Herbal meal is grass that has been dried in a special way and formed into granules. This food is easily digestible by animals, can be stored for a long time and retains all the nutrients and vitamins. This feed is used both in large and small agricultural farms. Among the main advantages of such food, it is worth noting its low cost and the possibility of long-term storage. Stocking up on regular dry grass is not always profitable, especially since the shelf life of hay is short. Herbal flour takes up minimal storage space and can be stored for a long time.

Brief analysis of the business: Costs of organizing a business: 300 - 1500 thousand rubles Relevant for cities with a population: for rural areas Situation in the industry: low level of competition Difficulty of organizing a business: 2/5 Payback period: 1 - 2 seasons

The development of agriculture is gradually gaining momentum, especially since this industry has recently received good support from the state. That is why the production of feed, in particular grass meal, can bring good income.

Another advantage is the almost complete absence of competition in this production market, which significantly increases sales opportunities. Sales can be established even on the local market, since farmers have already positively assessed the use of grass meal in feeding.

The production of grass meal is a simple process, which undoubtedly also adds to the advantages of this industry. Production equipment is easy to buy, inexpensive and takes up little space. Thus, you can set up production at home - provide your farm with grass flour, and also supply it to nearby farms.

We recommend reading:

- wood flour production

- cow breeding

- Is it profitable to engage in beekeeping?

- growing asparagus

- crayfish farming business

Granulated grass meal

Grass meal in granules is an excellent food that does not change its composition during storage and retains all the beneficial substances.

Production

It is easy to establish the production of herbal flour; for this you need special equipment and a separate room. The choice of production equipment will depend primarily on the scale. At the initial stage, for example, to prepare feed for your own farm, a mini-installation will be sufficient, which is inexpensive and does not require additional maintenance.

In the process of production development, equipment can be improved, productivity and volumes increased.

Procurement of raw materials

The production of grass meal is seasonal, but even in this short period of time you can stock up on raw materials and produce a large amount of feed. In such a short time, you can organize and establish production, stock up on raw materials and then sell them to large and small farms in bulk.

Raw materials are needed for production. Green mass is the name given to the raw material for future grass meal. This is ordinary grass, perennial and annual meadow grasses, beet tops, cereals, etc.

Grass granulation - why is it necessary?

The process of granulating grass meal makes a lot of sense, because the value of the product in the future increases many times over. Why is this happening?

Quick drying

The raw materials are dried in the shortest possible time, which (as with quick freezing) allows you to preserve the lion's share of valuable substances

Nutrient release

When crushed, the walls of grass cells are destroyed, more of their useful contents are released, which makes the raw material for granules more nutritious and easily digestible. At the same time, during the granulation process, as a result of a number of chemical processes, the nutritional value increases even more.

Flowability

The shape of the granules makes them universal, compact, and they are easily poured between bins and along feed distribution paths. The volume of mass is reduced significantly, and the loss of raw materials during transportation to the “end consumer” is reduced.

2 times more nutritious than hay

The nutritional value of 1 kg of grass pellets is 0.8 feed. units, while 1 kg of hay accounts for 0.4 feed units. At the same time, the carotene content in granules can be 20 times higher, just like vitamins and protein. With a long shelf life, the difference in the value of feed increases.

High price

The demand for herbal granules is quite high. Because of its advantages, granulated feed is valued higher than hay and flour in a free state - from 14,000 rubles per kg. Prices vary due to the composition of the mixtures.

Necessary equipment for the production of grass meal

The feed production technology is quite simple and consists of three stages:

- Grinding of primary raw materials.

- Withering and drying.

- Regrinding.

The output is a finished product, which can be converted into granules using special equipment.

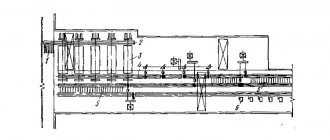

Herbal Meal Production Line

At the initial stage, farmers buy special mini-installations, but after that it is necessary to expand production if there is a desire to increase the volume of output.

