When choosing a home assistant, we are usually guided not only by appearance, but also by technical characteristics. And the engine of a washing machine is one of the important parameters that deserves close attention, don’t you agree?

We suggest you understand the performance characteristics, specifics of the design and functioning of different types of motors - for an objective assessment, we conducted a comparative analysis of the operating parameters of the engines.

In addition, they told us how to diagnose the engine, and also outlined the rules for connecting and operating the washing machine, compliance with which will extend the life of the home assistant.

Engine power of various SMA models

The washing machine motor converts electrical energy into mechanical energy, causing the drum to rotate. There are three types of motors for automatic washing machines:

- asynchronous motors - there are two- and three-phase. The power of such motors for washing machines reaches 180 - 360 W, their speed is not too high - up to 2,800 per minute during the spin process and about 300 during the washing process;

- commutator electric motors - can operate not only from direct, but also from alternating current. They are small in size and the engine speed can be adjusted electronically. The main disadvantage is the brushes, which wear out during use and have to be changed periodically. The power of the commutator motor reaches 380 - 800 W, the armature rotates at a frequency of 11,500 - 15,000 revolutions per minute;

- brushless - they are also called inverter. Such motors first became known in 2005, when Lg began installing them on its laundry washing machines. The main difference is that a belt drive is not required to connect the motor and the drum, everything happens directly. This type of engine is the most compact, structurally simple, and has the highest efficiency. The power of such electric engines are not inferior to the above samples, the number of revolutions in the process of squeezing clothes is 1,600 - 2,000 per minute.

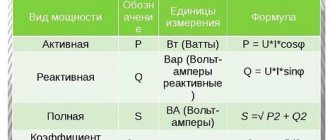

To simplify the issue, let’s figure out how much electricity in kilowatts the motor of your car can generate in an hour of operation. This data interests us more often, but what exactly is the power of the engine itself is a second question.

It is believed that the energy consumption of a device for washing clothes is formed from:

- electricity consumed by the motor, which during operation can vary depending on the operations performed;

- values of a water heating device, the average of which is 1.7 - 2.9 kW. And the amount of energy consumed will depend on the set water temperature;

- the pump power is 24 0 40 W, which is quite enough to drain the liquid;

- the total power value of the light bulbs, module, sensor devices, which reaches 5 - 10 W.

The power of the engine will determine how many revolutions the drum will make per spin. This number is reflected in the SMA spin class. Machines whose motor power regulator allows them to perform 1,600 revolutions per minute belong to group “A”. But this does not mean that you should purchase just such options - even at a mode of 1,000 revolutions, the laundry will be spun perfectly.

We suggest you read: What is the ideal temperature in the refrigerator?

Washing machines from different manufacturers are equipped with electric motors that differ not only in cost, but also in technical parameters. Here are the main devices:

MOTOR CESET MCA 52/64-148/AD9 – such engines are installed on Indesit and Hotpoint-Ariston machines, their power level at 11,500 rpm reaches 430 W;

MOTOR CESET MCA38/64-148/CY15 – motors for units from Kandy, Zerovatt and Hoover companies. At 360 W they produce 13,000 rpm;

MOTOR CESET CIM2/55-132/WHE1 – electric motors of this series can be found on washing units with a power rating of 800 W and a speed of 17,000. Examples of devices are Whirlpool and Bauknecht;

WELLING HXGP2I.05 WASHING – another engine option for Indesit, also found on Vestel. When spinning, the power is 300 W, during washing it decreases tenfold;

Elecronic Control Motor Haier HCD63/39 - this motor can be seen on Kandy or Haier; its power rating is 220 W, speed is 13,000;

HXGP2I Welling Electronic Control Motor - motors of this brand are installed on devices for washing clothes from Samsung and Ardo, their power does not exceed 300 W.

