Many gardeners grow grapes to make homemade wine. The berry processing operation includes: extracting juice and separating the pulp. You can crush and crush the berries manually (for small volumes) or in a press. More zealous gardeners use specialized crushers for these purposes. You can buy them factory-made or build them yourself. For self-production, it is necessary, at first, to study the types of structures and the basic functioning of the mechanism.

Varieties

All units are divided into mechanical (manual drive) and electrical (electric drive). Mechanical and electric presses may have completely different operating principles. The difference lies only in the absence or presence of an electric drive. Any type of grape crusher has a number of positive qualities and disadvantages. Winemakers choose a device taking into account the volume of processing and the required productivity.

With destemmer

A device equipped with a comb separator is a mechanism that not only crushes the berries, but also frees them from the stalks (ridges). This device has a simple structure. Grapes are placed in the tray, and an auxiliary roller is used to separate the berries and stalks. After this, the grapes are crushed using two crushing rollers placed on opposite edges. The pulp ends up in a special department. Mechanisms with a stalk separator are centrifugal-impact and roller.

Important. The use of a crusher with a manual destemmer is not practiced for Muscat table grape varieties. These grapes are harvested when the fruits are slightly withered and it is no longer possible to separate them from the stalks.

Without destemmer

In terms of their design, units equipped with a ridge separator and those without one do not have any significant differences, with the exception of the absence of ridges and the functionality of separating fruits from the cluster. The procedure for processing raw materials is implemented more slowly due to the fact that the grapes require advance preparation - separating the grapes from the scallops.

Mechanical

Mechanical presses are available for sale in two loading methods: horizontal and vertical. In most cases, this applies to centrifugal type devices. This type of crusher operates through a centrifugal (tangential) force, with the help of which the grapes hit the inside of the hopper with force. In this case, the fruits are not only perfectly crushed into small parts, but also saturated with oxygen.

Mechanisms of this type are used to make red wines. Because a satisfying yield of wine material with an increased amount of tanning and coloring compounds is obtained. This device, simultaneously with the fragmentation of the fruits, separates them from the stalks. The design of the unit includes: a housing equipped with a power-driven lid, a shaft with blades, a receiving hopper and a tray along which the ridges are removed.

Electrically driven

This design is equipped with two handles that activate the shafts and the ridge separator, squeezing out the juice. It is not difficult to modify the equipment by connecting both mechanisms into a complete manual or electrical control (installation of an electric drive).

Valkovaya

Crushers of this type are intended for separating grapes from the ridges with further crushing of the raw material. The structure of the roller crusher includes: a punching shaft, a perforated (with holes placed in a certain order) cylinder and 4 rolls made of food-grade rubber, which function in pairs. The operating principle of the crusher is as follows:

- the berries enter a device where, under the influence of beating shafts, the scallops are separated from the grapes and removed from the perforated cylinder;

- then the grapes fall through the perforations onto the shafts, through which crushing is carried out.

The crusher is equipped with auxiliary devices that adjust the distance between the rolls within 3–8 millimeters. This allows, if necessary, to apply gentle pressure on the berries, depending on their quality characteristics and variety.

Manual

If the harvest is small, then any crusher can be replaced with a manual device. To do this, you need to purchase a whisk for construction mixers. The use of a whisk made on the basis of metal rods will productively and freely crush grape berries, but at the same time it will not grind the seeds.

To crush grapes in a similar way, pour a small amount of berries into a container and beat with a whisk. In 2-3 minutes the pulp will be ready. Another good thing about using this crushing method is that after crushing it, you can safely remove the separated scallops. The finished pulp is poured into another container and left to ferment.

How to make a crusher with your own hands

Today in stores there is a wide selection of devices for processing the resulting grape harvest, in particular, a mechanical crusher for grapes DV-3. However, if for some reason you are not suitable or not satisfied with the existing assortment, you can take on making such a device yourself. A grape crusher is a simple device from a technical point of view.

Creating such a unit will not take much time and will not require significant financial investments. At the same time, the performance of a homemade crushing device is not a bit worse than the factory equipment.

The stages of creating the simplest design are as follows.

- Make a drawing of the device or use a ready-made one as a basis.

- Install a receiving hopper for filling raw materials. The configuration of the bunker is similar to an inverted truncated pyramid. The optimal material for its creation is hardwood (for example, oak). It is also possible to use stainless steel and plastic.

- A blade shaft (from 4 to 6 blades) is mounted along the lower section of the receiving hopper. To create it, you need to take a tube (30-40 millimeters in diameter) and stainless steel plates (15-20 centimeters in length, 8-10 centimeters in width). The plates must be welded to the tube in a checkerboard pattern (alternating the sides of the mating elements every now and then).

