METALS, substances consisting of atoms that easily give up electrons in the chemical process. reactions, and having characteristic properties - high electrical and thermal conductivity, plasticity, positive temperature coefficient. electric resistance, the ability to reflect light well, etc. M. include both M. itself (simple substances) and their alloys and intermetallic materials. compounds (intermetallic compounds), which differ from ordinary M. in a more complex crystalline. structure. In metallic state can be heavily doped semiconductors, as well as substances consisting of non-metal atoms, for example. polymer crystal $\ce{(SN)}_x$. Metallic Some chemicals also have properties. compounds (for example, crystals of oxides like $\ce{MoO_2, WO_2,}$ chalcogenides $\ce{NbSe_2, TaS_2}$), crystals containing organic. complexes (see Organic conductors), multicomponent materials with a perovskite structure (for example, $\ce{YBa_2Cu_3O_7}$) or with a layered structure (for example, $\ce{Bi_2Sr_2CaCu_2O_8}$), which are high-temperature superconductors.

In nature, M. exist in chemical composition. compounds – oxides, sulfides, etc., forming ores; $\ce{Au, Ag, Pt, Cu}$, etc. are also found in the native state.

Under normal conditions, M. are crystalline solids. structure (in the vapor state - mainly monatomic gases). The melting point of M is above 300 K (except for mercury, its melting point is –38.83 °C). Max. Tungsten has a melting point (approx. 3420 °C). When melting, M. retains its metallic properties. properties (see Liquid metals). Amorphous solid metals have been artificially created (see Amorphous metals, Metallic glass).

Most simple metals crystallize in body-centered cubic, face-centered cubic, and hexagonal close-packed lattices (see Metal crystals). Among other lattices is tetragonal with 1–2 atoms in a unit cell (for example, In). Only a small number of M. have a more complex structure, for example. low-temperature modification of Mn, in the unit cell of which there are 58 atoms. Mn. M., depending on the temperature and pressure, can exist in different forms. crystalline modifications. Some substances, depending on the crystalline structures can be M., dielectrics, semiconductors or semimetals, e.g. Sn (white tin with a tetragonal structure - M., gray tin with a cubic diamond structure - semiconductor), C (graphite - semimetal, diamond - dielectric) (see Polymorphism).

Metals and alloys usually consist of a large number of small crystals (grains) that are indistinguishable to the naked eye. The grains can have a round or elongated shape, be large or small, and be located relative to each other in a certain order or randomly. The shape, size and relative position, as well as the orientation of the grains depend on the conditions of their formation.

Historical reference

The term "M." came from the Greek. the words μέταλλον (from μεταλλεύω - to dig, extract from the ground), which originally meant “mines, mines” (in this meaning it is found in Herodotus in the 5th century BC). Plato called what was mined in the mines μεταλλεία. In ancient times and in the Middle Ages, it was believed that there were only 7 metals: gold, silver, iron, mercury, tin, copper, lead. According to alchemy. According to ideas, metals originated in the bowels of the earth under the influence of the “rays” of the planets and gradually improved, turning into gold (see Alchemy). Alchemists believed that metallic substances are complex substances, consisting of the “beginning of metallicity” (mercury) and the “beginning of flammability” (sulfur). In the beginning. 18th century The hypothesis has become widespread that base metals consist of ash (“scale”) and the “beginning of flammability”—phlogiston. M.V. Lomonosov counted 6 M. ($\ce{Au, Ag, Cu, Sn, Fe, Pb}$) and defined M. as “a light body that can be forged.” In the end 18th century A. Lavoisier refuted the phlogiston hypothesis. In a manual on chemistry (1789) he gave a list of simple substances, 17 of which he classified as M. ($\ce{Sb, Ag, As, Bi, Co, Cu, Sn, Fe, Mn, Hg, Mo, Ni, Au , Pt, Pb, W, Zn}$). With the development of chemical methods. research, the number of known M. increased. In the 1st half. 19th century satellites of Pt were discovered, some alkaline and alkaline earth minerals were obtained by electrolysis, and the separation of rare earth minerals began, with chemical previously unknown metals were discovered in the analysis of minerals. In 1860–63 $\ce{Cs, Rb, Tl, In}$ were discovered by spectral analysis. In the end 19 – beginning 20th centuries the existence of magnetism, predicted by D.I. Mendeleev on the basis of his periodic data, was confirmed. law. Discovery of radioactivity at the end. 19th century entailed the search for natural radioactive metals. Beginning in the 1930s–1940s. By the method of nuclear transformations, radioactive metals, in particular transuranium elements, were artificially obtained.