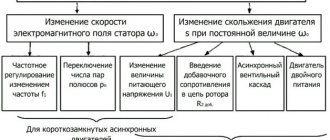

By drive type

Drives are divided into:

The simpler the drive, the more reliable it is. This option includes a direct drive, which is attached to the drum axis and is quieter, frees parts from additional load, increasing service life, and reduces vibration. But, despite the huge number of advantages, machines with such drives are produced only by well-known brands, and their range is very small.

A brushless motor is also called an inverter motor or a direct drive motor. This is the latest technology developed by the Korean concern LG. The spread of this type of motor began in mid-2005, and since then, thanks to its excellent performance, durability and compactness, the inverter drive has firmly occupied a leading position.

Today, other companies use this technology, including Haier, Samsung and Whirpool. Reliability, significant superiority of direct drives over commutator and asynchronous motors, the ability to greatly reduce the size of washing machines, wear resistance, a small number of parts and other advantages have significantly expanded the scope of brushless motors. They were appreciated and began to be used in equipment from Bosh and AEG.

The design of such a motor consists of only a rotor and a stator, just like an asynchronous one. However, its effect is completely different. The drive is connected directly to the drum, which eliminates the use of connecting elements - the most vulnerable parts of the motors. The control circuit in such motors is of a three-phase inverter type.

The main advantages of motors of this type are:

- simplicity of design;

- convenient location in the washing machine;

- compactness;

- low vibration level of the machine;

- Efficiency is higher than that of other types of engines;

- no belt or brushes that require regular maintenance;

- relative noiselessness.

The engine is the “heart” of the washing machine, one of its main components, on which the performance of the equipment depends. The main characteristics of this part are power and number of revolutions per minute.

When buying an automatic machine, we rarely pay attention to these parameters. Or maybe in vain? That’s why we decided to talk about how much power the engine has in a washing machine, and what it affects

Pros and cons of the profession

pros

- The master receives a very good income.

- Different formats of work and profit are possible: private customers, piecework payment, service center or manufacturing companies.

- There is enough work both in megacities and on the periphery.

- You can quickly complete initial training, which lasts 3-4 months.

- The opportunity to take courses at the employer’s company, which allows you to gain knowledge, a number of practical skills and subsequent stable orders.

Minuses

- The master is not protected from unforeseen situations and claims from clients.

- The working day may be irregular.

- Possible unfavorable working conditions.

Inverter motor - a successful development

The efforts of engineers led to the invention, among others, of an inverter motor in a washing machine. Thanks to its appearance, new generation machines have surpassed all previous models in energy efficiency by as much as 20%.

In addition, another “bonus” has appeared - automatic shutdown, which helps save on electricity bills.

Features of inverter motors:

- The induction motor is not equipped with brushes, which means they will not wear out. Nothing will have to be changed, as in brushed and brushless motors.

- A machine with such an engine spins at a speed of 1600 revolutions in 1 minute - the laundry coming out of the drum is almost dry.

- Washing machines with inverter motors, again due to the absence of brushes, have become famous for being silent. Depending on the selected mode – “Wash” or “Spin” – the noise level fluctuates in the range of 53-76 dB.

Inverter motor saves water

Thanks to the modified design and slight tilt of the drum, you can significantly save water. Maybe for some 10% will not be an impressive figure, but for users who actively use the machine, this will be a compelling argument.

The drum of the machine with an inverter engine also allows you to conveniently load and unload things for washing.

Increases washing efficiency

“Faster, higher, stronger” - this almost Olympic principle is implemented through the Beat Wash system, which involves the presence of a 3D sensor. This is what increases the efficiency of washing.

The system can make adjustments to the trajectory of items moving along the drum in order to achieve ideal laundry balance. All this provides the so-called “three-dimensional” washing.

- Washing becomes delicate: the laundry does not wrinkle or curl haphazardly.

- The system adapts to the washing and characteristics of different types of fabric.

- Beat Wash can reduce the time required for a cycle depending on the type of laundry loaded.

All about the inverter motor

Let's look at what an inverter motor is in a washing machine. The principle of operation of such an engine is that a frequency converter, more simply an inverter, is responsible for its speed.