If we talk about the necessary equipment, then this is:

- crusher - for grinding grass mass;

- conveyor - for convenient supply of raw materials and simplification of manual labor;

- cooling columns;

- granulator - to convert the resulting raw materials into granules;

- packaging and packaging equipment.

If you organize a business, you need to buy all the equipment at once, which can be expensive. If production is expanded gradually, then you can get by with minimal costs. Also, if there is a need to save money, equipment can be purchased from little-known manufacturers.

Also, the cost of the equipment will depend on its power. For example, for a beginner, a mini-workshop with a total capacity of up to 500 kg/h will be enough. If production is necessary to provide feed exclusively for your own household, you can even purchase equipment with a capacity of up to 200 kg/h.

In total, the purchase of such equipment will cost an entrepreneur from 300,000 to 500,000 rubles, and this is the minimum. Not everyone has such funds, but this does not mean that you need to abandon this idea of organizing a business. You can purchase equipment for producing herbal flour with your own hands. It will cost less, but manual labor will be required.

We recommend reading:

- vermicompost production –

- sunflower oil production –

- ecowool production –

DIY herbal flour

It is worth noting right away that high-quality grass flour without special equipment simply will not work. The raw material (grass) must be dried correctly - for a certain time and at certain temperatures.

To make it at home, you need a crusher, and to convert it into granules, you need a granulator. With the right approach, the availability of certain tools and skills, such equipment can be made independently. Keep in mind that it is not so easy to establish sales of such products; you will need to purchase a mini-installation.

If you wish, then with the help of a crusher and a mini-production plant you can set up the initial stages of your business. Herbal flour is in great demand among farmers, so the return on investment for this type of business is high. Even after investing financial resources in production, you can quickly evaluate the results and payback.

Green feed production technology

The process of making herbal granules consists of several stages, the specifics of which must be strictly observed, which will allow you to obtain a high-quality product suitable for feeding animals and poultry, as well as for sale.

Procurement of raw materials

Features of the collection:

- Grass mowing is done in the morning, since the period from 6 to 10 am they contain the maximum amount of carotene.

- Meadow grass up to 30 cm high is mowed, legumes up to 50 cm high.

- Raw materials that have entered the stage of budding, spikelet formation, and vegetation are not used.

Freshly cut grass is collected and simultaneously crushed by specialized combines. Within three hours, the raw materials must be sent for drying, otherwise the grass may rot and quickly lose its beneficial properties.

Drying

Drying of the grass is carried out in a drying drum, into which the mass and hot air produced by a heat generator are supplied.

Pellets produced from wood waste through a granulator can be used as fuel for the generator, which is another saving point for farms.

The crushed herb dries in less than a minute. At the same time, the raw materials must maintain a certain level of humidity - for grass cuttings 10-15%, flour 8-12%. At a moisture level of 6% or less, the protein and carotene content in the product decreases. The mass, with a moisture content of 15% or more, overloads the crushing machine and clogs the sieve.

Splitting up

The dried herbal mixture is sent for grinding in a rotary or hammer crusher. The raw material is ground into the smallest particles and passed through a sieve with cells of a given size. Unloading takes place via a conveyor or through a pneumatic hose. The herbal mass is placed in a storage hopper, inside of which a mixer operates, which prevents caking of the raw material. The bunker is intended not only for short-term storage of grass, but also for its dosing for subsequent feeding into the granulator chamber.

Granulation

From the receiving hopper, the green mass is fed by a screw into the mixer, where it undergoes disinfection with hot steam, then moves to a pressing unit equipped with a press shaft and an annular matrix. The raw material ends up between the rotating shaft and the inner surface of the matrix and is forced through dies (holes) by pressure. The length of the granules is adjusted by cutting with a statistical knife.

Cooling

To avoid loss of nutritional value, the newly obtained granules are cooled in a special column. Using cold air, the temperature of the granules is brought to ambient temperature. In addition, particles are filtered out in the cooling column, which are uncompressed and are subsequently reused.

Packing

A weighing dispenser is used for weighing. Packaging of granulated feed is carried out in craft bags of 30-50 kg, which is convenient for small wholesale, or in big bags - 1 ton of product each - for medium wholesale. In case of large wholesale, the granules are not packaged; the products are loaded into a car hopper.

