Sugar-dusted crow's feet cookies were an invariable attribute of tea drinking in childhood, and today many housewives are looking for the same recipe as their grandmother's in order to return to childhood at least for a short while.

Crow's feet are easy to make - anyone can knead the dough, and you only need a minimal set of ingredients. If you want to spice up the classic recipe a little, then the selection includes apricot and lemon varieties of cookies.

Throw yourself a little celebration, bake some cookies and dedicate the evening to pleasant nostalgia. A cup of aromatic tea and Houndstooth curd cookies will help you plunge into memories.

Cookies Goose feet made from cottage cheese

These sugar cookies melt in your mouth. Try making tender, slightly crispy baked goods. Choose high-quality cottage cheese with a high percentage of fat content so that the dough is airy. Country cottage cheese is ideal.

Ingredients:

- 350 gr. flour;

- 200 gr. cottage cheese;

- 200 gr. Sahara;

- 100 gr. butter;

- 1 tsp baking powder;

- 1 tsp vanilla.

Preparation:

- Grind cold butter with cottage cheese. You should end up with crumbly crumbs.

- Sift the flour. Mix it with vanilla and baking powder.

- Add the flour to the butter-curd mixture.

- Knead the dough with your hands. It should turn out homogeneous. Form into a ball. Wrap in film and put in the refrigerator for an hour.

- Roll out the dough into a layer 2-3 mm thick.

- Use a mold or glass to cut out circles.

- Pour sugar into a plate. Roll each circle in sugar on both sides.

- Fold the circle in half, and then in half again. You should end up with triangles. Press them with your finger at the edge so that the “legs” do not open.

- Bake cookies for 30 minutes at 180°C.

Using stamps

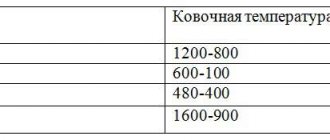

Matrices can be used both in manual forging and when using various presses and pneumatic hammers.

The technology of such forging works is as follows.

- The stamp you need is placed on the anvil.

- The workpiece is heated to malleable temperature.

- The heated blank is placed on the stamp and the so-called metal rolling is carried out with hammer blows.

- Excess elements are chopped off with a chisel or cut off.

When working with matrices such as lance, crow's foot, sheet and other similar ones, use rolled products in the form of a rod, circle or square of the appropriate size.

When a double-sided pattern is made, the heated blank is placed between the two halves of the matrix and, applying hammer blows, the configuration of the forged product is formed.

When using pneumatic or other mechanized hammers, the matrix can be installed on the hammer head (usually on the lower fixed one).

Dies are also mounted on various presses.

If during manufacturing it is necessary to make additional operations (for example, holes), the product is stitched separately using the appropriate tools.

The technology of using matrices became the founder of such a type of production as stamping. The manufacturing principle is similar, only machines are used instead of manual work.

Crow's feet with apricot jam

A small amount of jam will diversify the taste and make it more interesting. The cookies turn out quite sweet, so don’t coat them too much in sugar.

Ingredients:

- 350 gr. flour;

- 1 tsp baking powder;

- 100 gr. Sahara;

- 200 gr. cottage cheese;

- 100 gr. butter;

- a pinch of vanillin;

- 150 gr. apricot jam.

What kind of devices are used?

Cold forging is characterized by various curls, bends, twisted rods, etc. Almost every type is made on a separate device - a specific machine. They can be driven manually or electrically. For small volumes “for yourself”, manual cold forging machines are used. Although they are not particularly productive, they are much easier to manufacture. If it is necessary to put production on stream, similar devices are made, but with electric motors. In this case, there is almost no need to physically work, but the complexity of making the device increases significantly. In our material we will talk about manual machines for cold forging.

What devices are used:

- Torsion bars. With their help, tetrahedral rods or strips of metal are twisted in the longitudinal direction. The result is twisted columns, which are also called torsion bars.

This is what a torsion bar and the machine of the same name look like - Flashlight. On this device, the rod is also twisted in the longitudinal direction, but it is also additionally bent in the transverse direction. It turns out something similar to a flashlight. Hence the name of the device.

This is how they make a flashlight - Twisters or snails. Form flat curls of different diameters.

Device for cold forging snail - for forming curls - Bending machines or benders. Allows you to bend rods or reinforcement at the required angle anywhere.

For bending anywhere and at any angle - bending machines (bending machines) - Wave. In fact, this is also a bend, but of a more complex design - it allows you to change the direction of bending, obtaining wavy parts.

Machine "Volna" - for the formation of the appropriate relief - Devices for processing the ends of parts - inertial stamping machines or other home-made devices.