- We insert the blade shaft into the holes located in the lower segment of the receiving hopper.

- We fix the net in the lower section of the receiving hopper. Its diameter should correspond to the size of the grapes being processed. You can prepare at once a certain number of elements from steel mesh with different cell sizes and replace them taking into account the type of grapes used.

- The shaft is driven by a handle. To do this, you need to bend the rod (at least 10-12 millimeters thick), giving it the shape of a broken line. One edge of the handle is fixed to the shaft.

- The basis of the device is the frame. It must be put together from wooden parts in dimensions that slightly overlap the dimensions of the lower section of the bunker. It should be at least 15 centimeters in height.

- 2 shafts are attached to the frame with a distance between them of 2-3 millimeters. In order for the shafts to rotate towards each other, pulling the fruit inward, 2 gears are required. They can be taken from any mechanical device or ordered from a workshop that carries out turning work. It is especially important that the parts are of the same type. Gears are mounted on shafts from the outside of the frame.

- It is worth placing a handle on one of the shafts.

As a result, the most simple crushing device for processing grapes is ready for use. Whether to buy a factory crusher for grapes or make a simple device with your own hands is up to everyone to decide at their own discretion.

In any case, this simple technique will facilitate and speed up the procedure for preparing the initial wine product.

To learn about the types and rules for using a grape crusher, see the following video.

Home winemaking is a complex, time-consuming, but at the same time interesting and exciting activity. Those who deal with large volumes of crops resort to using various devices to make their work easier and speed up the process. The material contains information about grape crushers (pressers).

Purpose and principle of operation of the crusher

Crushers are designed to process grapes and obtain a mixture from which wine is subsequently made. These devices are widely used in industrial production and at home in the production of wine products. They can be purchased ready-made or made independently using drawings and diagrams.

Among the components of the crusher:

- loading compartment (hopper);

- parallel rollers that crush the grapes;

- compartment for collecting pulp.

Did you know?

The oldest winery known today was found in Armenia.

It is dated to 4100–4000. BC e. The operating principle of the unit is simple:

- Grapes are loaded into the loading compartment.

- The crushing rollers begin to move using a mechanical or electric drive.

- As a result, the pulp with juice is released from under the skin, and pulp is obtained, which is collected in a special compartment.

There is a gap between the crushing rollers, thanks to which the berries are crushed and the seeds remain intact.

This is important because when crushed they will add bitterness to the drink. As a result of the operation of the unit, it is possible to achieve the following results:

- separate the juice from the pulp;

- clean the pulp from vines and seeds;

- separate other parts of the plant (if necessary).

Types of crushers for grapes

Today there are several types of devices for crushing grapes. They can be manual or electric, with or without a comb separator. They are made of wood, plastic, stainless steel. The principle of their operation is almost the same. Let's take a closer look at each of the varieties.

With and without comb separator

Thanks to the grape ridges, the wine acquires a rich and tart taste. However, if there are too many of them, it will spoil the quality of the drink - it can become bitter, unattractive in color, and cloudy. If you are working with varieties from which red wine is made, then you can leave the ridges. However, when producing a white drink, this is unacceptable: the ridges must be removed. Accordingly, when choosing a device for obtaining pulp, it is necessary to take this point into account and choose designs depending on the variety of grapes to be worked with and the type of wine. Devices with a comb separator come in 2 types:

- Roller.

- Impact centrifugal.

Did you know?

Jugs containing sediment left from grape wine have been discovered in Iran. They date back to 5400–5000 BC. BC e. It is known that in those days the drink was prepared to preserve perishable varieties. It is unknown whether it was used in ancient times for intoxication.

Roll crushers

This type of device has two or more parallel grooved, smooth or bladed rolls with four, six or eight blades. The distance between them can be adjusted. They rotate in different directions. This variety is the most popular among winemakers.

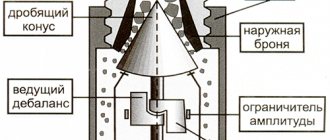

Centrifugal impact crushers

Pressers belonging to this variety are made vertical and horizontal. The principle of operation is that crushing of grapes and separation of ridges is carried out due to impacts during rotation of the rotor. With the help of such devices, it is possible to achieve maximum pulp purification from foreign impurities.

Mechanical crushers

A mechanical or manual device for crushing grapes has a handle. With its help, the crushing rollers begin to move. Such a unit should be selected if the volume of processed products does not exceed 500–700 kg. The most popular designs are made of stainless steel, as they can be easily disassembled and washed.

