What is asphalt and how is it produced on an industrial scale?

The word “asphaltos”, which came to us from the ancient Greek language, means “mountain resin”. This name helps to understand what modern asphalt is made of. It can be natural and artificial. The first is a mixture of petroleum products and rocks.

People have noticed how nature, by passing oil through the ground, creates a substance that can become liquid and soft when heated, and hard and durable when it cools. They began to cover roads with this material, and humanity invented its synthetic analogue.

Artificial material is now actively used for road construction all over the world. It consists of the following components:

- Sand . Acts as a filler. It is also used to increase the strength of the road.

- Crushed stone. This is a reinforcing substance, thanks to which the finished frozen layers do not crack.

- Bitumen resin. It is a kind of glue that binds all components of the coating.

In asphalt plants, the base components are first mixed and brought to a boil. Mineral materials are prepared separately, cleaned and dried. Bitumen is mixed with these components at a temperature of about 140 degrees. The mixture is delivered hot to the installation site.

Sales of products

Main consumers of asphalt:

- Organizations that monitor the condition of roads and repair them;

- Businessmen who are responsible for the condition of sidewalks, parking lots and other things.

Beginning entrepreneurs can start paving squares or sidewalks. To find more clients, you can go around nearby areas and post advertisements. When making personal contacts, hand people your business card.

Another effective way to promote products is advertising in the media. The most important thing is to establish contacts and conclude contracts for the supply of asphalt. If you can find enough clients, you can expand your business over time to make more profit.

How and from what can you make asphalt yourself?

Using a similar technology, you can make material for garden paths with your own hands. At home, it will not be possible to create asphalt that can become a surface for heavily loaded roads. However, such material is quite capable of strengthening garden paths or the entrance to the site. For it you need to find the following ingredients:

- sand;

- crushed stone or gravel;

- bitumen resin in solid form.

In addition, you will need tools to produce homemade asphalt. You need to stock up on a wide container for mixing the components, a metal barrel, a bucket, a mesh for sifting sand, and a shovel.

Components and production of hot asphalt

The ingredients described above are suitable for hot asphalt. It is recommended to add polymeric materials to the mixture.

To create asphalt at your dacha, you will need the appropriate equipment: a hearth with a fire, a container for mixing components, tools for mixing asphalt. A metal barrel of machine oil or diesel fuel is suitable as an asphalt mixer. The asphalt cooking process can be seen in the video below. It consists of the following steps:

>

What is cold asphalt and how to make it?

A cold analogue of a homemade mixture for covering garden paths is a material that appeared in our country quite recently. Its main advantage is the ability to lay asphalt even in winter: it is suitable for work at 20 degrees below zero.

The composition contains special bitumen with a high degree of viscosity. In addition, the mixture contains high-quality plasticizers and modifiers that work on the “cold welding” principle. This material allows you to create paths in the country or near the house with a long service life.

It is impossible to make a cold mixture for paths with your own hands. This process requires the use of high technology. However, every summer resident has the opportunity to buy a ready-made mixture for cold asphalt paving.

New asphalt from old

With the right approach, new asphalt can be welded from old. Road workers throw out such material near areas being repaired. There is no need to pay for it, so making new asphalt from used asphalt is one of the most economical options.

To create a hot mixture you will need 100 kg of old coating, 10 kg of bitumen, and the same amount of resin. The process consists of the following steps:

- Asphalt grinding. The mixture particles should not be larger than 40 mm. The crushed material is poured into a homemade hot “asphalt mixer”. 70 liters of boiling water and sand are added there.

- Cooking new material. The contents of the barrel are heated to a boil and cooked for several hours.

- Production of the binding component. Resin and bitumen, taken 10 kg each, are boiled in a metal bucket. The hot mixture is poured into an “asphalt mixer” and mixed. The finished asphalt can be immediately laid on the prepared area.

Applying markings and signs

Applying lines and marks with thermoplastic or paint will mark the asphalt surface and indicate any necessary warnings. For example, on the site in front of the house you need to mark out parking spaces for cars. Or put a warning sign about the danger for drivers. Thermoplastic is most suitable for these purposes since it is wear-resistant, has good adhesion to asphalt and has a long service life. Thermoplastic must be applied using special equipment, since it is necessary to constantly maintain a high temperature in the boiler and thoroughly mix the plastic mass.

This is interesting: Hair styling paste for women 2022

p, blockquote 19,0,0,0,0 —>

p, blockquote 20,0,0,0,0 —>

If it is not possible to use specialized equipment, then the following recommendations must be followed:

p, blockquote 21,0,0,0,0 —>

- The asphalt surface must be dry and clean, then the plastic will adhere securely to the surface.

- The melting point of plastic is in the range from 140 to 180 ºС. After the plastic has melted, it must be constantly stirred to avoid the appearance of clots.

- To apply thermoplastic, you need to use ready-made molds that will allow the plastic mass to harden on the asphalt.

- The cooling time of thermoplastic is only a few minutes.

p, blockquote 22,0,0,0,1 —>

We looked at two methods of laying asphalt, thanks to which you can obtain a high-quality and durable coating. The first method is beneficial when paving large areas. And the second is for arranging a household plot. In any case, a properly laid asphalt pavement will withstand heavy loads and will last a very long time.

Asphalt laying technology

Simply spreading a hot resinous mixture on the ground will not work. The area for asphalting should be prepared in advance. It is necessary to carefully consider where the paths will be located. It should be borne in mind that it is undesirable to plan them next to a vegetable garden or flower bed: the asphalt surface evaporates substances harmful to health. Crops will accumulate these fumes.

