- Punch: a detail you can’t do without

- Punches for press brakes from Rolleri

To obtain unique metal products, it is often impossible to do without the use of specialized hydraulic equipment. With its help, metal sheets are subjected to bending and forming processes, giving them the look desired by the customer. The equipment consists of molds consisting of a matrix and a punch for a sheet bender. These parts are located at the bottom and top of the clamp, and perform a joint mechanical effect on the workpiece.

Types, thicknesses and geometry of bending material

Rimax Group LLC offers bending of sheet blanks according to customer drawings with a length of up to 4000 mm

and a thickness of up to 16

mm

in Moscow, the Moscow region and throughout the Russian Federation

at an attractive price. Bending material is black and stainless steel, aluminum and its alloys. Metal bending is of greatest interest to customers in the cities of Balashikha, Mytishchi, Lyubertsy, Elektrostal, Korolev and Orekhovo-Zuevo.

The maximum bending force of the presses is 220 tons.

WE DESIGN BENDING REAMERS “FROM ZERO” according to your sketches, drawings and technical specifications. WE ARE READY TO OFFER RADIUS BENDING according to your specifications. If the required tool is not available, we will design and manufacture a bending tool for your product.

Below is a table of bends. It contains information about bending radii, minimum flanges, required forces on certain dies

:

| Theoretical table of radii, forces, lengths and minimum dimensions of flanges and dies for free bending | ||||||||||

| Thickness | Matrix stream width | Structural steel | Stainless steel | Aluminum | ||||||

| Radius | Min. Shelf | Max Length | Radius | Min. Shelf | Max Length | Radius | Min. Shelf | Max Length | ||

