It is easy to drive a nail into a porous aerated concrete wall, but such a fastening will not withstand fixing furniture or plumbing fixtures. Therefore, aerated concrete anchors are used - fastening systems that can withstand heavy loads, for example, hanging furniture. Aerated concrete blocks are widely used in construction, but they are a fragile building material and if the fasteners are selected incorrectly, cracks may appear. The specificity of the anchors ensures reliable fixation of heavy objects without deformation of the walls. You can install the anchor system yourself, without the help of a specialist.

Fastening building structures to aerated concrete

On such fragile walls it is necessary to fix not only wires and pipes, but also heavy structures: floors, roofing elements, etc.

In such cases, fixing self-tapping screws into aerated concrete is not a solution; a serious decision is needed. As a rule, it is carried out during the process of laying walls, when a monolithic reinforced concrete armored belt is made at the installation level of such structures. During pouring, studs and other embedded parts are installed into it, onto which the fastening is subsequently carried out.

If for some reason you did not make an armored belt, or did not provide mortgages in it, fastening is carried out only with chemical anchors.

When choosing fastenings for aerated concrete walls, take into account such features

When choosing hardware, take into account the strength of the working surface, the dimensions of the parts and their resistance to corrosion.

The higher the density of the material, the stronger the aerated concrete. This indicator sets the load limits on the fastener. Technical characteristics in digital terms are indicated on the packaging of building blocks after the letter D.

The strength of the connection is affected by the size of the dowels. Thus, when fixing massive structures, products of large diameters and lengths are used.

The resistance of fasteners to corrosion ensures the possibility of their use when installing external structures and arranging unheated premises.

Design features of fasteners for cellular concrete

When choosing fasteners for aerated concrete, you need to pay attention to the following parameters:

- How dense are the wall blocks? The density marking is indicated in the form of numbers after the letter D. The larger the number, the fewer pores in the material, therefore, the greater the density. The load limit when pulling out fasteners depends on these indicators. They can be found in the instructions that are sold complete with the material.

- Fastener parameters. This refers to length and diameter: the larger the indicators, the higher the ability to withstand loads. These parameters are also indicated in the instructions for the material.

- How resistant the material is to corrosion. This parameter needs to be given special attention if the fasteners will be installed on the outside of the garage or in a room where it is constantly cold. In this case, it is necessary to choose hardware that will be covered with protection.

- Selection of tools. It is recommended to choose tools that do not involve impacts during the installation process (for example, a hammer will not work). The best solution would be a hand drill, a special punch or a brace.

- Correct installation. Even the strongest fasteners do not guarantee results if they are installed incorrectly.

Scope of application

Chemical anchors in aerated concrete are used less frequently. It is used in cases where it is necessary to provide reliable fastening for massive objects. Mechanical anchors are not capable of supporting, for example, the weight of massive equipment.

Epoxy compounds are used mainly on solid bases. They are used for fastening:

- wall structures;

- beams;

- fences along roads;

- creating noise-insulating screens;

- when installing reinforcement outlets;

- when installing attachments.

This composition can be used:

- in a humid environment;

- under the water;

- both outside the building and for interior work.

Its composition:

- does not create stress in the structure of the porous wall;

- does not contain styrene;

- creates fastenings with smooth reinforcement.

The hardening of the mass depends on the air temperature. The time can last from 7-180 minutes. or 7-48 hours.

Polyester anchors are used to create:

- enclosing structures;

- when installing façade elements;

- for installation of translucent elements;

- during installation of utilities.

Typically, threaded rods are installed along with polyester compounds. The polyester anchor does not contain styrene. Therefore, it can be used on interior and exterior fasteners. The polyester anchor takes from 2 to 30 minutes to set and hardens from 25 to 180 minutes.

The anchor bolt for aerated concrete can be smooth or threaded if a vinylester anchor is used. It is used to create fasteners in wet substrates. It does not create unnecessary stress in the structure of aerated concrete. This adhesive solution is safe because it does not contain harmful substances. It is used for making internal and external fasteners. Does not create stress after installing fasteners in the structure of the aerated concrete block. Hardening is observed after 15 minutes or a day.

Epoxy acrylate anchor composition has become more widely used due to its properties. The period of setting and hardening of the composition is 2-24 and 15-180 minutes, respectively. Epoxy acrylate retains its properties when the temperature drops to -5°C, and also resists fire in case of fire for up to 2 hours. Epoxy acrylate anchor composition is suitable for anchoring floor slabs in aerated concrete houses.

Anchor types

Chemical anchor for aerated concrete after tearing out

The main reason why standard anchors, for example, dowel-screws, are not suitable is the weak uniform opening of the spacer element. Aerated concrete crumbles quite easily under loads and internal pressure, which is why the fastening of such a dowel can weaken, and the mounted equipment, and even more so furniture, can collapse.

The same applies to dowel nails driven with a pneumatic gun - they do not have an expanding part at all, and are held in place only due to the strength of the material into which they are driven.

Different pore sizes inside the block

As already mentioned, blocks come in different densities. Look at the photo above to see this clearly. The D600 version looks clearly stronger, although it is not the densest block - the strongest brand has a density of 1200 kg/m3. You can also screw standard fasteners into such structures, being sure that they will hold securely.