The asphalt is laid on a flat, compacted surface. Without the right foundation, you won’t be able to build a path.

Designing a site to be covered with asphalt

Considering the odors that asphalt emits, I recommend making an asphalt covering at the entrance to the house for a car. Similar paths can be laid between the buildings on the site: from the mansion to the summer kitchen, change house, garage, bathhouse, toilet, etc.

Before excavation work begins, markings are made and the thickness of the crushed stone that will serve as the base of the path is determined. For pedestrian paths, a layer of asphalt of 7 cm is suitable. The road for a car needs to be made more solid, at least 15 cm thick. The crushed stone base for such a road should have a height of about 40 cm.

Excavation work: soil removal, leveling and compaction

How to lay asphalt correctly?

Asphalt concrete, or asphalt, is a multi-component mixture of bitumen, sand, gravel or crushed stone. To improve its technical characteristics or to reduce cost, its composition may include additional fillers such as cement, crumb rubber, mineral and polymer additives.

The volumetric content of components in asphalt concrete and their names can vary over a wide range, but bitumen, as the main binder, is always present in this mixture.

The reliability of asphalt pavement depends on the use of high-quality components in the mixture, their uniform mixing, and maintaining temperature conditions during production and storage. In addition, the planned location for laying the asphalt pavement should be as close as possible to the place of its production, so that the time for transporting the material is as minimal as possible.

Feasibility study of the project

Opening the production of asphalt concrete mixture with a minimum capacity of 3-5 tons per hour will require the following costs.

Capital investments

- Purchase of equipment: RUB 1,176,600.

- Delivery: 250,000 rub.

- Transport costs: RUB 100,000.

- Purchase of raw materials: 500,000 rub.

- Other expenses: RUB 200,000.

Total: 2,226,000 rubles.

Calculation of revenue and profitability

| Production t/shift | 25 |

| Number of shifts, per month. | 30 |

| Output, per month, in t | 750 |

| Wholesale price for 1 ton in rubles. | 2 300 |

| Revenue, rub. | 1 725 000 |

| Profitability, % * | 30 % |

| Payback, per month. | 6 |

* Level of profitability according to the expert opinion of the author of the material.

Questions and answers on the topic

No questions have been asked about the material yet, you have the opportunity to be the first to do so

Mini asphalt plant - a new stage in the development of your business at a reasonable price

In recent years, in our country, the requirements for the quality of road surfaces have been constantly increasing, especially taking into account the upcoming 2022 FIFA World Cup. They, to paraphrase the Olympic motto, need faster, better, cheaper. On the other hand, road workers are under pressure from counterparties: suppliers, subcontractors, creditors, etc. How can a road company cope with all these challenges and still make a solid profit?

offers a profitable solution for small businesses: an asphalt mini plant. Its purchase will allow you to receive a stable flow of construction materials for roads and increase the profitability of your business.

Advantages of purchasing a mini plant:

— Reducing the cost of laying the road surface by eliminating the services of resellers and transport companies;

- Full control over the timing of construction and repair work thanks to the organization of a continuous flow of building materials of our own production;

- Improving the quality of road surfaces through direct control of the production of all building materials: asphalt concrete, bitumen, etc.

Advantages and disadvantages of the material

The main advantages of laying asphalt are:

- affordable cost, especially in the case of small-scale applications;

- possibility of fast preparation in factory conditions;

- durability of the coating, subject to compliance with the manufacturing and installation technology;

- the relative simplicity of laying asphalt in the presence of special equipment.

The disadvantages of asphalt and concrete are:

- a sharp decrease in technical characteristics when heated under the influence of sunlight;

- evaporation of bitumen when heated and the release of harmful fumes;

- the need to maintain the required temperature until the asphalt pavement is laid.

At the same time, despite the presence of serious shortcomings, a price alternative to asphalt concrete has not yet been found. A path made from paving slabs will be noticeably more expensive.

Work to improve the quality and versatility of the material is being carried out as part of the selection of more effective mixtures. Good performance is achieved by adding polymer mixtures and reducing the volume fraction of bitumen.

Applications and uses

- It replaces crushed stone or sand.

- Excellent for finishing basement floors.

- Laying asphalt chips on a summer cottage for finishing paths.

- Sometimes used as a decorative element by landscape designers.

- This material can be used to repair lightly trafficked roads.

Purpose of the constituent components

The first asphalt was made from natural bitumen. Then they began to use bitumen, obtained as a result of oil distillation, when heating liquid hydrocarbons. Today it is the most common binder for the production of asphalt concrete mixtures.

Sand, gravel or crushed stone in asphalt play the role of the main working fillers. Sand is necessary to more evenly distribute pressure within the asphalt layer and fill voids between individual stones. Together with bitumen, it binds larger fractions of stone, holds them and does not allow them to go up beyond the layer.

Fractions of gravel and crushed stone determine the group of asphalt concrete and its area of application. All asphalt pavements are conventionally divided into three groups according to density, depending on the size of the stones used:

- dense, with a gravel fraction of 5-10 mm, for paving courtyards, sidewalks, paths and other surfaces with low load;

- porous, with a stone size of 10-20 mm, for laying lower layers in multi-layer coatings;

- highly porous, with a crushed stone fraction of 20-40 mm, for use on critical sections of highways.

