When building a house or renovating an apartment, there is often a need to secure some heavy objects, be it a water heater for the bathroom, a wall unit for a child's room, or a china cabinet. And at the same time, a margin of safety is required.

Ordinary dowels with plastic spacers cannot always help in this matter; “heavy artillery” is needed here - these are anchors.

An anchor (“anchor” in German) is a bolt with a thread and a nut; the kit also includes a spacer part; such fasteners are designed for attaching weighty structures. From the photographs you can understand the features of the anchors, as well as their scope of application.

The history of the development of this fastener dates back to 1973, when a German council of experts began working on the calculation of permissible anchor fastenings. And in 1998, the regulation on the use of metal anchors in concrete ETAG 001 was issued.

In addition to solving household repair issues, anchor bolts are used in the construction industry; therefore, there are many types of anchors, from simple ones - created for fixed structures, to specific ones - solving issues of constant pressure and bending on the fastening element.

Advantages and disadvantages of anchor connections

Disadvantages include:

- Expensive cost;

- A lot of installation tools are required (puncher, hammer, screwdriver, wrench);

Advantages:

- Increased safety margin;

- Copes with pull-out loads;

- Long service life;

- Increased level of security.

An important characteristic of anchors is the material of manufacture. Only high-quality structural steel is used to make anchors or durable aluminum-based alloys.

The material used to make anchors must withstand loads and deformations. In addition, resistance to corrosion is an important quality, because anchor connections last for decades, so brass, aluminum and stainless steel are used, which do not rust.

When installing anchors in wet rooms, you should choose them with a thicker galvanized layer.

Basic designs of mechanical anchors

According to their design, mechanical anchors are also divided into the following main types.

Bolt and nut

The simplest type of spacer fastener, which is a rod (bolt) with a conical end, a sleeve with four cutouts and a nut. The nut acts as a lock - with its help the structure is fixed in a pre-drilled mounting hole, the diameter of which is equal to the diameter of the sleeve. After driving the rod into the hole, the nut is turned clockwise, thereby moving the rod outward. The tapered end of the pin expands the sleeve in the area of the cutouts, thereby securing the structure in the hole.

Anchor bolts are available in various sizes: the diameter of the rod is from 6 to 28 mm, the length is from 60 to 300 mm. Anchor bolts are used when working with dense materials (concrete, brick, stone).

Bolt with ring

Ceiling anchor, usually used for attaching light fixtures, ceiling chandeliers, cables, electrical cables, suspended ceilings, etc. Fasteners of this type, as an exception, can also be used on walls.

The only difference between such a fastener and an anchor bolt with a nut is that its outer end ends with an eyelet, which is necessary for hanging a hinged device or product. Fastening of such a structure is carried out in a similar manner: the fixing nut, located directly behind the end in the form of a ring, allows you to open and fix the sleeve in the hole.

Hook bolt

A fastener in the form of a bolt having a hook-shaped head. Used for fastening heavy structures to solid concrete, stone or brick foundations. The principle of fastening is similar to other connections in the form of a bolt with a nut - after tightening the fixing nut, the sleeve is deformed and secured in the drilled hole.

Hex Bolt

An anchor of this type is analogous to a bolt with a nut, but here a standard bolt is used instead of a rod (stud) and nut. When the bolt is tightened with a wrench, the tapered end deforms the sleeve, thereby filling the walls of the hole and securing the structure in it. Also available in a screwdriver version.

Double-spacer

Double Expansion Mechanical Anchors - Another expansion bolt and nut. The difference is that the design uses two sleeves (bushings, couplings) - short and long. The short one goes inside the long one with its cone-shaped end. When the nut is screwed in, the short sleeve expands with the cone-shaped end of the rod and, in turn, expands the long sleeve. Double-expansion anchors can also have a ring or hook end. Anchors of this design are used to increase the reliability of fastening.

Nails

Nail-type anchors are used when working with brick, concrete and stone foundations and are intended for fastening lightweight structures. They have the shape of a hollow nail, inside of which a wedging element is placed. The anchor is driven into the hole manually or using a power tool.