Its task is to convert alternating current into direct current, and then to generate alternating current of the required frequency. The good thing about the process is that the engine speed is controlled with high precision to maintain the required frequency.

The main feature that distinguishes an inverter motor from any other is the absence of brushes. The rotor of the engine, as in all others, rotates according to a single principle - under the influence of an electromagnetic field.

Pros:

- High coefficient of efficiency (efficiency).

- Durability (no replaceable parts).

- Accurately maintain the required speed and instantly reach the desired speed.

Checking the functionality of the mechanism

There are machines on sale only with inverter and commutator motors, so we will consider these two varieties, leaving out the asynchronous one.

We are looking for a breakdown of the direct drive motor

The inverter is not intended for home repair. The best option is to try system testing, if your machine model is capable of this.

Self-diagnosis will display a fault code, its decoding and will help you understand where the problem is and whether the services of a specialist are needed.

The testing method and error codes are different for each machine. Before testing, you need to empty the drum of laundry and close the hatch tightly

If you still want to remove the inverter, follow the correct algorithm:

- Disconnect the device from the power supply. It is recommended to wait a few minutes until all elements are completely de-energized.

- Unscrew the bolts and remove the back panel.

- We find the screws under the rotor that secure the wiring and unscrew them.

- Before disconnecting the wires, we take photographs or sketch them, so that later we can correctly connect all power sources.

- Remove the central bolt that holds the rotor. During the process, you need to hold the rotor to prevent rotation.

- We remove the rotor assembly, and behind it the stator.

- Disconnect all wire connectors.

Now you can inspect the engine. It is unlikely that it will be possible to thoroughly test the operation of the inverter. What can be done? Check the integrity of the rotor winding.

The Hall sensor often breaks down in such engines. Whether it is operational can only be determined in a workshop if the part is replaced with a new one.

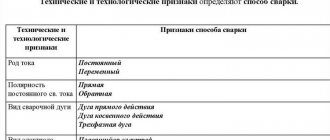

We carry out diagnostics of the belt drive

To check the collector, you must first remove it from the housing. To do this, remove the back panel, disconnect the wires and unscrew the bolts. It is permissible to pry with a screwdriver in the places where the bolts are attached, where dirt often accumulates and sticking occurs.

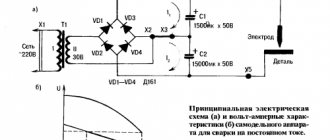

Now let's start diagnostics. We connect the wires of the stator and rotor windings according to the diagram. We connect it all to electricity. There is nothing wrong with the device if the rotor starts rotating.

This testing method has its own characteristics: it is impossible to test the operation of the engine in different modes, plus there is a risk of a short circuit from direct connection

To avoid a short circuit, you can connect a ballast in the form of a heating element to this circuit. We connect the ballast from the rotor side. It will begin to heat up, thereby protecting the engine from combustion.

The collector is a structure of several parts and they all require inspection. First in line are the notorious brushes. They are located on the sides of the body. We take them out and inspect them.

If they are worn out, they need to be replaced. A clear sign of such a need is that the engine sparks when rotating. To buy new brushes, take your old ones with you and write down information about the model of the washer.

The next element is the slats. They serve as current transmitter conductors to the rotor. These parts are glued to the shaft and if the motor jams, their detachment is possible.

If you have access to a lathe, it can be used to remove minor flaking. Don't forget to clean off the shavings with fine sandpaper.

Pay close attention to burrs and peelings on the lamellas; they are often the cause of unsatisfactory operation of the washing machine motor.

Now let's move on to the stator and rotor windings. If a short circuit occurs in them, the collector heats up, which causes the thermistor to operate. The result is that power is lost or the mechanism stops working altogether. We test the windings with a multimeter in resistance mode.

