The “smart” greenhouse opens the windows itself

If watering, heating and ventilation in the greenhouse work on their own, the summer resident does not have to spend 24 hours with his vegetables.

Automation installed in a greenhouse by a zealous owner will leave him more free time. Overheating of plants can destroy all the painstaking work of growing, because the seedlings will simply die. They vitally need timely ventilation. Let's look at how a “smart” greenhouse can open and close the windows independently, without human intervention.

Need for ventilation

All residents of apartment buildings know that the only way to get fresh vegetables in winter or early spring is in the store. But those who have at least a small plot of land at their disposal can arrange a vegetable feast for themselves during cold weather and crop failure. For these purposes, greenhouses are often installed in vegetable gardens. Such outbuildings can be made of various materials: from thick industrial film to heavy glass. The most popular greenhouses today are made of polycarbonate.

The main operating principle of a greenhouse is to create the most comfortable conditions for growing crops.

Several factors contribute to this.

- Temperature maintenance. For the greenhouse to fully function, the temperature inside must be at least 22-24 degrees Celsius.

- Optimal air humidity. This parameter is developed for each individual plant. But there is also a certain norm, which ranges from 88% to 96%.

- Ventilation. The last point is a combination of the previous two.

In order to normalize the required temperature and humidity in the greenhouse, it is necessary to provide air baths for the plants. Of course, you can do this yourself. In the morning - by opening doors or windows, and in the evening by closing them. That's what they did before. Today, agricultural technological progress has made it possible to invent devices for automatically opening and closing windows in greenhouses.

It should be understood that standard methods of creating drafts for plants are unacceptable. Too sharp a change in temperature or humidity level can cause deterioration in the condition of the crop and its death. While film greenhouses have the option of self-ventilation (due to the lack of tightness of such structures), glass and polycarbonate buildings really need automatic ventilation.

In addition to monitoring these indicators, there is also a risk of the development of pathogenic bacteria and microorganisms that negatively affect the growth of vegetables and fruits. Many insects also prefer warm and humid places for their deployment. Periodic air baths in greenhouses will bring them discomfort. This way, no one will encroach on your future harvest.

In order not to worry and not to run to the greenhouse every half hour or hour, checking all the indicators, agricultural experts advise purchasing and installing thermal actuators. What it is and how it works, we will understand further.

Hydraulic cylinder principle

As you know from a school physics course, any liquid expands and contracts under the influence of temperature. This law can be used to create a device that opens and closes windows. If you place liquid, for example, machine oil, in a sealed hydraulic cylinder, then when the room temperature rises, it will expand and extend the rod. The rod will move the window frame, and ventilation of the greenhouse is ensured. And vice versa, as soon as it gets colder, the oil will return to its original state, the rod will lower, and the window will close.

Hydraulic cylinder

Attention! If the diameter of the cylinder is 50-55 mm, and the length is 50 cm, then 800 g is placed in it. oil (can be used). When the temperature in the greenhouse increases, the rod of such a tool lifts a load of about 10 kg. This may not be one window, but several connected into one system.

Advantages of the method:

- installation does not require electricity;

- it is quite possible to do it yourself;

- The hydraulic cylinder does not require constant maintenance.

Disadvantages of the method:

- the side frame, which rotates along a vertical axis, will not fall under its own weight if the rod is removed. In this case, a return spring will have to be attached to the device.

- if a cold wind suddenly blows, the window will not slam shut at that very moment. Closing will occur after 15-20 minutes when the oil has cooled.

A hydraulic cylinder for a greenhouse can be purchased in a store or made by yourself

Pros and cons of a hydraulic cylinder for a greenhouse

Among the advantages that a hydraulic cylinder has are the following positive criteria:

- To set up such a mechanism, there is no need for electrical lines. The system operates independently according to the laws of physics;

- The simple design helps you quickly create such a product for equipping your own greenhouse at home;

- The design does not require complex maintenance.

This mechanism has its drawbacks. They are as follows:

- It is first recommended to use a return spring, which ensures gradual lowering and raising of the window frame. The fact is that the design of the window, when the volume of the working mixture inside the hydraulic cylinder is reduced, will not be able to close completely;

- During a sharp drop in temperature outside the greenhouse, the hydraulic cylinder will not be able to close the window opening at a time when the temperature regime may sharply drop to sub-zero levels. Oil and water cool quickly inside a sealed container.

