Chemical milling gives the product an ideal shape.

Chemical finishing of iron is a set of technological processes due to which the physical and chemical properties of the metal surface change. The technology is practiced only at high temperatures and in active media (solid, liquid or gaseous). The end result of chemical treatment is a change in the physical and chemical properties of the diffuse iron layer.

Purposes of processing

The considered method of finishing metal products makes it possible to increase strength indicators and enhance the anti-corrosion protection of the product. In addition, the service life of the treated substances increases. The advantages of iron diffuse surface finishing include:

- Performance. Most reactions proceed quickly, which allows the technology to be used on an industrial scale;

Chemical milling - Versatility. Practice has shown that even on a lathe it is possible to improve the performance of the element being processed with the correct choice of finishing method;

- Elimination (in most cases) of thermal or mechanical effects. The absence of these types of influence increases the performance qualities of the processed raw materials;

Etching (chemical milling) is the most common finishing method. The technology is used to work with thin metal sheets and a large number of small elements. Etching is widely used in various fields and mass production of materials with improved technical characteristics.

Studied thermal engineering, cementation of bushings

Chemical and mechanical preparation of surfaces for painting

Typically, the chemical surface preparation process consists of the following stages.

- 1. Degreasing and cleaning. 2. Removal of corrosion products or oxides. 3. Activation. 4. Conversion processing. 5. Final treatment (passivation, washing with demineralized water). 6. Drying.

Between all stages of preparing the surface for painting, rinsing with water is carried out, preferably in two stages.

For harsh operating conditions of coatings (open atmosphere), it is necessary to apply a complete technological process for preparing the surface for painting with the application of protective conversion coatings. If painted metal products are used indoors at normal humidity, then you can limit yourself to degreasing only.

Our institute has developed a wide range of weakly and moderately alkaline compositions of the KM brand for degreasing, consisting of a mixture of salts (phosphates, borates, soda ash, silicates) and surfactants. They can be used in dipping baths or spray installations.

The following compositions are recommended for degreasing steel: KM-1, KM-19, KM-17, KM-22; for non-ferrous metals - KM-25, KM-18M. For degreasing and interoperational storage of steel and cast iron parts - KM-27, HOS-3.

If only degreasing is used to prepare the surface of ferrous metals for painting, then passivation must be carried out to prevent secondary corrosion during drying. A good result is achieved by using solutions based on chromium (trivalent or hexavalent).

Note that it is unacceptable to use solutions of sodium nitrite, tri- and monoethanolamine for passivation before painting metal.

The list of all stages of the surface preparation process for painting, including conversion treatment, depends on the type of metal.

What conversion treatment is used for ferrous metals?

Steel products are phosphated before painting. During the phosphating process, an inorganic coating of poorly soluble phosphate salts of heavy metals is formed on the metal surface.

Phosphate coatings according to their composition are divided into crystalline (zinc phosphate) and amorphous (iron phosphate). Zinc phosphate coatings are superior to iron phosphate coatings in terms of corrosion resistance, therefore they are recommended for preparing the surface of products for painting that are used in harsh climatic conditions.

Zinc phosphating

used for preparing the surface of car bodies, agricultural machinery, and building structures;

iron phosphating

- for metal furniture, household appliances, lamps, etc.

The complete phosphating process consists of at least 5 - 6 stages and can be carried out by immersion and spraying methods.

The operation of iron phosphating can be combined with degreasing, then the number of processing stages is reduced to three or four.

The industry produces modern phosphating compounds developed by our institute for surface preparation before all types of painting.

The creation of new phosphating compositions follows the path of improving the consumer properties of the formed phosphate coatings and the environmental characteristics of the phosphating process. This is achieved by introducing additional nickel and manganese cations into the formulations and reducing the concentration of zinc.

In the automotive industry, compositions for crystalline phosphating KF-12, KF-14, KF-15, KF-16, created to replace KF-1, KF-3, are successfully used.

For simultaneous degreasing and amorphous phosphating, a new composition KFA-10 has been developed, which forms thickened iron phosphate layers with increased corrosion resistance instead of KFA-8.

Features of surface preparation for painting metals belonging to the non-ferrous group

Of the non-ferrous metals, galvanized steel and aluminum, as well as their alloys, are most often painted.

If the operating conditions of the products make it possible to limit the preparation of the surface for painting by the degreasing process, then it is necessary to take into account the special instability of these metals to the effects of alkaline detergents.

When processed in highly alkaline aqueous compounds, they become etched and darken, so it is recommended to use special detergent compositions to degrease them.

