Aerated concrete surfaces have a cellular type of structure; for this reason, fasteners for aerated concrete blocks must be selected with special attention. With the help of such devices, heavy elements are installed on the walls and the gas block is fastened to the wall. The following types of fasteners are available for sale: dowel (nylon or frame), anchor (chemical and mechanical), self-tapping screw. Before choosing the right fasteners, you need to know the density and strength of gas silicate blocks.

When choosing fastenings for aerated concrete walls, take into account such features

- The density characteristics of aerated concrete products are indicated by numbers. And the higher the indicator, the fewer cells the material has, and accordingly the strength will increase. The load limits up to the breaking out of the fastener will depend on these data, as indicated by the manufacturer's instructions written on the packaging.

- Dimensions of fasteners - length, diameter. For heavy loads, it is recommended to choose larger fastener parameters. Load-bearing capacities are indicated on packaging or in quality certificates.

- The material must be resistant to corrosion. These parameters are especially important during installation work carried out on load-bearing walls outside or in rooms without heating. In this case, steel hardware should be coated with a protective agent.

Making holes in the base with impact instruments is strictly not recommended. This incorrect installation technique will make the fastening system ineffective. The best tools for making holes are a brace, a hand drill equipped with a special punch.

Why you shouldn’t attach excessively heavy structures to gas block and foam block

About the gas block

Autoclaved aerated concrete has thermal conductivity characteristics close to foam plastic because, like insulation, it contains air bubbles in its structure. At the same time, foam plastic has almost zero load-bearing capacity.

Why should a gas block be so much more durable? It should be noted that it copes well with a load evenly distributed over an area, for example, in wall masonry. But it does not tolerate local loads from ordinary dowels and anchors, that is, it simply does not hold

And no matter what the manufacturers of such blocks say, you need to load the material locally with great care - use special fasteners, spread them over a large area, do not hang very heavy structures without a metal frame

Excessive load on aerated concrete can lead to similar consequences

The weakest point of an aerated block in terms of load-bearing capacity is variable pressure. Periodically attaching and removing any heavy structure from an anchor will contribute to the crumbling of the material around the fastener and failure of the attachment point.

About the foam block

Foam concrete is used less frequently in modern construction, and on average it is heavier and stronger than aerated concrete. Of course, strength depends on the class of the material - the higher the class, the more durable it is, but at the same time it loses somewhat in its heat-insulating properties.

Perhaps we can say that the foam block is somewhere between concrete and aerated concrete in terms of strength. However, when choosing an anchor for foam concrete, it is better to be guided by the same principles that apply when using aerated concrete.

Types of fasteners and performance of work

As a composition for filling holes for chemical anchors or dowels, products based on the following types of resins are used:

- epoxy;

- epoxy acrylate;

- polyester;

- vinylester.

When choosing the type of base, the quality of the adhesive composition will be determined by many factors and operating conditions of the fastener. An anchor, working on a mechanical principle, is a rigid metal rod that is driven or screwed into a structure, the surface layer where it is necessary to secure a structure intended for a specific object. The load will be distributed evenly throughout the fastener.

Chemical anchor

This type of fastening, such as a chemical anchor, is a fairly new and already in demand method. The builders appreciated it. Chemical anchoring has its advantages and disadvantages. The advantages of a chemical anchor include:

- high load capacity factor on fasteners;

- compliance with GOST, the chemical composition is safe and environmentally friendly;

- versatility, it is used for any building material;

- high resistance to weather fluctuations and low temperatures;

- low price when compared with steel anchors.

The disadvantages include:

- strict adherence to technology;

- purchase of special equipment, namely brushes, pumps, guns and drills;

- additional time for the chemical solution to harden.

Chemical fasteners for foam concrete include a threaded steel pin, maybe a special rod, a chemical mixture, and additional bushings.

Chemical anchor fastening sequence

- Use a drill to make a cylindrical hole. Then it needs to be shaped into a cone with an expansion in depth.

- The finished hole is thoroughly cleaned. You can use a pump for this.

- A centering sleeve is inserted into the base.

- A chemical solution is poured into the hole through the sleeve; a construction gun is used for this.

- The threaded rod (stud) is screwed in.

- Leave time until the chemical solution hardens completely.

The chemical anchor kit includes an easy-to-use package with a dispenser. Installation is easy, while achieving high structural strength.

Fastening chemical anchors

And so, for fastening light structures and decorative elements, ordinary self-tapping screws are quite suitable. They can be designed for working on wood or on cellular concrete. Nails for aerated concrete should have a wedge shape or a curved tip inside the concrete cavity.

For heavy structures, such as plumbing fixtures, kitchen cabinets, boilers, it is worth using foam concrete fasteners with wedging dowels. Reliable fixation is achieved precisely thanks to the internal stop. All hardware must be resistant to corrosion. This especially applies to mountings on an external wall.

Dowel

Fastening for aerated concrete blocks made of dowels is used for all types of concrete products. Traditional types of fasteners for aerated concrete walls:

- A dowel-nail made of steel enters the sleeve, while the part at the base opens and cuts into the structure of the material at a certain angle.