Hydraulic cylinder from spare parts for a machine

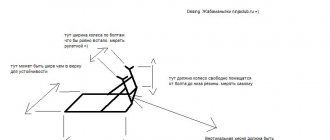

For vertical vents, a mechanism assembled from scrap materials is ideal. It is capable of lifting even the heaviest frames, as long as the windows swing open along a horizontal axis. To create it, you need to improve the automobile gas piston.

You will need:

- the hydraulic cylinder itself. Its role can be played by stops for the trunk of Moskvich, Niva, Zhiguli (models VAZ 2108, 2109) or hydraulic cylinders from trucks that lift the cabin;

- epoxy adhesive;

- drill.

Hydraulic cylinder for a greenhouse from a car stop

Stages of work:

- Drill a hole in the bottom of the stop. Be careful and wear glasses when working. Gas escaping from the hole may carry chips into your eyes.

- Using a large diameter drill, increase the hole to 9 mm.

- We press on the rod and push it into the cylinder so that the piston remains at a distance of 30-35 cm from the hole.

- We degrease the resulting cavity with a solvent.

- After the cavity has completely dried, we prepare the epoxy glue for work.

- For greater convenience, the cylinder should be secured in a vice with the hole facing up.

- The piston must be lubricated with oil so that it does not touch the grease-free walls.

- Now let's create a glue plug. Pour glue into the cavity so that it completely covers the hole.

- After the glue has dried, the piston must be moved away by pulling the rod. Since it's oiled, it shouldn't stick.

- In the same place, only in the glue, drill a hole with a diameter of 9 mm.

- We cut threads in it in increments of 1.25 using an M10 tap.

- We strengthen the finished device under the window so that the rod lifts the transom when extended.

Horizontal hydraulic cylinder for greenhouse

What is a thermal drive

This is a smart device that allows you to automatically manipulate the doors and transoms of greenhouses. Moreover, human presence is not required at all. There is no need to supply electricity to the greenhouse or buy batteries for the device.

It does not have a motor and does not have a complex circuit with temperature sensors. Meanwhile, when a certain heating of the environment is reached, it starts to move and opens the window. Then, when the temperature drops, it closes it.

For its operation, the thermal drive uses a substance that begins to melt at +23°C. Cyclohexanol has such properties. Turning into liquid, it expands, filling a special chamber. At the same time, it puts pressure on the rod, which in turn moves the door, forcing it to open. As the temperature drops, the liquid contracts, pulling the rod in.

The thermal drive is designed for very long operation, because there is practically nothing to break in it. Only the warranty period is 10 years. Moreover, the manufacturer assures that during this time it will not let you down. But in fact, the uninterrupted service of the device continues even after the warranty.

The device is very easy to install and anyone can do it without the help of a specialist. After installation, no additional adjustments are required. Yes, they are impossible due to the simplicity of the mechanism. At the same time, he has enough force to lift the ceiling frame.

The liquid pushes the rod with a force of 10 kgf, and the hydraulic cylinder can withstand pressure up to 200 kg. This is more than enough to prevent the doors from closing even in stormy gusts of wind. Smooth opening begins to occur at +24°C, and closing - at +22°C.

Hydraulic cylinder from an office chair

If you cannot purchase a car piston, you can use a piston that raises and lowers the seat of an office or computer chair instead. On one side of the unit there will be a plastic valve stem, on the other - a metal one.

Advice. In order to get rid of metal shavings that arose during the alteration process, you need to wash all parts in gasoline.

The hydraulic cylinder is assembled according to the same principle as the previous version.

You will need:

- chair lift cylinder;

- tools.

How is an automatic ventilation device installed?

The device for automatic ventilation of greenhouses “Autovent XL” has the ability to set the operating temperature of the window opening from 12 C.

Having purchased one or another device for automatically opening windows in a greenhouse, you should install it correctly. There is nothing complicated about this (the installation process is necessarily described in the instructions included with the device), but you must also adhere to some unwritten rules listed below:

First of all, you need to think about the location of the opening windows themselves. When constructing the greenhouse itself, it is necessary to provide that its openable elements (windows, windows) will not be located on the side from which the strong wind is blowing. In addition, it is desirable that the opening parts are located at the top of the greenhouse. Installation of lighter devices, for example the Danish “Megavents”, is carried out directly on the window frame, which simplifies the work. But the “UFOPAR” hydraulic cylinder weighs almost 4 kg and is attached to the frame of the greenhouse

It is important that the frame element to which this or that machine is attached is strong enough to hold the expected load. All opening devices operate based on temperature. It is important that this is exactly the air temperature in the greenhouse

Therefore, if necessary, the device should be protected from sunlight with a screen. If the device is not equipped with hurricane protection, you can make it yourself by equipping the windows with special tapes, chains, cords that do not allow opening beyond the prescribed angle. It is important to properly maintain the device during its operation. Instructions for its maintenance are included in the factory kit.

