Natural stone - marble, granite, slate, etc., in finishing and construction work, probably has no equal in aesthetics and practicality. Same as for the cost. Only very wealthy people can afford to purchase such materials for decorating their home or apartment. This is probably why a good alternative has appeared - artificial materials, which in appearance and characteristics are in no way inferior to the originals. The production of artificial marble today can be considered one of the most profitable areas in the production of building finishing materials.

Brief analysis of the business: Costs of organizing a business: 40-43 thousand rubles Relevant for cities with a population: from 100 thousand people Situation in the industry: low competition Difficulty of organizing a business: 2/5 Payback: from 2 months

Despite the protracted economic crisis in the country, the demand for building materials is not falling. A wide range of artificial stone choices allows it to be used in a variety of areas of construction, and its natural appearance, reliability, strength, and, of course, price make it one of the most popular building materials. Moreover, it should be noted that the technical properties of artificial marble are the same as those of natural stone, and in strength and resistance to wear it even surpasses the “original”.

Where exactly is artificial marble used? First of all, it is a material for finishing office and administrative premises. It is also used to make massive window sills, countertops, bar counters, bathtubs, and used for finishing staircase steps.

What does the artificial marble production line consist of?

The first step is to install the vibrating table. Its main purpose is the processing of concrete elements and reinforced concrete products, so we cannot do without it. It is worth drawing your attention to the fact that this composite material consists of polyester resin, as well as a mineral-based filler.

In principle, cement-sand mixtures are quite strong and have many advantages over polymer concrete. But let's continue to look at the equipment. As noted above, we need a vibrating table, preferably a forming one, it will allow us to give a certain shape to our workpiece.

You also need a cup sprayer and a mixer for mixing the solution. Of course, we will need forms, we need to think about this in advance. It all depends on why, or more precisely, for what field of activity we produce marble. Well, now in more detail about how the manufacturing process itself goes.

Possible problems

It may seem that the technology for molding cast marble is simple. And indeed this is so, anyone can learn it. However, without training and practical exercises, you will not be able to master it. Often, beginners simply spoil the stone; it turns out to be shagreen (orange peel effect), porous, covered with cracks and shells. In order not to waste time on your own mistakes, do not waste money on damaged forms - study our technology and immediately begin effective and profitable work.

See also: Cast artificial stone

Return to the "Articles" section

Artificial marble technology

A distinctive feature of cast stone is that you can get absolutely any color. This is achieved by adding various pigments. The binding element is polyester resin; it is this component that affects the strength of the material. So, it all starts with us finding raw materials. As a rule, these are sand, cement, pebbles (used as filler), water, dyes and 1% plasticizer.

We sift the material on a vibrating table, and then use cement, sand and pebbles to make a solution in a concrete mixer. Before this, we prepare the forms; they must be clean and dry. A dye is added to the mixture; it is better if there are several pigments. It is important to achieve uniformity of the material, which is why the entire process is accompanied by constant stirring. At the final stage, the product is poured into a mold and sits there for about 10 hours, after which it can be removed. As you can see, the equipment for the production of artificial marble is quite simple.

Why is this interesting?

Cast marble attracts consumers with its novelty. So far, on the Russian market, and even in large cities, there are not many professional production facilities producing these products. The most important thing is that the low cost of this stone allows us to produce unique exclusive products at affordable prices. Judge for yourself - one kilogram of this material costs a little more than forty rubles (at cost). So even after paying all taxes, rent, and staff salaries, the entrepreneur receives a decent profit. And thanks to our production technology, you can launch such a business in the shortest possible time.

About the features of the material

It was already noted above that artificial marble has many advantages over polymer concrete. The material does not burn and does not conduct electricity or heat. This allows it to be used in places with elevated temperatures (heating radiators, stoves, fireplaces), etc.

Such marble practically does not interact with chemical elements such as alkali, gasoline, acetone, etc. Any kind of contamination is quite easy to remove, so it is suitable for use in public toilets and similar places.

Another important indicator is the durability and environmental friendliness of cast stone. The examinations showed that even when heated, the material does not emit harmful substances. It is thanks to its unique qualities that it is widely used in all areas, especially since the equipment for the production of artificial marble is not complicated, and its price is low.

ART molding of cast marble - a new business in two weeks

We offer you a unique technology for casting products from artificial stone (cast marble).

This is a great idea for a small business, a family company, which can be implemented in just 2-3 weeks after studying the technology. You may be interested in: Fiberglass technology What is cast marble

Cast marble is an inexpensive artificial stone, which is made on the basis of polymer resins and fillers, and is covered with gelcoat on top. The production technology is quite simple. Liquid resin mixed with hardener and filler is poured into a specially prepared mold. The mold is pre-coated with gelcoat - a special polymer, which subsequently creates a smooth, durable layer on the surface of the product that is resistant to moisture and ultraviolet radiation. Despite its apparent simplicity, there are quite a lot of nuances in this technology (you can learn them by completing training with us).

Here are just some of the positive properties of cast marble that are interesting to consumers:

- beauty - luxurious appearance;

- Durability - Resistant to dents, high strength, scratches and chips. Resistant to ultraviolet radiation and chemicals.

- hygiene – the smooth surface is easy to clean from dirt and does not absorb moisture;

- variety of colors - cast marble, using various fillers and gelcoats, can be given almost any color, both similar to natural stone and bright futuristic;

- low price, especially when compared with the same products made from natural marble and stone.

- Low thermal conductivity allows the stone to be warm to the touch, and high moisture resistance allows it to be used in damp rooms.

Cast marble is used to produce products for a wide variety of areas of life. It will definitely be in demand on the market. Countertops for home interiors and catering establishments, designer sinks, stylish bathtubs, etc. are made from this material. It can also be used to cast facade elements, balusters for stairs, decorative flowerpots, flower stands, memorial monuments, etc. And all these products will look stylish and expensive, and will not be afraid of water, heat, frost and ultraviolet radiation.