Expansion anchors

Expansion anchors are more often used for fastening heavy structures (metal doors). These are metal cylindrical bushings with grooves on the body. When the nut is tightened with a wrench, the bushing expands over the entire surface and rests closely against the base material.

The advantage of these anchors is their ability to withstand heavy loads in the perpendicular and longitudinal directions.

Classifications

Anchors are classified according to service life:

- Permanent.

- Temporary.

By size, fasteners are divided into:

- Small (up to 5.5 cm long and up to 0.8 mm in diameter).

- Medium (up to 12 cm long and up to 1.2 cm in diameter).

- Large (up to 22 cm long and up to 2.4 cm in diameter).

According to the base material, anchors are distinguished:

- For dense concrete, brick or stone materials.

- For hollow brick and concrete foundations.

- For sheet materials - plasterboard, chipboard and fibreboard.

Yandex.RTB RA-1479455-8

- Mechanical

Fastening is carried out due to the direct mechanical effect of the working part of the anchor on the base (wedging, friction, stop, material resistance, etc.).

- Chemical

Additionally, a gluing mechanism (force) is used; for fastening, adhesive based on polyester resins is used.

Mechanical anchors according to the technique of insertion into the base are divided into the following types:

- Wedges.

- Spacers.

- Hammers.

- Screw.

- Bushings.

- Expandable.

- Spring.

Spacers

Expansion anchors are a classic type of this type of fastener. They are a rod in the form of a bolt or pin with a cone-shaped end and an external element in the form of a sleeve, bushing or spring ring. The conical element, under the influence of the translational movement of the rod, expands the sleeve and secures the structure in the base.

Expanding

An expansion anchor consists of a threaded rod, which can be a bolt, stud or screw, and a sleeve consisting of 4 longitudinal petals with a spring ring and a cone nut on one side. When the rod rotates, the cone nut unclenches the sleeve petals, as a result of which the anchor expands and is secured in the base due to friction.

Wedge

Wedge fasteners are a long rod, at the end of which there is a deformation sleeve. After screwing the rod into the drilled hole, the sleeve petals expand. This type of fastener can withstand heavy loads.

Spring

Spring anchors are used when working with thin-walled bases, for example, when arranging the interior. Often, spring anchors are used as ceiling anchors and are equipped with a hook. The anchor is secured by unrolling the spring.

Screw

Screw anchors, or Molly bolts, are used when working with hollow structures with low load-bearing capacity - hollow brick, plasterboard, particleboard and fiberboard, etc. The Molly bolt is equipped with a special collet, which, when the bolt is tightened, opens and rests against material on the reverse side.

Bushing

Sleeve-type anchors consist of 3 or more elements, the main one of which is the collet - a spring split sleeve. The sleeve anchor design also includes a riving element and a threaded rod. When the anchor is twisted, the wedging element enters the collet and pushes it apart, thereby securing the fastener to the base.

Drivers

The basis of the driven anchor is a metal deformation sleeve with a conical hole, cuts in the body and internal threads. A firing pin is installed at the bottom of the sleeve. The sleeve is installed into the drilled hole manually or using an air gun. When the outer end of the sleeve is struck, it is deformed, after which a bolt or pin is screwed into the sleeve, necessary for fastening any object.

Fasteners for hollow materials

Double-expansion anchors are metal products consisting of steel bushings mounted on a stud. When tightening the nut on the outside, the bushings located inside diverge, the sleeve is deformed over the entire surface, because The bushings diverge in different spacer zones, which ensures reliable fixation in the wall; anchors of this type are almost impossible to remove after installation.

“Butterfly” anchors with an expansion mechanism are suitable for lightweight structures; they are used to fasten interior parts (pictures, sconces, shelves) to flat materials no thinner than 10 mm (plasterboard, chipboard, plywood).

The “wings” of the anchor open and are tightly fixed on the back side of the material. The reliability of the assembly depends on the base into which the anchor is screwed.