Advice! From here we will draw the first conclusion - in order to decide on the type of anchor for aerated concrete, first find out its brand. If there is no data, then it is better to play it safe by taking one of the options that we will consider today. Of course their price will be higher, but it's worth it.

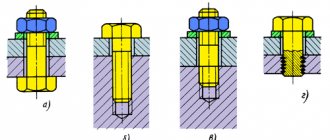

Mechanical anchors for cellular concrete

Anchor bolts for aerated concrete Hilti HPD

Mechanical anchors for cellular concrete are often called butterflies, due to the visual similarity of the wedged spacer element to this insect.

They are made of metal, like the one shown above, or have a plastic dowel.

As you can see by looking at the photo selection, the range of mechanical anchors is quite large, and we have not yet shown the whole variety.

- Each of the presented models has a certain resistance to vertical and horizontal loads, which must be taken into account when selecting fasteners. You can try to get such information in a store by looking at the specification, but from experience we know that this is almost impossible to do in Russian conditions. Therefore, once you know the mass of the load being hung, look for the necessary data on the Internet.

- All anchors for foam blocks wedge perfectly inside these products. However, many of these designs can damage the load-bearing face of the block when overtightened. For this reason, the manufacturer equips them with a special cuff, border or mark that allows you to limit tightening.

- All models shown can be successfully used for any porous materials.

- To fasten doors and window frames, special models of anchors called frame anchors are used.

Frame anchors for aerated concrete

- If you need to install any lightweight structures, for example, fasteners for air ducts, pipes, and various decorative steel elements, you can use HUS-H type anchor screws.

Hilti HUS3-H6 – self-tapping anchor

Installing these elements is intuitive:

- First, a hole is drilled in the desired location;

- According to the type, a dowel is screwed or hammered into it;

- The screw element (nut, self-tapping screw, bolt) is tightened.

That's the whole procedure. However, it must be remembered that mechanical anchors cannot be used for very heavy loads.

Chemical anchors

For these purposes, chemical anchors are used, which, after installation, become almost one with the block.

Installed chemical anchor in aerated concrete

The operating principle of such an anchor is not much different from a mechanical one, except for a different installation method and the properties of the material used.

pros

The spacer element of such an anchor is an adhesive composition that fills the mounting hole. A metal screw part is installed inside, which can be attached to from the outside. This solution is also suitable for any porous materials.

Here are its advantages and disadvantages:

- The walls of the drilled sleeve do not experience pressure, and even, on the contrary, are strengthened with an adhesive composition. If you remember, in the photo with the torn out anchor there was firmly adhered concrete around the glue.

- The mounting hole is completely sealed.

- Nice cost solution

Minuses

The disadvantages include:

- Quite a long hardening time (up to 48 hours) until the fastener can be used.

- The connection is inseparable - the glue, together with the core, hardens tightly. The only way to carefully remove the protruding part is to cut it off with a grinder and fill the hole with putty.

It is the latter feature that forces one to resort to such a solution only when hanging particularly heavy objects (furniture, TVs, etc.). By the way, pieces of reinforcement can also be immersed in them to create strong bonds with the base.

Chemical anchor installation

Types of filling

The mass with which the mounting holes are filled may have a different chemical composition.

Usually it happens:

- Epoxy;

- Epoxyacrylate;

- Vinylester;

- Polyester.

Similar formulations are sold in tubes or capsules.

Many factors depend on the composition of the mixture, some of which we will now outline:

Vinylester resins are excellent for fixing heavy products operated at subzero temperatures. They feel great when installed in damp conditions, so they are actively used outdoors. They do not contain styrene, the effects of which are considered harmful to the human body.

Epoxy resins are also very popular among builders, because they are able to withstand the largest and heaviest objects, for example: various protective screens, technological equipment for various purposes, etc. Such anchors are mounted on aerated concrete blocks, starting from grade C20.

They consist of two components, which are mixed in a certain proportion, after which they begin to actively harden.

- Epoxy chemical anchors can be installed in high humidity conditions and even under water;

- Like other compounds, they do not create internal stress in a foam concrete structure;

- Suitable for both external and internal use due to the absence of styrene;

- The coupling strength is sufficient even for the use of smooth fasteners.

- It has a very high fire resistance class - R120, which means that when the composition is exposed to an open flame, it will be able to maintain its basic physical properties for 120 minutes.

Important! Polyester compounds are also suitable for indoor and outdoor use. They are harmless to human health and are also among the fastest drying.

The rate of hardening of a chemical anchor depends, first of all, on its chemical composition (can vary from 15 minutes to 48 hours) and environmental conditions (humidity, temperature). The instructions on the packaging will tell you the exact timing of the subsequent installation of the hanging structures.

Installation diagram of a chemical anchor in foam concrete

Why you shouldn’t attach excessively heavy structures to gas block and foam block

About the gas block

Autoclaved aerated concrete has thermal conductivity characteristics close to foam plastic because, like insulation, it contains air bubbles in its structure. At the same time, foam plastic has almost zero load-bearing capacity.