The widespread use of M. has led to the fact that their main. physical properties were studied back in the 19th century. Microscopic M.'s theory began to develop in the 20th century. In 1900, P. Drude proposed a model of magnetism in which electrical conductivity is carried out by a flow of electron gas filling the gaps between atoms. H. Lorentz developed Drude's idea by applying kinetic theory to electron gas. theory of gases. However, built on the application of classical laws. mechanics and statistics, the Drude-Lorentz theory could not explain some experiments. data. In 1927–28, W. Pauli and A. Sommerfeld eliminated a number of shortcomings of the Drude theory, suggesting that the main. Part of the electron gas in magnetism at normal temperatures is in a degenerate state; These works formed the basis of modern electronic theory of metals.

In 1929–30, F. Bloch and L. Brillouin examined the influence of periodicity. crystal fields lattices onto electron gas, which led to the creation of the band theory of solids. The application of the theory of exchange interaction to electrons in magnetism (W. Heisenberg, P. Dirac, 1928) made it possible to understand the nature of ferromagnetism and to discover new magnetically ordered states of magnetism—antiferromagnetism (L. Neel, 1932) and ferrimagnetism. In 1911, H. Kamerlingh Onnes discovered the phenomenon of superconductivity. The study of the interaction of electrons with each other and with the lattice made it possible to reveal the nature of this phenomenon (J. Bardeen, L. Cooper, J. Schrieffer, 1956). The study of normal, superconducting and magnetically ordered materials is three main. directions of modern microscopic theory of metals.

Do absolutely pure metals exist? - Metalist's Handbook

Material from Dwarf Fortress Wiki

A useful production diagram for obtaining various metals and alloys from ores.

Metal

is a material obtained by smelting ore in a smelter, which turns that ore into pure metal ingots (one special metal is smelted into plates instead of ingots).

Some metals can be combined with others to make alloys

with better features or greater value.

Metals are used by dwarves to forge weapons, armor, furniture, and crafts at the forge.

Smelting ore into ingots increases the base value from 3 to 5. The base value is multiplied by the material value to obtain the final ingot value.

Alloys[edit]

There are 11 pure metals in Dwarf Fortress (plus a twelfth special metal). Combining their ingots or source ores additionally gives 14 more types of alloys.

Some alloys are more valuable than their starting components, and some are crafted specifically to enhance the stats of future weapons or armor, although many alloys provide neither stat increases nor wealth increases (alloy value changes are listed in the appropriate column in the table below).

The main reasons for using alloys:

- increasing the combat characteristics of weapons and armor;

- increasing the value and saving of rare components (for example, using silver-containing ore instead of pure silver);

- obtaining materials of a different color (for example, rose gold has a purple tint) for furniture, decorating rooms, marking levers or creating mosaics on the floor.

- saving fuel, for example, when smelting bronze: during one production step, a unit of fuel is consumed in the smelter, and the output is the number of ingots according to the number of components used.

The number of new alloy ingots is always equal to the number of used component ingots; at the same time, when smelting metal, four ingots are obtained from each unit of ore.

The full production chain can be found in the article on smelting.

