Those who want to learn how to make a jig blank with a thin-rolled metal crown using a punch and a matrix have come to the right page.

A few words about the procedure, methods and devices necessary for making crown blanks for homemade jigs of various shapes, which you wouldn’t be ashamed to show to your friends while fishing.

First, you should make punches designed to form recesses of the required shape in a piece of thick metal (matrix). The same devices are used to press out a concave cavity in the crown blank of a homemade jig.

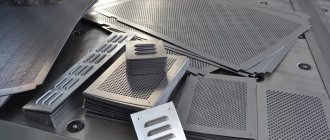

A matrix in the form of an aluminum plate with impressions of the working ends of the punches - vertical drifts - are shown at the top in the photo. Any of the cavities can be used to make an impression in the crown of the jig.

Pipe bender: review and analysis of options for home-made structures, calculations, drawings, implementation

When setting up a household, sooner or later you are faced with the need to bend a pipe. In a city apartment - less often, but also. The prices for pipe bending tools and accessories, both for sale and for rent, are not exactly exorbitant, but, to put it mildly, they are not encouraging. Therefore, there are more than enough people who want to make a pipe bender with their own hands, and the purpose of this publication is to help them find a design suitable for their specific purpose and give effective practical recommendations for its manufacture.

Amateur craftsmen make a wide variety of installations for bending pipes, from simple devices to real bending machines, see figure:

But a considerable part of homemade pipe benders bend according to the principle “as it happened, so it will be.” At the same time, those who happened to see the insides of an airplane or rocket probably noticed the bundles and intricacies of pipes, bent, sometimes in the most bizarre way, cleanly and evenly “just like it was.” But no “highly cosmic” secrets, respectively. no production equipment. At aerospace factories, pipe bending is done by low-level workers or even apprentices. The secrets lie in the correct proportions of certain features of the manufacture of pipe bending machines and devices and in choosing the type that is suitable for a particular job. In this article, these “secrets” are revealed, with an emphasis on a pipe bender for a profile pipe, since, on the one hand, it is professional pipes that are most needed in private households, and on the other hand, their bending is much more difficult than round ones.

Note : the rest of the article discusses cold flat production-technological and, in part, decorative-art bending. So, if you are eager to set up mass mechanized production in your own barn, well, say, hyperbolic coils for moonshine stills, then see somewhere else.

Shapes of jig crowns

Popular crown shapes for homemade jigs are shown in the drawing. Based on the selected outlines of the upper surfaces of the baits, we make punches, with the help of which the crowns of the jigs are stamped into the matrix.

Blue outlines the contours of the blanks - the crowns of homemade jigs for winter or summer fishing.

The orange color corresponds to the shape of the solder poured into the crown after machining the homemade product.

The shapes of the working ends of the drifts make it possible to increase the volume in the cavity of any crown by increasing the depth of the cavity punched in the aluminum. With the help of such a simple operation, you can increase, along with the volume and weight of the finished homemade jig, while keeping the shape of the homemade jig unchanged.

Black paste shows the direction of the hook forearm soldered into a homemade jig.

In the third hexagon-shaped jig from the left, the hook shank can be soldered into the corner between the side edges or in the middle of one of the side ribs of the future homemade jig.

Compare and make sure that the outlines of the homemade jig blanks shown in the picture correspond to the shapes of the working surfaces of my punches.

For summer fishing, homemade jigs with a flattened shape and gliding properties are more suitable. To control the jigs, I use a side nod when hooking a telescopic fishing rod.

But I repeat once again, the shapes of homemade jigs for your fishing trips can be completely different. It’s just that the working ends of the punches should be sharpened differently for them.

Just in case (for an amateur), I depicted the various shapes of the crowns of a dozen more popular homemade jigs for summer and winter fishing. For some homemade products, making punches at home will require a lot of time. But, believe me, your work will be compensated by fish catches.

Bending defects

At military councils, it is customary first of all to report on the enemy. So we will begin our debriefing with what needs to be avoided.

Typical pipe bending defects are shown on the left in the figure:

Defects in bending of round and profile pipes

For household and other general purpose pipelines, taffy and wave are acceptable, which together reduce the lumen area of the pipe by no more than 10% at the narrowest point. On pipes for gases and refrigerants, any stretch and, especially, a wave, are undesirable, because There may be microcracks there. A wave, even a small one, is unacceptable in tubular power elements of building structures and mechanisms, since it sharply and unpredictably reduces their load-bearing capacity.