Why should a gas block be so much more durable? It should be noted that it copes well with a load evenly distributed over an area, for example, in wall masonry. But it does not tolerate local loads from ordinary dowels and anchors, that is, it simply does not hold

And no matter what the manufacturers of such blocks say, you need to load the material locally with great care - use special fasteners, spread them over a large area, do not hang very heavy structures without a metal frame

Excessive load on aerated concrete can lead to similar consequences

The weakest point of an aerated block in terms of load-bearing capacity is variable pressure. Periodically attaching and removing any heavy structure from an anchor will contribute to the crumbling of the material around the fastener and failure of the attachment point.

About the foam block

Foam concrete is used less frequently in modern construction, and on average it is heavier and stronger than aerated concrete. Of course, strength depends on the class of the material - the higher the class, the more durable it is, but at the same time it loses somewhat in its heat-insulating properties.

Perhaps we can say that the foam block is somewhere between concrete and aerated concrete in terms of strength. However, when choosing an anchor for foam concrete, it is better to be guided by the same principles that apply when using aerated concrete.

Characteristic

Aerated concrete is rightfully recognized as one of the most practical and affordable materials. It makes durable and strong houses, as well as reliable outbuildings. However, you need to take into account that this material has a cellular structure, when faced with which you need to take into account many nuances. The main characteristic feature of this material is its fragility and pliability. Porous blocks can be trimmed or cut off the excess part without any extra effort. And we must also not forget that special fasteners are used for such a structure. Traditional fasteners, as a rule, do not adhere well to such foundations, which is why the whole point of their use is lost.

For aerated concrete, special dowels should be used. The design of such parts is a sleeve in the form of a spiral, on the surface of which there are ribs. When screwing in a self-tapping screw, the last elements become wider, so they fit firmly into the loose aerated concrete surface. This simple but effective device can easily withstand impressive loads. With the use of special dowels, home owners have the opportunity to hang heavy decorative objects of any size on the walls.

Modern manufacturers produce these types of dowels in two variations. They differ in design features.

- According to the shape of the fixation ribs. Such fasteners can be equipped with a classic helical spiral or have cone-shaped ribs. The edges of the latter may resemble spiral-like blades.

- By installation method. The dowels are either screwed into the base or driven into it. Screw-in types are considered to be the most reliable. It is recommended to use driven-in fasteners if the aerated concrete floor is planned to be equipped with a collet.

Fastening building structures to aerated concrete

In general, the process of installing fasteners is similar for all options. First of all, a hole is made, and then the cartridge is inserted. The only difference can be with a chemical anchor, since it uses glue.

Chemical anchors are secured as follows:

- Preparatory work. You need to drill a hole using a drill.

- Next, the hole needs to be cleaned of dust. To do this, use a brush or a medical bulb.

- A cartridge with a chemical composition is installed. To do this, you need to insert a capsule with glue into the recess. The last one is squeezed out.

- An anchor is screwed into the hole.

- You need to wait until the glue dries. There are times when you need to wait 2 days for complete drying. It all depends on the composition, but temperature, humidity and other environmental features are also considered important factors.

- Once the compound has hardened, you can install the washer and nut.

The installation process using a mechanical anchor, dowel nail or self-tapping screw is the same, but without the use of glue.

This is what the fastening looks like inside aerated concrete.

Video on the topic:

Each fastening method has its own advantages and disadvantages. When choosing, you should take into account the material, density, and characteristics of the room.

Previous entry How to attach a window sill to a plastic window Next entry Features of attaching gates to brick pillars

What type of anchor should I choose?

To install fastening systems, there is no need for special knowledge; basic repair skills are sufficient.

Dismantling hardware with adhesive solution disrupts the structure of the blocks.

The advantage of the chemical type of fastenings over the mechanical type is the ability of the former to withstand maximum loads. Otherwise, the choice of fixation method depends on the characteristics and weight of the object that needs to be fixed to the wall. If work is carried out with heavy suspended structures that are not planned to be moved over time, chemical anchors are used. It must be remembered that this type of insertion of a steel rod does not allow it to be removed from the wall without a trace. It is convenient to use mechanical rods to install hangers, shelves and similar furniture. They are easy to install, and after installation they can be immediately used to place the necessary items. It is important to consider the density of aerated concrete. Mechanical anchors are not suitable for fragile building materials.

Dowel

The part is a spiral-shaped bushing with ribs on the surface. At the moment the screw is screwed in, they expand, due to which they firmly fit into the soft surface of the base. Such fasteners can be made of galvanized steel or plastic.

The first option is the most common and is considered the most expensive. It is used when installing profiles, installing attachments and furniture, and fixing various pipelines. Such fasteners have become widespread in fire-hazardous spaces.

Metal dowels for aerated concrete are produced in 2 modifications, which differ in design features and installation methods. The parts can either be screwed into the base or driven into it. The latter option is used if the aerated concrete floor is planned to be equipped with a collet.

Based on the shape of the fixation ribs, fasteners with a classic helical spiral and dowels in the form of a cone, equipped with spiral blades, are distinguished. The design of metal elements also provides for the presence of a locking flange or cuff, thanks to which the part will not rotate.