Pure metals[edit]

Metal Name Color Tile Ore or Reaction Used Density Melting Point Material Value Value Change Notes

| Aluminum | ≡‼7:7:1 | Native aluminum | 2.70 | 11188°U | 40 | +0 | |

| Bismuth | ≡‼5:5:1 | Bismuthinite | 9.78 | 10488°U | 2 | +1 | Bismuth bronze production only |

| Copper | ≡‼6:4:0 | Native copper, Malachite, Tetrahedrite | 8.93 | 11952°U | 2 | +0, +0, -1* | Forging any weapons, armor, ammunition and pickaxes |

| Gold | ≡‼6:6:1 | Native gold | 19.32 | 11915°U | 30 | +0 | |

| Iron | ≡‼0:7:1 | Hematite, Limonite, Magnetite | 7.85 | 12768°U | 10 | +2 | Forging any weapon, armor, ammunition, pickaxes and anvils |

| Lead | ≡‼0:7:1 | Galena | 11.34 | 10589°U | 2 | -3* | |

| Nickel | ≡‼7:3:0 | Garnierite | 8.80 | 12619°U | 2 | +0 | |

| Platinum | ≡‼7:7:1 | Native platinum | 21.40 | 13182°U | 40 | +0 | |

| Silver | ≡‼7:7:1 | Native silver, Horn silver,Galena (50%), Tetrahedrite (20%) | 10.49 | 11731°U | 10 | +0, +0,+5*, +7* | Forging edged weapons and ammunition |

| Tin | ≡‼7:3:0 | Cassiterite | 7.28 | 10417°U | 2 | +0 | |

| Zinc | ≡‼7:3:0 | Sphalerite | 7.13 | 10755°U | 2 | +0 |

Special metals[edit]

| This article contains a small spoiler ! You may be better off not reading this information. |

Metal Name Color Tile Ore or Reaction Used Density Melting Point Material Value Value Change Notes

| Adamantine | ≡‼3:3:1 | Raw adamantine | 0.200 | 25000°U | 300 | +50 |

|

| Divine Metal | ≡‼0:0:1 | none | 1 | No | 300 |

|

How to distinguish copper from other metals

For most of us, knowledge about copper and its properties is limited to a school chemistry course, which is quite enough at the everyday level.

However, sometimes there is a need to reliably determine whether a material is a pure element, an alloy, or even a composite material.

The opinion that this information is needed only by those who are engaged in the acceptance or delivery of scrap metal is erroneous: for example, on amateur radio forums, topics are often raised about how to distinguish copper in wires from copper-plated aluminum.

Briefly about element No. 29

Pure copper (Cu) is a golden-pink metal with high ductility, thermal and electrical conductivity. Chemical inertness in an ordinary non-aggressive environment is ensured by a thin oxide film, which gives the metal an intense reddish tint.

The main difference between copper and other metals is color.

. In fact, there are not so many colored metals: only gold, cesium and osmium are similar in appearance, and all elements included in the group of non-ferrous metals (iron, tin, lead, aluminum, zinc, magnesium and nickel) have a gray color with varying intensity of shine.

An absolute guarantee of the chemical composition of any material can be obtained only through spectral analysis. The equipment for carrying it out is very expensive, and even many expert laboratories can only dream of it. However, there are many ways to distinguish copper at home.

with a high degree of probability.

Determination by color

So, we have before us a piece of unknown material that needs to be identified as copper. The emphasis on the term “material” rather than “metal” was made specifically, since recently many composites have appeared that are very similar to metals in appearance and tactile sensations.

First of all, we consider color. It is advisable to do this in daylight or “warm” LED lighting (under “cool” LEDs, the reddish tint changes to yellow-green). It is ideal if there is a copper plate or wire for comparison - in this case, errors in color perception are practically eliminated.

Important: old copper products can be covered with an oxidized layer (a greenish-blue loose coating): in this case, the color of the metal must be looked at in a cut or saw cut.

Determination by magnet

Color matching is a reliable but not sufficient method of identification. The second step of independent experiments will be a test with a magnet. Chemically pure copper is classified as diamagnetic - i.e. to substances that do not respond to magnetic influence.

If the material under study is attracted to a magnet, then it is an alloy in which the content of the main substance is no more than 50%.

However, even if the sample did not react to the magnet, it is too early to rejoice, since often an aluminum base is hidden under the copper coating, which is also not magnetic (this can be eliminated by filing or cutting).

Determination by reaction to flame

Another way to identify copper is to heat a sample over an open fire (gas stove, lighter or regular match). When heated, copper wire will first lose its shine and then turn black-brown, covered with oxide. This method can also be used to cut off composite materials that, when heated, begin to smoke and form a gas with a pungent odor.