Storage

To store herbal granules, a dry, dark, ventilated room is allocated, in which the temperature is maintained within +4 degrees and humidity up to 75%.

We organize the production of herbal flour

In addition to properly organized production, it is necessary to take care of the premises, personnel and hangars for storing finished products.

Room

The production premises must first of all meet all established norms and standards. Certain humidity and air temperature are quite important indicators during manufacturing. Violation of standards can lead to the fact that the final product will simply be of poor quality. The size of the room will depend on the volume of production.

Staff

At the initial stages, a large staff will not be needed; production can be handled independently.

In general, it is necessary to take into account that workers will be needed for the following purposes:

- grass cutting;

- procurement of raw materials and their transportation;

- direct production of products.

Fillers and packers will also be needed. If there is special equipment, then the need for workers is reduced.

Storage of finished products

After flour is produced, it is stored in the warehouse itself. If flour is stored in bulk in a non-granulated form, then a significant loss of nutrients occurs, which is why granulation and briquetting is recommended.

Granulated flour can be stored in paper bags for up to 1 year without loss of nutrients, provided that certain air humidity and temperatures are maintained.

Benefits of Herbal Granules

- Each granule contains a full range of nutrients and vitamins and is well absorbed. Granulated feed provides balanced nutrition for livestock and poultry all year round, which actively increases the weight gain of young animals, egg production in birds, and milk yield in cows, goats and sheep. When using grass pellets, the cost of purchasing other feeds is reduced.

- The feed is compact, takes up little space, is resistant to temperature and humidity changes, and can be stored for a long time without loss of nutritional properties. Properly prepared granules have a smooth, non-porous surface and do not crack or crumble.

- The granules do not clog the beaks of birds, do not disrupt the functionality of the masticatory apparatus in livestock, do not irritate the mucous membranes, and improve the functioning of the gastrointestinal tract.

- Granular feed is convenient to distribute automatically and mechanized.

- Low cost at a fairly high selling price, which is beneficial for the feed business.

Profitability of grass meal production

The profitability of this business is quite high, this is based on the great demand for such food. The costs of preparing and growing raw materials are low, and the manufacturing technology is quite simple. This allows you to organize a business at home. Despite the fact that the business is seasonal, its return on investment is high and all money invested in organizing the process is returned quite quickly.

Profitability analysis proves that within six months there is a real opportunity to return all the funds spent and already receive direct income from the business. Organizing this type of business will cost from 300,000 to 1,500,000 rubles, depending on the type of equipment and its capacity.

During times of shortage of fresh food (winter, spring), the demand for products increases noticeably, and sales turnover increases.

A specialist tells us more about vitamin-herbal flour:

Production of dry food in Russia

In Russia, the volume of such procurement is about 7,000,000 tons annually. Granulated grass meal is widely used to create feed mixtures. The products are used by farms to feed young cattle and pigs. Poultry farms buy large quantities of product to feed birds. The production of herbal granules as a business has a good chance of development, because the demand for products is increasing every year. Dry compact feed is very convenient for storage and reduces the amount of losses during the preparation and transportation of feed.

The composition of herbs dried at high temperatures is an important factor influencing the growth of product popularity. An important source of protein, vitamins and minerals, it contains about 0.80 feed units, about 130 units of fully digestible protein, and more than 200 mg of carotene. That is why the production of herbal flour and herbal granules is a promising activity that attracts entrepreneurs with a high level of income.

Where to buy a granulator

offers household and industrial feed granulators, as well as spare parts for them. You can purchase equipment of various capacities from us, with economical energy consumption and low maintenance requirements.

Our advantages

- Favorable prices, affordable even for a novice farmer or entrepreneur. Direct cooperation with manufacturers allows us to sell products without intermediary markups.

- Delivery of goods without delays.

- We supply products of excellent quality. Official guarantee included.

- Discounts are provided to wholesale and regular customers.

You can ask any questions, find out the cost, or place an order by calling +7 (915) 114-35-30 or by sending an e-mail.