Corrosion resistance is the main advantage of plastic products. The materials used for them are polypropylene and polyethylene. The positive characteristics of the parts include their efficiency, environmental friendliness, and immunity to aggressive environments. Such dowels are not intended for outdoor work, since with the onset of cold weather the plastic may burst.

A separate group consists of fasteners for aerated concrete made of nylon. They are more wear-resistant, so they can be used for cladding facades. Together with them, galvanized screw elements with 2 types of heads are used - countersunk or hexagonal. The disadvantage of this type of fastening is the high price.

Depending on the scope of application, there are several types of dowels:

- Universal. It can be mounted in any concrete surface. In a solid base, fixation occurs in a standard way. In a cellular coating, the product is rolled into a persistent knot. However, the load-bearing capacity of universal dowels is lower than that of spacer elements.

- A dowel-nail that has a wide range of applications. At the moment of fixation, a nail is inserted into the fastener, rather than a screw being screwed in. In order to avoid turning the part, use a sleeve.

- The “pancake-like” structure of the frame dowels allows you to reduce the load on the porous surface of the block.

Results - the best fasteners for aerated concrete

We hope that this article allowed you to understand the principle of operation of various types of fasteners for aerated concrete blocks. Each of them should be used depending on your needs and requirements for the quality of fasteners.

You need to understand that it is not worth saving on fastening elements, since most often the cost of the attached elements significantly exceeds the amount of savings. We believe that this is not worth the risk.

Focusing on your budget, you can opt for high-quality German dowels, which have good corrosion resistance and strength characteristics. They are not very expensive, but are widespread and available at any hardware store.

If you need absolutely reliable fastening, then we advise you to pay attention to the leader among fastening elements - a chemical anchor. Its strength (and therefore price) exceeds the price of other types of fasteners. However, thanks to this type of fastening, you can be absolutely sure of the quality of the fasteners.

Tool and surface features

Installation tools:

- electric hand drill;

- drill bit with pobedite tip;

- hammer;

- a wrench or screwdriver for screwing in a screw;

- adhesive mixture for chemical anchor;

- special gun for glue mixture.

The main condition when installing objects and accessories is the correct choice of hardware.

Aerated concrete, having a porous structure, is a relatively fragile material, so the question arises - what kind of hardware is needed to ensure that the fastening is reliable and meets all the operating requirements of the structure.

There is a wide range of products that make it possible to fasten structures reliably and quickly.

From the video below you will learn about fasteners for aerated concrete.

Why does foam concrete need special fasteners?

Foam blocks are made from water, sand, cement and a special foaming agent. The blocks are cellular, the material is fragile enough for installation of various fasteners.

The main distinctive features of foam blocks: low weight, low density, high level of hygroscopicity, porous structure. For the most part, properties act as advantages during the construction and operation of buildings, but not at the moment of attaching some objects to the walls.

The structure of foam concrete is porous, the adhesion to materials is not very good, so the blocks cannot always cope with the loads, and therefore special dowels are provided for them.

Properly selected fasteners for foam blocks will not only secure equipment or furniture with high quality, but will also strengthen the working structure and significantly increase the percentage of permissible loads.

Fasteners for foam blocks require a certain design of fixing parts - they usually consist of the following elements: a screw, a ring, a half-ring, a side, an empty sleeve with a spacer. Many anchors are made with teeth, which become a reliable obstacle to the part turning.

There are also chemical anchors for foam blocks, which are created specifically for use and provide maximum quality of fastening. In this case, the main task of the dowel is to create internal support in the block during the expansion process inside the aerated concrete and preserve the fragile material from destruction.

Dowels can be of different diameters and lengths, made of metal or plastic, and are supplied in packs of 50-1000 pieces. According to the scope of application, they are intended for external/internal work, according to the installation method - driven, screwed and others (chemical anchors are distinguished separately).

Chemical anchor

This type of fastening, such as a chemical anchor, is a fairly new and already in demand method. The builders appreciated it. Chemical anchoring has its advantages and disadvantages. The advantages of a chemical anchor include:

- high load capacity factor on fasteners;

- compliance with GOST, the chemical composition is safe and environmentally friendly;

- versatility, it is used for any building material;

- high resistance to weather fluctuations and low temperatures;

- low price when compared with steel anchors.

The disadvantages include:

- strict adherence to technology;

- purchase of special equipment, namely brushes, pumps, guns and drills;

- additional time for the chemical solution to harden.

Chemical fasteners for foam concrete include a threaded steel pin, maybe a special rod, a chemical mixture, and additional bushings.

Chemical anchor fastening sequence

- Use a drill to make a cylindrical hole. Then it needs to be shaped into a cone with an expansion in depth.

- The finished hole is thoroughly cleaned. You can use a pump for this.

- A centering sleeve is inserted into the base.

- A chemical solution is poured into the hole through the sleeve; a construction gun is used for this.

- The threaded rod (stud) is screwed in.

- Leave time until the chemical solution hardens completely.

The chemical anchor kit includes an easy-to-use package with a dispenser. Installation is easy, while achieving high structural strength.