This porosity distribution determines the ability of asphalt to transmit moisture and drain it into the drainage layer for further discharge into the ground. Therefore, highly porous material is more difficult to install, but its service life is much longer.

Finely ground chalk, limestone or sandstone are added as mineral fillers. They fill the last remaining voids and make the asphalt path more uniform. Moreover, the best mineral filler is made from sandstone, as a chemically neutral substance.

By adding crumbled rubber, crushed to sizes of 1.0-1.5 mm, ductility and hydraulic stability increase. Therefore, asphalt with it is often used to cover the roofing of workshops of industrial enterprises. Asphalt concrete with rubber crumbs is less likely to crack and has spring properties.

Polymer additives in the form of reinforcing plastic fibers significantly increase the strength of the material. This cooking technology is used only for the most critical areas. The strength of an asphalt path can also be increased by adding cement to it, but in this case you cannot use limestone as a fine filler.

Do-it-yourself asphalt production

Self-made asphalt does not allow it to be used for laying highways and city streets. However, such material can be effectively used for arranging garden paths or areas with low weight load during operation. To make your own asphalt you will need:

- ordinary, even unwashed sand;

- fine gravel or crushed stone;

- solid bitumen resin with a melting point of no more than 120°C;

- wide bucket or concrete mixer;

- metal barrel and bucket;

- shovel;

- wide sieve or metal mesh for sifting sand.

Prepare a dry mixture of sand and gravel in a bucket or concrete mixer in a ratio of 1:2 by volume. Place the barrel on the stand and light a fire under it. Pour a bucket of water inside.

At the same time, place a bucket filled one-third with water on another fire. When the water in the bucket begins to boil, put bitumen in it to heat and melt. Pour the crushed stone-sand mixture into the barrel. Boiling water in a bucket and barrel will ensure that the temperature is maintained at 100°C.

Pour the crushed stone-sand mixture into the barrel and wait until the water boils. Boil the bitumen in water until the bitumen melts and the water gradually boils away. Then pour the molten bitumen into a barrel with a crushed stone-sand mixture and begin to actively mix. It is recommended to use a metal pipe or other durable object for mixing. At the time of pouring, there must be boiling water in the barrel; hot bitumen cannot be poured into cold water.

The ratio of the volume of bitumen to the volume of crushed stone-sand mixture is approximately 1:15. More accurately, the density of asphalt can only be determined visually.

In order to improve the plasticity of the asphalt mass, simplify mixing and facilitate subsequent laying, you can use special plasticizers or liquid detergent. The plasticizer is added in accordance with the instructions, liquid detergent at the rate of 1 glass per 40-50 liters of asphalt.

As soon as the water has boiled away, the homemade asphalt is ready and can be laid on the path. If by this time you have not completed the preparatory work, then add water to the barrel again. Please note that you can only add boiling water; cold water falling on a hot surface can instantly boil and lead to burns.

Making asphalt with your own hands

And the cycle repeats. Time intervals and temperature conditions may vary.

►The finished mixture is unloaded into vehicles. If there is a need for a storage hopper, the drying and mixing unit is lowered lower, and the installation is additionally equipped with a scraper conveyor and a storage hopper.

Power supply:

2-4 bunkers with sector gates equipped with pneumatic actuators; Horizontal belt conveyor; Bucket elevator or scraper conveyor;

Drying and mixing unit:

Loading box, firebox, burner; Reversible drum; Preliminary cleaning stage, unloading box Cyclone block; Dust auger; Smoke exhauster; Chimney; Twin-shaft mixer; Frame design; Weighing bitumen dispenser; Bitumen pumping unit; Fuel tank

Bitumen farm

Bitumen container with thermal insulation 10-20 tons Bitumen tap Du80 - 3 pcs. Bitumen pumping unit

Pneumatic system

Piston compressor, pneumatic distributors, pneumatic cylinders, moisture separator.

In addition, it offers its customers not only high-quality equipment, but also a full range of maintenance services. Thus, by contacting us and ordering an asphalt mini plant and a package of services for it, you can forget about technical problems and problems with the quality and supply of materials, and focus on developing your business. Do you require large volumes of building materials, and a mini plant is not enough? We also offer high-performance, full-scale asphalt mixing plants with the capacity you need.

Call us right now at 8 (351) 277-82-72, and very soon you will be able to expand your business and take it to a new level of profitability!

We offer competitive price lists for asphalt, concrete, concrete mixes, plaster mortars and laboratory services. Products are manufactured in accordance with relevant GOST standards.

Price for asphalt concrete from July 09, 2022.

| Type and brand of asphalt concrete mixture (asphalt concrete) | Price per 1 ton, including VAT (18%), rub. |

| For the top coat | |

| Crushed stone-mastic mixture ShchMA - 15, ShchMA - 20 (gabbro, Viatop, PBB 60) | 4550 |

| Crushed stone-mastic mixture ShchMA - 15, ShchMA - 20 (Gabbro, Viatop) | 3975 |

| Fine-grained mixture type B M 1, type A M 1 (Gabbro, surfactant) | 3080 |

| Fine-grained mixture type B M 2 | 3020 |

| Fine-grained mixture type B M 2 | 3010 |

| Sand mixture type D M 2 with the addition of crushed stone fraction 5-20 mm up to 10% | 2980 |

| Sand mixture type D M 2 | 2980 |

| Sand mixture type GM 1, 2 | 3450 |

| For the bottom layer of coating | |

| Fine-grained porous mixture M 1, M 2 | 2940 |

| Coarse-grained mixture dense B M 1.2 | 2980 |

| Coarse-grained porous mixture M 1.2 (crushed stone fr. 20-40 M 1200) | 2880 |

| For the base | |

| Black crushed stone, coarse-grained, highly porous M 2 | 3040 |

The asphalt concrete mixtures produced comply with GOST 9128-2013 and have certificates of conformity No. ROSS RU.AG70.N00184, issued by Profi-group LLC, reg. No. RA.RU.11 KO 01