Machines for shaping the ends of rods. In this case - crow's foot

For a beginning craftsman, the most relevant machine for cold forging is a snail. Only with its help you can make many interesting things - from a fence and gate to a bench and other similar products. In second place in terms of necessity is a torsion bar machine. It adds variety to the details. All the rest can be purchased or made as you improve and gain skill.

Crow's feet cookies without cottage cheese

It would seem that these cookies without cottage cheese lose their “zest” and completely change in taste. In fact, kefir makes the dough even more tender, and the cookies become softer and acquire a creamy taste.

Ingredients:

- 500 gr. flour;

- 150 ml. kefir;

- 180 gr. butter;

- 1 tsp baking powder;

- 1 egg;

- 100 gr. Sahara;

- a pinch of salt.

Preparation:

- Grate the cooled butter on a coarse grater.

- Stir in the sifted flour. Grind both ingredients - you should get crumbs.

- Beat eggs with sugar. Pour into crumb mixture.

- Add baking powder and add a little salt to the mixture. Pour in kefir.

- Knead the dough with your hands and let it sit in the refrigerator for an hour.

- Roll out the layer to a thickness of 3 mm.

- Cut out circles with a glass or mold.

- Pour sugar into a plate. Roll each flatbread on both sides. Fold them in half twice to form triangles.

- Place on a baking sheet. Bake for half an hour at 180°C.

How to make a die for forging

Today it is not difficult to purchase ready-made stamps with various shapes, including standard sheets, crow's feet, peaks, clamps and others.

However, how can you make forging dies with your own hands, what do you need for this and what materials should you use?

Material

The matrix material must have high qualities, because the finished stamp will constantly be in contact with heated workpieces, and, moreover, will constantly experience shock and compressive loads.

To make such a template, you can take steel from a car axle shaft, as shown in the video presented:

You can also make a matrix on the surface of the striker of one of the working hammers.

Or any other piece of steel with excellent properties to resist deformation and strong heating will do.

What you need

To make a matrix, you will need the appropriate tool: grinder, chisels, hammers and others.

There are types of stamps that are made on a milling machine. For example, like in this video:

The previous video perfectly shows how to make the simplest type of matrix - a crow's foot, using only a grinder, a file and a welding machine.

Manufacturing process

The complexity of manufacturing matrices depends on the pattern applied to its surface. Elementary embossing such as crow's feet or clamps is much easier to make than, for example, figured peaks or sheets. Complex designs will have to be applied with chisels and chisels.

- To make a simple crow's foot stamp, a blank is prepared. Its surface is leveled.

- On the working side you need to make markings in the form of diverging lines. Initially, the central axis is knocked off, and only then two or three branches from it.

- I use a grinder and a cutting wheel to make cuts along the lines, deepening them along the edges.

- Using an angle grinder, you need to form triangular projections along the slots.

- After which the entire relief is finished with a file.

- If a double-sided crimp is made, you need to make a mirror image from the same piece of material with protrusions that exactly match the depressions on the first matrix.

- The crimp is connected in the form of tongs.

- The striking side can be further strengthened with a striker welded on top.

- For convenient use of double-sided crimping, you can additionally make a stopper from a pipe or other similar material.

- Additionally, the steel must be hardened to increase its strength properties.

If everything is done correctly, then such a homemade matrix will serve for a very long time.

An even simpler stamp for the production of crow's feet can be a bar of steel with longitudinal grooves cut and brought to the desired shape. On this form you can very simply make a one-sided design by hand forging.

What can you add to the material in this article? Share your experience in making dies for forging metal, as well as techniques for using them in forging work. Join the discussion in the comments section of this article.

Crow's feet with lemon

These cookies can be made with margarine, but only buy a good product that will allow the dough to rise during baking. The citrus taste and aroma will amaze your guests.

Ingredients:

- 350 gr. flour;

- 100 gr. margarine “Home”;

- 100 gr. Sahara;

- 150 gr. lemon jam;

- 1 egg;

- 1 tsp baking powder;

- 180 gr. cottage cheese;

- 30 gr. lemon zest.

Preparation:

- Chop the cooled margarine with a knife. Grind into crumbs together with cottage cheese.

- Sift the flour. Mix it with baking powder. Combine with cottage cheese and margarine.

- Break an egg into the dough. Stir. Add lemon zest. Knead the dough with your hands. Place it in the refrigerator for an hour.

- Take out the dough and roll it into a layer 2-3 mm thick.

- If the jam is thick, beat it with a mixer.

- Cut out circles from the dough using a glass. Roll each one in sugar and squeeze a little lemon jam into the center. Try not to overdo it, otherwise the jam will spread and the cookies will not look aesthetically pleasing.

- Fold the tortillas in half. Roll again. You will get triangles. Press them lightly with your hand.