| 1,0 | 8 | 1,3 | 6 | 4200,0 | 1,3 | 6 | 4200,0 | 1,3 | 6 | 4200,0 |

| 1,2 | 8 | 1,3 | 6 | 4200,0 | 1,3 | 6 | 4200,0 | 1,3 | 6 | 4200,0 |

| 1,5 | 8 | 1,3 | 6,5 | 4200,0 | 1,3 | 6,5 | 4200,0 | 1,3 | 6,5 | 4200,0 |

| 12 | 1,9 | 9,5 | 4200,0 | 1,9 | 9,5 | 4200,0 | 1,9 | 9,5 | 4200,0 | |

| 2,0 | 12 | 1,9 | 10 | 4200,0 | 1,9 | 10 | 4200,0 | 1,9 | 10 | 4200,0 |

| 2,5 | 16 | 2,6 | 13 | 4200,0 | 2,6 | 13 | 4200,0 | 2,6 | 13 | 4200,0 |

| 3,0 | 22 | 3,5 | 17,5 | 4200,0 | 3,5 | 17,5 | 4200,0 | 3,5 | 17,5 | 4200,0 |

| 4,0 | 35 | 5,6 | 27 | 4200,0 | 5,6 | 27 | 4200,0 | 5,6 | 27 | 4200,0 |

| 5,0 | 35 | 5,6 | 28 | 4200,0 | 5,6 | 28 | 2930,0 | 5,6 | 28 | 4200,0 |

| 50 | 8,0 | 37 | 4200,0 | 8,0 | 37 | 4200,0 | 8,0 | 37 | 4200,0 | |

| 6,0 | 50 | 8,0 | 38 | 4200,0 | 8,0 | 38 | 3250,0 | 8,0 | 38 | 4200,0 |

| 63 | 10,1 | 47 | 4200,0 | 10,1 | 47 | 4200,0 | 10,1 | 47 | 4200,0 | |

| 8,0 | 50 | 8,0 | 40,5 | 2500,0 | 8,0 | 40,5 | 1666,7 | 8,0 | 40,5 | 3125,0 |

| 63 | 10,1 | 49 | 3100,0 | 10,1 | 49 | 2066,7 | 10,1 | 49 | 3875,0 | |

| 10,0 | 80 | 12,8 | 62 | 2700,0 | 12,8 | 62 | 1800,0 | 12,8 | 62 | 3375,0 |

| 100 | 16,0 | 75 | 3700,0 | 16,0 | 75 | 2466,7 | 16,0 | 75 | 4200,0 | |

| 12,0 | 100 | 16,0 | 77 | 2400,0 | 16,0 | 77 | 1600,0 | 16,0 | 77 | 3000,0 |

| 160 | 25,6 | 116 | 4200,0 | 25,6 | 116 | 2900,0 | 25,6 | 116 | 4200,0 | |

| 14,0 | 160 | 25,6 | 118 | 2700,0 | 25,6 | 118 | 1800,0 | 25,6 | 118 | 3375,0 |

| 16,0 | 160 | 25,6 | 120 | 2600,0 | 25,6 | 120 | 1733,3 | 25,6 | 120 | 3250,0 |

Read also: Why the spray gun spits paint

We also offer additional services for the development and/or modification of developments, adjustment of contours, development and modification of design documentation.

Please send your requests for order estimates along with drawings to the company's email address: E-mail: [email protected]

.

Bending tool

A press punch refers to a bending tool that functions as a die.

It is used in sheet bending machines for processing sheet metal made of steel, stainless steel, coated metals, etc. Since a lot of pressure is applied to the tool when bending a part, durable grades of tool steel are used for production. The working parts of the products must be hardened using a laser machine or induction heating.

Our catalog contains the following types of bending tools:

- A

- T

- W

- L

In addition to the tools presented in the catalog, it is possible to produce bending punches with fastenings B, C, D, E, F, etc. according to customer drawings.

Price list for bending sheet blanks:

We offer a price list for sheet metal bending services. Our prices are valid from March 1, 2022.

The minimum order value for bending is 5,000 rubles. excluding the cost of materials. If the Customer significantly increases the volume of subsequent orders, then the amount is 5,000 rubles. included as a discount on your next order.

on the machine

Description of the punch for the TOP.175-60-R5 ROLLERI press brake:

Gooseneck type punch. Designed primarily for bending parts with long flanges. Made from quality 42Cr alloy steel. Working surfaces are hardened by induction hardening to HRC 54-60 (1980-2200 N/mm 2 ). All working, fastening and joining surfaces of the punch are ground.

The press brake punch TOP.175-60-R5 ROLLERI is a bending tool. It is installed on a press brake and is designed for bending sheet metal at a given angle. The punch is used in conjunction with a matrix. The sheet of metal being processed is placed between the die and the punch. The punch for the TOP.175-60-R5 ROLLERI press brake exerts direct pressure on the sheet of metal being processed from above, pressing it into the die. Thus, the sheet of metal being processed is bent along its entire length at a given angle, repeating (in some cases approximately) the shape and angle of the punch and matrix.

ATTENTION! We have developed the StrongTonn program, which calculates the bending force and other parameters. Go to the homepage with the program

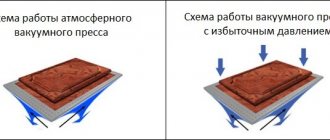

There are two bending methods:

We are talking about free and air bending, when there is an air gap between the sheet and the walls of the V-shaped matrix. This is the method that is most commonly used.

The "sizing" method is an old method that is used in certain cases where the sheet is pressed completely against the walls of the V-shaped die.

What steels are punches made from?

The following steel grades are used for punches:

- U10A, X, X12M, X6VF, U8A and 8HF - for punching punches with a simple or complex shape of the cutting contour (56-60 HRC), stripping molds (X12M, X6VF with a hardness of 58-62 HCR).

- U8A, 8ХФ, Х12М and Х6ВФ - for bending and forming punches of simple shape (54-58 HRC) and complex shape (56-60 HRC).