Do-it-yourself hydraulic cylinder

It's possible that you don't have a car part or a computer chair. Using the same principle, you can make a completely homemade system.

Advice. All connections must be absolutely tight, otherwise the design will not work.

To assemble you need to have:

- any bendable material, for example, polycarbonate or tin;

- plastic pipe;

- sealed chamber, you can use a ball;

- tools.

DIY hydraulic cylinder for a greenhouse

Stages of work:

- We create a container in the form of a cylinder ourselves, using bendable material. Plexiglas can serve as the bottom and lid. We attach it at our own discretion. Some people use tape, but it doesn't last long.

- We make the piston so that it moves freely in the cylinder, but sits tightly. It can be made from metal, plexiglass, wood treated with an antiseptic.

- You need to drill holes in the bottom and cover of the cylinder.

- A deflated rubber chamber from the ball must be placed inside the cylinder under the piston. Connect it to the tube and thread the tube into the hole at the bottom of the cylinder. As soon as the air temperature rises, the ball will inflate and push the piston.

- From the side of the cylinder cover, you need to insert a rod into the hole so that it fits snugly against the piston.

- Air will enter the ball through a tube coming from a separate container, that is, from the receiver. This could be a canister or paint can.

- It is better to pass two pipes through the receiver. One will attach to the ball in the cylinder. The other, spare, will serve for pressure regulation and calibration. It must be closed with a removable plug.

- Attach the rod to the window frame.

Calibration of this version of the device is possible using a free hose. By manually applying pressure, the hydraulic cylinder can be adjusted to respond to a specific temperature.

Types of main structures for greenhouse ventilation

Option #1 – electric

An electric automatic machine for ventilating greenhouses consists of a fan and a thermostat, which turns it on as soon as the air temperature in the greenhouse reaches a certain point. Their main advantage is high sensitivity and convenient adjustment, as well as unlimited power. They do not take up much space, can be located anywhere in the greenhouse, and the algorithm for their operation can be of absolutely any complexity - both simple and “smart”.

But the electric mechanism for ventilating the greenhouse is not reliable enough and depends entirely on the uninterrupted supply of electricity. For example, turning off the lights for just a few hours on a hot day can ruin a whole year's harvest. That is why it is advisable to take care of backup power in advance using an installed battery with recharging from a solar panel on the roof of the greenhouse.

Option #2 – hydraulic

The advantage of hydraulic devices is the autonomy and high reliability of the entire system. Hydraulic designs are simple, have great power and durability. They are a system of levers with a sensor connected to a transom.

The operating principle of this system is quite simple: as soon as the weight of one of the lever arms changes, the entire “yoke” tilts in the other direction and opens the transom. Then, when the air is sufficiently cooled, the reverse process occurs. Moreover, all the levers are two containers connected to each other like communicating vessels with just one flexible thin hose. The container that is inside the greenhouse is sealed and contains a sufficient supply of air - this is the “thermometer”.

But the container on the outside acts as a “weight” on the transom. Therefore, if the air inside the container is heated by the air in the greenhouse, part of the liquid is squeezed out into the outer container. It becomes heavier and opens the transom. And when the air in the greenhouse cools, the vapors inside the container are compressed again and the container sucks back the water. The outer one becomes lighter and the spring returns to the counterweight. Even a schoolchild can make such a pneumatic system. But it can only be used in a very small greenhouse or greenhouse.

But devices whose operating principle is based on the pressure force of an expanding liquid (be it water or oil) have serious disadvantages:

- In most ready-made models, transoms close under the influence of their own weight, and therefore this design cannot be used for the side windows of a greenhouse (unless you experiment with a spring).

- In the event of a sudden cold snap, the liquid in the cylinder cools down within 20 minutes, and all this time the transoms are still open, which is why cold dangerous air enters the greenhouse.

But, despite their disadvantages, hydraulic cylinders still have an undeniable advantage over other machines - for example, the ability to lift really heavy weights.