Determination through chemical experiments

The reaction with concentrated nitric acid is indicative: if the latter is dropped onto the surface of a copper product, a green-blue color will occur.

A qualitative reaction to copper is dissolution in hydrochloric acid followed by exposure to ammonia. If a copper sample is left in an HCl solution until completely or partially dissolved, and then ordinary pharmaceutical ammonia is dropped into it, the solution will turn intensely blue.

Important: working with chemicals requires precautions. Independent experiments should be carried out in a well-ventilated area using personal protective equipment (rubber gloves, apron, goggles).

How to distinguish between copper and its alloys?

Copper alloys are widely used in industry.

Over many years of research, it has been possible to obtain many materials with unique properties: high ductility, electrical conductivity, chemical resistance, strength (all depends on alloying additives).

The most common are bronze (with the addition of tin, aluminum, silicon, manganese, lead and beryllium), brass (with the addition of 10-45% zinc), as well as copper-nickel alloys (nickel silver, cupronickel, copel, manganin).

Chemical properties and methods of preparation

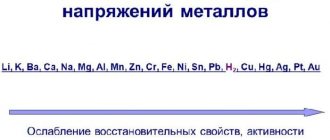

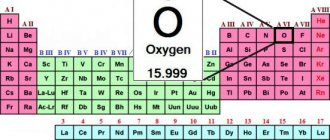

In long form periodic. chemical systems elements the border between elements-M. and non-metal elements is drawn diagonally from B to At: M. are located to the left of this line (M. include about 90 known chemical elements, more precisely, all elements except $\ce{H, B, C, Si, N, P, As, O, S, Se, Te,}$ halogens and noble gases). Based on the structure of the atom, molecules are divided into intransitive and transitional; Among the intransitive metals, alkaline and alkaline earth metals are distinguished; among the transition metals, $d$- and $f$-metals are distinguished, as well as rare earth, platinum, transuranium, and other metals (see article Chemical elements).

Metal atoms are characterized by lower ionization energies than nonmetal atoms. Periodicity is clearly expressed in the change in the ionization energy values of metal atoms with an increase in their atomic number: in general, with an increase in the atomic number within a department. period, the ionization energies of metals increase with an increase in the serial number within the range. groups are decreasing; deviations from this trend are due to the structure of the electronic shells of atoms (for more details, see the article. Periodic table of chemical elements).

The weak connection of valence electrons with the nucleus of an atom is explained by many. properties of M., manifested in chemical. processes: the formation of positively charged ions (cations), the formation of basic oxides and hydroxides with basic properties (bases), the replacement of hydrogen in acids, etc. In chemical. in reactions, metals act as electron donors (reducing agents); in chemical crystals compounds with other elements, as well as in aqueous solutions of compounds form mainly. elementary cations (in solutions - aquacations). M. can be part of complex anions, for example. permanganate anion $\ce{MnO_4^-}$, including complex ones, for example. acidocomplex $\ce{[Fe(CN)_6]^{4–}}$. In complex ions and polar molecules, metal atoms are centers of positive charge. The ability to form negatively charged elementary ions is uncharacteristic of M. (nevertheless, formally negative oxidation states of M. are found in a number of complex compounds).

The most common chemical a reaction characteristic of all M. is oxidation. M.'s ability to oxidize varies over a very wide range. Mn. M. are oxidized by atmospheric oxygen already at room temperature, but the rate and mechanism of the reaction very much depend on the nature of the M. Most M., when interacting with oxygen, form oxides, alkaline (except for $\ce{Li}$) and alkaline earth M. - also peroxides and superoxides. Oxidation leads to the formation of an oxide film on the surface of compact metal. Such films, as a rule, have a loose structure, and their formation does not protect metal from further oxidation. Very dense films that protect metal from further oxidation are characteristic, for example, of $\ce{Al, Ti, Cr,}$, which are stable in air, although they have a high chemical activity. Alkaline metals are extremely unstable in air. A number of metals (for example, $\ce{Li}$) react with nitrogen at room temperature, other metals (for example, $\ce{Mg, Zr, Hf, Ti} $) – when heated; In this case, nitrides are formed. Mn. Metals actively interact with hydrogen (hydrides are formed), halogens (halogenides), sulfur (sulfides), phosphorus (phosphides), and other nonmetals. The most active metals react with carbon, forming carbides and acetylenides. As a result of metallation of organic. molecules form organometallic compounds. When metals are fused with each other, they form solid solutions or intermetallic compounds.

