is comfortable for your hand to hold it.

Top view of the slope

To allow the tool to slide freely along the window or door frame, we make a cutout in the workpiece equal to the width corresponding to the dimensions of the door frame or window frame.

In order for the fry to move easily along this guide, you also need a hole through which the loops will “pass.” It is made round in the corner of a cutout made in a board or plywood. The diameter should be slightly larger than that of the loops so that the fry does not touch the loops when moving.

Many people simplify production - instead of all the cutouts, they drive a nail into the end part (then the workpiece should be a little thicker). To prevent it from scratching the surface on which it will move, bite off the cap and wrap it with electrical tape.

In both options, one end of the block with a cutout or nail moves along the window frame, and the opposite side moves along pre-nailed slats, like guides.

Homemade tool rocks the internet

This video shook up the community of invention lovers on the world wide web. The master thought about this idea for years and finally brought to the public discussion an idea that was ingenious in its simplicity and radically profitable for those who used to chisel walls with a hammer drill, realize their inclinations as a woodpecker and a brilliant builder-grinder, and now can make themselves rich for free, working in silence a workshop in a garage or even in a separate building.

And at the same time, you don’t have to spend money and take money saved for beer out of your stash. All this is free - the master loves to show the whole world the useful things he comes up with.

How to use malka - step-by-step diagram

Step 1: Preparing the walls and window opening

All walls of the room in which you plan to make slopes must be completely plastered. As a rule, the plaster ends at window openings. The slopes themselves must be prepared, cleaned of dust and treated with soil. Also, if the window was installed using polyurethane foam, the protruding excess must first be removed with a knife.

Step 2: Select the “dawn angle”

Now we need, first of all, to decide on the angle at which it will be carried out. To do this, we install the block along the edge of the window frame and, by moving the pen, determine the angle along the edge of the window opening from the wall side. We record the result obtained on the small scale and check the compliance along the perimeter of the window opening. If, when checking, the selected angle does not coincide with the selected value, it is necessary to cut the plaster from the side of the wall or change the angle on the grinder.

Step 3: Leveling the slope angle

Usually, on a window opening, the plaster ends up in a chaotic manner; even corners are created when working with slopes. In order to make ideal slope angles, you just need to install the rail on the wall along the edge of the slopes around the perimeter of the window. To do this, we use a small tool to determine where the edge of the slats will be located, and fasten it with self-tapping screws or ordinary nails to the wall. Don’t forget to check the rail vertically with a building level; it must be strictly level.

Step 4: Apply the solution, set the angle

When the slats are installed on the corners of the slopes, we begin to apply the plaster mixture. To do this, apply the solution to the slope with a trowel at an angle, preferably with a slight excess. After sanding, remove excess plaster mixture and set the slope to the direction of the angle. In this case, install the block on the window frame, exactly as we did during measurements, and slide the block along the frame from bottom to top. At the same time, the pen will remove excess and level the working surface. If after the work done there are holes on the slope, add mortar and again remove the excess with chalk.

Malka is a convenient carpentry tool. The small scale is used to measure and move any angles.

It is convenient to use when laying laminate, parquet, partially tiles, etc. The mould consists of two elements connected to each other with a bolt and nut. The bolt and nut are tightened a little so that the small can folds and unfolds while remaining in the desired position.

How to use an adjustable grinder - step-by-step instructions

The adjustable screed is used in various areas of construction for entrusting corners. For example, it is used when creating slopes for doors, windows, or when it is necessary to cut off any part, including when covering the floor with tiles or laminate.

Instructions for using the tool:

Work continues the next day, when the solution dries. Use a plaster float. They use it almost like a small one.

The difference lies in the ability to scrape the plaster to zero; a float cannot measure the corners.

Having treated the slopes properly, they achieve their smoothness and aesthetic appeal. Malka allows you to avoid installing beacons and reduce the time spent on repairs.

Source

Design and purpose of the fry

The usual, simplest malka consists of two elements:

- pads - a fairly wide block with a slot;

- feather - a thin strip, which, when assembled, hides in the slot of the block.

These elements are connected to each other by a screw pair. The design of the screw pair can be completely different, but there are two fundamental differences: the screw can be protruding, and then, most often, instead of a regular nut, a wing is used to conveniently fix the relative position of the block and the feather, or it can be recessed.

The latter option is more convenient for installing the bait in the right place, but is less practical for fixing given angles and, as a rule, is more technically complex.

Sometimes, but rarely, on the feather, and even less often, on the last, dimensional marks are applied. But the malka is not a measuring tool, but a marking tool. Its task is to fix the size and transfer it to the workpiece, or to workpieces, when replicating identical products. Although, the desire of many manufacturers for universal unification has led to the creation of digital cameras equipped with liquid crystal displays. With memory, zeroing the result in a given position and other attributes of modern digital instruments, but such devices only have a common design, and functionally they are, rather, protractors.

Digital fry

They try to build everything into the small machine - even a bubble of a level, which generally does not fit well with the list of basic work performed with the help of the small machine.

Malka-9

Malka-5

Malka digital

Mechanical improvements are also trying to catch up with digital sophistications, supposedly expanding the functionality of the tool.

Malka-2

Malka-3

Malka-7

Malka-8

In our opinion, of all this abundance of technical solutions, more or less useful is the device of a groove in the feather, which allows you to vary its length, which in rare cases, but still, can be useful. And we will confirm our, for many ambiguous, conclusions with examples of work where malka is truly irreplaceable.

Purpose of the goniometer and main tasks

The tool in question can be found in carpentry shops and workshops, where it is simply impossible to do without a protractor. When finishing premises, this tool is used by specialists who know that without it it is impossible to measure an indirect angle with maximum accuracy.

