Welding is a type of work that is carried out using special equipment with the mandatory use of a system to protect the eyes and face from electric arc flashes of the metal being welded.

Arc welding is a welding process in which exposure to thermal energy melts the parts being joined. Direct current or high frequency current acts on the surface being welded, bonding it to other metal products. The weld seam is formed at the site of the weld pool, resulting from the action of an arc on the edges of the parts being connected.

What is electric arc welding - classification and methods

Electric arc welding is one of the methods of joining metal parts, which is characterized by its own operating principle. Within the framework of this technology, to obtain seams, a high current is simultaneously applied to the electrode. As a result of this interaction, an electric arc is formed.

This definition gave the name to this type of welding. Another name is fusion welding. The second name is due to the fact that when a high current is applied, the metal in the affected area takes on a liquid form.

There are several types of arc welding, each of which has its own characteristics.

Types of arc welding

Depending on what devices and technology are used to produce seams, arc welding is divided into the following types:

Manual.

As part of this technological process, the workpieces are moved and welded by a technician. The advantages of this method include the ability to connect metal parts in any conditions.

Disadvantage - the risks of getting a poor-quality seam due to specialist errors increase.

Mechanized.

As part of this technological process, workpieces are fed to the machine using appropriate equipment. But the parts are welded by a person.

A number of sources distinguish semi-automatic electric arc welding technology as a type of mechanical welding. In this process, the torch is moved by the worker himself, while the wire feeding, arc ignition process, and connection formation are performed by specialized equipment.

Automatic.

The process in this case is completely automated. That is, special equipment is involved in feeding and welding workpieces. These devices independently (according to a previously entered program) determine the intensity of the flame, regulate the supply of consumables, and more.

Depending on the technology used to protect the seam obtained under this influence, arc welding is classified into the following types:

- without protection - the process takes place in the open air (typical for manual electric arc welding technology);

- in a vacuum - the process occurs automatically in an environment in which there is no air;

- using gas mixtures that prevent oxidation of the compound;

- submerged - the metal is protected by slag, which is formed during melting.

Combined methods are also used. To protect the welded joint, the following gases are used:

- helium;

- carbon dioxide;

- argon.

Shielding (active or inert) gas is supplied through a special device - a welding torch nozzle, which is equipped with welding machines.

Depending on the nature of the impact, this technology is classified into the following types:

- In a bun. This technique uses a bundle of electrodes that are connected to each other to pass a direct electrical charge. The method allows the use of currents in a wide range of values.

- Lying electrode. The method involves laying with a coating 50-120 cm long in a corner or a pre-cut joint. Next, a copper bar is installed, under which an electric arc is applied.

- Inclined electrode. This technique is used to improve productivity.

Taking into account the nature of combustion, electric arc welding is divided into the following types:

- Open arc. The method is used for manual welding and shielding gases.

- Closed. With this technology, the arc is present in the molten material, remaining invisible to the welder.

- Half open. Part of the arc in this case is visible above the metal. Electric arc welding of this type is used to join aluminum workpieces using automated equipment.

If you want to know what silumin is and where it is used, read our article.

Depending on the type of equipment and the characteristics that need to be given to the future seam, electric arc welding is carried out using a consumable or non-consumable electrode. In the first case, copper, aluminum, cast iron or steel rods are used. Consumable electrodes are used as filler material.

If you want to learn more about welding with a non-consumable electrode - tig welding, then follow the link and study.

Electrode marking

The quality of welds and the strength of the connection are decisively influenced by the correct selection of electrodes. The manufacturer indicates the description, characteristics, and markings on the packaging. From the information posted, you can find out what metals are connected with these electrodes, the preferred spatial arrangement, the diameter of the rods, and the composition of the coating.

The marking is located after the name, brand in the form of a sequence of letters and numbers. The first letter indicates the purpose of the electrodes:

- U - for connecting parts made of medium-carbon steel with a low content of alloying additives;

- T - for welding heat-resistant alloy steel;

- N - for surfacing;

- A - for welding plastic metal compositions.

The second letter indicates the thickness of the coating: M - thin layer, C - medium layer thickness, D - thick layer, G - very thick coating. The third letter is the rod type; For consumable electrodes, use the letter E.

The numbers after the first three letters indicate the mechanical properties of the connection: tensile strength under tensile load, relative elongation. They are important for specialists performing critical connections.

The properties of the coating are indicated by the following letters:

- A - acid coating;

- B - basic (alkaline) coating (UONI-13/45);

- C—cellulose coating layer;

- R - rutile (ANO-4).

The last digits of the marking indicate the preferred spatial position of the electrodes during the welding process and the characteristics of the welding current.