When choosing anchor products, it is necessary to take into account: the characteristics of the material of both the anchor and the base surface, the weight of the fixed equipment, installation principles and, of course, stock up on the necessary tools.

The design of anchors, unlike other fastening connections

Yandex.RTB RA-1479455-7

A classic anchor is a combined metal structure consisting of a non-expandable (body or base) and an expansion (working) part. The base may be a bolt, screw, pin or nail, the spacer may be in the form of a sleeve, cone, sleeve, etc. When using a fastening element, the working part expands and, due to friction and resistance of the material, holds the structure in the base material.

The main difference between an anchor and a dowel that is similar in design and purpose is the material of manufacture. A dowel consists of a soft part, usually plastic, in which a fastening element, for example a self-tapping screw, is fixed. The principle of fastening the dowel is based solely on the frictional force between the working surface of the fastening joint and the base.

Since the anchor is usually made of alloy steel or other metals (brass, aluminum), its fastening principle is based not only on friction between the main and working parts, but also on the resistance of the material. Anchors are able to withstand more severe dynamic loads than fastening joints using dowels.

Installation requirements

Before you begin installing a stud anchor, you must make sure that the base is thick enough to accommodate the object to be fastened on it. When mounting massive objects on concrete structures with thin walls, the stated holding strength is by no means guaranteed.

To avoid trouble, you need to follow one important rule. It is formulated as follows: the distance from the end of the installed anchor-stud to the edge of the concrete base should be no less than one and a half diameters of this part. For example, if such a fastener is fixed with an M16 thread to a depth of 86 mm, then the minimum permissible thickness of the mounting base for it is:

T =16×1.5+86 = 110 mm.

Another parameter that must be calculated is at what distance the installed anchor studs should be located from one another. When fastening points are placed close together, the stresses created in all of them are summed up. For this reason, it is possible that cracks may occur in the concrete. To prevent this, you should listen to the following expert recommendation: the value of the center distances is not less than 10 diameters of the anchor-stud, and the edge distances are not less than 5. The relevant data regarding the most common standard sizes of these fasteners are given in the table.

| Thread diameter | Distance (min) from edge | Standard edge distance | Center distance (min) | Center distance standard |

| M20 | 130,0 | 152,0 | 110,0 | 303,0 |

| M16 | 70,0 | 123,0 | 90,0 | 246,0 |

| M12 | 60,0 | 105,0 | 70,0 | 210,0 |

| M10 | 55,0 | 90,0 | 60,0 | 180,0 |

| M8 | 50,0 | 71,0 | 55,0 | 141,0 |

| M6 | 45,0 | 60,0 | 50,0 | 120,0 |

The unit of measurement is millimeters.

In addition, during installation you should pay attention to the following points:

- If the nut is not tightened sufficiently, the tapered shank will not fully enter the spacer sleeve. The created fastening may weaken in the future, due to which the degree of reliability of the entire structure will decrease. However, it happens that the anchor-stud is firmly fixed in the base material, even when displaced from the required position;

- Over-tightening the nut will also have a negative effect. For this reason, the tapered shank will fit into the spacer too tightly. This may lead to destruction of the mounting base.

To prevent these phenomena, when tightening the nut, you need to use a wrench equipped with a torque attachment. The recommended tightening force is usually indicated by the manufacturer in the accompanying documentation for the stud anchor.

Marking of anchor bolts

When planning to use anchor bolts for concrete, you need to learn how to determine the dimensions by markings. Let's figure out how the abbreviation stands for the example of a fastener with the designation M8 10/35x90:

- The alphanumeric designation M8 indicates the thread diameter;

- the number 10 corresponds to the diameter of the drill for making a cavity in concrete;

- the number 35 indicates the maximum thickness of the attached material;

- the number 90 characterizes the minimum depth of the hole for installing the anchor.

Knowing how anchor bolts are marked, it is easy to select fasteners to perform a specific task.