A characteristic defect in bending rectangular corrugated pipes is a “propeller” (in the center in the figure), when the pipe twists along its axis during the bending process. An arch or semi-arch that is bent with a “propeller” is most often impossible to fix until it is suitable for use. The reason for the “propeller” is the asymmetrical distribution of technological loads during bending, and bending equipment for profile pipes must ensure their correct spreading over the workpiece.

Another characteristic defect, but of round thin-walled pipes made of soft metals (copper, aluminum) is a “bun” (on the right in the figure), an external and/or internal longitudinal scar; Most often, the flattening of the pipe is noticeable to the eye, hence the name. There will definitely be a microcrack in the “bun” somewhere. A chronic leak in the house water supply or an air conditioner losing freon is not a cheap “fix”, but a leak from the fuel pipeline is simply dangerous. Building structures that include tubular elements with a “bun” are prone to sudden destruction. The reason for the “bun” of bent pipes is the incorrect choice and/or setting of a pipe bender.

Main rules

The main causes of defects in pipe bending are incorrect (usually too small) bending radius and a short technological shank (“tail”), the distance from the end of the pipe closest to the bend to its beginning. The “tail” is needed not only for reliable fastening of the pipe, the “tail” is also an absorber for the release of technological stresses. A perfectly correct pipe bender can produce a wave or a defect (parasitic bend).

The rules for choosing the bending radius of the pipe RIZG and the length of the technological shank L are summarized in the table:

- If the difference between the real and the nearest tabulated values of the pipe diameter P is more than 10%, the values of the initial calculated values are calculated by interpolation. Otherwise, we take the nearest one.

- The tabulated RIZG is reduced to the relative value rIZG, i.e. It is expressed in pipe diameters D or heights H.

- For pipes with a diameter of up to 10 mm, 1 is subtracted from rIG.

- For pipes with a diameter of 11 to 15 mm, 0.85 is subtracted from rIG.

- For pipes with a diameter of 16 to 24 mm, 0.75 is subtracted from rIG.

- For pipes with a diameter of 25 to 40 mm, 0.65 is subtracted from rIG.

- For pipes with a diameter of more than 40 mm, 0.5 is subtracted from rIG.

- Convert the relative rIZG back to the numerical (millimeter) RIZG.

- From the obtained value of RIZG, take the nearest practically convenient larger one.

Example: you need to bend 24x24x1.5 from a steel pipe, i.e. already classified as thin-walled, complex semi-arches for a flower house or hut. The structure is non-residential, light, the complex semi-arch is not a load-bearing structure (see below), i.e. "plumbing" wave and taffy are acceptable. We take data for the pipe H=25. According to the table we find rIZG = RIZG/H = 80 mm/25 mm = 3.2. Subtract the correction (for pipe H=25!): 3.2 – 0.65 = 2.55. Convert back to millimeters (again according to the table H=25!): 2.55x25 = 63.75 mm. That is, if we take a new bending radius of 65 mm instead of the “defect-free” 80, then the selection of bending devices and work will be simplified, the possibilities of artistic expression by the shape of the structure will increase, and there will be no visible and/or dangerous defects in the finished structure.

Note : For some types of pipe bending devices, e.g. mandrel and 3-roller, see below, the initial (starting) “tail” does not seem to be needed. But its role in this case is played by the not yet bent remainder of the workpiece, so it is impossible to cut the original pipe in advance exactly to size, otherwise it will be defective. A cut for a single “tailless” product, for example. a curl for cold forging, cut in stock for the “back tail” the same as the “front”. The stock goes to waste, so it is better to bend products without straight sections at the beginning and/or end in batches sequentially from one pipe, then only the very last “tail” will go to waste.

Simple - radius

A specific pipe bender is designed for a bend radius within certain limits. But to select a design prototype, you immediately need to know only its very general meaning:

Prototype selection

Based on the entire complex of the above indicators, a pipe bender of a certain design is selected. Among those available or partially available for self-production are devices, tools and machines for bending pipes:

- manual bending lever – bends round pipes with walls of normal thickness to medium and large radii. Thin-walled pipes flatten and crumple; on profile ones, a “propeller” appears when the lever is slightly swung to the side. It certainly produces acceptable defects. Bend for additional installation or, with an additional control template, along the profile for additional installation. Simple, cheap, non-volatile. No permanent production area is required for placement. Mobile: can be carried manually over long distances. Low productivity, high bending labor intensity and worker fatigue. Quite high demands on the operator’s physical strength, qualifications, endurance and conscientiousness. Scope of application – single non-standard parts of building structures;