- U10A, U10 or SCh 32-52 for drawing, flanging punches, as well as for the manufacture of parts from corrosion-resistant steel grades.

Steels 6ХВФ, Х12Ф1 and 7Х3 are used in the case of stamping of products from transformer steel and other hard materials.

Free bending

This direction has certain limitations.

Character traits:

- The traverse presses the sheet to a selected depth along the Y axis into the die groove using a punch;

- The sheet is “in the air” and does not come into contact with the walls of the matrix;

- This means that the bending angle is determined by the position of the Y axis and not by the geometry of the bending tool.

On a modern press, the Y-axis adjustment accuracy is 0.01 mm. To answer the question of what should be the bending angle corresponding to a given position of the Y axis, it is necessary to find the corresponding position of the Y axis for all angles.

Below is a table showing deviations of the bending angle from 90° for different deviations of the Y axis.

| a° / V mm | 1° | 1,5° | 2° | 2,5° | 3° | 3,5° | 4° | 4,5° | 5° |

| 4 | 0,022 | 0,033 | 0,044 | 0,055 | 0,066 | 0,077 | 0,088 | 0,099 | 0,11 |

| 6 | 0,033 | 0,049 | 0,065 | 0,081 | 0,097 | 0,113 | 0,129 | 0,145 | 0,161 |

| 8 | 0,044 | 0,066 | 0,088 | 0,110 | 0,132 | 0,154 | 0,176 | 0,198 | 0,220 |

| 10 | 0,055 | 0,082 | 0,110 | 0,137 | 0,165 | 0,192 | 0,220 | 0,247 | 0,275 |

| 12 | 0,066 | 0,099 | 0,132 | 0,165 | 0,198 | 0,231 | 0,264 | 0,297 | 0,330 |

| 16 | 0,088 | 0,132 | 0,176 | 0,220 | 0,264 | 0,308 | 0,352 | 0,396 | 0,440 |

| 20 | 0,111 | 0,166 | 0,222 | 0,277 | 0,333 | 0,388 | 0,444 | 0,499 | 0,555 |

| 25 | 0,138 | 0,207 | 0,276 | 0,345 | 0,414 | 0,483 | 0,552 | 0,621 | 0,690 |

| 30 | 0,166 | 0,249 | 0,332 | 0,415 | 0,498 | 0,581 | 0,664 | 0,747 | 0,830 |

| 45 | 0,250 | 0,375 | 0,500 | 0,625 | 0,750 | 0,875 | 1,000 | 1,125 | 1,250 |

| 55 | 0,305 | 0,457 | 0,610 | 0,762 | 0,915 | 1,067 | 1,220 | 1,372 | 1,525 |

| 80 | 0,444 | 0,666 | 0,888 | 1,110 | 1,332 | 1,554 | 1,776 | 1,998 | 2,220 |

| 100 | 0,555 | 0,832 | 1,110 | 1,387 | 1,665 | 1,942 | 2,220 | 2,497 | 2,775 |

Read also: Safety head inserts for thread-cutting chucks

Free bending: advantages

- High flexibility

- Low tooling costs

- Compared to calibration, less bending force is applied

- Possibility of changing bending

- Low costs due to the need for a press with less force

All this, however, is theoretical. In practice, you can spend the money saved on purchasing a lower force press that allows you to take full advantage of air bending on additional equipment, such as additional backgauge axles or manipulators.

Air bending: disadvantages

- Having less precise bending angles

- Lack of applicability for specific bending operations

Advice:

- It is advisable to use air bending for sheets with a thickness of over 1.25 mm; For sheet thickness of 1 mm or less, it is recommended to use calibration.

- The smallest internal bending radius must be greater than the sheet thickness. If the inner radius must be equal to the sheet thickness, it is recommended to use the calibration method. An internal radius less than the sheet thickness is permissible only on soft, easily deformable material, such as copper.

- A large radius can be achieved by air bending by using stepwise movement of the backgauge. If a large radius must be of high quality, only the special tool calibration method is recommended.