The stator is checked in buzzer mode. The ends of the wiring are tested one by one with probes. If there is no signal, the part is fine. You can determine the location of the short circuit by connecting one probe to the wiring and the second to the housing.

The probes are applied to the engine lamella. The display shows less than 20 Ohms - we have a short circuit, more than 200 Ohms - a break in the windings

If the device is silent, this is normal. If a breakdown is detected, you will need to create a new winding to repair it yourself, and this is difficult for a non-specialist.

If you still need to replace the engine, it is usually enough to simply install a new part in place of the old one. After all the manipulations, do not forget to turn on the machine and check its operation.

Advertising tricks of manufacturers

In the instructions for washing machines, manufacturers indicate all the parameters and characteristics, and the user, studying them, realizes how much new products benefit in many respects, such as energy efficiency and durability. Companies under no circumstances deceive customers, but sometimes they leave out small nuances that significantly reduce the value of new technologies. This is done for advertising purposes to increase sales.

Energy efficiency

As the advertisement says, inverter machines help save up to 20% of electricity compared to collector models. Yes, this is indeed true and the savings occur due to more precise adjustment of the load on the motor - with a small load of laundry, the drum is not fully spun up and energy is saved.

But the most important thing is that in the machines, the largest amount of electricity is consumed not by the motor, but by the heating elements that heat the water. Therefore, real savings are 2-5%, and when fully loaded they are reduced to zero.

Silence

Brushed motors make a lot of noise, while inverter motors operate as quietly as possible and do not make any sounds. This is partly true, motors with brushes are noisier, but inverters also have a characteristic squeaking and whistling sound.

Spin speed

The new products can actually spin clothes at the highest speed, reaching 2000 rpm. This is a very significant advantage of an inverter washing machine for buyers who dream of quick washing and almost dry laundry. But few people know that with such a spin speed, things quickly become unusable and sometimes, instead of a well-wrung item, people take out shreds of it. And delicate or woolen items a priori do not require a strong spin, so think about how necessary such speeds are.

Durability

Now ask yourself a question: how long do you want to use your washing equipment? Typically, users expect a maximum of 15 years, but even during this time, technology will make significant progress and new, improved and more technologically advanced models will appear. A service life of 10-15 years is established for the commutator drive.

Most buyers worry about brushes that wear out, but their service life is up to 15 years with a daily load of two hours. Even if they wear out, the cost of replacing them is negligible.

Another point that affects durability is the combined location of the drum shaft and engine. Indeed, such an arrangement has a lot of advantages and the absence of various additional loads, and an increased mechanical life, but there is also a minus - one, but significant.

No rubbing parts

This statement can be called an outright lie. There are no brushes in the inverter motor, but there are bearings and they have the same service life and wear rate as in conventional motors.

Manufacturers provide warranties for inverter motors for up to 10 years, but for other parts of the washing machine, warranties are limited to 3-7 years. Equipment is also affected by such factors as, for example, voltage surges, which reduce all newfangled technologies to banal breakdowns not included in the warranty service. And the cost of repairing inverters is very high. Therefore, it is recommended to correctly connect and install the washing machine, as well as operate it carefully, following the basic rules, and the equipment will delight you for many years.

Source

Which car with an inverter motor to choose

The modern market is overflowing with household appliances. In this regard, people have a question: “Which machine to choose?” The housewife should compare all the characteristics to choose what is most suitable.

Indesit machines are equipped with additional functions that save energy. In addition, they have a mode that allows you to deal with dirt and grass marks. This function will be useful for those who have athletes in their family. If you wish, you can even wash your sneakers. The inverter motor handles the load perfectly.

Another leader is Bosch. In addition to the silent engine and original design, the advantage of these machines is that they are capable of washing up to 10 kilograms of laundry at a time. The drum does a great job with carpets, long curtains and other bulky items.

Each housewife must choose the machine that suits her best.

Engine from an old washing machine characteristics - Machine tools, welding, metalworking

Any washing machines become unusable after a certain period of time, and most often they are simply sent to a landfill. But some details from it can be given a second life.