- Bake for half an hour at 180°C.

These simple and delicious cookies will become your family's favorite treat. You will need a minimum set of products. If you make the dough ahead of time, you can make the cookies in minutes.

Overview of matrices

All matrices are used in forges to produce, as a rule, decorative elements that are often repeated. These can be various leaves or balls, which will take a lot of time to produce manually. Also, such elements, as a rule, must have the same parameters, which is also quite difficult to do.

What does a forging die look like? Externally, it is a metal board with concave relief embossing, which depicts the necessary element.

Quite often you can see such stamps on sale with the most common shapes: a houndstooth, a peak or a plant leaf.

Matrix sheet

Peak matrix

Matrix crow's foot

Today they are made from the appropriate grades of steel, which also undergoes additional heat treatment. As a result, such stamps are durable and can be repeatedly used in production.

In addition to the examples shown, there are many other matrices with different images and shapes.

The use of matrices has a deep history. In the 15th-17th centuries, the so-called basma stamping was widespread in Rus', with the help of which decorative decorations were made on books, chests, and icon frames. For this technology, matrices were made of copper, wood or stone. The working method was as follows: sheet metal (2-2.5 mm) was laid on the stamp, covered with lead on top and struck with a hammer. The resulting image could be completed using coinage.

Such stamps are used in two ways: either they are placed under the workpiece on an anvil, or they are attached to the hammer head.

Conductors for bending

The matrices can be either one-sided or double-sided, when the patterns in a mirror image are located on the improvised crimping tongs.

Similar devices are used when bending metal in order to obtain various curls. For this purpose, a conductor is used in the form of a plate and a strip attached to it, repeating the shape of the coil.

Such devices are used in cold forging, producing identical twisted elements.

How are dies used for production and what blacksmithing techniques are used?

Cold forging machines

Below we will give you instructions on how to assemble cold forging machines yourself.

Machine "snail"

Making a snail machine is one example of independent design, and it makes no sense to give advice with an exact indication of the dimensions of all parts. You need to be guided by your idea of the operation of the machine, how and what will bend, how many turns of the spiral will be enough for high-quality work, what size the lever with the tabletop will be. If you understand the essence of the machine manufacturing process, then the assembly itself will not cause any particular difficulties.

Machine “snail”

Manufacturing of main machine components

Frame.

The process of bending an iron rod exposes the machine to heavy loads, so when making the frame for the “snail”, only a metal corner, channel or thick-walled pipe is used. Do not make a frame from wooden beams; such a table cannot withstand prolonged loads and collapses.

Tabletop.

The tabletop for the “snail” is made of a metal plate cut in the shape of a circle, at least 4 mm thick. From the same slab, a second tabletop is cut out, repeating the shape of the first. The snail segments will be placed on the second tabletop and the products will be bent. During the cold forging process, the tabletop takes on the bulk of the load, so there is no need to save money and make it from a thinner sheet of iron.

Main shaft and lever.

The main shaft is placed centrally between the tabletops and is attached to the base using four right triangles. The shaft can be made from a thick-walled pipe of the required diameter. The lever is attached to the shaft using a ring and rotates around it; in addition, a roller is installed on the lever for bending the rods on the upper tabletop.

Machine diagram

Marking and installation of attachments

Depending on whether you want to produce only the same type of samples or you need more artistic products, there are three options for the snail device. Option #1. This is the simplest of the three options; its essence is that the outline of a spiral is drawn on the tabletop.

Drawing of the snail segments

At its core, this is a drawing of future products that you will produce on the machine. After applying the diagram, it is enough to cut out several segments from thick strips of iron of different widths that follow the line of the drawing and weld them to the tabletop according to the markings. With such a static “snail” you can make simple bends. Option #2. The second option is the most popular among homemade machines; it involves making a collapsible snail from removable parts. Holes are drilled along the contours of the markings into which threads are cut. Next, templates for the stop segments are made from cardboard or plywood and metal overlays are made from them. Finally, holes are drilled in the pads, which should coincide with the mounting sockets on the tabletop. To secure the segments, bolts are mainly used, but you can also make cylindrical stops. This “snail” design will allow the production of spiral-shaped workpieces with different radii on one machine.

“Snail” made of metal strips

Option #3. In the third option, instead of collapsible stop segments, several removable modules are made with different volute options, which change as needed. The module is made of a piece of iron onto which segments repeating parts of the spiral are welded.

Snail modules

Machine assembly.

- Install the frame in a place where you will have easy access to the machine from all sides.

- Concrete the legs of the frame in the floor or secure the frame in another accessible way.

- Weld the main table top to the frame.

- Install the main shaft by welding it to the tabletop and strengthening it with triangles.