Fastening chemical anchors

And so, for fastening light structures and decorative elements, ordinary self-tapping screws are quite suitable. They can be designed for working on wood or on cellular concrete. Nails for aerated concrete should have a wedge shape or a curved tip inside the concrete cavity.

For heavy structures, such as plumbing fixtures, kitchen cabinets, boilers, it is worth using foam concrete fasteners with wedging dowels. Reliable fixation is achieved precisely thanks to the internal stop. All hardware must be resistant to corrosion. This especially applies to mountings on an external wall.

Tips and tricks

When installing dowels into a gas block, you cannot use a screwdriver, since this device runs on electricity, which makes it more difficult to control. Such a device can strip the thread by twisting the screw

When making a hole for dowels in a gas block, it is important to note that they should not be larger than their diameter. Otherwise, the fasteners simply will not hold securely in the base

The depth of the holes should be slightly greater than the length of the dowel. The tip of the screw must leave the dowel for the fastening to be as reliable as possible.

Many people, having become acquainted with dowels, begin to use them at any opportunity. However, experts do not advise using too powerful fastenings if you plan to hang hooks, pictures and other small items. For such purposes, simple plastic fasteners, the size of which is about 8 mm, are more suitable.

About fastening for aerated concrete - a nylon dowel and a metal dowel (crocodile), see the following video.

Types of fasteners and performance of work

The type of product is selected depending on the expected load:

- for fastening hanging mirrors or lamps, nylon dowels with a cross-section of up to 12 mm are suitable;

- when installing pipelines and bulky objects, choose metal parts;

- frame types of fastenings are used to fix window and door frames;

- universal facade dowels are used when installing external profiles for facing slabs;

- Only light objects are attached to wood screws - photo frames or decorative elements.

Installation is carried out in several stages.

In order for the products to fit tightly into the base, it is necessary to drill the holes correctly. To do this, it is best to use a hammerless drill or a hammer drill with the impact turned off. The drill should have a cross-section 1 mm smaller than the fastener itself. The only exception is steel hardware. For them, the hole will be reduced by 2 mm.

After cleaning the recess from concrete dust, install a dowel. The plastic fastener is screwed in using a screwdriver. Metal parts are driven into the mounting hole with a hammer. During the work, it is necessary to ensure that the product does not warp.

At the final stage, screw in a self-tapping screw or a standard mounting bolt. In this case, it is not advisable to use an electric tool, since when connecting to an aerated concrete block, the screw element may be damaged.

How to use an aerated concrete anchor

The principle of installation of fastening anchors and dowels is not complicated, but there are several nuances. We recommend that you read our instructions to be completely sure of your actions. All work can be divided into three simple stages: drilling a hole, installing fasteners and installing a spacer element.

Drilling holes

You can use a drill or hammer drill. To speed up drilling, it is recommended to use the hammer drill mode. A correctly selected drill will allow you to obtain a hole of the desired diameter.

After the preparatory work and compliance with safety precautions, you can start drilling the hole we need:

- The angle between the hammer drill and the wall surface must be straight to prevent the drill from slipping and causing injury;

- It is important to drill away from the joints between aerated concrete blocks, since the density of the joints is significantly less than the density of the aerated concrete block itself;

- It is important to mark in advance the locations of the electrical wiring lines;

- To make a hole you need depth, make a special mark on the drill; an ordinary marker or a piece of construction tape is perfect for this.

Installation of fasteners

After the work has been completed, the dowel itself must be placed in the resulting hole. If you have selected the diameter correctly, then the hardware cannot be installed without a special tool. Most often, the dowel is simply driven in with a hammer until it stops. If the fastener has a thread, it must be screwed in. For this, an ordinary hexagon is used. Rotation is carried out strictly clockwise. With this installation method, metal fasteners have a great advantage, since they are more rigid and do not break during installation.

Installation of spacer element

At the third stage, wedging and final fastening of the dowel is carried out. If the main element is a nail, then it is driven into the dowel, while the screws are installed by screwing it into the body of the fastener until it stops. Separately, it should be noted the fastening of the chemical dowel. In this case, the metal pins are installed by hand without the use of additional tools.

Fasteners for cellular concrete

Using ordinary wood screws, only very light objects such as photo frames can be attached to aerated concrete. In all other cases, special fasteners will be required.

Fastening requirements

When choosing which fasteners to use for aerated concrete, you need to consider the following points:

The density of wall blocks, indicated in product labeling by numbers after the letter D. The higher it is, the fewer pores in the material, and the stronger it is. The load limit when pulling out fasteners depends on this indicator, and the manufacturer’s instructions on the packaging contain this information.

The numbers show how many kilograms are in a cubic meter of material

The fastener parameters are its length and diameter. The larger they are, the greater the load it can withstand. The load-bearing capacity must also be indicated on the packaging or certificate.

Chemical anchors have the highest load-bearing capacity

Corrosion resistance. This parameter is especially important when fastening into aerated concrete is carried out from external walls or in unheated rooms. Steel hardware must be coated with a protective layer.

Punch for aerated concrete

Mounting options

Let's take a closer look at which aerated concrete fasteners are used most often.