- The facade universal dowel is used when fastening a profile to an aerated concrete surface. For further installation of panels for the facade. The elements also allow you to hang wall cabinets and shelves.

- The nylon universal spacer dowel is used for attaching light shelves, curtains, baseboards, switches, and cable boxes.

- The frame dowel is installed when installing window and door frames and hanging furniture elements.

- A nylon dowel for a gas block is used with conventional self-tapping screws when installing facade subsystems made of wood and metal, windows, doors, suspended ceilings, pipelines and plumbing fixtures.

- Metal dowels with zinc coating are designed for a wide range of applications when working with any cellular concrete. They can also be used for attaching a gas block to a wall.

- A steel anchor for aerated concrete blocks will help solve such problems as fastening heavy objects - a boiler, an air conditioner, a hanging pipe, massive hanging furniture.

When the screws are screwed in, dowels made of galvanized steel move the segments apart, which allows the product to be securely fixed in the cellular material.

How to use?

The principle of installation of dowels is the same as for other types of fasteners. You need to act in the following order:

- first you need to prepare holes for the dowel, which should be smaller than the diameter of the fastening; for example, for 8 mm fasteners you will need to use a 7 mm drill;

- if you take a tool such as a hammer drill, then you need to turn off the impact mode; of course, it is advisable to use a drill, since it is more effective;

- the plastic fastener must be carefully screwed in using a screwdriver; if metal parts are used, then they should be driven into the mounting hole with a hammer;

- When performing work, you must ensure that the products do not touch or are positioned crookedly;

- when the cuff is installed all the way, you can proceed to screwing a self-tapping screw or a universal-type bolt;

- It is necessary to screw in the self-tapping screw using a screwdriver, adhering to the required depth.

The mounting anchor and installation method will depend on the future load

- when installing suspended shelves in aerated concrete, you must make a hole at an angle of 90 degrees and insert a dowel into which a screw is then screwed;

- If the task is to hang a light picture or install an electrical switch, it will be enough to use an ordinary self-tapping screw. Screwing should be done at an angle of 45 degrees to the partition.

To securely fasten heavy units or install massive metal doors, it is recommended to use chemical anchors. These are special capsules consisting of synthetic resins and organic polymers that can monolith a hole in a partition made of gas blocks and firmly hold a metal rod and threaded part in the structure.

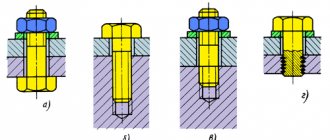

Mechanical anchor

Mechanical anchors for aerated concrete blocks are called “butterflies”, this is explained by the peculiarity of their design. The edges of the fasteners that will be mounted in the holes are split into pieces when the anchor screw is screwed in; as a result, the anchor takes on the shape of a butterfly. With this method, a good fixation is obtained in a pre-drilled hole.

Bolts or threaded rods that are screwed into the spacer part of the anchor can widen the hole in the aerated concrete. To prevent this, an anchor fastener is used, which operates according to a mechanical feature and has an edge that prevents further advancement of the threaded part. Mechanical butterflies are popular for securely fastening objects to walls built from aerated blocks and other building materials with a cellular texture.

Chemical anchor

When it is necessary to fix a heavy element on an aerated concrete surface, chemical anchor bolts are used. The principle of operation of such an adhesive anchor is similar to the principle of a mechanical anchor bolt, the only difference is in the use of glue during installation. This technique allows for highly reliable fixation in porous structures - foam concrete slabs, gas silicate partitions, porous bricks.

Fastening building structures to aerated concrete

On such fragile walls it is necessary to fix not only wires and pipes, but also heavy structures: floors, roofing elements, etc.

In such cases, fixing self-tapping screws into aerated concrete is not a solution; a serious decision is needed. As a rule, it is carried out during the process of laying walls, when a monolithic reinforced concrete armored belt is made at the installation level of such structures. During pouring, studs and other embedded parts are installed into it, onto which the fastening is subsequently carried out.

If for some reason you did not make an armored belt, or did not provide mortgages in it, fastening is carried out only with chemical anchors.

Work order

- Preparatory work - a hole is drilled using a drill.

- The planting recess is cleaned of dust; it is recommended to use a small brush or a medical bulb.

- Installation of a cartridge with a chemical composition. A capsule with adhesive mass is inserted into the hole or the glue is squeezed out of the tube.

- The anchor rod is screwed into the hole.

- It happens that for the adhesive solution to completely harden you will need to wait 48 hours. In addition to the composition of the glue, the duration of hardening is affected by the ambient temperature and other environmental factors.

- After the composition has hardened, install the nut and washer.

Installation of the fastener can be easily done by hand without the involvement of a qualified technician. Depending on the purpose, metal products that have anti-corrosion coatings and polymer agents are used.

Adhesive mixtures based on polystyrene resins also do not contain styrene; they can be used for installation outside and inside.