The cost of asphalt and asphalt concrete mixtures varies greatly among manufacturers. The ABZ Lint company offers its customers prices that are different from those of its competitors. Our price list for asphalt will allow you to navigate them. The plant's high-quality products are cost-effective and competitive; all mixtures are excellent building materials. They are widely used in road construction and repair.

from June 06, 2022

| Delivery of asphalt concrete mixture and inert materials. | ||

| Delivery volume | Delivery distance | price, rub. (including VAT 18%) |

| up to 15 tons | up to 20 km | 3525 per car |

| up to 30 km | 4425 per car | |

| up to 40 km | 5175 per car | |

| up to 50 km | 6150 per car | |

| over 15 tons | ||

| over 15 tons | up to 20 km | 235 per ton |

| up to 30 km | 295 per ton | |

| up to 40 km | 345 per ton | |

| up to 50 km | 410 per ton | |

| up to 75 km | 450 per ton | |

| up to 100 km | 490 per ton | |

| up to 125 km | 530 per ton | |

| up to 150 km | 560 per ton |

Standard unloading time is no more than 1 hour. More than one hour - a fine of 800 rubles. in 1 hour. The number of body lifts is no more than 5 times.

| Loading capacity of dump trucks | |||||

| Dump truck | Maximum load capacity | Conditional volume | Actual vehicle load, tons | ||

| a/b | sand | crushed stone | |||

| MAZ | 10t | 6 m3 | 9 | 9 | 8 |

| KAMAZ | 15t | 10 m3 | 12,5 | 12,5 | 12,5 |

| MAZ | 20t | 12.5 m3 | 18 | 18 | 18 |

| Renault, Volvo FM, 6*4 | 25t | 16 m3 | 20 | 20 | 20 |

| Renault, Volvo FMX, 8*4 | 30t | 18 m3 | 25 | 25 | 25 |

Prices – price list for concrete from ABZ Lint

Concrete prices from June 20, 2022

| Brand and strength class of concrete | Price per 1 m3 of aggregate fr. 5-20, including VAT (18%), rub. | |

| with delivery up to 5 km | ||

| Name of concrete | crushed gravel | crushed dense rocks |

| Ready-mix concrete B 7.5 M 100 W2 | 3580 | 4185 |

| Ready-mix concrete B 12.5 M 150 W4 | 3680 | 4295 |

| Ready-mix concrete B 15 M 200 W4 | 3790 | 4395 |

| Ready-mix concrete B 20 M 250 W4 | 3950 | 4535 |

| Ready-mix concrete B 22.5 M 300 W4 | 4155 | 4680 |

| Ready-mix concrete B 22.5 M 300 W6 | — | 5005 |

| Ready-mix concrete B 25 M 350 W4 | 4360 | 4920 |

| Ready-mix concrete B 25 M 350 W6 | — | 5310 |

| Ready-mix concrete B 30 M 400 W6 | — | 5425 |

| Ready-mix concrete B 35 M 450 W6 | — | 5475 |

| Ready-mix concrete B 40 M 500 W8 | — | 5520 |

The produced concrete mixtures comply with GOST 7473 - 2010 and have certificates of conformity No. ROSS RU. AG35. N02847, GOST 28013 - 98 and have a certificate of conformity No. ROSS RU. AG35. N04375, issued by LLC ", accreditation certificate registration No. ROSS RU. 0001.11AG35

| Concrete pump services (Putzmeister) | |

| Boom Reach | Cost per shift including VAT (18%), rub. |

| 22 - 24 m | 17 500 |

| 32 m | 20 500 |

| 36 m | 22 500 |

| 52 m | 40 500 |

The application for a concrete pump is made one day before the start of work. Prices include starting mixture.

Concrete mixtures are a sought-after product and are an excellent building material used for many purposes. It is used in the construction of buildings, creating structures, laying coatings, and carrying out repair work. Our “Concrete” price list contains basic information about the prices for these mixtures, as well as their delivery by road transport of the ABZ Lint production enterprise.

The price includes value added tax (VAT 18%) and delivery to a distance of up to 5 km from the place of shipment. Most mixtures include gravel or granite of fractions 5-20.

from May 24, 2022

| Delivery of concrete mixture. | ||

| Delivery volume | Delivery distance | Price per 1 m3, rub. (including VAT 18%) |

| from 5 m3 | up to 5 km | included in the price of concrete |

| up to 10 km | 160 | |

| up to 15 km | 310 | |

| up to 20 km | 380 | |

| up to 25 km | 450 | |

| up to 30 km | 520 | |

| up to 40 km | 620 |

When ordering less than 5 m3, the delivery cost is equal to 5 m3. Standard time for unloading special equipment: 1 m3 - 6 minutes. Cost of downtime: 1 hour - 800 rub. In exceptional cases, the time for supplying concrete to the site may be delayed by up to 3 hours

| Loading capacity of concrete mixers | |

| Concrete mixer | Conditional volume |

| Kamaz | concrete mixture 7 m3 |

| Chance MAN | concrete mixture 9 m3 |

| VOLVO FM 8*4 | concrete mixture 10 m3 |

We kindly ask you to take into account the weight and dimensions of the loaded vehicle, the possibilities of maneuver and access to the unloading site. The road surface must be hard, allowing passage of heavy vehicles. The customer is obliged to provide ABS flushing and drainage facilities in a designated area at the facility