- bending plate (board) - similar to a lever, but for small and medium radii. Manual mobility is limited to the construction site. Productivity is higher, and labor intensity, fatigue and required worker qualifications are lower than for a lever. Prem. applies. during construction work for the on-site production of parts of pipelines and tubular inlet and/or ventilation devices;

- bending template (conductor) - has properties similar to those of a bending lever, but is intended for bending thin-walled, soft metal and profile pipes. Defect-free bending according to the profile to size is possible. Very low productivity (especially for steel pipes) due to “sludge” for metal relaxation, see below. If there is no hurry (say, in winter before the summer construction season), a roller pipe bender can replace it. It is also possible to produce multi-radius architectural forms (with a counter-pattern). The required qualification of the worker in metal processing is initial;

- roller (rolling) pipe benders – manual bending of pipes up to 30-40 mm along a radius profile for pre-installation and to size. Bending radii are small. The complexity and labor intensity of manufacturing are low. A separate production area is not required; operator qualification requirements are minimal. Productivity is low. Defect-free bending of thin-walled soft metal pipes is possible. Mobile manually. Prem. scope of application – general purpose bends (see above) during plumbing and repair and construction work. The complexity and labor intensity of self-production is low;

- crossbow (crimp) pipe benders - similar in properties to roller benders, but with increased productivity for round pipes made of soft metals with walls of medium thickness. Rapid reconfiguration is possible during work. They are mobile to a limited extent (transported by road) or installed permanently. Self-production is not justified, see below. Most often used in the installation of home and apartment copper and aluminum pipelines. In production conditions - for making general purpose bends on steel pipes with a diameter of up to 60 mm;

- mandrel (bypass) pipe benders are also similar to roller benders, but bending with a variable radius is possible without a starting shank. The requirements for the employee's physical strength are quite high. The main purpose is the production of small fragments for architectural and decorative purposes and for artistic forging. The complexity and labor intensity of manufacturing on your own is very high.

- roller (rolling or broaching) pipe bending machines – high-performance bending of any pipes along large and medium radii. Installed permanently in a specially prepared room or on an equipped site; less often, they are transported to the place of work. Bending – defect-free in profile; perhaps - according to the profile in size. The main purpose is the production of radius construction arcs from corrugated pipe up to 80 mm wide.

DIY jig matrix

The matrix for stamping jig blanks is shown in the bottom position of the photograph. Making your own device from scratch will only take a few minutes if you select the appropriate metal.

It is clear that the metal for the matrix should be malleable and not too hard. Only in this case, on the surface of a metal bar, we can easily knock out impressions of the working surfaces of the punches with the profiles of the upper surfaces of the jigs.

But the material for making a matrix with your own hands should not be too soft, otherwise we will break the prepared recesses already when stamping the first jig blanks. In addition, the thickness of the matrix should be quite sufficient so that it does not begin to warp (bend) when struck with a hammer.

For making matrices with my own hands, I use aluminum bars with a thickness of 12-15 mm. They fully satisfy all the requirements presented above. And the prints of jig blanks, as they are broken, can be periodically corrected and updated until they are significantly reduced in size.

Let's figure out how you can stamp jig blanks of different profiles in a matrix.

Description of designs

The material presented above is sufficient for preliminary selection of the design of the pipe bending equipment required for this specific job. To clarify the final solution, we provide more detailed descriptions.

Lever arm

The design of a manual bending lever couldn’t be simpler, see fig. However, such a primitive device for centuries and millennia has bent details that sometimes baffle modern technologists. The pipe can also be laid simply on the ground by placing wooden blocks under it and securing it with staples driven into the ground. It is better to work with a lever with an assistant holding the workpiece, checking during bending against a pre-prepared template.

Manual Pipe Bending Arm

Plate

The bending plate (support-thrust manual pipe bender) has been known for as long as the lever. The design is in some way ingenious: the bending pipe itself is used as a bending lever, and instead of a “hole” (a clamp on the lever), its opposite is a strong support pin or several of them. In general, everything is according to Murphy’s laws: if it doesn’t work out as it should, try doing it the other way around.