They can serve for a long time and do not impart any foreign odors to wine products. At home, wooden mechanical structures are often used. The easiest way to make them is with your own hands.

Electrical

When using electric units, the process of obtaining wort occurs through the operation of a metal blade in the form of a screw or rotor. When it moves, the bunches are pushed out, and the pulp enters a special compartment. The productivity of such devices can vary from 1200 to 2300 kg/h.

Manufacturing materials

Grape juice is chemically reactive. For the manufacture of crushers, materials are selected that are resistant to long-term exposure to phenolic and other compounds contained in processed berry raw materials.

Suitable:

- chemical inert polymers;

- natural wood;

- durable organic glass;

- metal alloys with anti-corrosion properties or appropriate coating.

Wood is considered the most environmentally friendly material. Its disadvantage is the need for thorough washing and disinfection after each procedure for chopping grapes. This material is distinguished by high mechanical strength. Wood quickly deteriorates when exposed to moisture. The material is susceptible to infection by bacteria and infestation by insect pests.

Wood is resistant to long-term or constant mechanical loads and is relatively easy to process in the manufacture of grape crusher structures. The material has high viscosity and wear resistance. Another suitable option for making a grape crusher is metal alloys.

Use:

- stainless steel;

- duralumin;

- galvanized copper for the body;

- cast iron.

The latter option is the least preferable due to its heavy weight and complexity of machining. Stainless steel is distinguished by endurance, colossal durability, and hygiene. Metal alloys are easy to clean and do not transfer foreign odors and tastes to the berry product. Crushers are often made from composite materials by combining plastic, alloy and organic glass or wood.

The most expensive option is a home grape press with ceramic rollers. This material is distinguished by absolute chemical inertness, high strength, and resistance to long-term mechanical loads.

How to make a hand press with your own hands

It is possible to make a mechanical wood crusher yourself. It is advisable to resort to this process if the volumes of processed grapes are small, or when a person makes wine only for the purpose of personal consumption.

Important!

If there are no oak boards on the farm, the bunker can be made of stainless steel or plastic.

The following materials will be required:

- oak wooden boards;

- wooden beam (section 0.5×0.5 cm);

- rollers for crushing (suitable for a broken activator-type washing machine, used for spinning things, from rolling pins for rolling out dough, purchased in a store) - 2 pcs.;

- metal pins - 2 pcs.;

- metal gears - 2 pcs.;

- stainless steel mesh with cells measuring 10–12 mm;

- shaft with blades;

- colorless wood varnish;

- handle for rotation;

- pulp receiver.

Step-by-step manufacturing instructions are as follows:

Video: the process of making a separator comb for a grape crusher

So, a grape crusher can significantly speed up and simplify the process of producing raw materials for grape wine.

Important!

The materials from which a homemade grape crusher is made must be resistant to oxidation, since the juice is highly acidic.

It is easy to use, and can be purchased ready-made or made with your own hands, using drawings and recommendations.

A grape crusher is an indispensable tool for a winegrower. It allows you to quickly and efficiently chop the berries and separate them from the ridges. With this method, the grape seeds are practically not damaged. This is very important because they contain tannins that significantly worsen the taste of the future wine. Making a homemade grape crusher is not difficult, and you can use a variety of materials for this.

Installation of crusher with destemmer

This grape crusher has a ridge separation mechanism, which is mounted below the rollers. It is a semi-cylinder made of stainless mesh with 15x15 mm cells.

The shaft is made from birch cuttings. The blades are made from a plate 0.8-1.5 mm thick (stainless steel). They are attached to the shaft with copper or brass screws. Installed so that when rotating, movement occurs in the horizontal plane.

A half-cylinder is bent from a stainless mesh. The distance between the blades and the wall is left no more than 5 mm.

The crushed berries fall through the cells, and the ridges are moved for unloading.

Grape crusher - why is it needed?

A bunch of grapes consists of berries, they are attached to a kind of skeleton of twigs, which is called a ridge. Separating the berries from the ridge manually would require a lot of time, which is absolutely unacceptable for winemakers when harvesting. It is to speed up the process that devices called crushers are designed. They perform two functions:

- 1. They destroy the integrity of the berry, which accelerates the loss of juice and fermentation.

- 2. Separate the berries from the ridges.

Iron, plastic and wood are used to make crushers. The latter material is most preferable as the most environmentally friendly. According to the type of drive, the crushers are:

- manual;

- electric.

It is more expedient to use crushers with an electric drive when processing large volumes of berries. If the harvest is small, a manual “mill” will be enough.