M., having a variable valency (for example, $\ce{Cr, Mn, Fe}$), in compounds corresponding to lower oxidation states ($\ce{Cr^{2+}, Mn^{2+}, Fe ^{2+}}$), show recovery. properties; in higher oxidation states, the same M. ($\ce{Cr^{6+}, Mn^{7+}, Fe^{3+}}$) exhibit oxidation. properties. For aqueous solutions and electrolyte solutions, oxidation-reduction. M.'s properties are expressed using electrochemical. a number of voltages (see article Electrode potential). M., for which standard electrode potentials are less than –0.413 V, are oxidized by water with the release of $\ce{H_2}$ (alkaline and alkaline earth M. react with water at room temperature; M. such as $\ce{ Zn}$ or $\ce{Fe}$, react with water vapor at high temperatures). M. interact with alkali solutions to form soluble anionic hydroxo complexes ($\ce{Be, Zn, Al, Ga, Sn}$). Most microorganisms are oxidized by one or another acid. M., standing in electrochemical. a number of voltages to hydrogen, are oxidized by $\ce{H^+}$ ions and therefore dissolve under the action of non-oxidizing acids ($\ce{HCl}$ or dilute $\ce{H_2SO_4}$), but only if no insoluble products are formed; the reaction is facilitated by the formation of anionic complexes. Nitric acid, even diluted, oxidizes many metals. Moreover, if metal ions are stable in lower oxidation states, cationic complexes are formed, while in higher states, as in the case of, for example, $\ce{Re}$, anionic complexes ($ \ce{ReO_4^-}$). Some metals react with dilute $\ce{HNO_3}$ and $\ce{H_2SO_4}$ to form cationic complexes and are passivated into concentrated compounds. solutions of these acids. For dissolving low-active M., for example. $\ce{Au}$ or $\ce{Pt}$, use mixtures containing an oxidizing agent and a ligand donor necessary for the formation of soluble complexes (for example, mixtures of $\ce{HNO_3}$ with $\ce{HCl}$ or $\ce{HNO_3}$ with $\ce{HF}$).

An important characteristic of metals is their ability to form basic oxides and corresponding hydroxides, as well as salts—products of the substitution of a metal ion for a proton in acids. Using metal hydroxides as an example, one can trace the patterns of changes in the properties of compounds depending on changes in metallicity. nature of the element; in particular, the most typical alkaline compounds form the strongest bases (see Art. Alkalis). On the interaction of microns with the environment, leading to their destruction, see Art. Corrosion.

To obtain M. practical. have several meanings. basic methods: reduction of metal oxides with carbon or hydrogen; reduction of metal oxides by other metals (metallothermy); reduction of metal halides or sulfides with hydrogen or metals; thermal decomposition of suitable M compounds (for example, carbonyls); electrochemical methods. Since achieving the required performance characteristics are hampered by the presence of impurities in M., various types are used. metal purification methods (zone melting, extraction methods, etc.).

More information about the properties, methods of obtaining and purifying metal can be found in articles devoted to the department. M. or their groups. See also Metallurgy, Metallurgy.

Casting molds

The most ancient type of molds are those made from sand-clay molding mixture, or “earth.” Historically, centers of metallurgy arose near the deposits of sands that were ready in their composition for casting, for example, near the world famous Kasli iron plant. Mixtures are divided into coating and filling mixtures.

molds made from sand-clay molding mixture

To construct any matrix, a model is required - a life-size mock-up of the future product, but somewhat larger in size - equal to the amount of casting shrinkage.

The model is placed in the center of the formwork, or flask, and a layer of coating mixture is applied to it - heat-resistant and plastic. Then they begin to fill the flask layer by layer, carefully tamping each layer, with the filling mixture. The requirements for filling mixtures are much lower than for coating mixtures - they must withstand the pressure of the poured metal, maintaining the configuration of the casting, and ensure the release of melting gases. Afterwards, the model is removed from the mold and the melt is poured in its place.