The structure of the bending plate is clear from Fig. (left):

Bending plate (support-thrust manual pipe bender) and its “ground” modification for the manufacture of greenhouse frame arcs

The most common variety is 4x4. All common bends can be made on the slab for retrofitting (with acceptable defects). Interfering stops are simply removed; the missing ones are substituted. The installation pitch of the support pins is taken so that the thickest pipe used fits between them. A concrete slab can be poured directly onto the ground in some inappropriate place on the construction site, for example. where the foundation of the shed will be (inside, not under the tape!) or, say, a cesspool. Brand of ready-made solution – from M250; reinforcement is at least 2-tier. The holes to the pins are formed with wooden sticks, wrapped in film or generously greased with grease (worse). Pins for a concrete slab must be made with shanks as long as the thickness of the slab; You can also use simple round pins from sections of thick-walled pipe or steel rod.

The “earth” modification of the bending plate is shown in the center and on the right in Fig. Supports/stops – pipes or wooden stakes driven into the ground. On such a “machine” you can bend up to 5-6 greenhouse arcs from a pipe up to 16x15x2 at a time. An important feature: the pipe must be passed around the stops slowly, in several steps, otherwise due to the release of voltage, a defect is possible - a reverse wave. The film on it will be wiped all the time, and it is unlikely that it will be possible to install the polycarbonate coating efficiently. The laid arcs are left in the “machine” for a day (preferably up to a week) so that the residual stresses in the metal of the pipe “resolve” (relax) and the profile of the arcs does not “spill” beyond the permissible limits.

Note : based on the bending plate, you can make a universal support-thrust manual machine for bending pipes and rods, see video:

Video: homemade universal bending machine

Alternative metal for the matrix for jigs

One day, on occasion, I chopped up a lot of lead from the battery terminals of a ZIL-131, then melted it in a frying pan. The result was a pancake of very hard lead, apparently with some solid impurities. This kind of metal is also suitable as a matrix for making jig crowns.

From this metal you can make some simple lead jigs with your own hands.

The next page provides tips that will not hurt when making and soldering tin-lead jigs yourself.

Design and principle of operation of a pipe bender

The pipe bending procedure itself is practically not complicated, but requires special attention. During the bending process, it can receive defects in the form of stretching of the wall and a decrease in its thickness at the bending point, which will lead to a decrease in the strength of the pipe. Also, the bend location can change the configuration of the cut and take the shape of an ellipse instead of a circular cross-section, which significantly reduces the internal throughput of the liquid passing through the pipe.

Design Features

To ensure that bending defects are minimal, when choosing or manufacturing a pipe bender for work, you need to understand how it works. The manufacture of a pipe bending device consists of three stages:

- A punch (template) is attached to a special holder of the pipe bending device, along which the pipe blank will be bent.

- Using a pipe cutter, a pipe blank is cut to a certain length and installed in this bending device.

- Using a lever, a certain force is applied to the workpiece, as a result of which it bends at a certain angle.

Such manual devices for bending tubular blanks can be mechanically or hydraulically driven, and these two options are perfect for a home workshop.

The operating principle of almost all pipe bending devices is the same . The workpiece is fixed in a special device and, under a certain force, takes the required bending angle.

There are various pipe bending devices, and, naturally, each of them uses its own force system. For example, in crossbow or hydraulic type devices, a point force is applied to the bending section of the pipe.

According to another scheme, bending is carried out using several rollers, between which the workpiece is rolled, obtaining a certain bending angle. Pipe benders equipped with special inserts for pipes (mandrels) work according to this scheme.

What is a mandrel used for?

To understand the purposes for which mandrels are used, you need to know what can happen to a pipe during bending if you do not use a mandrel. For example, when bending a workpiece, two opposing forces act on some of its sections at the bending point:

- Compression of the wall of the inner radius, in which the metal, deforming, forms a wavy surface (corrugation).

- Stretching. In this case, the metal wall of the outer bending radius is stretched, due to which it becomes thinner. Naturally, this can weaken the strength of the pipe in the area of the bend by almost 50%.

If you do not use a mandrel, thin-walled copper, aluminum and other pipes made of soft materials can become especially deformed.

For the mandrel inserted inside the pipe before the bend, steel springs are usually used, selected to match the inner diameter of the pipes being bent. Sometimes the surface of the springs is coated with polyurethane to provide better stabilization of the pipe walls.

How to make a jig from a crown blank

If we intend to make our own jigs for fishing at great depths or good currents, then we increase the weight of the homemade products by increasing the size of the cavities in the jig blanks. To do this, we break the matrix metal under the punch to the required depth.

Next comes stamping and trimming the blanks along the contour, piercing holes in the crowns for winding the fishing line.

In order to independently make the jig you need for fishing, fill the selected shape of the workpiece with solder, solder the hook, and perform mechanical processing of the surface of the crown of the finished jig.