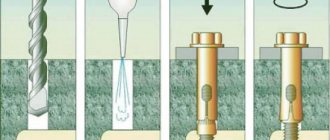

Driven - for fixing communications

Installation of such products is carried out using the driving method. These are ordinary dowels, only they are made not of plastic, but of high-carbon steel. In appearance, it is a seamless metal sleeve with a conical inner surface and longitudinal slits.

The anchor is driven into a pre-prepared hole with a hammer; during installation, the petals form support arms that have a high load-bearing capacity. After this, a bolt of a suitable diameter is screwed into the anchor, which passes through.

Such anchors are used for installing formwork, cable ducts and utilities, gratings, splinker and ventilation systems, and when installing pipelines.

| Advantages | Flaws |

|

|

Products in this group are conventionally divided into 2 categories: ordinary and special. The second group includes products of the “Zikon” series, which are highly expensive and require special tools for installation.

| Manufacturer | Type | Available thread diameters, mm | Examples and explanations of designations (dimensions in mm) | Peculiarities |

| Fischer (Germany) | E.A. | 6, 8, 10, 12, 16, 20 | EA M 8 8 – M 8 internal thread diameter EA SM 10 | Fischer Einschlanganker Steel 1.4401/1/4571, galvanized yellow-passivated or stainless steel A4 |

| EAS | 6, 8, 10 | Lightweight version of the EA anchor made of sheet steel, with collar | ||

| Hilti | HKD-S | 6, 8, 10, 12, 16, 20 | HKD-S M12/50 12 – M 12 internal thread diameter 50 – anchor length. | Flush Anchor Steel strength class 5.8. |

| HDI | Drop-in Anchor | |||

| Mungo | ESA | 6, 8, 10, 12, 16, 20 | ESA M 8 8 – M 8 thread diameter; | Einschlanganker Galvanized steel, yellow-passivated or stainless steel A4 |

| Sormat (Finland) | LA, LAH | 6, 8, 10, 12, 16, 20 | LA 12 12 – M 12 internal thread diameter. | Ly ö ntiankkuri LA – structural steel, electro-galvanized LAH – made of stainless acid-resistant steel A4. |

| Tox (Germany) | T.E. | 6, 8, 10, 12, 16, 20 | TE M16x65 16 – M 16 internal thread diameter. | Einschlaganker Galvanized steel, yellow passivated. |

| NOBEX (Italy) | DROP | 6, 8, 10, 12, 16 | DROP 12×50 [INOX] 12 – M 12 internal thread diameter 50 – anchor length. | |

| Koelner (Poland) | ST | 6, 8, 10, 12, 16, 20 | ST-08 08 – M 8 internal thread diameter. | Drop in anhor Galvanized steel, yellow passivated. |

| Wkret-met (Poland) | T.S.W. | 6, 8, 10, 12, 16 | TSW 10 10 – M 10 internal thread diameter. | Galvanized steel, yellow passivated. |

| Technox (Poland) | TSR | 5, 6, 8, 10, 12, 16 | TSR 8x30 | Tuleja stalova. Galvanized steel |

| Anchor Fasteners (Taiwan) | DRM | 6, 8, 10, 12, 16, 20 | DRM-12 | Drop in anhor Galvanized steel, yellow passivated. |

| INKA (Türkiye) | IDCA | 6, 8, 10, 12, 16 | IDCA08 | Çakmali Dubel |

Application of Anchor Bolt

Mechanical anchors are good for low-porosity substrates. Chemical models are indispensable for materials with an abundance of gas capsules, for example, cellular types of concrete. Installing an anchor bolt If you focus on the structure of the fastener: -A bolt with a hook or ring is good for fixing hinge systems, objects on cables and chains. It is important to be able to remove the item from the bolt to move it to a new place, or wash it and hang it back. -A bolt with a nut is used for dense and monolithic bases, since the spacer fastening system is not effective in porous and soft materials. The nut perfectly holds gates and stairs, secures cables and pipelines.