If it is necessary to carry out a complete technological process of preparing the aluminum surface with the application of a conversion (chromate or non-chromate) coating, then the oxide film must be removed from the aluminum surface for painting by etching in strongly alkaline or acidic solutions.

If the products are slightly greasy, the etching process can be combined with degreasing.

Domestic manufacturers of products made of painted aluminum and galvanized steel have the erroneous opinion that these metals do not require complete surface preparation for painting with the application of conversion coatings.

The practice of operating products made of these metals in humid conditions has shown that in the absence of conversion treatment (chromatation, passivation, phosphating), light white corrosion forms under the paint coating layer, causing loss of adhesion up to peeling of the coating.

Today, the most effective method of preparing a metal surface for painting is chroming.

In practice, the processes of yellow chromating (Alcon-1, Ecomet A-001) and green chromating (Alcon-4) are used. However, the use of chromating is limited due to the high toxicity of chromium compounds. Our institute has developed and implemented a no-rinse, environmentally friendly chromate treatment process using Formichrome for processing coiled metal.

Leading European companies are beginning to introduce chromate-free processing of non-ferrous metals. For these purposes, chemicals are used based on complex fluoride compounds of zirconium, titanium or processing to obtain coatings from complex oxides of nickel, cobalt, and oxysilanes.

For processing zinc and galvanized steel, phosphating can be successfully used instead of chromating, especially if steel is processed at the same time.

What technologies are used to prepare the surface of non-metallic surfaces: polymers, wood, concrete, slate, asbestos cement?

Our laboratory is developing technology and compositions for the chemical preparation of metal surfaces for painting.

In practice, we were faced with the preparation of the surface of plastic products, and good results were obtained when using the acidic degreasing composition KIMOS-5.

However, the choice of composition and technology for preparing the surface for painting should be carried out specifically for each type of polymer.

What methods are used to control the quality of surface preparation for painting?

Since the process of preparing a surface for painting is multi-stage, its quality control must be carried out after each stage of processing. In practice, primarily visual inspection of the surface is used.

The quality of degreasing is assessed by wiping the surface with a white rag or by the wettability of the surface with water during subsequent washing. The degree of cleaning from rust and corrosion products is determined by examining the surface at five times magnification.

If conversion treatment is used, then quality control of phosphate and chromate coatings is carried out on witness samples: the mass of the coating per unit surface and the size of the crystals are determined.

The most important indicator of effective surface preparation for painting

— good characteristics of the paint and varnish coating: corrosion resistance and physical and mechanical properties.

How does surface preparation affect the properties of paint and varnish coatings?

A certain difficulty lies in the fact that the influence of the quality of surface preparation on the properties of a complex paint and varnish coating does not always appear immediately after painting. And often the consumer pays for violations associated with preparing the surface for preparation.

For example, paintwork is poorly applied to a poorly degreased surface; oil residues can cause crater formation. If the quality of degreasing is poor, the coating has poor adhesion.

Poor final rinsing or use of hard water causes osmotic swelling, especially in polyester powder coatings when used in wet conditions.

The cause of osmotic swelling of paint and varnish coatings, the formation of bubbles, and adhesion failure is the manual preparation of the surface for painting using water-soluble degreasers without rinsing and hot drying.

The durability of the paint and varnish coating, protection against filamentary and under-film corrosion is directly related to such stages of surface preparation as phosphating, chromate and passivation.

Poorly carried out preparation of the surface for painting or an incorrect choice of its stages will necessarily manifest itself in the destruction of the paintwork, the faster the more severe the operating conditions.

How to choose the right materials and technology for preparing specific surfaces to be painted?

The choice of surface preparation technology for painting depends on three main factors: the operating conditions of the painted products, the type of metal and the condition of the original surface. GOST 9.402-2004 "ESZKS". Paint and varnish coatings. Preparing metal surfaces for painting involves dozens of different surface preparation schemes for different metals and operating conditions.

It is the operating conditions that determine whether the process of preparing the surface for painting will be complete, including conversion treatment, or whether it is sufficient to limit it to cleaning only.

The type of metal determines the type of conversion treatment (phosphating, chromating, passivation). The condition of the original surface (presence of rust, scale, oxide layers) dictates the need to use etching or mechanical cleaning operations.

In addition, it is necessary to take into account the type of paintwork materials used, product dimensions, production space, available equipment, and financial capabilities.

Application methods and type of coatings place demands on the quality of conversion coatings, especially when using electrodeposition or applying powder coatings.

The dimensions of the product and the production program determine the method of applying the compositions:

- immersion in baths or spraying in chambers;

- cyclic or continuous conveyor.