Prices for solutions from June 20, 2022

| Plaster solutions | Price per 1 m3, including VAT (18%) |

| with delivery up to 5 km | |

| Solution M 50 | 2985 |

| Solution M 75 | 3095 |

| Solution M 100 | 3205 |

| Solution M 150 | 3400 |

| Solution M 200 | 3510 |

| Solution M 300 | 3990 |

The produced concrete mixtures comply with GOST 7473 - 2010 and have certificates of conformity No. ROSS RU. AG35.

Laying asphalt pavement

Do-it-yourself installation work begins with making planning decisions and markings. At this stage of work it is necessary to clearly define:

- with the location of the track;

- its width and height above ground level;

- with the type of curb and its installation height;

- with places for laying drainage systems.

When determining the location of the path, you should take into account the presence of possible underground utilities, the location of garden trees and the direction of slopes for rainwater drainage. After making decisions, you need to drive pegs around the perimeter of the future asphalt pavement, defining its exact contours.

Along the marked contour, it is necessary to dig a so-called “trough” or trench, 15 cm deep. Lay a layer of geotextile non-woven fabric on its bottom, which will prevent the germination of weeds and allow moisture to freely drain into the lower layer of soil.

Asphalt laying scheme.

Install and secure the curb and fill the “trough” to the top with crushed stone. The surface must be thoroughly compacted. The durability of the asphalt pavement depends on the quality of the compaction.

Next, you should buy asphalt or prepare it yourself and lay it on top of crushed stone in a layer 4-5 cm thick at a time. Pre-leveling can be done with an inverted rake or a wooden mop.

During the leveling process, it is necessary to check for slopes using a building level. The best way to compact the asphalt concrete layer on a garden path is to use a vibrating rammer.

It should be noted that the process of laying asphalt with your own hands depends on weather conditions. These works should not be carried out at sub-zero temperatures or in damp rainy weather.

Stages of paving

For laying asphalt, it is recommended to choose dry weather with a positive temperature of ≥ 10 degrees.

The step-by-step procedure includes the following work:

- On a sheet of graph paper, a diagram of the location of the house, outbuildings, paths to them, the area around the house and the passage for the car is drawn to scale. The roots of growing trees can deform the covering, so it is desirable that the trees are located at a distance of ≥ 2 m from the intended contours.

- Calculation of material requirements. It is recommended to cover the entire area with geotextiles with an overlap on the walls and cover it with a layer of sand 10 cm thick, crushed stone for the paths will be needed 5 cm thick, for the platform 15 cm, and directly for the driveway 25 cm, the number of enclosing elements is calculated according to the length of the contours, subject to asphalting. Asphalt will be required in the amount of 1 t per 10 m2 with a layer thickness of 5 cm; on driveways it is recommended to lay asphalt in two layers (5 plus 3 cm). The order is made for hot, fine-grained mixtures; sandy ones can be laid on the paths, but they are also hot.

- Prepare the following tools:

- a shovel for each worker;

- durable cord;

- mop-mop made of a meter-wide board with a handle 2.5 m long;

- a manual rammer, which is a piece of timber or round log with a square metal plate (20 cm side) fixed at the base and a handle in the form of a longitudinal wooden plank nailed on top;

- manual roller weighing ≥ 100 kg.

To periodically lubricate the tool to prevent hot asphalt concrete from sticking to it, you will need a small amount of diesel fuel.

- Transferring the outlined contours to the terrain with wooden pegs.

- Excavation of soil to the depth of the listed layers with removal of roots of weeds, bushes and trees. The asphalt surface should be level with the surrounding surface of the earth or rise up to 5 cm (it all depends on the terrain and your desire). Base seal.

- Installation of curbs at the same level as the future asphalt concrete or 2...3 cm higher. First, curbs are installed along the edges of the path or area, leveled in height, a cord is pulled along which intermediate elements are laid out. Fixation of curbs is carried out using cement mortar and filling with compacted soil.

- Backfilling with sand, for effective compaction, wetting the sand cushion with water is used, laying geotextiles to reduce the pressing of crushed stone into the sand.

- Laying crushed stone with careful rolling with a roller. Larger fractions are placed downwards, and decluttering is carried out on top with smaller fractions. Compacted crushed stone is poured with bitumen mastic.

- The delivered asphalt is unloaded in separate piles. To prevent it from cooling down, the layout must be done quickly with the assistance of several assistants. Leveling is done using a motor mop. One person begins rolling the surface with a hand roller; to achieve greater effect, a person with a solid build can stand on the roller. With the provided transverse slopes, rolling is carried out from the bottom up. The movement of the roller should be smooth, without jerking. It is important to maintain the same number of passes on all lanes. It is unacceptable to stop the roller on areas that have not frozen to avoid sticking to the coating. In hard-to-reach places, the asphalt is compacted using hand compactors. We must not forget about the need to periodically wet the instruments with diesel fuel. If possible, it is recommended to roll most of the surface with large rollers or vibrating plates, available in specialized organizations. This will significantly increase the strength and quality of the laid coating.