What is manual arc welding

As is the case with other welding methods, welding welding involves exerting an impact on the workpiece, which leads to the melting of the metal in a certain zone. This happens due to the formation of an arc, which occurs as a breakdown effect between the electrode and the part.

Manual welding is not much different in characteristics from other methods of producing seams. The main difference is that in this case the entire procedure is carried out by a person. That is, manual electric arc welding involves independent preparation and installation of products, as well as joining parts without the use of automated equipment.

But within the framework of this method, low-, medium- and high-alloy steels, cast iron, as well as alloys of various metals are welded.

Read about how to weld cast iron in our article.

For RDS, special electrodes coated with a protective coating are used. The latter creates an environment that prevents metal oxidation.

Electrodes are selected for each group of materials separately, taking into account the conditions in which the product will operate.

For example, for welding stainless steel 12Х18Н10Т, TsT-15 electrodes are used if the part being welded will operate at temperatures up to 640-650 degrees, and the same steel is welded with EA400 electrodes if the working temperature of the part is not higher than 340-350 degrees.

And for welding black steel, UONI or OK 46 electrodes will be used.

a brief description of

The procedure and basics for performing manual arc welding are determined by the relevant GOST, which establishes:

- types of joints that can be obtained using RDS welding;

- the shape of the prepared edges;

- features of the seam obtained by manual welding;

- cross-section of edges and seam;

- the thickness of parts that can be joined using manual electric welding.

The type of electrodes used for RDS determines the order of work. In this case, the rods are selected taking into account the characteristics of the workpieces. Manual arc welding is used to join metals of different thicknesses and types. The choice of coated electrodes depends on these parameters.

That is, when manual arc welding of ferrous metals, one rod is used, and for heat-resistant steels, different rods are used.

If non-consumable electrodes are used, then filler wire must be introduced into the joint being created (provided that the metal thickness exceeds 1 mm and no work is carried out on cutting the edges C1).

Manual arc welding, like other methods, requires compliance with safety precautions. This is due to the fact that in this case an arc is formed, which heats the metal to a temperature of 5 thousand degrees.

The essence of manual arc welding

Manual arc welding is a method of joining metal using special equipment. This technology does not involve automation of the process. The equipment used in such cases ensures the formation of an arc, which is formed at the point of contact of the electrode (consumable or non-consumable) with the metal product.

During this process, the contact point is heated to high temperatures, causing the material to melt.

The manual type of electric arc welding is also divided into several types:

- one-, two- or multi-electrode (the difference lies in the number of rods used, which determines the speed of work - the more, the faster);

- with direct or alternating current;

- single- or three-phase arc welding.

The choice of arc welding scheme, or method of obtaining a seam, is determined by the tasks set. According to this criterion, the following techniques are distinguished:

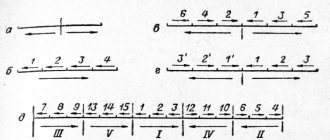

- Short seam (length up to 250 mm). The parts are welded “on pass”, that is, continuously along the entire joint.

- Medium length seams (250-1000 mm). With this welding method, the electric arc is applied from the middle of the future seam to the edges. In this case, the specialist moves the electrode in a stepwise manner.

- Long seams. With this electrode welding scheme, the rod is guided from the edges to the middle.

The manual arc welding technique is also influenced by the type of electrodes chosen.

Features of arc welding

In comparison with other methods of obtaining a joint, the features of this type of welding are as follows: in order to create a strong seam, you need a closed circuit through which alternating, direct or high-frequency pulsed current is supplied. An arc in such conditions occurs immediately after the electrode touches the workpiece due to the instantaneous supply of voltage.

With this effect, a liquid melt is formed, in which the metal of the workpieces being joined is mixed. After the welder removes the electrode, the material begins to cool, which leads to crystallization of the latter. This creates a strong seam.

The melt area that forms in the electrode moving zone is called the weld pool. The rod used in this technology includes flux. The latter melts when heated, forming a gas that protects the affected area from oxidation.

These features of manual welding appear when work is carried out on joining non-ferrous metals. When heated, such a material exhibits high chemical activity. Therefore, to avoid oxidation, non-ferrous metals are welded using gases that are supplied to the work area.

Within this technique, several methods of moving the rods are used:

- triangle;

- loop formation;

- zigzag or crescent forward or backward.

To avoid mistakes and to obtain a reliable seam when manual arc welding with coated electrodes, the following rules must be observed:

- Current must be supplied to the rods continuously.

- The surface and electrodes are dried before starting work. If this is not done, the process will be accompanied by the formation of sparks, and the seam will ultimately turn out to be fragile.