What effort?

Due to the different material properties and the effects of plastic deformation in the bending zone, the required force can only be determined approximately. We offer you 3 practical ways:

Table

In each catalog and on each press you can find a table showing the required force (P) in tons per 1000 mm bending length (L) depending on:

- sheet thickness (S) in mm

- tensile strength (Rm) in N/mm2

- V – matrix opening width (V) in mm

- internal radius of the bent sheet (Ri) in mm

- minimum height of the bent shelf (B) in mm

An example of such a table is the required force to bend 1 meter of sheet in tons. Tensile strength 42-45 kg/mm2. Recommended ratio of parameters and force

| V | Ri | B | S | |||||||||||||||||||

| 1,0 | 1,2 | 1,5 | 1,8 | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | 4,5 | 5,0 | 6,0 | 7,0 | 8,0 | 9,0 | 10 | 12 | 15 | 18 | 20 | |||

| 6 | 1 | 4,5 | ||||||||||||||||||||

| 8 | 1,3 | 6 | 8 | 12 | 17 | |||||||||||||||||

| 10 | 1,7 | 7 | 7 | 9 | 14 | 20 | ||||||||||||||||

| 12 | 2 | 8,5 | 6 | 9 | 12 | 18 | 21 | |||||||||||||||

| 16 | 2,7 | 11 | 6 | 9 | 13 | 16 | 25 | |||||||||||||||

| 20 | 3,3 | 14 | 7 | 10 | 13 | 20 | 29 | 39 | ||||||||||||||

| 25 | 4,2 | 18 | 8 | 10 | 16 | 23 | 31 | |||||||||||||||

| 30 | 5 | 22 | 9 | 13 | 19 | 25 | 34 | |||||||||||||||

| 32 | 5,5 | 23 | 8 | 12 | 18 | 24 | 32 | 40 | ||||||||||||||

| 35 | 5,7 | 25 | 11 | 16 | 22 | 29 | 37 | 45 | 65 | |||||||||||||

| 40 | 6,7 | 29 | 14 | 20 | 25 | 32 | 40 | 57 | ||||||||||||||

| 45 | 7,5 | 32 | 17 | 23 | 29 | 35 | 50 | 69 | 90 | |||||||||||||

| 50 | 8,4 | 36 | 26 | 32 | 46 | 62 | 81 | |||||||||||||||

| 60 | 10 | 43 | 21 | 26 | 38 | 52 | 68 | 85 | 105 | |||||||||||||

| 70 | 12 | 50 | 22 | 33 | 44 | 58 | 73 | 90 | 130 | |||||||||||||

| 80 | 13 | 57 | 29 | 39 | 50 | 64 | 79 | 113 | ||||||||||||||

| 90 | 15 | 64 | 35 | 45 | 57 | 70 | 101 | 158 | ||||||||||||||

| 100 | 17 | 71 | 41 | 51 | 63 | 91 | 142 | 205 | ||||||||||||||

| 120 | 20 | 91 | 42 | 53 | 76 | 120 | 170 | 210 | ||||||||||||||

| 160 | 27 | 112 | 40 | 57 | 89 | 127 | 158 | |||||||||||||||

| 180 | 30 | 126 | 79 | 114 | 140 | |||||||||||||||||

| 200 | 33 | 140 | 102 | 127 | ||||||||||||||||||

Attention! For accurate calculations, the following GOSTs must be taken into account:

- GOST 19903-74 Hot-rolled sheets (Table 3) (link to table),

- GOST 19904-90 Cold-rolled sheets (Table 2) (link to table).

When rolling, deviations in the thickness of the metal are possible, and precise measuring instruments (for example, a micrometer) are required.

