Grain processing is one of the leading types of business in many countries. Not only large enterprises are engaged in the production of flour and other products. Small agricultural firms equipped with compact flour-grinding equipment successfully compete with them. In Russia, the need for mini-mills increased in the late 90s, which led to the emergence of numerous developments of equipment in this category by different manufacturers. It is easy for a farmer or company to select a mill model with optimal performance and the required set of functions.

To produce flour-based food products, varietal and wallpaper grinding of wheat or rye grain is used. Cereal grains are hard and tough, and have a structure that is heterogeneous in strength and density. Therefore, equipment for processing crops must meet a number of requirements, the main one of which is the sufficient completeness of the technological line.

The process of grinding grain to the desired fraction is handled by mini-mills equipped with roller machines (roller mills). Mills have a mechanical effect on grains and destroy their structure . Modifications of equipment with a different number and arrangement of rollers, type of feeding mechanism and rest of the working rollers (manual or automatic) are supplied to the market. Despite the variety of models, the operating principle of all devices is the same.

Description and purpose

The mill complex includes modules: grain cleaning, humidity adjustment, grinding, and transportation.

The grain cleaning department is equipped with machines that remove impurities of various types. The grain continuously moves along the production line.

- A pneumatic separator cleans grain from particles with aerodynamic properties different from grains.

- The machines of the grain cleaning unit separate impurities that differ in grain size (sieves are used), cockle and chaff; clean the stuck dust, loosen the stuck lumps of earth, remove the top shells (hard wallpaper).

- The second pneumatic separator removes light impurities.

The cleaned grain is sent for humidification, and then fed through a magnetic separator into the soft upholstery. Here the covers are removed from the grains.

Several blocks of roller machines are installed in the grinding sector.

Each block is equipped with 3-4 machines and a common electric drive for all. Grain and cereals are ground using two types of grinding systems: torn (coarse grinding) and grinding (fine grinding). Roller machines are designed for grinding wheat and rye grains. Wheat is used to produce premium, 1st, 2nd grade flour and feed flour. From rye - seeded, peeled baking flour and feed flour.

When choosing a model, take into account the characteristics of the original product:

- Type of cereal – rye, wheat;

- Wheat variety - hard or soft;

- Grain quality – moisture content, content of individual impurities.

Most of the developments have a compact design, which reduces the cost of building premises and installing machines, i.e. operating costs.

Wear surfaces

Actually, this is one of the main operational factors of the negative spectrum, which is determined by the intensity of the mechanical impact on the loading material. Obviously, the roll segments that are primarily subject to wear are the roll segments, which have to be replaced periodically. The problem is that the highest coefficients of friction are present when processing hard raw materials, which require the use of highly abrasive teeth. It is in such operating modes that the disadvantages of medium-speed roller mills appear, the wear of which imposes considerable maintenance costs. On the other hand, roll manufacturers are not standing still, offering increasingly high-quality abrasive segments for grinding, provided with high-chromium cast iron surfacing.

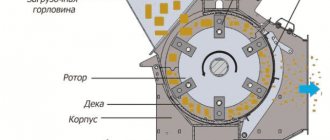

Roller machine design

The machine is equipped with rollers made of two layers of cast iron: gray (internal) and white (external). The surface of the outer layer is corrugated; Moreover, the number of grooves on the grinding roller is twice as large as on the torn roller. An important characteristic is the hardness of the roller material. It varies between 48-55 Rockwell units. Different models differ in parameters: roller diameter, length of the working area, depth of the bleached layer.

The number of rollers and their orientation in space (horizontal, vertical) depends on the model. The rollers rest on bearing supports. On a massive, stable frame, as a rule, there is a connector for removing the rollers.

There are numerous options for technological flour milling lines on the market. They differ in productivity and range of finished products.

Principle of operation

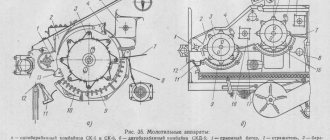

The mill must include a receiving hopper. The grain from it is fed to a torn system, the rollers of which are distinguished by large grooves.

After the first stage of processing on a tattered system, particles of different sizes are fed into a basement bunker, and from there to a mill sieving machine. In installations there are up to three torn systems, where the grinding cycle is sequentially repeated .

At the same time, sorting is carried out into fractions: flour, bran, other products (cereals, duns). These sieves are fed to a roller machine with fine cutting grooves. Here the product also goes through three stages of grinding, during which flour and bran are again separated from the mixture.

The next stage is knockout. The grinding product arrives here via pneumatic transport. This type of transportation creates air currents that favor better aspiration. At the same time, the flowability of the product increases by reducing its temperature. Another advantage of using pneumatics is the absence of condensation on the internal surfaces and rollers of machines, on gravity feeds and sieves.

Control system

Modern mill models provide electronic process control with automation elements. The operator can adjust the speed of movement of the rolls, the rate of supply of raw materials into the loading neck, the rotation parameters of the separator rotor, grinding characteristics, etc. In automatic mode, air flows are adjusted with grinding pressure. Having set the initial data, you can expect to obtain the desired particle size distribution at the output of the product without interfering with the work process. Since roller mills operate at high power and are connected to three-phase networks, they are required to be provided with protective devices. They also operate automatically in cases of short circuits, motor overheating or severe voltage fluctuations in the network.