Unfortunately, due to lack of financial resources, optimal technology is often abandoned at the expense of painting quality.

Materials for surface preparation are selected when the technologies and equipment for preparing the surface for painting are known.

Nowadays the market offers a wide range of domestic and foreign compositions, when choosing which you must be sure that these materials will provide the necessary quality of surface preparation for painting, and their price corresponds to the quality.

In conclusion, I would like to note that the choice of surface preparation technology and the materials used for painting is an important step and should be done individually for each specific case with the involvement of qualified specialists. Contact us - we will always help.

Types of chemical-thermal methods

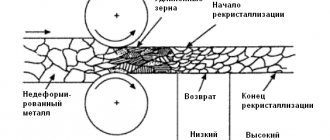

During chemical treatment, different reactions occur, however, on the surface of the workpiece the same processes occur in the same sequence. Chemical finishing stages:

- Beginning of the reaction. At this stage, the transfer of diffusing substances to the element being processed occurs;

Chemical-thermal treatment of metals - Diffusion;

- Completion of the reaction. At this stage, the physical and chemical properties of the metal are improved;

- The final processing of the substance is often carried out on a lathe or milling machine to consolidate the acquired properties.

In modern metallurgy, several chemical treatment methods are practiced:

- Cementation is the process of saturating a metal product with carbon. Chemical processing makes it possible to obtain a unique substance with a durable shell and a soft core;

- Nitriding is the process of saturating the surface layer with nitrogen in order to improve the material’s resistance to wear and corrosion;

Types of chemical and thermal treatment - Boridation is a set of technological processes for saturating metals with boron. Raw materials saturated with boron have high wear-resistant qualities, especially against friction and dry sliding. In addition, boron creates a layer on the metal surface that increases resistance to cold welding. Also, borated materials are resistant to alkaline substances and various types of acids;

- Aluminizing is the processing of metal using aluminum on a machine. The technology makes it possible to obtain materials that are resistant to aggressive gases (hydrogen sulfide or sulfuric anhydride);

- Chrome plating is the process of enriching the upper layers of metal with chromium. Chrome plating does not increase the strength of a metal product, but it increases wear resistance and corrosion resistance. It is worth noting that hard chrome plating significantly improves the properties of metal products, for example, the treated substance increases strength, wear resistance and corrosion resistance.

Cyanidation, nitrocarburization

This is a technology for saturating steel with nitrogen and carbon. In this way, steels with a carbon amount of 0.3 - 0.4% are processed.

The ratio between carbon and nitrogen is determined by temperature. As it grows, the share of carbon increases. If oversaturated with both elements, the layer becomes brittle.

The layer size is affected by exposure time and temperature.

Cyanidation is carried out in liquid and gaseous media. The first method is also called nitrocarburization. In addition, according to the temperature regime, both types are divided into high and low temperature.

In the liquid method, salts with sodium cyanide are used. The main disadvantage is their toxicity. The high-temperature version differs from carburization in speed, greater wear resistance and hardness, and less deformation of the material. Nitrocarburization is cheaper and safer.

Nitrocarburization of steel

The final mechanical treatment is first carried out, and the fragments that are not subject to cyanidation are covered with a layer of copper 18 - 25 microns thick.

Features of chemical finishing of metal on a machine

Metal processing on a machine can only be carried out after preparing the product using special devices - primary preparation units. Preparation takes into account the physical and chemical properties of the workpiece, as well as the individual needs of each department in the enterprise.

Methods of influencing metal:

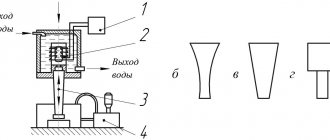

- Spraying is applied to parts that are used in dead-end or pass-through applications. The advantages of this method are the possibility of mass preparation of elements;

Methods of influencing metal - Immersion. This technology requires the production of separate containers with special solutions. Such a machine usually has mechanisms for laying out and mixing the metal product. After immersion, the material is sent to the drying chamber, where the final formation of its new physical and chemical parameters occurs. The processed parts are sent to a warehouse, from where they are transported to enterprises, where other machines will work with them; Steam blasting of metal

- The steam jet method is used to prepare large mechanisms or large metal sheets. The preparation process begins with cleaning the metal surface from grease and dust. Simultaneously with cleaning, phosphating of the treated surface occurs. It is worth noting that at this stage all work is performed manually and not on a machine. Primary processing ends with thermal exposure - the surface of the workpiece is treated with a blowtorch. Heat treatment is carried out simultaneously with the addition of active elements.