“Rule 8”

When bending low-carbon steel, the width of the die opening should be 8 times greater than the thickness of the sheet (V=8*S), then P=8xS, where P is expressed in tons (for example: for a thickness of 2 mm, the die opening /=2x8=16 mm means that you need 16 tons/m)

Bending force and length

The length of the bend is proportional to the force, i.e. the force reaches 100% only with a bend length of 100%.

For example:

| An effort | Bending length |

| 100% | 3000 mm |

| 75% | 2250 mm |

| 50% | 1500 mm |

| 25% | 750 mm |

Read also: Storing fasteners in the workshop

Advice:

If the material is rusty or not lubricated, 10-15% should be added to the bending force.

Sheet thickness (S)

DIN allows a significant deviation from the nominal sheet thickness (for example, for a sheet thickness of 5 mm, the norm ranges between 4.7 and 6.5 mm). Therefore, you only need to calculate the force for the actual thickness you measured or for the maximum specification value.

Tensile strength (Rm)

Here too, tolerances are significant and can have a major impact when calculating the required bending force. For example: St 37-2: 340-510 N/mm2 St 52-3: 510-680 N/mm2

Advice:

Don't skimp on bending force! The tensile strength is proportional to the bending force and cannot be adjusted when you need it! Actual thickness and tensile strength are important factors when selecting the right machine with the right force rating.

V – matrix disclosure

According to the rule of thumb, the opening of the V-shaped matrix should be eight times the sheet thickness S up to S=6 mm: V=8xS, for greater sheet thickness it is necessary V=10xS or V=12xS

The opening of the V-shaped matrix is inversely proportional to the required force:

- a larger opening means less bending force, but a larger inner radius;

- smaller opening means more force but smaller inner radius.

Inner bending radius (Ri)

When using the air bending method, most of the material is subject to elastic deformation. After bending, the material returns to its original state without residual deformation (“reverse springback”). In a narrow region around the point of application of the force, the material undergoes plastic deformation and remains in this state forever after bending. The greater the plastic deformation, the stronger the material becomes. We call this “strain hardening.” The so-called “natural internal bending radius” depends on the sheet thickness and die opening. It is always greater than the sheet thickness and does not depend on the punch radius.

To determine the natural inner radius we can use the following formula: Ri = 5 x V /32 In the case of V=8xS, we can say Ri=Sx1.25

The soft and easily deformable metal allows for a smaller internal radius. If the radius is too small, the material may wrinkle on the inside and crack on the outside of the bend.

Advice:

If you need a small inside radius, bend at slow speed and against the grain.

Minimum shelf (B):

To avoid the flange falling into the die groove, the following minimum flange width must be observed:

| Bend angle | B |

| 165° | 0.58 V |

| 135° | 0.60 V |

| 120° | 0.62V |

| 90° | 0.65 V |

| 45° | 1.00 V |

| 30° | 1.30 V |

Elastic deformation

Some of the elastically deformed material will “spring back” after the bending force is removed. How many degrees? This is a relevant question, because only the actually obtained bending angle is important, and not the theoretically calculated one. Most materials exhibit fairly constant elastic deformation. This means that a material of the same thickness and with the same tensile strength will spring back by the same amount at the same bending angle.

Elastic deformation depends on:

- bending angle: the smaller the bending angle, the greater the elastic deformation;

- material thickness: the thicker the material, the less elastic deformation;

- tensile strength: the higher the tensile strength, the greater the elastic deformation;

- fiber directions: elastic deformation is different when bending along or across the fibers.

Let us demonstrate what was said above for the tensile strength measured under the condition V = 8xS:

| Tensile strength in N/mm2 | elastic deformation in ° |

| 200 | 0,5 – 1,5 |

| 250 | 1 – 2 |

| 450 | 1,5 – 2,5 |

| 600 | 3 – 4 |

| 800 | 5 – 6 |

All bending tool manufacturers take elastic deformation into account when offering free bending tools (eg an opening angle of 85° or 86° for free bends from 90° to 180°).