Advantages of using the device

Advantages of producing pulp with an automatic crusher:

The simplest wooden model can be assembled with your own hands. It will become a handy tool for owners of small vineyards.

Devices made of wood and stainless steel are popular. They are not subject to oxidation and corrosion. This ensures long-lasting use as the juice is highly acidic.

The only drawback is the inability to use certain types of units for processing nutmeg varieties.

Shaft crusher - step-by-step manufacturing instructions

A device of this type is most preferable for self-production. For this you will need:

- Oak bars 50x50 for making the frame.

- Oak boards, plywood, sheet iron or plastic for making a bunker.

- Wooden rollers - 2 pcs.

- Gears, identical in size - 2 pcs.

- Lever.

- Tank for collecting pulp.

First you need to assemble a frame from oak bars into which the rollers will be installed. The length of the frame depends on the diameter of the pulp collection tank on which such a pulper will be installed. The width of the inside of the frame should be slightly larger than the length of the bolsters.

Wooden ribbed rollers are attached inside the frame at a distance of 2–3 mm from each other, the shape of which is shown in the drawing above. Gears are installed on their axles outside. You can make rollers yourself from round-shaped blanks, such as rolling pins. One option is to use old rollers for spinning clothes from an activator-type washing machine. They need to drill six rows of holes with a diameter of 10 mm to a depth of 5 mm.

A handle is attached to one of the shafts, which sets the rollers in motion. Then a receiving hopper is installed on top. It can be made from any materials. It is made in the form of an inverse truncated pyramid. Now all that remains is to install the crusher on the pulp collection container. You need to rotate the handle in such a way that the rollers rotate towards each other, pulling the berries into the space between them and pressing them like a press.

After the homemade crushing apparatus has been assembled and tested, you can begin to improve it. For example, equip the shafts with an electric drive. To do this, you need to install a pulley instead of a handle, and use an electric motor with a belt drive to rotate it. You can connect a drill or screwdriver as a motor.

To separate the ridges, you can install an additional device called a comb separator. It is a mesh that is installed on top of the rollers. A screw mechanism is mounted above it, which is activated by rotating the roller drive handle.

After the grape harvest, many farmers begin the process of making wine. Home winemaking is a very complex and time-consuming process, but the result is worth the time and effort. Experienced winemakers who process a large amount of harvest per season know that they cannot do without special equipment for crushing grapes; in particular, they will need a grape crusher with a destemmer.

Budget crusher-stemmer for grapes.

Last ed. 31 Aug. 15, 15:43 from Kalevanych

But there is one caveat: 50% of the separated berries remain uncrushed. Kalevanych, 30 Aug. 15, 21:31

what if the mesh is smaller? Alex52, 31 Aug. 15, 20:41

Yura, what if the mesh is smaller? Alex52, Aug 30 15, 22:41

Since there was no free barrel, I had to make a stand for the crusher. Well, it turned out to be even more convenient, take the pan and carry it anywhere. Today I crushed table grapes “Nadezhda AZOS”, they are not good for food, just grass, and the wine is mediocre, I’ll try to make port from it this year. Its berries are 1.5-2 cm, and the lattice on the deck is 1x3 cm. It took one and a half times more time to crush, the clusters are too long, up to 30 cm, and accordingly the ridges are long, and it took longer to twist, but still only 1-2 berries They remained on some ridges and had to be torn off manually. But the berries are crushed 100%, not a single whole berry. It took 30 minutes for 100 kg of time; it would have taken half a day to do this manually. This means that for technical grapes you need to look for a finer mesh, so that the mesh is 6-7 mm, so that the berries do not fall through freely.

Hobby_189. Budget crusher-stemmer for grapes. Questions from winemakers.

Last ed. 04 Sep. 15, 20:08 from Kalevanych

In order not to create a new topic, I will post my very budget comb separator. The bunch is separated from the berries in seconds. A two-bucket tank fills up in 15-20 minutes without effort. My 10-year-old daughter does this for joy.

Last ed. 26 Sep. 15, 20:34 from CAMOBAP

How can I look at your comb separator? Kalevanych, 26 Sep. 15, 14:27

Do you simply grind the grapes through this sieve (or I don’t know what to call it correctly)? Bors, 26 Sep. 15, 20:41

Technical varieties with dense, packed bunches cannot be grated on such a grater Kalevanych, 26 Sep. 15, 23:36

Added after 3 hours. 42min:

Last ed. 27 Sep. 15, 13:33 from CAMOBAP

The main thing, of course, is for the wine to turn out, and not to measure against pussies with destemmers! CAMOBAP, 27 Sep. 15, 09:51

I ground it with a drill in 5-10 minutes. Launched CHKD. Standing there, she began to wander.