Some more useful information

It is worth saying a few words that in some cases, after the material has hardened and you have taken it out of the mold, it will require additional mechanical processing. It consists of polishing and smoothing the edges. In principle, this is necessary if the casting stone has an important purpose and must have an ideal shape.

In some cases it makes sense to use chemical additives, for example to increase mechanical resistance. If the operating conditions of the material require it. It is advisable that your workshop has several shifts of employees; the area for each team should be about 20-25 square meters.

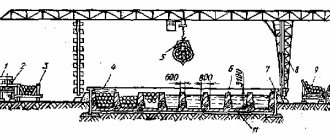

Don't forget to buy pallets on which you will place the finished material. It is advisable to carry out delivery to the warehouse using a railway or conveyor (conveyor). The second case is only suitable if the warehouse is nearby.

Our production technology

We invite you to learn the unique technology of ART molding of cast marble in just 5 days. As a result, you will gain skills that will allow you to open your own unique business in your city in just 2-3 weeks. The unique features of our technology are your competitive advantages, which will allow you to launch production with minimal initial investment. These features include:

- Low electrical requirements. The equipment you will need when using our technology will operate from a standard 220 volt outlet. You do not have to run a three-phase 380 Volt line into the workshop to operate the machines.

- In order to start the production of cast marble

, you will need a room with an area of 20 square meters. This small workshop will fit everything you need. - Also, the premises do not have to be equipped with sewerage and running water.

- You don't need heavy equipment to produce cast marble

, so you don't have to invest a lot of money at the first stage. - To operate successfully, you only need 2-3 staff. This is a great option if you want to organize a family business.

- You will not need specialists with professional education - in just five days of our training you will receive all the skills necessary to produce unique things from cast marble.

- Our cast marble production technology

is suitable for the production of individual pieces, individual orders, small series or even medium series.

Business relevance and target audience

Artificial marble is a material that imitates natural stone in properties and appearance. The advantages of imitation over real marble are low price and wider scope of application.

With the advent of a substitute for natural stone, interior and exterior design has reached a new level. The material is easy to install, easy to maintain and has excellent performance qualities.

Artificial marble is used in interior and exterior decoration, and in landscape design. In many ways it even surpasses the original. The stone is reliable, strong and durable, lightweight, able to regulate humidity and transfer heat, and does not deform. It can be covered with unusual patterns.

The demand for the material is constantly growing, and the market itself is far from being filled. In Russia, inexpensive and beautiful stone is in demand.

Marble production: what are the benefits of production?

In order to organize the production of large quantities of marble from concrete, you do not need to have deep knowledge of construction and perfect mastery of innovative technologies.

Among the advantages of business are:

- minimal costs for purchasing equipment;

- the production process can be implemented in a small area (saving on rent);

- low level of competition - in our country there are few companies producing artificial marble;

- consistently high demand for quality products;

- the technology for making marble from concrete is not difficult, you can master it yourself;

- optimal ratio between the cost of raw materials and the selling price of products (profitability of about 300%).

Knowing how to make marble-like concrete, you can organize large-scale production from literally “nothing” (meaning the affordability of the raw materials). You can endlessly improve your marble production methods by experimenting with colors and shapes.

Chemical additives for the manufacture of concrete products

1. Fiber is light synthetic fibers with a length of 6, 12, 20, 40 mm. with low density (0.91 g/cm3), but high strength characteristics (170-260 MPa). The main area of application of fiber is dispersed reinforcement, carried out in a wide variety of binders. Polypropylene fiber is most widely used because it has a low cost, is not subject to corrosion, does not weigh down concrete structures and piece goods, and also exhibits very slow physical aging. The use of polypropylene fiber does not require any additional equipment - its share is introduced into the solution as a standard component. Fiber can improve the strength characteristics of concrete, reduce the shrinkage of concrete products, which makes it possible to increase the crack resistance of structures.

2. Superplasticizer S-3 - developed by Russian specialists. It is an analogue of foreign superplasticizers such as “Mighty 100” (Japan), Sicament, Melment (Germany), not inferior to them in quality. Superplasticizer S-3 in an amount of 0.2 - 0.7% by weight of cement makes it possible to obtain cast, self-compacting concrete mixtures that practically do not require vibration, and with a decrease in mixing water consumption, concrete of increased strength with constant mobility of the mixture. It is possible to use both of these effects partially, i.e., obtain mixtures with increased mobility compared to the original and at the same time slightly increase the strength of concrete by reducing water consumption. The most effective areas of application of superplasticizer S-3 are the production of concrete products with high performance properties and excellent appearance.

Description of chemical additives

Characteristics of artificial stone

Not only marble made from concrete is called artificial stone, but also ceramic granite. The production technology of these materials is almost identical. But they are used in different ways.

Ceramic granite is considered harder and more resistant to mechanical damage, so it is more often than marble used for coatings in areas with intense pedestrian traffic: floors in shopping centers, supermarkets, subways, and transport centers. In residential premises, porcelain tiles are used to cover the walls and floors of hallways, kitchens, and bathrooms.

Marble is less durable, but thanks to the dyes it has a beautiful pattern. Its scope of application is tabletops and bar counters, railings of fences and stairs, decorative elements, plumbing components, window sills and artificial columns.

Custom concrete marble can come in almost any shape, color and pattern. These parameters depend solely on the imagination and solvency of the buyer.

Natural marble is in many ways inferior to its artificial counterpart. A tabletop made of natural material will weigh 3-4 times more than one of a similar shape and size - made of synthetic material.

The color palette of natural stone is limited, while artificial marble can be painted in any shade and can even be made to glow.