Punch 1″, SOROKIN, 7.203

Punch 1″, SOROKIN, 7.203

with delivery throughout Russia: Moscow, St. Petersburg, Rostov-on-Don, Nizhny Novgorod, Samara, Chelyabinsk, Yekaterinburg, Novosibirsk and other cities.

A

- Abakan

- Azov

- Alexandrov

- Aleksin

- Almetyevsk

- Anapa

- Angarsk

- Anzhero-Sudzhensk

- Apatity

- Arzamas

- Armavir

- Arsenyev

- Artyom

- Arkhangelsk

- Asbestos

- Astrakhan

- Achinsk

B

- Balakovo

- Balakhna

- Balashikha

- Balashov

- Barnaul

- Bataysk

- Belgorod

- Belebey

- Belovo

- Belogorsk

- Beloretsk

- Belorechensk

- Berdsk

- Berezniki

- Berezovsky

- Biysk

- Birobidzhan

- Blagoveshchensk

- Bor

- Borisoglebsk

- Borovichi

- Bratsk

- Bryansk

- Bugulma

- Budennovsk

- Buzuluk

- Buynaksk

IN

- Velikie Luki

- Velikiy Novgorod

- Upper Pyshma

- Vidnoe

- Vladivostok

- Vladikavkaz

- Vladimir

- Volgograd

- Volgodonsk

- Volzhsk

- Volzhsky

- Vologda

- Volsk

- Vorkuta

- Voronezh

- Voskresensk

- Votkinsk

- Vsevolozhsk

- Vyborg

- Vyksa

- Vyazma

G

- Gatchina

- Gelendzhik

- Georgievsk

- Glazov

- Gorno-Altaisk

- Grozny

- Gubkin

- Gudermes

- Gukovo

- Gus-Khrustalny

D

- Derbent

- Dzerzhinsk

- Dimitrovgrad

- Dmitrov

- Dolgoprudny

- Domodedovo

- Donskoy

- Dubna

E

- Yegoryevsk

- Yeysk

- Ekaterinburg

- Elabuga

- Dace

- Essentuki

AND

- Zheleznogorsk

- Zheleznogorsk

- Railway

- Zhigulevsk

- Zhukovsky

Z

- Zarechny

- Zelenogorsk

- Zelenodolsk

- Zlatoust

AND

- Ivanovo

- Ivanteevka

- Izhevsk

- Izberbash

- Irkutsk

- Iskitim

- Ishim

- Ishimbay

Y

- Yoshkar-Ola

TO

- Kaliningrad

- Kaluga

- Kamensk-Uralsky

- Kamensk-Shakhtinsky

- Kamyshin

- Kansk

- Kaspiysk

- Kemerovo

- Kineshma

- Kirishi

- Kirov

- Kirovo-Chepetsk

- Kiselevsk

- Kislovodsk

- Klimovsk

- Wedge

- Klintsy

- Kovrov

- Kogalym

- Kolomna

- Komsomolsk-on-Amur

- Kopeisk

- Korolev

- Kostroma

- Kotlas

- Krasnogorsk

- Krasnodar

- Krasnokamensk

- Krasnokamsk

- Krasnoturinsk

- Krasnoyarsk

- Kropotkin

- Krymsk

- Kstovo

- Kuznetsk

- Kumertau

- Kungur

- Mound

- Kursk

- Kyzyl

L

- Labinsk

- Leninogorsk

- Leninsk-Kuznetsky

- Lesosibirsk

- Lipetsk

- Liski

- Lobnya

- Lysva

- Lytkarino

- Lyubertsy

M

- Magadan

- Magnitogorsk

- Maykop

- Makhachkala

- Mezhdurechensk

- Meleuz

- Miass

- Mineral water

- Minusinsk

- Mikhailovka

- Mikhailovsk

- Michurinsk

- Moscow

- Murmansk

- Moore

- Mytishchi

N

- Naberezhnye Chelny

- Nazarovo

- Nazran

- Nalchik

- Naro-Fominsk

- Nakhodka

- Nevinnomyssk

- Neryungri