Well, yes, there is a little bit. It’s impossible to shovel a ton by hand, and there are remnants of ridges even on the factory comb separator. Kalevanych, 27 Sep. 15, 14:40

In order not to create a new topic, I will post my very budget comb separator. The bunch is separated from the berries in seconds. A two-bucket tank fills up in 15-20 minutes without effort. CAMOBAP, 19 Sep. 15, 23:22

I didn't understand something Andor, 04 Nov. 15, 11:01

Source

Working principle and application

Let's first figure out what a mechanical crusher for grapes is, and what a destemmer for grapes is.

So, a grape crusher with destemmer is a special device used to separate grapes from the stems. The device has a simple operating mechanism: such a crusher consists of a loading tank, a compartment for accumulating cake and a grinder in the form of two crushing rollers, which are located opposite each other.

Why is it necessary to separate the berries from the ridges, you ask? At the time of harvest, the ridges are still green; if they are not removed, acid and tannins will enter the grape juice, which negatively affects the taste of the wine.

A mechanical or manual crusher is widely used both in home winemaking and in the production of wine on an industrial scale. However, for processing large batches of grapes, it is better to use an electric crusher, the power of which allows you to process a large amount of the harvested crop in a short period of time.

How does this miracle device work? Grapes are poured into the loading container, which are literally crushed by crushing rollers. We draw your attention to a small but very important detail: there should be a small gap between the rollers so that the grape seeds remain intact. If the rollers are so close that the seeds rub together, the wine can be considered spoiled. Tannins, which are present in grape seeds, give the drink bitterness, viscosity and strength.

Advantages and disadvantages

To assess the need and usefulness of a grape crusher, it is recommended to familiarize yourself with the advantageous qualities of the equipment:

• obtaining high-quality pulp that does not contain a large amount of components foreign to the product;

• rational use of energy and time;

• simple and durable design, which can be improved endlessly;

• the possibility of using improvised means when assembling the crusher;

• the use of stainless steel sheet material for assembling the unit reliably protects against the formation of rust during operation, and also prevents the formation of foreign odors in the juice.

The equipment does not have any significant drawbacks, except that it is not possible to use units with a destemming machine to obtain pulp from nutmeg varieties.

Types of crushers

Modern stores offer a wide range of crushers for processing harvested crops from vineyards. Crushing devices existing today can be classified according to several characteristics:

- type of control (mechanical/manual and electrical);

- material of manufacture (wood, plastic and metal);

- type of loading (horizontal and vertical);

- with or without comb separation.

There are two types of crusher-stemmers for grape processing: roller crushers and centrifugal impact crushers.

However, if for some reason the existing range is not suitable for you or you do not like it, you can try to make such a device yourself. A do-it-yourself grape crusher is a simple design from a technological point of view. The production of such a device does not take much time and does not require serious investment. At the same time, the effectiveness of a homemade crushing unit is no worse than factory equipment.

Device Features

You can make a grape crusher with your own hands according to several schemes.

Important! For production, materials are used that do not enter into chemical reactions with juice: stainless steel, plastic, glass or wood.

After completing the processing of a certain amount of fruit and berry raw materials, the installations are washed with alkaline solutions and then rinsed with clean water.

Desaleters

An important option for a mechanical device is a destemmer. It separates the ridges (tassels) from the berries. The principle of operation is that the size of the branches significantly exceeds the flow area of the perforation holes.

Required materials and tools

The success of any business depends on the degree of preparation of the “master”. Before you start making a homemade crushing unit, you need to find drawings of such a device on the Internet or draw yourself.

The next stage is preparing the necessary tools and materials. It is best to take a complete set of tools so that you don’t waste time looking for a hammer or screwdriver.

So, what materials do we need to make a crusher? Based on the notes of those winemakers who have already made similar devices with their own hands, we need to prepare:

- oak boards for the loading hopper (you can also use plastic or stainless steel);

- rollers – 2 pcs.;

- gears of the same size - 2 pcs.;

- beams with a section of 50x50 mm for a wooden frame;

- lever;

- pulp reservoir.

Operating rules

The first launch of a self-made unit is carried out in test mode in order to check the performance, reliability of the assembly, and the quality of processing of the berry product. If necessary, increase or decrease the gaps. After checking, the results are analyzed. Weigh the separated ridges and finished raw materials. The sum of both masses is compared with the weight of the original product. This allows you to determine the level of losses during processing.