For castings of complex configurations, with intricate details and internal cavities, composite models and molds made of several parts are used.

Metal molds

Casting is also carried out in metal molds. They are used for large runs of cast parts, in cases where high dimensional accuracy and low surface roughness of the casting are required, as well as for some metals that are active in a heated state. The melting temperature of the mold material must be significantly higher than the temperature of the melt being cast.

Metallic state

M. can be represented as substances consisting of positive. ions and free electrons (conduction electrons). Electrons compensate for the repulsive forces acting between positively charged ions, and thereby contribute to their binding into a solid or liquid (metallic bond, see article Chemical bond). Conduction electrons determine electrical, magnetic, optical. properties of metals, as well as their thermal conductivity, and at low temperatures - heat capacity. The role of electrons in the compressibility of M. and other mechanical engineering is significant. properties; their presence makes M. plastic. A change in the electronic spectrum sometimes causes phase transitions in M., during which a change in crystalline. the structure is of a secondary nature (for example, a transition from the normal state of M. to the superconducting or from paramagnetic to ferro- or antiferromagnetic).

The most important characteristic of metal. states – the number of conduction electrons $n$ per 1 cm3 (or their number per unit cell of a crystal or per 1 atom). As a rule, of all the electrons in an atom, only the valence ones are collectivized. This makes it possible to chemically properties of the atoms that make up the crystal, and according to its geometric. structure, determine $n=Z/V_0$, where $Z$ is the number of valence electrons, $V_0$ is the volume of the unit cell.

Mn. the properties of M. can be explained by considering that conduction electrons are an ideal degenerate gas of fermions, and the role of ions is reduced to creating a potential well in which electrons move (Drude–Lorentz–Sommerfeld model; see Drude theory, Sommerfeld theory). In this model, the rate of degeneration $T_\text F$ of electron gas is of the order of 104–105 K, i.e., at almost any temperature of the existence of magnetism, the electron gas in it is degenerate (see Degenerate gas).

A more complete explanation of the properties of metal is given by the band theory of a solid body, which considers the movement of parts. electron in periodic field with potential $U{\bf (r)}$ created by crystalline ions. lattice and the remaining electrons (one-electron approximation): $U({\bf r}+a)=U{\bf (r)}$, where ${\bf {r}}$ is the spatial coordinate of the point, $a$ is lattice period (see Bloch electrons).

The periodicity of U(r) allows one to characterize the stationary state of a conduction electron by a quasi-momentum ${\bf p}=ℏ{\bf k}$ ($ℏ$ is Planck’s constant, ${\bf k}$ is a quasi-wave vector), similar to the momentum of a particle in free space. The wave function of an electron in a stationary state is the Schrödinger solution of the electron equation, corresponding to its own. electron energy value $ℰ_s$. Wave function and eigen. the energy value (unlike the case of a free electron) is periodic. quasi-momentum functions. The index $s$ numbering the solutions of the Schrödinger equation is called the zone number, $ℰ_s({\bf p})$ is the electron dispersion law or the electronic spectrum of the crystal corresponding to the field. In every allowed energy. the electron state zone fills the band between $ℰ_\text{min}$ and $ℰ_\text{max}$. Zones may overlap, but their individuality is preserved. Using dispersion laws, you can calculate the density of electronic states in energy. zone.

Rice. 1. Scheme of filling the energy bands of a metal (a), semimetal (b) and dielectric or semiconductor (c). Bold lines limit the filled states ℰ(p), thin lines - empty states, dashed...

The band nature of the spectrum and the Pauli principle make it possible to formulate the fundamental difference between M and a dielectric. Since no more than 2$N$ electrons can “fit” into each zone ($N$ is the number of atoms in the crystal), then, depending on the number of electrons per 1 atom and the relative arrangement of the zones, two cases can occur: or basically state (at T=0 K) there are zones partially filled with electrons (Fig. 1, a, b), or there are only completely filled zones and empty ones (Fig. 1, c). In the first case, the crystal is M (Fig. 1, b corresponds to a semimetal), in the second, it is a dielectric (or semiconductor).