Today on the construction market there are many offers of high-quality “pushers” for greenhouse vents. They are all different in appearance, but their operating principle is the same - a small elongated hydraulic cylinder is filled with oil, which expands under the influence of increased air temperature in the greenhouse itself and pushes out the rod. The rod is connected to a system of levers and a window. When the oil cools, the reverse process will occur and the window will close.

Although the installation of such a system is primitive, it is important not to forget about the following points:

- The hydraulic cylinder must be heated not from the sun, but from the air, and therefore it requires a sun shield.

- For additional insurance against strong gusts of wind, you need strong tapes and chains that are attached to the vents.

- The entire system is adjusted with a special nut at the end of the cylinder, and therefore, before tightening it, you must wait until the optimal temperature in the greenhouse is approximately 25 °C.

Among the domestic ones, the best automatic pushers for vents are considered to be Volya hydraulic cylinders - the lightest, most compact and inexpensive.

Option #3 – bimetallic

Bimetallic ventilation of greenhouses is a simple system consisting of special metal or metal and plastic plates, which have different coefficients of thermal expansion. So, when heating up, one of the plates bends strongly and opens the window, and when cooled, it straightens out again, which closes it. Bimetallic structures operate completely autonomously and are inexpensive to manufacture. The only drawback is the insufficient power, because such a plate can only open a very small window without any distortions or swelling. And you can’t often find such things in ordinary greenhouses.

Hydraulic cylinder installation

The last step for any of the three devices is installation. It is recommended to hang hydraulic cylinders from the ceiling, because this is where warm air collects. The device must be protected from direct sunlight, otherwise an overheated device will open the window, and the plants below will be cold. You can protect the hydraulic cylinder with foil or any other material that reflects the sun's rays.

Installing a hydraulic cylinder on a window

The stem can be installed in different ways. For example, nail it to a wooden frame. But then you will no longer open the window manually. Or just place it tightly under the transom.

An automatic ventilation system, the main element of which is a hydraulic cylinder, can be easily made with your own hands. And then the vegetables, berries, herbs or flowers in the greenhouse will not be hot even in the hottest summer.

Automatic opening of the greenhouse: operating principle

Modern production of components for automated greenhouses offers gardeners many options, varying in size, appearance, efficiency and cost.

Today, automation for greenhouses according to the principle of operation differs in:

- Hydraulic installations. Such openers work on the principle of increasing pressure in containers with liquids when exposed to high temperatures. Hydraulic systems are the safest. Their disadvantages include a delay in closing the transoms, which can negatively affect the condition of the plants.

- Electrical. Such systems are the most accurate, easy to install and do not take up much space. The downside of the devices is the need for a permanent connection to the power grid. If the greenhouse is fully electrified, to eliminate the possibility of the devices stopping, you can purchase an electric generator.

- Bimetallic. Opening and closing in the case of bimetallic systems is based on the ability of metals to expand. Such installations can be used to automate homemade windows on a wooden frame: they will not be able to open heavy transoms or doors.

You can equip any window (top and side) and door with automation.

Tools and materials

If you are going to make a hydraulic press with your own hands, then you will need the following tools, consumables and equipment:

- welding equipment;

- electrodes;

- metal hacksaw or grinder (angle grinder).

In addition, you will need the following elements that will make up your future garage press: a hydraulic jack, two springs that will pull the movable platform to its original state. If you find an old bridge fungus in your garage left over from a renovation, it can be used as an element of a pulling device for homemade presses with a lower jack. In this case, the fungus is put on the jack rod, the upper part of the springs is attached directly to it, and the lower part is fixed to the frame.

The type and quantity of materials required to build a press greatly depends on the chosen design option.

In order to make a press from a jack, you will need the following rolled metal:

- channels (no less than 8 numbers), rectangular or square pipes (with dimensions no less than 40x40), corners with a shelf width of no less than 50 mm;

- a steel sheet with a thickness of at least 8 mm, which will be used as a reliable foundation for the entire structure;

- a piece of steel strip 10 mm thick - for the manufacture of guides and stiffeners, if necessary;

- a piece of pipe - for making sockets for the head of the jack rod.

Let's calculate the structural elements

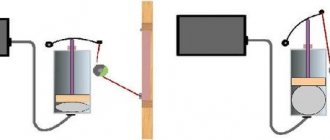

To open the greenhouse, a gas lift rod with a diameter of 8 mm, moving 15 cm, displaces the volume of liquid:

ΔV=πD2/4хl = 3.1415 x 0.82/4 x 15 = 7.54 cm3.