A high-quality homemade mechanism should ensure a reduction in volume by no more than 1-2% of the original volume of raw materials. The number of branch fragments in the useful mass is analyzed. It should be no more than 1% of the total mass.

The operating rules for the crusher provide for periodic disassembly and cleaning of the unit. This possibility is included at the design stage of a device for crushing grapes. You can make your own unit with two-level rollers, which will significantly increase the efficiency of processing the berry product.

Step-by-step instruction

All the necessary materials have been purchased and prepared, a set of tools is at hand - you can get to work. Don't forget to take the drawing you made earlier, which will be easier to navigate. So let's get started:

- We make a loading hopper from oak boards, which is shaped like an inverted truncated pyramid.

- We take a roller and draw 6 longitudinal lines on it. Along the length of each line we drill holes with a diameter of 10 mm and a depth of 50 mm. The distances between the holes should be about 50 mm. We repeat a similar procedure with the second roller.

- We make a wooden frame from the beams, in the center of which we attach the rollers. Don't forget to leave a gap of 2-3 mm between the rollers.

- On the outside of the frame we install the gears on the gear shafts.

- We assemble the entire structure. On the reservoir for collecting pulp we fix a frame with rollers, on which we install a loading hopper on top.

- We attach a handle to one of the axes of the rollers, which will operate our device.

The most primitive crusher for processing grape harvest is ready for use.

Press

This manual grape crusher is simple and low cost. The device will require a stainless steel container with a tap, oak planks, a stainless steel strip (you can use a perforated one), a car jack, and a welded frame. To begin with, the inner container is assembled from oak planks. Holes are drilled at the ends of the bars at the top and bottom, fishing line and stainless wire are threaded through. This creates the frame of the future internal container. Its height must match the height of the stainless steel tank. Next, using a strip, the resulting structure is fastened together. A gap of 2-3 mm should be left between the bars. The next step is to make a wooden support for the press. It is also made from wooden blocks.

Its diameter should be slightly smaller than the diameter of the inner wooden container. A metal container is fixed to the frame, the internal wooden part is installed in it, grapes are poured in, and a support is placed under the press. As a force, you can use a screw system or a car jack. The second option is more affordable and is available to every car owner. The jack is installed on a wooden cover so that in the future the upper part of the frame becomes the second point of support. It is also necessary to prepare several bars and planks. They may be needed when working with a jack. The tap opens and the juice starts squeezing out. Don’t forget to place a container under the stream for juice.

Purpose and description of the device

In the modern world, where they try to automate all work, it is impractical to use primitive manufacturing methods. Crushers are used to prepare grape juice. They are designed to crush berries and form a mixture for further distillation of wine. These devices are used for processing grapes both on an industrial scale and at home.

The chopper has a fairly simple but effective design. The simplest device consists of a loading hopper, at the bottom of which there are two parallel rollers. The hopper is mounted on a wooden frame, and the rollers rotate using a gear system and a handle.

Some designs may also have a container for chopped berries. Although you can use a wooden vat or plastic barrel.

How does a crusher work?

After harvesting, grapes must be processed as soon as possible. Berries are poured into the loading hopper. The grinding rollers are located at some distance. Thus, when the grapes fall between them, the berries are crushed, but the seeds remain intact.

Important!

If the gap between the rollers is minimal, then there is a possibility of crushing the grape seed.

In this case, the tannins contained in it will get into the juice or wine and give them bitterness and viscosity. By turning the handle, the rollers begin to move. The gear system is designed in such a way that when it starts to move, the rollers rotate in different directions. Grape berries that fall between them are crushed.

Their skin bursts and the pulp and juice are released, and the rotation of the rollers pushes them into the pulp vat.

Types and selection criteria

For large volumes, using a manual crusher will not be practical. Therefore, let's figure out what types of crushers there are and the criteria for their selection.

Mechanical and electrical

Mechanical or manual, as it is also called, is widely used for manufacturing at home or in small-scale industrial production. This installation must be serviced in pairs.

So, one person rotates the handle, starting the mechanism, and the other fills the loading hopper.

How quickly grapes will be processed using such a crusher depends on the force applied to the lever, as well as on the loading speed of the hopper. Most often they are used for crushing grapes with a volume of no more than 500 kg. Unlike mechanical ones, electric ones are more convenient to use and can be serviced by one person. According to the principle of operation, they are identical, and differ only in the use of an electric motor, which starts the crushing mechanism.

The advantage of this installation is uniform crushing.