- The welding cable must not have cracks. Such defects may cause equipment damage.

For manual arc welding (MAW) with coated electrodes, 220 V inverters are mainly used.

To work, a welder must pass certification and be included in the NAKS register. Read more in our article.

Advantages of manual arc welding

As is the case with other welding methods, RD has advantages and disadvantages due to the characteristics of this technique. Among the advantages of this method are the following:

- the ability to weld metal in any conditions;

- welding is carried out in any position of the workpieces;

- you can combine different alloys and metals;

- the method is easy to learn;

- high mobility.

But these advantages are partially offset by the fact that during manual arc welding with consumable electrodes, many harmful substances are released. This method is also characterized by low productivity. In addition, welding metals less than 2 mm thick requires a lot of experience, since when working with such materials there is a high probability of “burning” and other consequences leading to damage to the workpiece.

Electrode welding principle

The technological process of electric arc welding is based on several principles, including breakdown and short circuit. It is worth focusing special attention on the first of them. It is based on the breakdown of a dielectric, which is formed as a result of filling the interatomic space with charged electrical particles. Positive charge is created by ions, and negative charge is created by electrons.

There are many situations in which breakdown is possible for any dielectric. But regarding electric arc welding, here a breakdown of the air mass is formed between the mass and the electrode. During operation of the equipment, a charge with a low voltage and at the same time high current strength is formed on the consumables - from 80 to 200 amperes. In addition, a huge density is created, the value of which is several thousand A/m2.

The moment the electrode touches the surface to be welded, a short circuit is formed. As a result, a high power electric field is generated. It is in this field that the breakdown occurs.

Operating principle

In this method, current is supplied to the workpiece through a rod, which forms a welding arc. The latter is concentrated radiant energy that heats the metal to its melting point. Due to the fact that the current is supplied strictly to a certain point, the remaining parts of the workpiece are not damaged during this arc welding scheme.

A seam between metal products is formed during the crystallization of the material, which starts immediately after the heating stops. That is, this process starts during the cooling of the treated area, including due to forced cooling. In this regard, the connection requires a certain time to gain strength, determined by the cooling rate.

Effect of electrode feed speed

The feed rate of the welding electrodes must provide the required amount of molten material supplied. Not having enough of it can lead to undercutting. This factor is very important in both direct and reverse polarity when welding.

During electric arc welding, due to the rapid movement of the rod along the joint, the arc power may not be enough to heat the metal. The result is a shallow seam that lies on top of the metal. The edges remain unmelted.

Slow advance of the electrode leads to overheating. In this case, it is possible to burn the surface and deform the thin metal.

Modern welding machines have a wide range of different functions and capabilities. Nevertheless, at the moment, most of the quality work done is still determined by human skill.

Manual welding technique - creating an arc

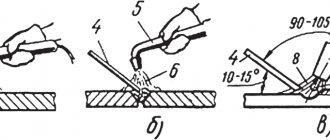

When working with consumable electrode arc welding, the arc is fired after the technician touches the work area with the rod. This process is started in two ways:

- touch and lift - the arc is formed after the rod is slowly withdrawn from the metal surface;

- by striking (like a match) - an arc is formed by quickly striking the end of the rod along the surface.

The second option is considered more preferable. However, when working in hard-to-reach places, the first method is used.

How to cook correctly is written in detail in our article. Come in!

Features of welding thin metal

In everyday tasks, we are most often faced with the need to join thin metal. In this case, it is necessary to remember the basics of inverter welding for beginners, namely the importance of connecting the product to the correct pole. Thin parts are connected to the “minus” of the welding machine.

To learn how to weld correctly and get beautiful seams, you need to practice.

Here are some useful tips that can help improve your skills:

- start cooking using the minimum current;

- form the seam at an angle forward;

- use reverse polarity;

- secure the part to reduce distortion during welding.

Welding arc area

When electric arc welding of any type (RD or RDS), 3 zones are formed between the electrode and the metal surface:

- cathode - located between the arc column and the surface of the rod;

- arc column - located between the cathode and anode;

- anodic - this zone is presented in the form of an anode spot and a near-electric part, in which the current is formed due to the flow of electrons emanating from the arc column.

In this electric welding scheme, the cathode is heated by electron bombardment.

Some metals have their own characteristics and must be welded using special technology. Such metals include aluminum, and you can read in detail how aluminum welding is performed in our article.

Stages of the procedure

All professional and amateur welders operate according to the following algorithm:

- Preparation involves thoroughly cleaning all surfaces and securing the workpiece in the workplace.