- Neftekamsk

- Nefteyugansk

- Nizhnevartovsk

- Nizhnekamsk

- Nizhny Novgorod

- Nizhny Tagil

- Novoaltaysk

- Novokuznetsk

- Novokuibyshevsk

- Novomoskovsk

- Novorossiysk

- Novosibirsk

- Novotroitsk

- Novouralsk

- Novocheboksarsk

- Novocherkassk

- Novoshakhtinsk

- New Urengoy

- Noginsk

- Norilsk

- Noyabrsk

- Nyagan

ABOUT

- Obninsk

- Odintsovo

- Ozyorsk

- October

- Omsk

- Eagle

- Orenburg

- Orekhovo-Zuevo

- Orsk

P

- Pavlovo

- Pavlovsky Posad

- Penza

- Pervouralsk

- Permian

- Petrozavodsk

- Petropavlovsk-Kamchatsky

- Podolsk

- Polevskoy

- Prokopyevsk

- Chill

- Pskov

- Pushkino

- Pyatigorsk

R

- Ramenskoye

- Revda

- Reutov

- Rzhev

- Roslavl

- Rossosh

- Rostov-on-Don

- Rubtsovsk

- Rybinsk

- Ryazan

WITH

- Salavat

- Salsk

- Samara

- Saint Petersburg

- Saransk

- Sarapul

- Saratov

- Sarov

- Free

- Severodvinsk

- Seversk

- Sergiev Posad

- Serov

- Serpukhov

- Sertolovo

- Sibay

- Slavyansk-on-Kuban

- Smolensk

- Solikamsk

- Solnechnogorsk

- Pinery

- Sochi

- Stavropol

- Stary Oskol

- Sterlitamak

- Stupino

- Surgut

- Sizran

- Syktyvkar

T

- Taganrog

- Tambov

- Tver

- Timashevsk

- Tikhvin

- Tikhoretsk

- Tobolsk

- Tolyatti

- Tomsk

- Troitsk

- Tuapse

- Tuymazy

- Tula

- Tyumen

U

- Nodal

- Ulan-Ude

- Ulyanovsk

- Urus-Martan

- Usolye-Sibirskoye

- Ussuriysk

- Ust-Ilimsk

- Ufa

- Ukhta

F

- Fryazino

X

- Khabarovsk

- Khanty-Mansiysk

- Khasavyurt

- Khimki

H

- Chaikovsky

- Chapaevsk

- Cheboksary

- Chelyabinsk

- Cheremkhovo

- Cherepovets

- Cherkessk

- Chernogorsk

- Chekhov

- Chistopol

- Chita

Sh

- Shadrinsk

- Shawls

- Mines

- Shuya

SCH

- Shchyokino

- Shchelkovo

E

- Elektrostal

- Elista

- Engels

YU

- Yuzhno-Sakhalinsk

- Yurga

I

- Yakutsk

- Yaroslavl

Delivery

Courier delivery:

We will deliver:

-

in Moscow from

350 rubles.

, outside the Moscow Ring Road: Delivery calculator ▼

Distance from MKAD:

Item weight: kg

Cost of delivery 180

rub

Transport company:

from Moscow Delivery information ►

(Dispatch of TC is carried out on 100% prepayment)

Delivery distance:

Item weight: kg

Cost of delivery 180

rub

Pickup: Entrance and entry into the territory - Free.

Address:

108820, Moscow, vn.ter.g. settlement "MOSRENTGEN", village of Dudkino, ter. SNT "FRIENDSHIP" plant ATE-1, vld. 49 page 1 Directions ►

Payment

Choose the most suitable payment method for yourself Read more ▼

| Payment to the courier (cash/card) | Electronic money transfer | Cashless payment (for legal entities) |