Let's start with the traditional types:

| Image | Application |

| When a smooth steel nail enters the sleeve, its base opens and enters the material at an angle. Suitable for all types of concrete. |

| Universal façade dowel | Allows you to attach a profile to aerated concrete to fasten facade panels and hang wall cabinets and shelves. |

| Used only for small loads: fastening light shelves, curtains, baseboards, switches, cable ducts, etc. |

| Helps to fasten window and door frames and wall cabinets to aerated concrete. |

| Nylon dowel for aerated concrete | Special development for aerated concrete. It is used with conventional self-tapping screws when installing wooden and metal facade subsystems, windows, doors, suspended ceilings, sanitary equipment, and pipelines. |

| Designed for any cellular concrete, the scope is wide. |

| Steel anchor for aerated concrete | Solves the problem of how to attach heavy objects to aerated concrete: water heaters, air conditioners, hanging pipes, heavy wall cabinets, etc. |

All these elements may have other varieties that differ from the images shown in the table. For example, turbo dowels with self-tapping threads are made from nylon.

Turbo dowel FTP K

And made of galvanized steel - four-leaf toothed expansion dowels. Their segments move apart when the screw is screwed in, reliably biting into cellular materials.

Steel expansion dowel

As already mentioned, one or another hardware and fastening method are chosen depending on the expected load.

If you need to fasten aerated concrete shelves, you need to carefully drill at a right angle, insert a dowel into the hole and screw a screw into it.

Shelves with covered mounting on aerated concrete wall

- And to hang a light picture or install an electrical switch, a simple self-tapping screw screwed at an angle of 45 degrees to the wall is enough.

- If you need to securely fasten heavy equipment or install a metal entrance door, it is best to use chemical anchors.

When installed, they are capsules made of synthetic resins and organic polymers that seal holes in a wall made of aerated concrete, firmly holding a metal rod or threaded rod in it.

The advantages of such fastening include exceptional reliability and durability, the adhesive base is not susceptible to thermal expansion and resistance to aggressive environments.

No special qualifications are required for fastening with chemical anchors; everything can be done with your own hands.

For this:

- A hole of the required depth is drilled in the wall, its bottom is slightly expanded by oscillating movements of the drill;

- Construction dust is blown out of the hole, and a sleeve is inserted into its neck;

- The cavity is filled with adhesive solution using a mounting gun;

- An anchor rod is immediately installed into it;

- After the solution has hardened, fastening can be done.

The price of such fasteners is higher than that of other types, but the reliability does not raise the slightest doubt.

Types of fastening

Mechanical

When choosing an anchor, you should take into account the porosity of aerated concrete walls and the mass that needs to be hung on it.

The mechanical type of fastening system consists of a rigid metal rod that is screwed or driven into the concrete surface. The reliability of the anchor is ensured by uniform distribution of the load over its entire area. Mechanical anchor systems for gas or foam concrete are called “butterflies” because of their design. The metal working parts of the rods, which are inserted into the concrete, open like petals when the threaded part of the system is screwed in. This is how the anchor looks like a butterfly. This guarantees reliable fastening.

Bolts or threaded rods that are inserted into the anchor spacer can deform the hole prepared in the concrete wall during screwing. To avoid this, mechanical anchors are equipped with special cuffs that prevent them from being pressed through the bolt threads. Such butterfly anchor systems are used for fixing objects and massive structures on walls made of any porous building material.

Mechanical fasteners vary in how they install the internal element. If the rod is screwed in, the force is transmitted through the thread. When hammering, pressure is applied to the wedge. It is better to use stainless steel fixtures. Imported HILTI anchors have this property. In the line of devices for cellular building materials, they are labeled HPD. If you need to fix a relatively light object on the wall, it is recommended to choose HUS-H anchor screws.

Thanks to a special fastening system for hardware, they do not destroy the porous structure of the wall.

Advantages and disadvantages

The disadvantages of the mechanical type of fastening include its unsuitability for working with low-density cellular building materials. The advantages of the technology are:

- ease of installation;

- acceptable price;

- possibility of fixing heavy objects.

Chemical

Chemical type anchor systems have the following components:

- threaded element made of galvanized steel;

- adhesive mixture;

- threaded rod;

- additional bushing.

A chemical type anchor is similar to an ampoule of glue consisting of synthetic resins. An adhesive suspension is introduced into the drilled and cleaned hole, which after hardening becomes a monolith with concrete. This securely secures the metal screw into the wall. You can only tear it out with a piece of concrete. This type of fixation is considered more reliable than metal or plastic dowels. Such fasteners can withstand greater loads than mechanical ones. The chemical anchor for aerated concrete is equipped with a dispenser. It is used to measure the required volume of glue and the level of its distribution in the wall cavity. The further the glue penetrates into the aerated concrete, the stronger the anchors hold.

Fastening with the help of special substances is more durable and reliable.

Advantages and disadvantages

The positive qualities of chemical fastening systems include:

- Complete sealing of the working hole.

- There is no pressure on the walls of the drilled hole, which prevents its deformation.

- Service life more than 50 years.

- The internal part is not subject to corrosion.