- The appearance of an arc. For it to form, you need to apply voltage and touch the metal with the tip 2-3 times with quick movements.

- Carrying out a seam - speed and angle varies depending on the physical characteristics of the material.

- Final processing - unevenness should be removed, excess scale should be removed, and the joint should be cleaned.

Sometimes additional operations are required, such as preheating the workpiece or supplying shielding gas. However, the main elements of the algorithm are reflected correctly.

Power supplies

The following power sources are used for RDS welding:

- Transformer. A rarely used power source for manual arc welding with coated electrodes. To work with a transformer, many years of experience are required, since this device is characterized by a significant drawback - inconsistent voltage.

- Rectifiers. It differs from a transformer only in a number of structural parts, thanks to which direct current is generated.

- Inverters. The devices create alternating current with a stable voltage. This type of electric welding equipment is used to join metals manually. Inverters are complemented by protection against sticking of electrodes and an arc stabilization system.

- Semi-automatic devices. This type of equipment is presented in the form of inverters, which are complemented by a wire feeder.

The type of welding equipment is selected taking into account the tasks assigned.

Read more about the types of welding machines in our article.

Forward and reverse polarity

Melting of the metal for welding occurs under the influence of an arc. It, as noted above, is formed between the surface of the product and the electrode, since they are connected to opposite terminals of the device.

There are two main options for welding, differing from each other in the order of connection and called direct and reverse polarity.

In the first case, the rod is connected to the minus, and the part to the plus. In this case, an increased flow of heat occurs into the metal. As a result, a deep and narrow melting zone is formed.

Direct and reverse polarity.

With reverse polarity, the electrode is connected to the positive, and the product to the negative. In this case, the melting zone is wide and shallow.

The choice of polarity is entirely determined by the product you are working with. Welding can be performed with two types of polarity. When choosing, you should take into account the fact that the element connected to the positive is subject to greater heating.

For example, it is difficult to weld thin metal products due to possible overheating and burning. In this case, the part is connected to the minus. Currents are also selected according to the diameter of the electrode and the thickness of the metal. This data is taken from a special table.

Electrodes used

According to the standards of manual electric arc welding technology, electrodes coated with a special coating are used to create a high-quality seam. The type of the latter is selected taking into account the type of metal being processed. Rutile coating is considered optimal for working at home.

Rods of this type are distinguished by the following features:

- Beginner welders can work with such a coated electrode.

- There is a wide range of rutile-coated electrodes on the market.

- When heated, rutile electrodes form a zone with a high hydrogen content, which negatively affects the quality of the seam.

- During operation, strong splashing of molten metal is possible.

When choosing rods for electric welding, you need to pay attention to the markings. The latter allows you to understand for which metals the electrodes are suitable.

Manual arc welding technology

Before welding begins, the metal is protected and cut into blanks. Next, the power source starts up.

The arc is ignited in two steps:

- The electrode comes into contact with the surface, resulting in a short circuit.

- The electrode is removed from the surface to a distance equal to the diameter of the rod.

If necessary, ignition is carried out by striking the electrode along the surface. In this case, the metal is heated in several zones.

After ignition, a melt of material is formed in the place to which the electric tog is connected. To create a strong connection, the welder must hold an arc with a length of 0.5 to 1.1 times the diameter of the rod until the end of the work.

Moving the Electrode

When performing RDS welding, it is recommended to guide the rod, making oscillatory movements from side to side along the line of the future seam. This will ensure a strong connection.

Depending on the position of the workpieces, the following welding techniques are used:

- lower position—full penetration of connections is carried out;

- vertical position - the rod is guided from top to bottom so that the molten metal flows into the formed joint;

- ceiling position - constantly pause welding work to reduce the size of the melt and prevent the metal from falling down.

The width of the resulting seam directly depends on the diameter of the rod used.

What is welding

Welding is one of the leading technological processes of metal processing.

The great advantages of welding have ensured its widespread use in the national economy. Welding is used to produce ships, turbines, boilers, aircraft, bridges, reactors, high-rise buildings and other necessary structures. Welding is the technological process of obtaining permanent connections by establishing interatomic bonds between the parts being welded during their local or general heating, or during plastic deformation, or the combined action of both.

A welded joint of metals is characterized by the continuity of their structures. To obtain a welded joint, it is necessary to carry out intermolecular adhesion between the parts being welded, which leads to the establishment of an atomic bond in the boundary layer.

If the cleaned surfaces of two metal parts to be joined are brought together under compression under high pressure so that a common electron cloud can arise, interacting with the ionized atoms of both metal surfaces, then we obtain a strong welded joint. Cold welding of ductile metals is based on this principle.