Electric crushers vary in grape processing capacity. Thus, there are crushers with a capacity of 500 kg/hour, 700 kg/hour, 1500 kg/hour and 2000-2300 kg/hour, which are used in small production.

The device, whose productivity does not exceed 500 kg/hour, can be used in home wine production. Large wine production companies use crushing plants with a capacity of 10-15 t/h and even 40-70 t/h. The power of electrically driven crushing devices averages 0.75 kW for a capacity of up to 2000 kg/h and 1.5 kW for processing grapes with a volume of 2000-2300 kg/h.

Types of Shredders

Crushers according to their design are divided into roller and centrifugal. Roller mills are most widely used, as they best meet the technological requirements for the production of raw materials for wine.

The operating principle of such grinders is based on the use of two or more rolls of different shapes. Mostly used are corrugated, bladed or smooth shapes. The use of this type of crusher allows you to obtain high quality wort.

The centrifugal crusher uses a high speed rotor. In this case, the grapes are crushed as a result of the impacts of the rotor. Using a crusher allows you to obtain the maximum amount of coloring matter. It is used to make wort from red grape varieties.

Material of manufacture

The modern market offers a variety of crushers that differ in shape, size, performance and, of course, material. So, depending on the material used, crushing plants are wooden, plastic and made of painted or stainless steel.

Important!

The main requirement for the material from which the crusher is made is resistance to oxidation, since grape juice is highly acidic.

The most widely used wood chipper for home production is the wooden chopper. And for production, entrepreneurs most often choose stainless steel crushers, which are presented in a large assortment.

Load Type

Shredders with different types of loading are available on the modern market. There are designs with vertical and horizontal loading hopper.

Most often, these types of loading refer to a centrifugal crusher or, as it is also called, CDG. Roller grinders are produced with a vertical loading type.

Device size and weight

There are various designs of shredders available for sale, which also differ in their dimensions.

Manufacturers offer mechanical crushers of various designs, but their dimensions are clearly standardized. For example, a shredder with a loading hopper of 15 kg and dimensions of 650 * 470 mm has dimensions of 1000 * 390 * 490 mm and a weight of 18 kg, a shredder with a comb separator for the same hopper volume has a weight of 35 kg and dimensions of 1120 * 460 * 580 mm with bunker dimensions 460*760 mm.

A mechanical crusher with a hopper of 25 kg and dimensions of 1000 * 630 mm has a weight of 29 kg and dimensions of 1210 * 620 * 400 mm, and the same grinder with a comb separator will have dimensions of 1210 * 520 * 690 mm, a weight of 40 kg and a hopper size of 1000 * 500 mm.

Electric crushers also come in different sizes:

- a chopper with a capacity of 1200-1500 kg/h has dimensions of 1210*600*690 mm and a weight of 51 kg;

- a shredder that processes up to 2000 kg/h weighs 50 kg and its dimensions are 1330*570*610 mm;

- The crusher with a capacity of 2000-2300 kg/h has dimensions of 1180*680*900 mm and weighs 94 kg.

Availability of a comb separator

The taste of juice or future wine depends on the amount of tannins it contains.

They can get into the pulp when crushing seeds or chopping grape ridges.

Since the ridges ripen longer than the grapes, they contain a large amount of tannins. If they are not removed, the wine will be more tart, and if their content is high, it may even taste bitter. To eliminate them, shredders with a comb separator are used.

The operating principle of such crushers is to use an additional shaft, through which the ridges are separated from the berries. The berries are sent for further processing to a pair of crushing shafts, and the ridges end up in a separate container.

This type of grinder is used in the production of white wines. When separating the ridges, it is also necessary to take into account the type of future wine and the grapes used. For example, in the production of Bordeaux, only ¾ of the stems are removed from Verdot grapes, and ½ from Merlot and Malbec grapes.

Did you know?

When producing red and white wines in Argentina and Chile, crushers without destemmers are used, and since the ridges are not separated, the difference between these wines differs only in the fermentation period of the pulp.

When producing Muscat wines, it will not be possible to use a crusher with a destemmer, since the grapes are harvested when the berries are already raisined and dried, and the stems from such berries are difficult to separate.

Types of grape presses

For large quantities of raw materials, the most popular models are made from the following materials:

- stainless steel;

- plastic;

- varnished wood.

All components of the device that come into contact with the product must not oxidize. The most popular are mechanical (manual) and electrical devices made of stainless steel. Their components are convenient to disassemble and wash. They are durable and do not allow the appearance of foreign odors.

To process more than 500 - 700 kilograms of berries, it is recommended to use only a crusher with a motor.