- Place the rotating lever onto the shaft.

- Install the top tabletop by welding it to the main shaft.

- Place the snail segments on the tabletop.

After assembly, test bend the rod. To learn more about assembling a snail cold forging machine, watch the video:

Torsion bar machine

This machine is designed for uniaxial longitudinal twisting of a workpiece from a transverse or square rod.

Torsion bar machine

A channel or I-beam is used for the base of the torsion bar machine. A thick iron strip is attached to it by welding, onto which a vice is installed to clamp the stationary part of the rod. The vice is secured with four bolts with a diameter of M16 or more. To increase the clamping strength of the bar, corrugated sheet steel plates are welded onto the vice. On the opposite side of the base, guide rollers are installed, to which a clamping unit for the movable part of the workpiece is attached. It is made of a steel bushing, in which it is necessary to provide holes for clamping bolts located at an angle of 120 degrees. The bolts must have a flat end and be made of high quality steel. Both clamping devices must be positioned coaxially; to do this, they must be checked using a level, a plumber's square and a caliper.

Types of machines

Next, you need to make a handle for turning the moving part of the clamp. Its lever should hit as long as possible to reduce the applied force. It is better to make the handle itself with a rubber bushing to prevent the hand from slipping during operation. After the machine is fully assembled, it is checked for the reliability of the moving elements and the accuracy of the deformation of the bar. After checking, the machine is attached to the support frame.

A simple model of a torsion bar machine

How to make a torsion bar machine with your own hands, watch the video:

Machine "gnitik"

To qualitatively form a corner in a product produced by cold forging, you will need a machine called a “bend”. It consists of a steel plate with a movable stop on which there are two support shafts and a lever.

Machine “gnutik”

The workpiece is placed between the wedge and the support shafts. After this, with the help of a lever, the wedge is shifted towards the shafts, which leads to bending of the workpiece.

Computer model of the machine

Making such a machine is quite simple, the main thing is to follow the given drawing and use tool steel, since during operation a large load is placed on part of the device. You can also watch how to make a “gnitik” machine in the video:

Wave machine

It would be more correct to call this machine a controlled wave. The equipment of the machine consists of a pair of steel disks with a diameter of 140 mm, which are bolted to the worktop. The axis of rotation of the universal wrench is fixed to the drive disk.

Machine “wave”

Wave control occurs as a result of changing the distance between the disks. When the bar is rolled around the drive disk with a knob, a pattern is formed, after which the bar is removed from the conductor and a pattern is formed on the other side. You can watch the machine in action in the video:

Machine - press

A press is needed to form the ends of the rods. This machine works on the principle of a flywheel; first, by rotating the bar with weights, the screw striker is pulled back until it stops. After this, a replacement stamp is inserted into the slot and the workpiece is placed. Next, quickly spin the bar in the opposite direction and leave it to rotate freely. Finally, the striker hits the stamp shank strongly, due to this, a force sufficient for stamping is developed.

Rolling press

As for the manual rolling mill, you can make it yourself, but you still have to order special steel rolls, bearing bushings and shafts, and buy gears in the store. Only “crow’s foot” and “leaf” tips can be produced on such a machine.

Connecting and painting parts

Elements produced by cold forging are connected in two ways:

- Welding - parts are welded to each other, and the scale is ground off with a grinder or other grinding machine.

- Clamps - this type of connection looks much more beautiful. For clamps, stamped strips of metal with a thickness of 1.5 mm or more are used.

Finished products are painted using blacksmith enamels or acrylic-based metal paints.

Connecting parts using welding

Torsion bar machine

As already mentioned, these cold forging machines allow you to make longitudinal bends on the rod. This is a relatively simple design. The main task is to fix one end of the rod motionless, attach a lever to the second, with which you can twist the workpiece.

A piece of profiled pipe with a thick wall (at least 3 mm) is suitable as a base. The retainer can be welded from the same rods, leaving a square gap of the required diameter. You can use a properly sized cable clamp (available at a rigging store). Any of these stops is welded to the base.

Cable holder - great for holding rods

Next, you need to somehow ensure grip and torsion of the second part of the workpiece. This can be done using two bearing units. A pipe of a suitable diameter is inserted inside, and a handle is welded to it on one side - the design resembles the letter “T”. On the other hand, a clamp is made in the pipe: four holes are drilled, nuts for 12 or 14 bolts are welded into them. The result is a good clamp - the bolts are tightened after the rod has been inserted.

Bearing unit

Workpiece clamp

This is what the design looks like as a whole

Next - a matter of technique - use a lever to screw in the required number of turns. This is not to say that this work is for weaklings, but with a lot of leverage, everything is not so difficult.

An even simpler machine for making torsion bars using cold forging is in the next video.