In this way, you can make jigs with polished shiny or matte surfaces from thin-walled crown blanks. The technology for making jigs for summer and winter fishing is described in detail on the next page of the topic.

A little explanatory material about the choice of shapes for a batch of homemade jigs with shiny crowns.

Types and production of bending devices

There are not so many ways to bend a pipe, but there are quite a large number of devices for performing these actions.

Moreover, they can be of very different types. In order to make a pipe bender for a round pipe correctly with your own hands, you can draw up drawings yourself or download them freely from the Internet. Based on the principle of influencing a round pipe workpiece to bend it at a certain angle, there are various types of pipe benders.

Crossbow type model

These models of pipe bending devices are driven by hydraulic or screw drives.

During the processing of the workpiece, the model is bent in the form of a crossbow arm, from which the name of the bending device comes. The design of a crossbow pipe bender has some difficulties in manufacturing, but its power and technical capabilities are quite large. The device itself can be made with several functions, for example, using it as a bending machine and a hydraulic press.

Depending on the design of the rigid metal frame, the machine can operate in a horizontal position (the jack or other power device is located horizontally) and in a vertical position.

The design consists of a rigid frame and two rollers mounted on special racks welded to the platform. A jack is located in the center between the racks, and clamps are attached to the axes of the rollers, ensuring free fixation of the workpiece that is placed on them.

A punch for a pipe bender (shoe, template) can be made from old rollers, pulleys, or bent and cut along pipes.

The work of the crossbow machine is carried out in this way:

- The pipe blank is placed on the rollers and secured with clamps.

- A shoe (a template with a certain bending angle) is attached to the jack.

- The jack presses on the center of the workpiece with a shoe and smoothly bends it to a given angle.

Using the same technique, you can make a small manual pipe bender, with which you can easily bend durable thick-walled pipes of medium and small diameter. For this purpose, you will need to purchase a small hydraulic jack, two rollers, make a punch and a durable T-shaped metal nozzle for the jack.

The entire design of the “crossbow” mechanism must have a large margin of safety. Otherwise, if the workpiece falls out of the fixing brackets under the pressure of the jack, the operator may be injured.

Roller system

Such pipe bending models are also called rolling models.

Using this system, you can bend round or profile pipes, as well as steel reinforcement to a large radius. An ideal device for preparing arcs for canopies or greenhouses. The main elements of this type of device are three metal rollers, matched to the diameter of the pipe workpiece being bent. The workpiece is placed on two outer rollers and the third, located in the center, is rolled along the pipe. Under its force, the part gradually bends, acquiring a certain bending radius.

The system can be driven by a hand crank or an electric motor through a special gearbox for a pipe bender. The quality of the resulting product processed using this device is quite high, and the pipe itself, in contact with the metal rollers, receives virtually no damage.

The advantage of a rolling pipe bender is its small size, due to which the tool takes up little space in any home workshop and can easily be mounted on a workbench or wall. And due to the fact that it is made entirely of metal, the workpiece can be heated with a blowtorch or gas torch during its bending to facilitate work.

The simplest device

For urgent work that requires a hand-held round pipe bender to quickly bend an angled elbow, such as for a home plumbing project, a simple bending device can be made using the tools at hand.

To do this, you should prepare a lever from a piece of metal round pipe with a diameter of approximately 32-42 mm or thick, preferably smooth fittings. The length of the lever should be in the range of 1−1.5 m, depending on the workpiece being bent. A ring of thick-walled pipe trim approximately 30-40 mm wide is welded to one end of the lever. The inner diameter of the ring must be larger than the outer diameter of the workpiece prepared for bending.

Instead of a ring, you can weld two rods from a thick smooth rod to the lever. The rods are welded perpendicular to the lever and parallel to each other. The distance between them must be greater than the outer size of the workpiece prepared for bending.

The bending process is carried out as follows: P

- The workpiece is laid on a hard, flat surface, it can be asphalt, concrete floor, reinforced concrete panel or thick board.

- The tubular blank prepared for bending is threaded into the ring of the manufactured device or inserted between its pins, after which, acting on the lever with muscular force, it is bent.

Winding machine

Pipe bending machines of this type differ from other bending devices in that the pressure roller presses the workpiece directly against the template itself, as if winding the pipe around it. This allows you to bend ring-shaped and spiral parts from workpieces, which is completely impossible to do on conventional pipe bending machines.