As the temperature at the junction of parts increases, the amplitude of vibrations of atoms relative to the constant points of their equilibrium state increases, and thus conditions are created for easier connection between the parts being connected. The higher the heating temperature, the lower the pressure required for welding, and when heated to melting temperatures, the required pressure becomes zero.

The physical essence of the welding process is very simple. The surface atoms of a piece of metal have free, unsaturated bonds that capture any atom or molecule that comes within range of interatomic forces. By bringing the surfaces of two pieces of metal closer to the distance of action of interatomic forces or, more simply, until the contact of surface atoms, we obtain, along the surface of contact, the fusion of both pieces into one monolithic whole with the strength of the connection of a solid metal, since the same interatomic forces act inside the metal and along the surface of the connection. The connection process after contact occurs spontaneously (spontaneously), without energy expenditure and very quickly, almost instantly.

The combination of individual volumes of a condensed solid or liquid phase into one common volume is accompanied by a decrease in the free surface and the energy reserve in the system, and therefore the thermodynamic process of combination must occur spontaneously, without supplying energy from the outside. A free atom has an excess of energy compared to an atom in a condensed system, and the addition of a free atom is accompanied by the release of energy. Such spontaneous association is observed between volumes of homogeneous liquid.

It is much more difficult to combine volumes of solid matter. It is necessary to expend a significant amount of energy and use complex technical techniques to bring the atoms being connected closer together. At room temperature, ordinary metals do not connect not only upon simple contact, but also upon compression with significant forces. Two steel plates, carefully polished and “fitted”, subjected to prolonged compression with a force of several thousand kilograms, are easily separated when the pressure is removed, without revealing any signs of connection. If connections occur at individual points, they are destroyed by the action of elastic forces when the pressure is removed. The joining of solid metals is hampered, first of all, by their hardness; when they come together, actual contact occurs only at a few physical points, and expanding the area of actual contact is quite difficult.

Metals with low hardness, such as lead, are firmly connected even with slight compression. With harder metals, the actual contact surface is very small compared to the total apparent surface, even on carefully machined and fitted surfaces.

Welding is a technological process of obtaining a tight, permanent connection of parts using molecular adhesion forces, while the connection material (weld) has the same physical and mechanical characteristics as the parts being connected.

All types of welding can be divided into two large groups - pressure welding and fusion welding.

Pressure welding uses the plastic properties of the materials of the parts being joined, while heating plays a secondary role or is not used at all. When pressure welding, the metal is heated to a plastic state due to the high electrical resistance of the contact zone and then upset by mechanical force, causing plastic deformation of the parts and their connection into one whole.

In fusion welding, the metal is heated to a liquid state (melting), and the edges of the parts being joined are melted simultaneously, forming a common pool of liquid metal; upon crystallization (solidification), the molten metal of the weld pool forms a strong connection that has a cast structure.

Thus, the welding process consists of the formation of strong bonds between atoms and molecules on the joined surfaces of the workpieces. For connections to form, the following conditions must be met:

- freeing the welded surfaces from contaminants, oxides and foreign atoms adsorbed on them;

- energetic activation of surface atoms, facilitating their interaction with each other;

- bringing the surfaces to be welded closer to a distance comparable to the interatomic distance in the workpieces being welded.

Depending on the form of energy used to form the welded joint, all types of welding are divided into three classes: thermal, thermomechanical and mechanical.

The thermal class includes types of welding carried out by melting using thermal energy (arc, plasma, electroslag, electron beam, laser, gas, etc.).

The thermomechanical class includes types of welding carried out using thermal energy and pressure (resistance welding, electric spot welding, diffusion welding, etc.).

The mechanical class includes types of welding carried out using mechanical energy and pressure (ultrasonic, explosion, friction, cold, etc.).

Based on the type of energy source used for heating, fusion welding can be divided into electric and gas. Gas welding uses the energy of combustion in an oxygen atmosphere of flammable gases - acetylene, substitute gases (propane, methane, hydrogen, etc.) and vapors of flammable liquids (gasoline, kerosene).

In electric arc welding, the main part of the heat required to heat and melt the metal is obtained due to the arc discharge that occurs between the metal being welded and the electrode. Under the influence of the heat of the arc, the edges of the parts being welded and the end of the consumable electrode melt, forming a weld pool, which remains in a liquid state for some time. When the metal hardens, a welded joint is formed. Energy required for

formation and maintenance of an arc discharge, is taken from DC or AC arc power sources. Arc welding is classified depending on the degree of mechanization of the welding process, the type of current and polarity, the type of arc, the properties of the electrode, the type of protection of the welding zone from atmospheric air and other characteristics.