A mill or protractor is a device that makes it possible to determine and fix oblique angles and transfer them to the required workpiece. In construction, the adjustable bevel is used when installing window slopes, window sills, and door slopes. Not every builder knows why a piece of wood is needed, which was confirmed by experiments conducted among vocational school students with a degree in carpentry.

Goniometers come in metal and wood, and even plastic. Wooden markers are more popular because they do not damage the surface of the products being measured. Metal baits are mainly manufactured with a length of 300 mm and with a built-in digital display. Plastic products are the cheapest, as they are less resistant to physical impact than the first two types.

Such tools are called digital, and they are used mainly by professionals, where maximum accuracy is important when carrying out work. The instruments under consideration, despite the material used to make them, consist of the following elements:

Digital protractors are extremely accurate, but they have a significant drawback - their high cost. Analogues of digital instruments are protractor minis. These are instruments that are designed with a conventional protractor.

Tool

For any task you need a tool. Plastering window slopes is no exception. The set of tools will depend on what materials you use.

In any case, you will need:

- good level;

- aluminum rule;

- pencil;

- fry;

- roulette;

- spatula 5 cm;

- plywood or metal block;

- Master OK;

- solution container;

- water container;

- hammer-pick.

A level that is too long will not work. It may simply not fit between the lintel and the window sill. At the same time, it is inconvenient to work short. Choose the golden mean, it will be a level 1 meter long. For auxiliary work, a gun with sealant and a knife will be useful.

You may also need a can of polyurethane foam to “blow out” the gaps between the window frame and the opening in which it is installed.

If you use cement-based, you need to get a grater and a grater. If using a rotband, a large and small trowel, as well as a 45 cm spatula and a sponge grater.

Overalls and work shoes should be comfortable and not interfere with movement. Since the plasterer's hands are in direct contact with the solution, it is best to get sealed nitrile gloves.

If you have seriously decided to master such a thing as the technology of plastering slopes, borrow or independently put together a normal plaster goat from boards. The work will be more fun, and it will be safer. Plastering from a stepladder or stool is a bad idea. It's very inconvenient and takes about twice as long.

Construction goat

How to make malka at home?

Of course, today all the necessary tools, in our case a small tool, can be bought at a hardware store. But sometimes situations arise when a device is needed now, and there is no time for it, or the necessary tool is simply not available for sale. Let's try to figure out how to make malka with your own hands from available materials. And here is what materials we need for these purposes:

- Wooden beam measuring 20 by 30 mm. We will make a block from it.

- Plywood with a thickness of 3 to 5 mm, it will be the moving part of the tool, the pen.

- Fastening element in the form of a nut and bolt.

- Electric drill and drill bit that matches the diameter of the fastener.

Having prepared all the components of the future instrument, you can begin assembling it. First of all, let's start making the pads. We measure 10 centimeters from the wooden block, more is possible, but you should not exceed the length of 15 centimeters. Use a hacksaw to cut the desired size of the future block. The next step in making the tool will be making a slot for the pen. To do this, make a cut on one side of the end base of the block, and for now put the block aside.

Now let's move on to making a feather, which can be cut from plywood or other suitable material. Let us mark on the plywood the future dimensions of the element, the width of the feather is 20-30 mm, the length can reach 300-400 mm. Advice! All dimensions given in this example can be changed at your own discretion. In the process of making a small tool, you can increase the length of the block and feather, the main thing is that it is convenient for you to work with the tool you have made. The feather is ready, and now it can be more accurately adjusted in the block.

Check the cut at the end of the block again; the feather should form an acute angle when you try to fold the tool, although, of course, this is not necessary in all cases. When everything is ready, you need to install the fasteners in place; to do this, align the parts at an angle of 90 degrees and drill a hole through with a drill. Then insert the bolt and clamp the parts together with a nut. Theoretically, our tool is ready, all that remains is to modify the pen a little. Move it in the block, and further process the protruding corners. The excess should be removed and the cut areas treated with sandpaper.

Malka is a tool that will help you measure the desired angle

If this is your first time encountering a new device, you cannot avoid the question: what is it and how to use it? As already mentioned, this device helps to measure angles, and let's take an angle of forty-five degrees as an example. We take such numbers for a reason, but mean cutting wood at the most popular angle. You can also choose any other value that interests you. Technically, a malka is a tool that can measure an angle from zero to one hundred and eighty degrees. So, let's start taking measurements.

- To begin with, we can find the angle we need already in the finished version and take measurements. You can also use a special device to set the angle to the degree you need.

- Next, fix the result obtained with a fastening bolt, preferably as firmly as possible.

- Afterwards, we apply the resulting angle to the part and draw a line with a pencil.

- Using a wood hacksaw or electric jigsaw, cut the corner according to the markings.

What is malka needed for?

When carrying out construction work, a malka is very rarely needed, but it really helps out at the right moments. Using low speed increases, the quality of work performed improves. Let's assume that we are laying laminate or parquet boards diagonally. We draw a line on the floor and select the angle (diagonal) we need. We apply the malt to the line, lay it out, pressing it against the wall.

We transfer the corner to the laminate and cut it off. After collecting a small section of the floor, apply the mortar directly to the finished part of the floor and measure the angle. Trimming the first row of tiles above a bathtub or above the floor may also be necessary. It often happens that a bathtub installed on a level has its drawbacks. You have to adjust the bottom of the tile by cutting it off. But after adjustment, the gap between the bathtub and the tile increases. To avoid this, we need to cut the bottom of the tile correctly the first time. The powder is applied to the side of the glued tiles and the bathtub. We transfer the line to the next tile and cut it off.