Glue made on the basis of epoxy resin is a popular means for installing anchor bolts in aerated concrete blocks, class above C20-25. In addition to reinforcing bars, fasteners are common in the following installation areas:

- various elements on the surfaces of walls, beams and road fences, which are made of concrete;

- screens that perform noise insulation functions;

- various technological units.

Scope of application

Chemical anchors in aerated concrete are used less frequently. It is used in cases where it is necessary to provide reliable fastening for massive objects. Mechanical anchors are not capable of supporting, for example, the weight of massive equipment.

Epoxy compounds are used mainly on solid bases. They are used for fastening:

- wall structures;

- beams;

- fences along roads;

- creating noise-insulating screens;

- when installing reinforcement outlets;

- when installing attachments.

This composition can be used:

- in a humid environment;

- under the water;

- both outside the building and for interior work.

Its composition:

- does not create stress in the structure of the porous wall;

- does not contain styrene;

- creates fastenings with smooth reinforcement.

The hardening of the mass depends on the air temperature. The time can last from 7-180 minutes. or 7-48 hours.

Polyester anchors are used to create:

- enclosing structures;

- when installing façade elements;

- for installation of translucent elements;

- during installation of utilities.

Typically, threaded rods are installed along with polyester compounds. The polyester anchor does not contain styrene. Therefore, it can be used on interior and exterior fasteners. The polyester anchor takes from 2 to 30 minutes to set and hardens from 25 to 180 minutes.

The anchor bolt for aerated concrete can be smooth or threaded if a vinylester anchor is used. It is used to create fasteners in wet substrates. It does not create unnecessary stress in the structure of aerated concrete. This adhesive solution is safe because it does not contain harmful substances. It is used for making internal and external fasteners. Does not create stress after installing fasteners in the structure of the aerated concrete block. Hardening is observed after 15 minutes or a day.

Epoxy acrylate anchor composition has become more widely used due to its properties. The period of setting and hardening of the composition is 2-24 and 15-180 minutes, respectively. Epoxy acrylate retains its properties when the temperature drops to -5°C, and also resists fire in case of fire for up to 2 hours. Epoxy acrylate anchor composition is suitable for anchoring floor slabs in aerated concrete houses.

Threaded rods

The kit with a chemical anchor intended for aerated concrete surfaces includes a threaded element, the diameter ranges from 0.5 cm to 3 cm, and the standard length is up to 38 cm.

How can you improve connection reliability? For ease of use of threaded rods, it is recommended to coat their surface with a solution specially designed for this purpose. A mark is placed on the side for the required depth of the bookmark, and the prepared tip design will facilitate more thorough mixing of the adhesive mass.

Characteristic

Aerated concrete is rightfully recognized as one of the most practical and affordable materials. It makes durable and strong houses, as well as reliable outbuildings. However, you need to take into account that this material has a cellular structure, when faced with which you need to take into account many nuances. The main characteristic feature of this material is its fragility and pliability. Porous blocks can be trimmed or cut off the excess part without any extra effort. And we must also not forget that special fasteners are used for such a structure. Traditional fasteners, as a rule, do not adhere well to such foundations, which is why the whole point of their use is lost.

For aerated concrete, special dowels should be used. The design of such parts is a sleeve in the form of a spiral, on the surface of which there are ribs. When screwing in a self-tapping screw, the last elements become wider, so they fit firmly into the loose aerated concrete surface. This simple but effective device can easily withstand impressive loads. With the use of special dowels, home owners have the opportunity to hang heavy decorative objects of any size on the walls.

Modern manufacturers produce these types of dowels in two variations. They differ in design features.

- According to the shape of the fixation ribs. Such fasteners can be equipped with a classic helical spiral or have cone-shaped ribs. The edges of the latter may resemble spiral-like blades.

- By installation method. The dowels are either screwed into the base or driven into it. Screw-in types are considered to be the most reliable. It is recommended to use driven-in fasteners if the aerated concrete floor is planned to be equipped with a collet.

Feasibility of application

Chemical injection compositions and ampoules are expensive, their purchase is advisable when working with hollow and porous types of concrete; in dense structures they are justified when installed near the edge or in the case of increased expected loads: tensile, vibration, weight. Anchors of this type can withstand the weight of steel elements, consoles, columns, facade systems, equipment, fences, and, if necessary, they are used for additional fastening of reinforcing bars. When choosing this option, the quality of the base material has virtually no effect on the reliability of the fixation; the products of Hilti, Fischer and their analogues are designed for use in concrete with cracks.

They are also advised to buy:

- In the absence of an accurate calculation of the hole size.

- At high seismic and vibration loads on the object.

- If necessary, violation of the recommended intervals: placement along the edge of the structure or next to an adjacent anchor. Unlike standard dowels for concrete, they do not have a thrust force.

- For use in conditions of high humidity (the chemical composition reliably protects metal fasteners for concrete from corrosion).

- For installation in fire protection systems, the fire resistance of specialized types reaches 2 hours.