For example, an engine from an old washing machine that has broken down can become the basis for a new homemade device or tool. There are many different options for using it to benefit your household.

True, all this depends on the imagination and skill of the home craftsman.

The type of electric motor chosen for homemade products depends on the age and model of the washing machine. For example, if it was an old washing machine dating back to Soviet times, then it most likely had a reliable asynchronous electric motor installed.

This washing machine motor has a power of 180 W, has excellent torque and is the most convenient motor for homemade products.

Also in the hands of the master may be a two-speed electric motor, a commutator motor or an engine from a modern SM of any model and class.

Second life of an electric motor

From an old, out of order washing machine, it is possible to make many homemade items for household needs. Many of its elements are suitable for this, including the body, drum, covers, etc. But units are most often made for use in household purposes, home workshops or garages - using a motor.

You can use the electric motor from a washing unit, for example, by making a homemade juicer for the kitchen, a vibrating table for the workshop, as well as making many other useful devices and accessories that can greatly simplify certain types of work for a home craftsman.

During the spin cycle the program freezes or the function does not work

The reasons for the lack of spin can be either mechanical or software at the level of control electronics. To exclude a breakdown at the electronics level, you need to run the spin function separately and see if fault codes appear on the control panel of the washing machine. If the machine has a touch control and a large screen, then a failure of the function will be accompanied by the symbols “ERROR”, followed by a digital error code. The analog control system is a little more complicated. It is represented by indicators that, when an error occurs, begin to glow or flicker.

One of the most common reasons for the failure of the spin function is the failure of the tachometer sensor or a break in the wires transmitting the control signal from the tachometer to the engine. In this case, DIY repairs seem to be quite problematic. Since it is necessary to have professional testing equipment.

Tachometer sensor

Mechanical causes of failure or poor performance of the spin function can be eliminated independently:

The belt transmitting torque from the motor to the drum has stretched. This problem occurs especially often in compact (narrow) washing machines.

Drive belt

Wear on engine brushes occurs during intensive use over a long period of time. At the same time, the washing machine works quite successfully at low speeds, but for spinning (maximum speed) the power is no longer enough.

Remove the electric motor

Remove the brushes

To replace the brushes, you need to remove the engine and find the brush holders on it (they may look different for different models), remove one of the brushes and purchase similar ones in the store. The need to replace brushes can be determined by the size of their protrusion from the brush holder. If at least one of them has less than 7 mm, then both cheeks need to be replaced.

Types of washing machine motors

The electric motor of the washing machine is a reliable part that very rarely breaks down. Therefore, motors from machines that have been used for 20-30 years are quite suitable for recycling. With their help, craftsmen construct lathes and emery machines, apple and grain crushers, small concrete mixers, lawn mowers and other useful household devices.

Let's figure out how electric motors differ, what features are typical for certain power devices. Let's tell you what elements different engines consist of.

Commutator motors are considered the most common today; they are found in most automatic machines. The design of such an electric motor contains:

- aluminium case;

- rotor;

- stator;

- two brushes;

- tachometer.

The number of leads for such motors can be from 4 to 8. Electric brushes are necessary here to create a connection between the rotor winding and the motor. The collectors are installed at the bottom of the automatic machine. Impulses from the engine are transmitted to the drum pulley via a belt drive.

Inverter motors are considered the most modern. They first appeared in cars of the South Korean brand LG in 2005. Today, this innovative development is already used by many manufacturers - machines with a direct drive system are produced by the brands Bosch, Samsung, Haier, Whirlpool, AEG and others.

Inverter motors are connected directly to the drum. These machines do not have a pulley or drive belt. The design of electric motors of this type includes:

- rotor (it is a cover with magnets);

- stator (these are several cages with coils);

- a frequency converter.

Inverters do not have brushes, which on the collectors have to be changed every 3-5 years. The armature is formed on magnets. During operation, the voltage is directed to the stator winding, converted into an inverter form.