- Finally, you can paint the entire asphalt area with special asphalt paints to obtain the required shades.

At this point the work can be considered completed.

Technology for recycling asphalt pavements

The need to save money when repairing and building new asphalt roads led to the development of an effective recycling system (reuse of materials). In this case, the asphalt removed from the road surface is processed, both in stationary factory conditions and in mobile equipment at the work site.

Using this technology, the asphalt concrete coating is removed using a special mechanism with a mechanical cutter - a remixer. Next, the removed material is crushed into a crushed stone fraction and can be used to prepare dry mixtures for the construction of road bases and fills for suburban highways and roads.

Asphalt base.

According to the second technology, the collected and crushed material is placed in a furnace and heated without fire to 170°C with the addition of the required amount of fresh bitumen and additives. This processing method is widely used when repairing city streets and courtyards, since the price, production and laying of asphalt in this case is much lower.

Recycling asphalt at home

An old road surface made from an asphalt mixture allows a home craftsman to arrange comfortable and neat asphalt pedestrian paths on his or her plot, which can easily replace paving slabs. This DIY asphalt can also be used, for example, to cover the floor in a garage or in front of it.

Only the top bitumen layer needs to be removed. The removed material must be broken into pieces as small as possible. The maximum fraction should not exceed 40 mm.

Next, prepare bitumen for mixing with the removed material in a ratio of 1:10 by weight as described above.

Productivity 5-15 tons/hour

Purpose: Production of asphalt concrete mixtures in small batches, in a limited area.

Composition: power supply unit, drying and mixing unit, bitumen production, pneumatic system.

Principle of operation

►The power unit hoppers are filled with inert materials.

The sector gate opens on the first bunker. The material enters the weighing conveyor. Thanks to the precise reloading function, the first fraction is weighed out. Then the remaining bunkers are activated in the same mode.

►A portion of inert materials weighed on a conveyor is poured into an elevator or skip hoist.

►Through the loading box, the material enters the reversible drum, which rotates in drying mode. After the material reaches a temperature of 1800, the drum stops and begins to rotate in the opposite direction. The material is discharged into the mixer.

►Simultaneously with the unloading of the inert, bitumen and mineral powder are fed into the mixer.

►During the drying process of materials, a new portion of inerts is dosed.

Methodology for checking the quality of asphalt road surfaces

Each manufacturer of building materials is required to issue the buyer of asphalt a certificate of product quality compliance with state standards. To do this, the plant must have a certified laboratory that can conduct the necessary set of tests. In addition, in all major cities there are independent laboratories for checking the quality of construction and manufacturing of materials.

At a construction site, testing occurs by drilling a core of a given diameter from the road surface and then restoring the road surface. Externally, the quality of the delivered asphalt can be determined by its temperature and the presence of a black, greasy film on the surface.

Hot asphalt and step-by-step instructions for its production

The main components of this material are crushed stone, ordinary river sand, bitumen resin, as well as polymer materials for laying on the surface. The last component is not always used, as it is expensive; it is used mainly in the construction of highways and highways. Despite the fact that all the components can be found in the shed, making a road surface at the dacha will be a little difficult. You should seriously prepare for this process

We need a container for mixing the “ingredients”, a fire (can be a fire) for 6-8 hours continuously, about 100 liters of water to cool the suspension, as well as one of the pastes to keep everything together. Its role can be played by resin or bitumen (preferred). Let's look at the manufacturing instructions step by step.

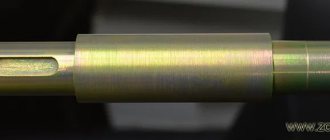

The first step is to make a prototype of a concrete mixer, since it would be irrational to “kill” an expensive and useful item. For our purposes, a metal barrel of oil or diesel fuel, in which a branded product is sold, is suitable. If you don’t have one, you can buy it for pennies (or borrow it for free) from any farmer or from the company itself that bottles oil into retail containers. They are often thrown into scrap metal as industrial waste. Close the lid and drill holes in the bottom center with an electric drill. We thread a metal rod (pipe, angle, square, etc.) and scald it using inverter welding so that there are no leaks anywhere. We weld an L-shaped twig to one of the edges, creating a “skewer”.

We pour crushed stone into our “concrete mixer”, add a little sand (2:1) and mix everything thoroughly. You cannot pick up wet building materials - they will immediately stick together, and it will be very difficult to pick them out from the metal walls.

In a separate container (it is best to take a 15-liter bucket), we need to heat the bitumen to a boil; for better elasticity, you can add shampoo to it. It will burn out later, but it will be much more convenient to stir. We also add polymers and plasticizers there.

You don’t need a lot of imagination here, just take and add boiling bitumen to a preheated barrel with crushed stone and sand. Important: do not mix if the barrel and all components are not warmed up - the bitumen will quickly cool down and mixing will be impossible. For convenience, you can first add 50 liters of water to a barrel and bring to a boil. After this, pour in bitumen and stir until the water evaporates.

The boiling point of water is 100 degrees, exactly what we need for bitumen to make it fluid and sticky. Remember not to overheat this material - it ignites at a temperature of 170 degrees, so watch the water. Just finished - pour it out!

The area in which you will pour asphalt must be thoroughly cleaned, preferably blown out with a compressor. After you pour in the hot mixture, you need to take a roller or any other tool (tamper) and compact the material. Be sure to wet the metal of the tool with water so that it does not stick to the bitumen during compaction.