The chemical method of installing an anchor is used only when it is necessary to fix heavy objects, for example, hanging furniture, televisions. Immersion into the mounting holes of the reinforcement is practiced in order to obtain a strong bond. Disadvantages of the method:

- The glue takes a long time to harden. It may take up to a day before you can start using the mount.

- The connection cannot be resolved. The adhesive becomes one with the aerated concrete and the inner core. To eliminate the free part remaining outside, it is cut off with a grinder.

- High price.

- Short shelf life.

Classification of self-tapping screws for aerated concrete and foam concrete blocks

| Profile | Diameter, mm | Length, cm | Photo | A comment |

| Nog | 7,5 | 7 — 20 | Dowel with dowel for foam concrete | Can be used in aerated concrete blocks without dowels. In foam blocks only with dowels. |

| Universal | about 6 | until 22 | Universal self-tapping screw for foam concrete | Average thread pitch. Can be mounted without dowels |

| Christmas tree (mef) | up to 8 | up to 20 | Christmas tree screw (mef) for foam concrete | Average thread pitch. Can only be used with mef dowels |

Dowels for self-tapping screws

Without dowels, self-tapping screws for aerated concrete are not often used due to the porous structure of the blocks. They are used for fastening lightweight structures. Thus, they can easily secure a reinforced mesh to an aerated concrete surface before applying plaster. For such fastening, self-tapping screws with a wide pitch and a length of at least 10 cm are selected.

In this case, it will not be possible to use a hammer drill, since the aerated concrete will crumble greatly. A drill with a thin drill bit is used. There is a way to screw self-tapping screws into a porous surface using machine oil. A few drops of oil are added to the prepared hole, so the hardware can be easily screwed in. The hardware will fit tightly, and it will be difficult to unscrew it in the future.

Self-tapping screws with a herringbone profile can be hammered into foam concrete blocks. The consumables along with the dowels are driven in “forever”; it is almost impossible to dismantle them. The work must be done quickly so that the prepared hole does not begin to crumble.

How to use?

The principle of installation of dowels is the same as for other types of fasteners. You need to act in the following order:

- first you need to prepare holes for the dowel, which should be smaller than the diameter of the fastening; for example, for 8 mm fasteners you will need to use a 7 mm drill;

- if you take a tool such as a hammer drill, then you need to turn off the impact mode; of course, it is advisable to use a drill, since it is more effective;

- the plastic fastener must be carefully screwed in using a screwdriver; if metal parts are used, then they should be driven into the mounting hole with a hammer;

- When performing work, you must ensure that the products do not touch or are positioned crookedly;

- when the cuff is installed all the way, you can proceed to screwing a self-tapping screw or a universal-type bolt;

- It is necessary to screw in the self-tapping screw using a screwdriver, adhering to the required depth.

Features of installing a frame anchor

Before installing the frame anchor, you need to prepare the surface. Old windows or doors are dismantled, the opening is cleared of remnants of building materials, potholes are sealed and all irregularities are eliminated. You will also need a tool - a hammer drill with an 8 mm drill, a standard and Phillips screwdriver, a hammer, a mounting pin.

After preparing the opening, installation work begins, which is carried out in the following order:

- The sashes or double-glazed windows are removed from the frame if a blind window is installed. This is necessary to reduce the weight of the structure and simplify the work. The frame is installed level, the position is checked with a level, if necessary, leveled and placed with bars. Evenness is the main condition that must be strictly observed.

- Carry out markings. Installation points are marked on the side at a distance of 300 mm from the top and bottom. A standard window can be fixed using four anchors. For large items, the number of dowels is increased.

- Holes are drilled in the frame with a metal drill, the diameter of which is from 8 to 10 mm, depending on the size of the anchor.

- A hole is drilled under the cap with a 16 mm drill for secret fastening so that the anchor dowel is completely immersed in the material and does not rise above the surface.

- Without removing the window, drill through the hole in the frame into the wall. The depth of the cavity should be 30 – 40 mm. If the installation is made into a wall made of porous or loose material - aerated concrete, foam concrete, then the depth must be at least 100 mm.

- Before installing the anchor, you need to tighten it as much as possible - tighten the screw until it stops. Place the part in the hole, it should fit tightly, and hammer in until it stops.

- At the last stage, the screw is tightened with a screwdriver or screwdriver.

To disguise the installation sites, you can use special colored plugs.

An anchor dowel is the best way to install doors and windows; it is indispensable when carrying out work on narrow slopes where it is impossible to use other types of hardware, as well as when installing floor coverings.

Selection and features of fastening anchors for foam and aerated concrete

Which anchors are best to choose?

Anchors should be selected based on the weight that will fall on each individual fastener:

- Anchors that can support up to 10 kg per fastener. Such products work mainly due to expansion and are a thickened plastic element that in working condition acquires a conical shape or expands inside the material. With their help you can hang small shelves, pictures, hangers, etc.

Anchors for fastening lightweight structures into aerated concrete

- Anchors for a mass of 20-25 kg. These are fasteners of a special shape that allow the load inside the material to be distributed over the maximum possible area inside the base. They usually have a helical shape, significant length and diameter. They can be used to hang, for example, heating system radiators, kitchen cabinets, and façade cladding systems.