Asynchronous motors are now almost never used in the production of automatic machines, but they are what are used in old activator washing machines. Such engines come in two- and three-phase types. You can find engines of this type on early models from Bosch, Kandy and Ardo.

The asynchronous engine in the machines is located at the bottom, it communicates with the drum through a drive belt. The design has a rotor and a stationary stator. Such engines are simple and easy to maintain. If bearings are changed in time, the devices can operate for decades without complaints.

Types of engines

The conversion of electrical energy into mechanical energy (rotation of the drum) in a washing machine occurs due to the engine. Engineers have developed three types of engines that are used in automatic cars:

- asynchronous motor;

- commutator motor;

- brushless motor.

Asynchronous type motors can be two-phase or three-phase. Modern washing machines manufactured after 2000 do not use two-phase motors. The power of such engines is 180-360 W, the number of revolutions is not high and does not exceed 2800 revolutions per minute during spinning; when washing, the revolutions are about 300. In machines with such an engine, spinning is only 400-600 revolutions per minute, in rare cases 800- 1000.

Asynchronous motors have practically been replaced by brushed motors, which are capable of operating on both alternating and direct current. They are smaller in size and have smooth electronic speed control. The main disadvantage is its design, which includes the presence of brushes; they wear out and become unusable. To restore engine performance, they need to be changed periodically. The power of commutator motors is 380 - 800 W, while the armature rotation speed varies from 11,500 to 15,000 rpm.

The brushless or inverter motor first appeared in washing machines in 2005, and LG was the first to use it. Its difference is that it is directly connected to the drum without a belt drive. It is more compact than the other two types of engines, simpler in design, and has the highest coefficient of efficiency (efficiency). In terms of its power, the inverter motor is not inferior to the previous ones and is capable of spinning the drum during spinning up to 1600-2000 rpm.

Dependence of energy consumption on power

Energy consumption as a whole depends on the power of the electric motor of the washing machine; in other words, how many kilowatts of energy the machine generates per hour. This is what interests the consumer most often, and not the power of the automatic machine’s motor. The energy consumption of the machine consists of:

- engine power consumption, during the entire wash it changes, during spinning more, during washing and rinsing less;

- heating element power, which averages from 1.7 to 2.9 kW. Moreover, the higher the water heating temperature, the greater the power consumption;

- the pump power, which is 24-40 W, is quite enough to pump out water;

- total power consumed by light bulbs, control module, sensors, etc. it is approximately 5-10 W.

The power consumption of the washing machine is calculated for the “Cotton” mode, in which the water is heated to 60C and the machine is loaded to its maximum. Based on this indicator, the washing machine is assigned an energy efficiency class, denoted by a Latin letter.

The more powerful the engine, the more revolutions the drum will make when spinning the laundry. This indicator is reflected in the spin class of the washing machine. Automatic machines rotating at a speed of 1600 rpm belong to class A. But it is not at all necessary to buy such a machine, because even with a spin of 800-1000 rpm, the laundry will be wrung out well, without the risk of being torn.

Motor power of different models of washing machines

Washing machines of different brands have different motors, so they have different technical characteristics and different prices. Let's give a few examples.

- MOTOR CESET MCA 52/64-148/AD9 – motor installed on Hotpoin-Ariston and Indesit washing machines, its power is 430 W and 11500 rpm;

- MOTOR CESET MCA38/64-148/CY15 – motor for the Candy, Hoover, Zerovatt washing machine, power is 360 W and 13000 rpm;

- MOTOR CESET CIM2/55-132/WHE1 – electric motor for Whirlpool, Bauknecht washing machines, power 800 W and 17000 rpm;

- WELLING HXGP2I.05 WASHING – motor for the Indesit or Vestel washing machine, spinning power 300 W, washing power 30 W;

- Electronic Control Motor Haier HCD63/39 – motor for Candy and Haier machines, power 220 W and 13,000 rpm;

- HXGP2I Welling Electronic Control Motor – motor for Samsung washing machine, power 300 W.