With and without destemmer for berry processing

For production using winemaking technology and processing of fruity white wines, the raw materials must be cleared of grape stems. They ripen earlier than the berries themselves. Because of this, they contain more tannins, which impart excessive bitterness. There are 2 types of such models:

- roller machines (high-quality spin due to a large number of horizontally located elements);

- impact-centrifugal (the process of separating the ridges is carried out due to rotor impacts).

The destemmer is a horizontal cylinder consisting of a shaft and helical blades. The raw materials first fall on this shaft, then they fall on the pressing elements. Devices without destemming are used when processing red varieties such as Cabernet Sauvignon, Merlot and others. This component gives a special aroma to the finished product. Devices with an additional ridge separator come in two types:

- roller;

- impact centrifugal.

A grinder or mill device without a built-in separator is used for processing red and wine grape varieties. For the Muscat and Isabella grape varieties, only options without this function are used, since this reduces the quality of the raw materials.

Read about wine grape varieties here.

Roll crushers

The most widespread, used to obtain high-quality raw materials for wine wort. The basis of the unit is a system of horizontal cylinders or blades with adjustable clearance. Operating principle of the unit:

- consists of rollers, built-in destemmer;

- have only vertical loading type;

- horizontally located rollers rotate in different directions;

- there is an adjustable gap between the cylindrical choppers;

- it is activated by turning the handle (mechanical version) or using a motor.

The rollers in different models have different shapes: corrugated, bladed, smooth. Lobed species may have 4, 6 or 8 lobes. The ridges are separated by a special device and then pushed out. Cylinders with a smooth or grooved surface are more often used.

Impact centrifugal devices

The centrifugal impact model uses a special rotor as its basis. Grinding and squeezing are carried out using the blows of a rotary mechanism. This technology helps to obtain the maximum amount of coloring substances. Design Features:

- vertical or horizontal loading type;

- electric type only;

- maximum yield of phenolic and coloring components;

- rotor rotation at a speed of 500 rpm.

At the same time, the ridges are separated and thrown out. The result is maximum wort yield.

Mechanical cars

The manual type of devices refers to the roller type of action. Wooden presses are often used to produce homemade wine. Large farms use stainless steel equipment to produce wort. The dimensions and weight of different models depend on the materials and components used. For example, crushers with de-stemming weigh more. The simplest unit consists of the following components:

- square bin;

- two smooth rollers;

- lower frame made of wood;

- gear system;

- side handle.

The vertical loading method is used. Such a device weighs up to 18 kilograms and is placed on a table.

Electric fruit and wine crusher

Allows you to fully automate the production of wort. Electric crushers include an additional ridge separator. The basis is made up of rotating helical-shaped metal blades or a rotor. They ensure the separation of grapes from the ridges. They are pushed out with a forward movement, leaving only juice and extraction in the hopper for further wine production.

Performance of different models:

- 1200 – 1500 kilograms per hour;

- up to 2000 kilograms per hour;

- 2000 – 2300 kilograms per hour.

How to make a simple grape crusher with your own hands

In order to assemble a grape chopper, you will need the following items:

- loading capacity;

- plywood body;

- rollers - 2 pcs.;

- gears - 2 pcs.;

- washers - 2 pcs.;

- metal frame;

- pen.

The loading container is made of stainless steel and is shaped like a trimmed trapezoid.

To make the bunker, steel 1 mm thick is used. The body is made of plywood 12 mm thick, and its size depends on the size of the rollers that will be placed in it.

The plywood is attached in such a way that one side is removable. For example, the side where the handle and gear system will be attached. The removable side makes it easy to disassemble and wash the crusher after use.

The roller drive is located inside the plywood body. They are made from glued plywood, which is turned on a machine, mounted on a 12 mm axis and set with glue. In order for the rollers to have the shape of gears, grooves must be made on them. The diameter of the rollers is 80 mm, and their length depends on the maximum possible size that can be clamped on the lathe.

They must be installed so that the gap between them is 3 mm. With this arrangement of the shafts, the grape seed will remain intact. After securing the rollers in the frame, two washers are installed on the outer side on the axles, and on top of them two gears with a diameter of 85 mm are installed.

A handle made of an iron pipe measuring 15*15 mm is attached to one of the gears. For ease of use, a tube is used as a handle, which will rotate around its axis.

The crusher body is mounted on a frame of 15*15 mm pipes connected by 20*2 mm steel strips. The metal frame is made in such a way that the crusher can be installed on the pulp container. All wooden parts of the crusher are varnished in 3 layers to protect them from caustic grape juice. This simple crusher design will be useful for any novice winemaker.