Advantages and disadvantages of roller mills

Small-sized roller machines are designed for the needs of flour mills, farmers, and private producers of different types of flour. Such mills, for example, model R6-АВМ-7, are allowed to be used in explosion- and fire-hazardous areas for storing and processing raw materials.

Mini-mills do not require large staff to operate them. The mechanisms are usually operated by 3-5 people.

Roller systems are used not only by enterprises that sell flour. Mini mills do an excellent job of crushing grain to produce high-quality feed. The degree of flattening is regulated by simply moving the valve in the hopper.

The production process is carried out continuously, operations replace one another without loss of time and labor thanks to direct-flow technology. Raw and partially processed grain products are transported by mechanical or pneumatic transport. Through gravity pipes they sequentially reach the line machines to go through all stages of grinding. Thus, the process lends itself to mechanization and automation.

Advantages of roller mills

Varietal grinding allows you to focus on the production of flour of the most popular grade - the highest. Selective crushing can be achieved by compact and easy-to-use small-sized roller machines. For this purpose, it is better to purchase units that include several pairs of working rollers. Using multi-step grinding of a grain product, grinding modes can be adjusted to take into account the properties of the grain. The process will be as close as possible to the technology for producing flour on an industrial scale.

The modular configuration of the systems allows you to change the number of modules, increasing the productivity of the mill. It is possible to combine components of different brands of equipment in modules. The mill can be equipped with different machines, for example, a grain cleaning module from one manufacturer, a sieving unit, a roller machine from another. Using such opportunities makes production cheaper and more efficient. Each owner completes the system based on the needs of his enterprise.

Examples of innovations: plate springs are used to prepress the rollers; a magnetic frame in front of the receiving chamber separates metal objects, preventing them from getting onto the rollers.

Competition between manufacturers leads to continuous improvement of flour-grinding equipment. By updating the designs, the models are becoming more and more reliable. The undeniable advantages of all models and modifications are mobility and autonomy.

Disadvantages of roller mills

Purchasing an installation requires large financial costs.

Roller mills are configured at the stage of assembling the technological scheme. They are practically not reconfigured due to technical difficulties.

Unit design

Using this equipment, you can perform a wide range of different tasks, in addition to direct grinding. This determines the complexity of the design of some models. In the basic version, the standard roller mill, the photo of which is presented above, includes the following parts:

- Load-bearing platform with supporting elements. A metal structure on frames that supports the weight of functional blocks. This part may contain both a stationary support and a chassis with wheels for movement.

- Actuator. Electric motor with gearbox and electrical infrastructure for connecting to the network (usually three-phase 380 V sockets are used).

- Mechanical drive part. The force from the engine to the working parts is transmitted through a system of bearings, buffer springs, belt elements, gears, V-belt transmission and pulley.

- Working bodies. Directly rollers with teeth that grind raw materials.

Examples of popular roller mill models

Here are two brands of flour roller milling machines with the characteristic features of this type of equipment.

Р6-АВМ-4/7/15/30/50 – aggregate roller mill from Kharkov

Equipment control is electrical. Accepts wheat, rye, oats, barley, buckwheat, as well as legumes and corn for processing. Allows you to obtain flour of the first and highest grades.

Weight and dimensions parameters:

- Weight: ≤6400 kg.

- Dimensions: 7x3.4x5 m. Dimensions are given without taking into account the bunker, frame, ladders and ladders.

Technical specifications:

- High quality flour produced is achieved with low power consumption. The average productivity of flour from basic grain grain is 7 tons per day. At the same time, the first grade takes up ~23%, the highest - about 50%.

- The length of the rolling line is 102 cm, the screening area is 14.1 m2. Product transportation is pneumatic.

- The installation is powered by 10 electric motors with a total power of up to 27 kW.

- Control is carried out via a remote control.

Installation of the mill does not require the construction of a special building. Its mechanisms are installed on a prefabricated, durable two-story frame.

Flour roller mills "Kharkovchanka" Stankinprom LLC

The family of mills includes models for various purposes: obtaining seeded and peeled rye flour; production of pasta grinding to produce second grade flour and pasta grits.

- The buyer can choose the model of the required productivity from a wide range - 10-500 tons/day.

- The equipment produces 65% of premium flour that meets the requirements of GOST.

- The process is fully automated.

- The mechanisms provide a high degree of purification, quality of grinding, and give a high percentage of flour grinding.

The system is characterized by a quick payback and durability of the grinding system. Upon individual order, the mill is supplied with additional options and equipment: computer process control, accounting of the initial and finished product, energy consumption; bunker for grain and flour batches, granulation line, etc.

Main characteristics

Due to the variety of structural devices, this equipment may have different technical and operational parameters. And yet, focusing on the average power level of the units, the characteristics can be presented as follows:

- The power potential of the electric motor is from 1300 to 5500 kW.

- The roll diameter of industrial models is up to 1500 mm.

- The roll length for industrial models is up to 2000 mm.

- The pressure exerted during rock crushing is up to 250 MPa.

- The height of the teeth in vertical roller mills is from 30 mm.

- The diameter of the plate for disk units is from 0.5 to 2 m on average.

- The rotation speed of the plate is about 3 m/s.

- Productivity – from 10 to 25 t/h.