So, automatic washing machines produced in the 2000s have a brushed or brushless motor. Their power consumption may vary, but for the consumer this does not matter much. It is more important to know how energy efficient a machine is, and this can be determined by the energy consumption class, which modern machines have A or A+.

Share your opinion - leave a comment

The windings are broken or shorted

Acceleration problems also arise when the winding is damaged: the motor does not start or the drum rotates very weakly. The fact is that short circuits occur in the wire turns, the engine begins to overheat, the thermistor is triggered, and the system urgently turns off the power for safety reasons. At the next start, the situation repeats until the temperature sensor burns out, and then the engine itself fails.

The winding is checked with a multimeter according to the following algorithm:

- turn on the tester in the “Ohmmeter” mode;

- we attach the probes to the adjacent lamellas;

- We evaluate the resistance (the norm is from 0.1 to 0.4 Ohms).

Repairing the winding yourself is very dangerous. It is better to turn to professionals or purchase a new engine.

Share your opinion - leave a comment

Differences from belt drive

Washing machines that have direct drive or a special belt have many differences. Let's focus on the main points.

- A direct drive has a direct connection between the rotor and the drum axle. In the case of belt-type units, the belt connects the pulley of the tank and the engine, due to which the drum rotates and stops.

- The engine in direct drive models is located under the tank and leads to strong friction of adjacent parts - bearings. Belt versions use special brushes that are designed to smooth out friction and also limit the transmission of current.

- The difference between belt and direct drive models lies in the price. The first options are usually cheaper than the second.

- Direct drive washing machines usually have more capacity. But belt models cannot boast of this, since in the design of the equipment a lot of space is allocated for installing brushes, belts and a pulley.

- Belt-type washing machine models usually operate quite loudly, creating strong vibrations. This problem is not typical for direct drive units.

- Direct drive machines have more powerful motors compared to non-drive devices.

- Designs without a belt drive are more stable, so direct drive models are more balanced than those with a belt.

- Repairing a belt machine is always cheaper than repairing modern direct drive machines.

We suggest you read How to remove a clip from clothes

Homemade concrete mixer

If you have started a small renovation that requires, for example, plastering the walls, a concrete mixer will come in handy. Once again, washing machine parts will come in handy.

As a result, you will receive a compact device with low power, which you won’t mind throwing away after the repair work is completed.

As a container for concrete, you can use the same drum with pre-sealed holes for draining water. It is best to use parts from a front-loading machine; there will be almost nothing to redo. To strengthen the body, use a metal corner, and for convenient movement of the concrete mixer, equip it with wheels. The main difficulty in the design is the manufacture of a “swing” for the correct tilt and subsequent pouring of concrete. How to do it correctly in the video:

Conclusions about engine power

How to find out how many revolutions a washing machine motor has? How to determine motor power? How can you avoid making mistakes in choosing technology based on this?

It's simple: washing machines made after 2000 are supplied to stores with brushed or brushless motors. Their power may differ, but this is not the most important indicator for the consumer, since the more pressing issue is the optimal energy efficiency class.

Therefore, if you don’t want to understand the technical nuances of motors, just choose a class A or A+ machine.

A useful video will tell you even more about the SM engine:

Carrying out disassembly

If you are wondering how to disassemble the Malyutka washing machine, then first you must remove the plug from the hole located in the back of the electric motor casing. The oblong hole of the impeller must be aligned with the hole in the casing. Through it, a screwdriver is inserted into the engine rotor. The activator is unscrewed.

You must insert a key into the hole in the activator housing and unscrew the housing. This will allow you to disconnect the tank. Disassembling the Malyutka washing machine at the next stage involves unscrewing six screws. Next, you can remove the flange and unscrew the locknut, as well as the rubber nut. They fix the switch. Now you can remove the washer and unscrew the screws that hold the casing halves together. Below it is an electric motor and other equipment elements.