If you follow the instructions, making asphalt at home will be safe, fast and even very interesting!

What is cold asphalt and what is its feature?

Quite recently, a rather interesting product came to the territory of Russia - polymer asphalt. Its peculiarity is that it can be laid at absolutely any temperature. Tests have shown excellent viscosity and adhesiveness even at -20C, which makes it possible to repair roads or make an entrance to a dacha even in winter.

It consists of fluid bitumen grade SG or MG 70/130, characterized by increased viscosity. It also contains special plasticizers and modifiers that act similarly to “cold welding”. Due to this, you can get excellent results even at subzero temperatures. The paths will have increased strength and will last much longer than regular asphalt. The technology has been implemented for more than 5 years in Russia, and now anyone can buy such material.

There is no point in looking for a method on how to make asphalt with your own hands, since cold technology implies a high-tech manufacturing process under pressure and is not available at home. Its cost is much higher than conventional road surfaces, so it is rarely used in industry. But every summer resident can buy the required quantity to make paths in the garden or a small driveway for a car. You can buy it in a regular store. Installation does not require special knowledge: you simply pour the mixture into the desired place and compact it in any convenient way, even with car tires.

How to make new asphalt from old road surface

Another very popular method of improving a site without much capital investment is to use old road surfaces as the main raw material for making a new one. To do this, we need about 100 kg of old coating, which is thrown away during highway repairs, fresh bitumen, 10 kg of resin for elasticity and a concrete hardener. Let's look at what needs to be done step by step.

We make a concrete mixer using an electric drill, an oil barrel and a twig as described in the first section of the article.

Use a hammer to break up all the large pieces remaining from the old road. Check that the fraction of all components is fine, up to 40 mm. Add a little sand there and mix everything. We begin to heat the barrel with old asphalt and sand placed in it, fill it with 60-70 liters of water, bring it to a boil and “cook the soup.”

Now is the time to take care of the liquid part. Since the old road surface already contains some bitumen, we will need 50% less of it. That is, we take about 10 kg of bitumen and 10 kg of resin per 100 kg of material, heat it to a boil. Then we pour it all into a heated barrel with other components, mix thoroughly with a metal rod.

Homemade asphalt from free components is ready. Now all that remains is to pour it into pre-cleaned holes or onto a site prepared for laying. Such material will serve you for many years and will be no worse than “branded” material.

What is asphalt

Asphalt, or more precisely asphalt concrete, is a multicomponent material that includes the following ingredients:

- Sand. It is necessary as a binder, and in some cases (when adding cement) it can increase the mechanical strength of the road surface.

- Crushed stone. It is a reinforcing component and does not allow finished layers to crack under the influence of significant loads.

- Bitumen resin. Acts as a paste for connecting all components, and also provides additional waterproofing of the canvas.

Sometimes polymer additives are introduced into asphalt concrete, which can ensure its high performance characteristics, but due to their high cost, they are used extremely rarely.

Assortment of crumb rubber in Leroy Merlin with prices

Rubber crumbs in the hypermarket are offered as “soft asphalt”. There are several color options for the material: brown-black, starry sky, green-black, gray-black, blue-black, red-black. The cost of the material is 1,502 rubles per package (weight 8.6 kg). The only exception in cost is crumb rubber in the “starry sky” shade - you need to pay 1,340 rubles for the packaging. The material is produced in Russia.

Crumb rubber, which is offered by Leroy Merlin, can be used for self-laying paths. The coating is durable and resistant. Does not fade under the influence of ultraviolet radiation and does not change its qualities with sudden changes in temperature. Since the coating is laid without seams and has anti-slip properties, its use will be relevant near the pool, on steps, sports or children's playgrounds. Also suitable for paths near a house, cottage or country cottage, for a park or square.

The coating is hard to damage mechanically, puddles do not accumulate on it after rain, and the surface does not wear out. The crumb rubber surface does not require special care. Can be installed in any climate zone. Rubber crumbs can be laid on any base surface. The material is considered safe for the environment and human health. In addition to the material itself, each package comes with instructions for its use.

Preparatory part

In order for asphalt made by yourself to fully perform its assigned functions, it is very important to follow the technology for manufacturing the material and adhere to installation recommendations. The first step in this direction, of course, is preparation.

So, what we need is to prepare all the necessary components (sand, crushed stone, bitumen resin); to ensure the possibility of “cooking” the composition: you will need a large metal container and a heat source (usually a fire is used). And also stock up on a large volume of water as a means of protection (to limit combustion).

Now let's talk about everything in order.

The first thing you should take care of is to make a container for mixing the components, because using a traditional concrete mixer to produce asphalt is an unjustified luxury.

It is quite justified to use a metal barrel (150 - 200 liters) as a container, to the bottom of which it is necessary to weld an L-shaped handle and ensure the ability to rotate the device around its own axis. By the way, you can read about how to make a concrete mixer yourself here.

Next, you should pour the dry ingredients into a metal container (2 parts of sand + 1 part of crushed stone) and mix them thoroughly.

In parallel with this, construction bitumen should be melted in a separate container (usually a large bucket is used). When performing this work, you need to be very scrupulous and take into account the possibility of ignition of the resin (sand and water should be nearby if extinguishing is necessary).

Some experts recommend adding regular shampoo to the bitumen. It will facilitate the mixing process and will evaporate immediately after the resin boils.