To ensure the resulting change in the volume of the working fluid with the coefficient of volumetric thermal expansion k=0.0008 when the temperature changes by 10 C, a total volume of working fluid is required equal to:

V=ΔV/ k / (t1-t2) = 7.54 / 0.0008 / 10 = 942 cm3

(0.942 liters.)

DU-25 water and gas pipe 2 meters long as a container for oil

, having a sufficiently large surface for heat transfer.

The internal volume of the pipe will be:

V=P D2/4 x L = 3.1415 x 2.5 x2/4 x 200 = 982 cm3

To install a filler valve (top), gas lift (bottom), the pipe must have 1” internal pipe threads on both sides.

To transition from the internal thread of the pipe (in our case 1”) to the thread of the faucet 1/2“ we use a standard nipple (photo 2) with a modified gas lift glued into it.

Photo 2. Options for gluing a modified gas lift into a 1″ fitting or into a 3/4″ thread.

We saw off the plug at the gas lift. Take care of your eyes, there is compressed nitrogen in the gas lift.

The design of the gas lift piston has a micro-valve that ensures the slow flow of a pure gas-oil mixture to ensure smooth stroke of the rod. In our case, the microvalve is likely to become clogged, which will lead to failure of the ventilation machine. To ensure free flow of oil, drill a hole with a diameter of 1-3 mm in the hydraulic cylinder piston. (photo 1). Wash the piston and cylinder from chips.

Photo 1. Gas lift pistons with holes for free flow of liquid.

The piston itself with the sealing ring will remain as a guide sleeve.

To further prevent the rod from being completely retracted into the cylinder, the edges of the cylinder can be “rolled” (photo 1).

We clean the inner surface of the thread (bushings, couplings) and the outer part of the gas lift from paint, rust, scale with coarse sandpaper to bare metal.

We wrap the gas lift with a cloth soaked in epoxy resin and drive it tightly into the drive, sleeve, coupling or nipple (photo 2).

The welded joint option is quite complicated, since it is necessary to prevent damage to the internal mirror surface of the gas lift cylinder along which the piston moves. In this case, you need to weld the gas lift in the very top part, where the piston does not reach (Photo 3).

Photo 3. Welding gas lift and 3/4″ threads.

The method of attaching the automatic ventilation unit to the lower support (Photo 4) and to the openable frame can be any, but we liked those shown in Photos 5, 6). In this case, the attachment points are located along the axis of the hydraulic cylinder and the rod is not subject to bending force.

Photo 4. Method of attachment to the lower support.

For free flow of oil, when the valve is open, the hydraulic cylinder must be connected to the atmosphere (Hole in the squeegee. Photo 5,6)

Culinary uses of a jack press

At the first stage, an accurate drawing is made, which should include all design elements. Their operational and technical characteristics are taken into account - overall dimensions, steel thickness, load capacity.

Before this, you need to choose the optimal set of tools and consumables. To process and weld metal structures, you will need a welding machine, a powerful drill, and a set of bolts and nuts. Blanks for a manual hydraulic press can be formed using a self-generator or an angle grinder. In order to secure the unit, holes will need to be made in its base.

Recommendations for assembling the machine:

Frame. The frame consists of 6 channels. The connection is made in two ways: welding and mechanically using screws;

auxiliary table. The optimal design is to install two channels with a gap between them;

Home use options

The use of a hydraulic press in a garage or home workshop is quite common. This type of press, which is small in size, can be used both for car repairs and for other types of work.

In particular, with the help of such compact equipment it is possible to press out bearings or silent blocks, as well as press new parts in their place. In addition to automotive repairs, a hydraulic press can be used for bending metal parts, creating the required pressure when gluing surfaces, briquetting waste, and squeezing out oil and liquid. Factory equipment for this purpose (even a manual hydraulic press) costs a lot of money, and not everyone can purchase it. Meanwhile, you can make such a press with your own hands, spending only money on purchasing the necessary materials.

Using a press as a juicer

What is noteworthy is that the design of a hydraulic press manufactured at home can immediately be adapted to solve a specific problem with a specific part or workpiece. A self-made press will not take up much space; to place it, it will be enough to allocate some space in a workshop or garage. Detailed instructions on how to make a hydraulic press are given below. There is also a video on this topic at the end of the article.