During operation, the roller itself is stationary, but the template, to which the end of the workpiece is rigidly attached, rotates around its axis, winding the pipe around itself, which is why machines of this type are called winding machines.

The drive on such devices is most often electric, since twisting the pipe into a ring requires a lot of force. The mandrel for the template must be removable, otherwise it will be quite difficult to remove the spiral-curved workpiece from it. The template can be made of wood, PCB or metal .

The advantage of the winding machine is its simple design, but the disadvantage is some limitation in the size of the template and the need for a powerful lever.

Wooden conductor

This design can be considered a break-in device, and the difference is that there is no pressure roller.

To make this device you will need thick plywood or boards; you can use a workbench or a massive chipboard slab as a base. A template is made from a thick board, one side of which is rounded to a certain radius. It is rigidly fixed to the edge of the workbench in such a way that the workpiece prepared for bending can be freely wrapped around it.

The end of the workpiece can be fixed with a primitive wooden stop made of timber or by cutting the same board from which the template was made. The pipe is bent using muscular force smoothly, without sudden movements, then its damage will be insignificant, and the acquired geometric shape will be accurate and even.

To prevent the bent part from jumping off the template (punch), it is advisable to make a semicircular recess around the perimeter of its rounded part, treating the end with a round rasp.

Fixing the pipe on the template can be done in another way by stuffing a rounded piece of plywood on top of it, which should protrude beyond its edge within 6-10 mm. True, this option is well suited if the tube has thin walls, since bending parts with thick walls requires more powerful forces, and the wooden punch may simply collapse.

Before you start bending the pipe, it is recommended to pour dry sand into it and plug both ends with wooden plugs.

This will help to avoid the appearance of waves (corrugations) on the workpiece on the inside of the curved section, and large stretching of the metal on the outer wall of the bend.

Of all the existing pipe bending machines, the most widely used is the self-made pipe bender, which operates on the principle of a rolling device. This model of pipe bender has virtually no disadvantages; it is light in weight and size, can be easily transported and takes up little space during storage.

Impression of a jig in a punch with a matrix

Using a hammer and punches with profiles of different shapes, we alternately punch indentations in the matrix - impressions that repeat the configuration of the working surfaces of the manufactured punches.

Then, using a file, we remove the excess metal that has come out near the imprints of future jigs, using this operation to level the surface of the aluminum bar. Our matrix with impressions for making do-it-yourself crowns for jigs of various shapes is ready for use.

As the punch prints wear out in the matrix, you can hammer the corresponding recess with a hammer and renew it again with your punch. Therefore, the matrix for making jig blanks lasts a long time.

And a few more words about the matrix material for making stamped jig blanks with your own hands.

Possibilities of a homemade tool

A pipe bender made from a jack is used for all types of work on bending pipes, profiles, sheets, rods and other types of workpieces. Parts can be made of non-ferrous or ferrous metals. When bending, it is necessary to use templates that do not damage the walls of the products.

Used for the following purposes:

- bending of thin- and thick-walled pipes;

- creating complex rounded shapes from rods and reinforcement;

- bending profiles with different sections - square, rectangular.

What pipes can be bent?

A pipe bender is a bending tool that is suitable for all types of cast or drawn, seamless or welded pipes. It allows you to deform workpieces of any diameter and thickness. To prevent material rupture, it is recommended to use specially designed configurations (rolled or mandrel).

Before performing work, you need to make sure that the part will bend in accordance with the technical requirements. Recommendations for using tools:

- with a wall thickness of 1 mm or more, crossbow pipe bending machines are used;

- pipes with a diameter of up to 30 mm can be bent using a jack with a load capacity of 5 tons;

- if the diameter is more than 30 mm, use tools made from a jack designed for lifting cars from 5 to 12 tons.

Using pipe benders

The tool allows you to produce the following products:

- arched or pitched structures for greenhouses;

- decorative fencing;

- awnings and canopies;

- car repair parts;

- arched structures for grapes or flowers.

Classification

According to the principle of operation, pipe benders are:

- Lever. Consists of a workbench and a bed. They work through the use of human strength and force increased by a lever of a certain length.

- Crossbow. Structurally, they consist of a punch, rollers, a T-shaped frame, and a hydraulic cylinder. The force is transmitted through a hydraulic cylinder.

- Roller. They consist of a frame, rollers mounted on it, a manual rotary drive or an electric motor, and a gearbox.

- Dornovye. Professional machines with a complex design, equipped with a large number of settings. They allow you to bend workpieces with high precision and create shapes of any complexity.