In M., the boundary of filling levels with electrons (Fermi energy $ℰ_F$) falls into the allowed band. Its corresponding isoenergy. surface ℰ({\bf p})=ℰ_F (Fermi surface) separates the region of states occupied by electrons from free states in momentum space.

Rice. 2. Fermi surfaces of tungsten (a) and gadolinium (b).

Fermi surfaces of alkaline metals ($\ce{Li, Na, K, Pb, Cs}$) are almost ideal spheres. This does not mean that the electrons of these molecules are not influenced by ions. Their effective masses differ from the mass of a free electron $m_0$, for example. y $\ce{Na}$ $m=1.24m_0$. All M., except those listed, have Fermi surfaces of a complex shape (Fig. 2).

Some properties of M. (mainly sample in a strong magnetic field) are very sensitive to the shape of the Fermi surface (see De Haas - van Alven effect, Shubnikov - de Haas effect), which made it possible to experimentally determine the Fermi surface of many. M. and intermetallic. connections.

The methods of band theory made it possible to determine the laws of dispersion and to clarify the origin of the separation. characteristic details of the electronic spectrum of M. With all the complexity of the laws of dispersion, the idea of M electrons as light (compared to ions) charged particles is correct at a qualitative level and allows, within the framework of the Drude-Lorentz-Sommerfeld model, to estimate the order of magnitude of the fundamentals. M characteristics - electronic heat capacity, electrical and thermal conductivity, skin layer thickness (see Skin effect), etc. For some compounds ($\ce{CeAl_3, CeCu_6, CeCu_2Si_2, UB_{13}}$, etc. .) unusual properties were discovered (for example, giant electron heat capacity), indicating that they contain electrons with an anomalously large effective mass.

At high pressures, when the volume per atom decreases, the atoms lose their individuality and any substance turns into a highly compressed electron-nuclear plasma, i.e., into a kind of M. Metallization of any substance occurs at a density of $≫20Z^2$ , where $Z$ is the atomic number of the substance. At such densities, most of the properties of matter are determined by the degenerate electron gas.

Main types of classification of metals

There are several types of classification of metals. Let's start with the main type - division into two large groups: black and colored. Ferrous metals are distinguished by a high melting point, density and increased hardness. Non-ferrous metals, in most cases, melt at lower temperatures and have increased electrical and thermal conductivity.

This division is due to the distribution of elements in nature. The extraction of ferrous elements accounts for more than 90 percent of the total mass of mined metals, while the non-ferrous group accounts for no more than 5-10 percent. It should be noted that the types of classification are conditional and are used depending on the purpose of the final product that is produced from these metals. Thus, for the manufacture of fasteners, classification according to technical characteristics is used, and for the manufacture of complex alloys, chemical and crystalline. Let's look at these types in more detail.

Chemical classification of metals

All elements in the periodic table are divided into four main groups, marked with Latin letters:

- S. Marked in pink.

- P. Yellow elements.

- D. Turquoise color.

- F. Green elements in the table.

Each group contains metals. Elements from the first two categories (S and P) are called simple, and elements from groups D and F are called transitional. Also, each group is divided into several more categories. Group S includes alkali and alkali earth metals, while groups D and F include platinum, uranium and rare earth metals. At the same time, there are exceptions in each group, from which we can conclude that the division of metals into chemical groups is conventional and is rarely used in practical areas. This division is interesting only for scientific research, and is practically not applicable in industry and production. For example, the manufacture of fasteners is based on technical aspects, and only to a small extent on chemical ones.

Classification of metals by crystal lattice

All elements have a so-called crystal lattice. An abstract structure that defines the arrangement of atoms and electrons, as well as their attachment to the nucleus. In amorphous materials such as glass, the atoms are arranged randomly and do not have a strict structure. In contrast to metals, which in solid form have a strictly structured lattice, with a clear structure of molecular elements. In total, there are 4 types of crystal lattices, which are easier to present in table form:

These are the most common types of crystal lattices often found in metals. In total, the classification system has 14 configurations, but in metals they are either extremely rare or not found at all. It should also be noted that the correct construction of the lattice is possible only with the natural solidification of the metal, without artificial accelerations. If the cooling process has been accelerated, the shape of the grate will change. In production, this is called hardening, as a result of which not only the molecular structure changes, but also the technical properties.