The next step is mixing bitumen with sand and crushed stone, for which the heated resin is simply poured into a barrel with bulk substances and mixed thoroughly (by turning). However, when performing this part of the work, it is necessary to take into account the fact that the barrel and the components in it must be well heated. Otherwise, the material will quickly cool down, and high-quality mixing will not be possible.

Water is a good indicator of the readiness of the solution. After all, if you pour hot water into a barrel with bitumen, sand and crushed stone, and then heat the whole substance, you can achieve good results. Well, the readiness of the asphalt will be indicated by the complete evaporation of the liquid from the barrel.

Material laying process

Of course, pouring homemade asphalt concrete onto an unprepared base is not justified. Therefore, before laying the material, it is advisable to clear the work site of debris, dust, or even blow it with air.

After that, the heated asphalt is poured onto the required area and compacted using a hand roller or tamper. It should be noted that in order to minimize the adhesion of the material to the tool, it is advisable to moisten the latter with water.

After hardening, the asphalt is suitable for use.

Features of laying cold asphalt

Recently, more and more often, owners of suburban real estate are using cold-type asphalt to equip their home areas. This product is sold in ready-to-use form and is a mixture of flowing bitumen, polymer fillers and modifiers (ensure the hardening process). Moreover, this particular product can easily be laid at subzero temperatures, which cannot be done with traditional material. While the performance characteristics and price parameters of this material are very higher than those of conventional asphalt.

The method of laying cold asphalt is practically no different from the option described above and boils down to the fact that the finished material is poured out in the required place and compacted using tampers or car wheels.

Composition and types of asphalt concrete

Asphalt concrete is an artificial material obtained by rational selection of mixture components and its compaction after laying. Depending on the incoming components, the ratio of their mass parts and physical characteristics, there are many types of asphalt, divided into brands and types.

The composition of any asphalt concrete includes:

- mineral powders obtained by crushing rocks with a high content of carbon compounds (limestone or other fossilized organic deposits). The high content of such powders gives the material increased viscosity combined with strength. The property of such mixtures to dampen internal vibrations of structures without the formation of cracks in the coating allows the construction of road passages on road bridges. Successfully used for paving roads and sites

- bitumen, contained in most types in small quantities (from 4 to 5%). The exception is cast mixtures containing ≥ 10% bitumen. Bitumen gives the mixture increased fluidity, facilitating its distribution over the coating area, and elasticity after compaction and hardening. The main use of cast asphalt is paving of areas with complex terrain and repairing road surfaces. Increased bitumen content is used for asphalts laid in harsh climatic zones, at low temperatures and the need to open traffic immediately after the completion of a section of road or bridge crossing;

- sand is used in most types of asphalt concrete, the only exception being mixtures with a high gravel content. Natural sands are thoroughly cleaned, while artificial sands, obtained by crushing rocks, are immediately ready for use;

- crushed stone or gravel, which plays the role of a protective component that forms the asphalt concrete frame to absorb significant loads.

This is interesting: Evening styling on a bob 2022

Based on the content of fillers, the following types are distinguished:

- A - from 50 to 60% crushed stone;

- B - 40...50% crushed stone or gravel;

- B - gravel or crushed stone from 30 to 40%;

- G - sand or screenings from crushing ≤ 30%;

- D - content of natural or artificial sands up to 70%.

Depending on the largest sizes of mineral grains in the mixture, they are divided into the following classes:

- coarse-grained first class - ≤ 40 mm. Used for paving highways with heavy traffic of heavy-duty vehicles and other highways of different classes;

- second class - with small grains ≤ 20 mm. Installed on pedestrian streets and squares;

- third - sand mixtures with grains ≤ 10 mm. Small fractions of grains are in close contact, which allows you to create perfectly smooth surfaces. The main purpose is pedestrian sidewalks, garden paths, improvement of courtyard areas and sports grounds.

The second brand is most widely used in asphalting roads, their repair and arrangement of private courtyards with the construction of transport entrances.

Depending on the laying temperature, asphalt mixtures are divided into 2 types:

- Hot, laid with a temperature of ≥ 110 degrees. The hot mixture is transported by special transport, called Kocher, or in dump trucks with a heated body. If necessary, preparation for asphalting is carried out by softening the base under the influence of high temperatures. After leveling, the mixture is rolled with rollers. The resulting durable coating is most widely used in road work and landscaping of urban and suburban areas;

- Cold ones, which are placed with temperatures ≥ 5 degrees. When preparing, bitumen with a reduced viscosity is used, which allows the mixture to remain in a loose state for a longer time, and after rolling it hardens faster. Most often, such asphalt concrete is used for pothole repairs, laying on sidewalks and courtyard driveways that are not subject to intense loads.

Any high-quality asphalt concrete can only be made from certified materials, therefore, when ordering, you must require quality certificates and a passport for asphalt concrete.

New asphalt from old

Recently, more and more often, after repairing the road surface by specialized services, old (cut) asphalt concrete is left behind. It turns out that you can also use it to make high-quality road surfaces. And all that is necessary for this is to break the pieces of old asphalt into small fractions and lay them in the required place in a layer of about 10 cm. Finally, the rocky base should be rolled with a road roller. It should be noted that these works should be carried out in warm weather so that the resin present in the cut asphalt melts a little and fills all the voids.

And in the end we offer the corresponding video:

If you liked the material, I will be grateful if you recommend it to friends or leave a useful comment.