In everyday life, a concrete anchor bolt is useful for periodically dismantled structures. These are doorways and suspended ceilings. - Wedge bolts are also used in dense and monolithic foundations, both for capital construction and private farmsteads. Wedges are used to attach advertising boards to foundations, posters to house facades, warehouse consoles to walls, and light fixtures to ceilings. In everyday life, wedge bolts are often used when installing punching bags and home sports corners. -Anchors-studs hold ceilings and partitions, supporting consoles, masts, cables and antennas. Some types of anchors for dense foundations are divided into those suitable for true monoliths and those that have cracked.

The stud bolt, for example, comes in the HAS and HST categories. Models of the latter allow you to securely fix objects to cracked concrete and make through fastenings. This increases the "weight" of HST anchor bolts in the eyes of builders. The nuances of using anchors depend on their weight, size, and material. There are, for example, brass or steel bolts. If the fastener is made of an iron alloy and is an M-6 size, it will withstand up to 2.8 kilonewtons of pullout. The shear anchor will withstand 3.6 kilonewtons. As a rule, the performance characteristics of anchor bolts are indicated on their packaging. It remains to correctly calculate the stress forces in the walls and ceilings. If you are not confident in your abilities in the exact sciences, it is better to order calculations from professionals or play it safe by taking the most reliable fasteners. They appear to be useful in most areas of construction, since they can even withstand load-bearing structures such as ceiling beams.

How to remove an anchor bolt from concrete

Anchor bolts are usually fixed in concrete. To remove an anchor bolt from concrete, all you need to do is unscrew the bolt from the anchor. Occasionally, problems arise with stubborn fasteners that do not want to unscrew; in this case, follow the instructions below.

Step 1

Select a socket wrench that matches the size of the bolt nut. Many bolts have the size printed on the top of the head.

Step 2

Remove the concrete bolt using a wrench. If it is rusty, lubricate it with oil, diesel fuel, gasoline or antifreeze and wait until the liquid is absorbed. After it is absorbed, try the key again.

Step 3

If the bolt is stubborn and won't come out, you might want to try a puller. Attach the puller to the drill and place it on the bolt. Drill into the concrete to the base of the bolt. Pull out the bolt using pliers.

Step 4

Insert the awl into the hole. Give the awl a few sharp blows with a hammer until it cuts all the way down to the base. Remove the bolt parts using pliers.

Step 5

If none of the previous methods helped, saw off the bolt head with a grinder. Sand or cut the top of the bolt so that it is below the surface of the concrete. Remove debris and fill the hole with concrete.

In land management

Anchor products made of plastic have found application in land management and are used to strengthen banks, construct road embankments and pipelines.

Fastening elements have increased impact resistance and frost resistance, and are able to withstand the effects of groundwater, hazardous chemicals and corrosion.

Plastic fasteners are T-shaped and range from 60 to 120 centimeters in length. When driving into the ground and installing the ATP clip, the fastening elements are connected by a polymer cable and form a three-dimensional geogrid.

Working principle and application

In the areas of fasteners with concrete, different stresses arise: torsion, fracture, displacement, spalling, tightening, and tearing.

The main basics of the functioning of concrete anchors:

- during the period of contact between the base substance and the fastener, F tr occurs. – pressure is produced by pins, iron devices;

- sometimes when anchoring, the substance provides resistance to rotation - due to the fastening fitting, the curved appearance of the base, enlargement;

- the force in the area where the base and fastening meet is compensated by touching forces during embedding or adhesion - this is how backfilling, even, adhesive staples work.

They are made of special steel according to GOST, treated with an anti-rust shell. The stick has D = 6-20 ml, L – up to 220 ml.

Each bracket contains the following components:

- pin;

- a body with a shell of cutting in this body;

- cork with special notches.

Foundation bolts play a major role in installation situations of tiled structures, pillars, loggia ledges, staircase areas, facing and wall paths, technical equipment, communications, hoods, overhead lighting fixtures, etc.

They are used to attach various equipment and hanging furniture to walls.