Anchors for fastening medium and heavy structures into aerated concrete

- Chemical anchors for 30kg and more. They are special solutions supplied in tubes. Under them, a long hole of large diameter is drilled in the aerated concrete base, cleaned, filled with the compound and a metal pin is inserted. After hardening, the solution essentially turns into a solid capsule, comparable in strength to concrete. At the same time, it takes on the local load from the suspended structures and, due to its large surface area, more evenly transfers this load to the aerated concrete. This solution allows you to attach boilers and other heavy interior and exterior elements to walls made of foam block and gas block.

Chemical anchors for fastening heavy structures to aerated concrete

When choosing an anchor for aerated concrete, give preference to dimensional products with a large surface area. The longer and thicker the anchor, the better.

Practical recommendations for fastening into aerated concrete

Before fastening it into aerated concrete with your own hands, remember that:

- Installation of fasteners must be carried out with a minimum distance from each other of 10 cm. Otherwise, the overlap of stress areas in the gas block can lead to its collapse and the fall of the structure being fixed. The greater the spacing of the anchors relative to each other, the better and more reliable the fastening.

- The anchor should not be attached close to the edge of the block; the minimum offset here is also 10 cm.

- As already noted, the class of aerated concrete largely determines its ability to withstand the fastening of massive structures. For example, a B2.5 class block will withstand approximately 2 times less weight compared to B5.0, although the latter is used extremely rarely in low-rise construction.

- Despite everything described above, it cannot be said that this or that fastening to aerated concrete can be considered 100% reliable. The material is fragile, and it will be better if heavy objects are secured through a specially mounted metal frame, rigidly fixed to the concrete floor and/or ceiling. At the same time, to save space, the frame can be “drowned” into easily chipped aerated concrete.

- It is necessary to drill holes in the gas block for anchors in the drilling mode without impact. The drill should be selected 1-2 mm smaller than the diameter of the dowel, so that after driving, the fastener “sits” tightly in the hole.

Video on the use of Fisher chemical anchors in walls made of various materials.

So, we figured out how and with what help you can attach to aerated concrete and foam concrete blocks. You can find out how to attach to other building materials in our next articles.

Basic operating principle and design features

In practice, two types of anchors are used, which differ in design and installation technology. Classic frame fasteners include the following parts:

- The bushing is made of steel with an anti-corrosion coating and protrusions in the upper part that prevent rotation during installation. There is a special groove at the bottom for the nut. When tightened, the sleeve increases in volume, thereby ensuring strong fixation at the base.

- Threaded screw - fits into the sleeve and provides fastening. The head configuration allows the use of power tools for installation.

- A cone-shaped nut is screwed onto a screw. When tightened, it moves towards the head, causing the bushing to wedge until it is firmly secured. The tabs should fit into the grooves to maximize the expansion of the bushing.

If you need to attach to a hollow base, then classic fasteners will not work. To do this, an improved modification of the anchor is used, with which it can be mounted both on a monolithic and with cavities base. Its design and installation principle differs from the standard product.

The main elements of hardware are:

- Steel bushing with slots at the bottom offset from the end. This is similar to a butterfly dowel in which the ridges move apart to secure the fastener into the hollow material.

- The stud has an extended threaded part so that the mount can be installed and secured as firmly as possible.

- A flat nut, since its task is not to wedge, but to tighten the sleeve.

An anchor dowel is a lightweight version of a bolt. The configuration of the head allows it to be screwed flush with the base, without protrusions above the surface. When the screw is screwed in, the sleeve wedges and a strong connection is formed.

Feasibility of application

Chemical injection compositions and ampoules are expensive, their purchase is advisable when working with hollow and porous types of concrete; in dense structures they are justified when installed near the edge or in the case of increased expected loads: tensile, vibration, weight. Anchors of this type can withstand the weight of steel elements, consoles, columns, facade systems, equipment, fences, and, if necessary, they are used for additional fastening of reinforcing bars. When choosing this option, the quality of the base material has virtually no effect on the reliability of the fixation; the products of Hilti, Fischer and their analogues are designed for use in concrete with cracks.

They are also advised to buy:

- In the absence of an accurate calculation of the hole size.

- At high seismic and vibration loads on the object.

- If necessary, violation of the recommended intervals: placement along the edge of the structure or next to an adjacent anchor. Unlike standard dowels for concrete, they do not have a thrust force.

- For use in conditions of high humidity (the chemical composition reliably protects metal fasteners for concrete from corrosion).

- For installation in fire protection systems, the fire resistance of specialized types reaches 2 hours.

Features of application

To install a mechanical sleeve in aerated concrete, you must follow the following rules:

- The drilled hole is cleaned of dust for better fixation.

- The depth of the hole must be greater than the fastener. The spacer will open properly if part of the screw remains outside.

When installing chemical anchors for aerated concrete, the prepared hole is filled ¾ with glue, otherwise it will come out when the steel rod is inserted. If you do not first clean the hole from dust and debris, the adhesive will not work. The hardening time of the glue depends on its composition, temperature and humidity of the environment and ranges from 2-15 minutes to 12-24 hours.