To finish the material using the listed methods, two types of equipment are used: stationary and mobile machines. It is worth noting that on a stationary machine the pressure can reach 5 atmospheres. High pressure ensures better penetration of chemical components into the upper layers of iron. Mobile equipment, as a rule, is not very powerful, so only rough processing of the workpiece is carried out with their participation.

Metal turning

The final preparation of the material is carried out on a lathe before chemical finishing. It is worth noting that on a lathe you can not only prepare, but also work with the workpiece. On such a device, thread cutting, drilling, reaming and countersinking of various holes are performed; turning grooves and cutting off parts. A stationary device is used to remove rust or remove the effects of corrosion.

Methods of mechanical processing of metals

A large group of methods for machining metals have one thing in common: each of them uses a sharp and hard tool in relation to the workpiece, to which mechanical force is applied. As a result of the interaction, a layer of metal is separated from the part, and its shape changes. The workpiece exceeds the dimensions of the final product by an amount called “allowance”

There are such types of mechanical processing of metals as:

- Turning. The workpiece is fixed in a rotating tooling, and a cutter is brought to it, removing a layer of metal until the dimensions specified by the designer are reached. Used for the production of parts shaped like a body of revolution.

- Drilling. A drill is immersed into a stationary part, which quickly rotates around its axis and is slowly fed towards the workpiece in the longitudinal direction. Used for making round holes.

- Milling. Unlike drilling, where processing is carried out only with the front end of the drill, the side surface of the cutter is also working, and in addition to the vertical direction, the rotating cutter moves both right and left and back and forth. This allows you to create parts of almost any desired shape.

- Planing. The cutter moves back and forth relative to the stationary part, each time removing a longitudinal strip of metal. In some machine models, the cutter is fixed and the part moves. Used to create longitudinal grooves.

- Grinding. The processing is carried out by rotating or performing longitudinal reciprocating movements with an abrasive material that removes thin layers from the surface of the metal. It is used for treating surfaces and preparing them for coating.

Metal grinding

Each operation requires its own special equipment. In the technological process of manufacturing a part, these operations are grouped, alternated and combined to achieve optimal productivity and reduce intra-shop costs.

Exposure to electricity

Electrical impact is a special type of metalworking associated with the use of high-intensity discharges. They are used to burn holes, form protrusions and openings. The method is designed for thick sheets. Graphite or brass electrodes serve as contact elements.

The capture of metal particles formed during the processing process is ensured by oil compositions.

Rice. 3 Cutting with graphite electrode

Working with welding equipment

By welding, permanent joints are formed, cavities and cracks are eliminated, and the geometry of the part is adjusted by welding plates or a layer of metal.

There are three welding methods.

- Gas. The components to be welded are heated by ignited gas. The fire source is acetylene, propane or butane. The work involves the use of liquefied fuel cylinders or an acetylene generator. The supply of combustible substance is regulated by the burner. Filler wire is used as a connecting element.

- Electric. There are three types of electric welding: manual, semi-automatic and automatic. In the first case, consumable electrodes are used, in the second - welding wire and protective (carbon dioxide) gas, in the third - robotic equipment that performs welding along a given contour.

- Chemical. Special compounds are used to heat and melt metal. During their reaction, a large amount of heat is released, which leads to fusion and welding of the components.

The latter welding method is used extremely rarely due to its complexity and high cost. With its help, work is carried out in hard-to-reach places.

Rice. 1 Electric welding

Pressure treatment

Processing of workpieces by pressure is carried out by stamping. The work is carried out on special machines that allow significant forces to be applied to the part. Actions may be accompanied by additional operations: upsetting, stretching, bending, etc.

Rice. 6 Metal stamping

Modern metalworking technologies

Each metalworking technology described above is standard. They have been used for quite a long time, they have firmly entered into mass production. However, there are new methods that are not familiar to everyone, but are still used mainly in private practice.

Plasma cutting

Plasma is a stream of hot ionized gas. It can replace mechanical cutting methods. This is an accurate, neat, and increasingly popular method.

Electrical discharge machining

Electrical discharge machining allows you to work with products of particular complexity: ultra-small, ultra-dense, etc. Surface changes occur under the influence of electrical discharges.

Laser welding

The technology is rarely used due to expensive equipment and high demands on specialists. However, the laser accurately and firmly welds parts from any alloy, which is why the technology is still relevant.

Ultrasonic processing of metal

This is a subtype of chiselling. Used when working with fragile substances: some semi-precious stones, gypsum, alabaster, etc. Operating range – 22 KHz.