Also, if the norms for the production of rolled metal are violated, a replacement in the crystal lattice may be observed. This leads to a complete change in the quality of the finished product. To ensure that production conditions are met, standardization standards have been developed to ensure that the finished product strictly corresponds to the technical description of its properties.

Technical classification of metals

The most complete classification system was proposed by Professor Gulyaev, although modern scientists do not agree with some of its aspects, nothing new has been proposed so far. So, ferrous metals are divided into 5 main subgroups:

- Iron metals. This includes manganese, cobalt, nickel, and of course, iron. The most common group in nature, used in alloys as the main component.

- Refractory. Elements with a high melting point. A measure of 1539 degrees Celsius was adopted as a standard.

- Rare earths. Elements that are expensive to mine and process include neodymium, europium, samarium and other metals used as additives to the base alloy. Even with a small percentage of intervention, they are capable of significantly increasing or completely changing the characteristics of the alloy.

- Alkaline. A special group, practically not used in its pure form. Most often used in nuclear energy. These include: lithium, barium, radium and others.

- Uranium. Thorium, uranium, plutonium. They are used exclusively in nuclear energy.

Non-ferrous metals are also divided into several subgroups. There are three of them:

- Lungs. Aluminum, magnesium, beryllium. They have a low specific gravity and are often used in aircraft manufacturing and other areas where a hard, but at the same time lightweight material is needed.

- Low fusible. Metals with the lowest melting point: zinc, tin, lead. They are used both in pure form, as a solder and connecting element, and as alloying additives that increase or change the characteristics of the alloy.

- Noble or precious metals. The rarest elements include: gold, silver, palladium, platinum. They have maximum resistance to corrosion and oxidation, due to which they are widely used in various industrial fields.

Almost all metals from the two groups can be mixed, that is, they can be used to produce alloys with the necessary technical characteristics.

Electrical properties

At room temperature, specific electrical conductivity $σ$ M. is about 10–8–10–6 Ohm–1 m–1; with a decrease in temperature it increases. A characteristic property of M. in a normal (non-superconducting) state is a linear relationship between the current density $j$ and the intensity $E$ of the applied electric current. fields (Ohm's law): $j=σE$.

Current carriers in M. are conduction electrons with energy close to $ℰ_F$. The reason is electrical. resistance - scattering of electrons on any violations of the periodicity of the crystalline. lattices: thermal vibrations of ions (phonons), electrons themselves, as well as various. defects - impurity atoms, vacancies, dislocations, crystal and sample boundaries (see Scattering of charge carriers). The measure of scattering is the mean free path $l$ – cf. distance between two successive collisions of electrons with defects:$$σ=nel/p_\text{F},$$ where $n$ is the concentration of conduction electrons (about 1022–1023 cm–3), $e$ is the electron charge, $ p_\text{F}=2π\hbar (3n/8π)^{1/3}$ – so-called. boundary Fermi impulse. At $T$=300 K, the free path l is about 10–6 cm; As $T$ decreases, the path length increases, reaching (for high-quality single-crystalline samples) 0.1–1 cm. Electricity increases accordingly. conductivity $σ$ and specific electric decreases. resistance $ρ=σ^{–1}$. The ratio of conductivity at $T$=4.2 K to conductivity at $T$=300 K characterizes the perfection and chemistry. purity of metals.

The resistance of the alloys is significantly higher than the resistance of pure M. The reason for this is the violation of the ideality of the crystalline. lattice (different atoms at lattice sites) and the presence of defects. In substances with large $ρ$, localization of electronic states occurs—conductivity disappears (see Anderson localization).

When metal melts, mobile electrons are retained in it, so a large electrical energy is also retained. conductivity, although the destruction of long-range order leads to an abrupt increase in resistance $ρ$. The exception is $\ce{Sb, Ga, Bi,}$ electric. the resistance of which decreases upon melting.

At $T→0$ K, for most M. the electrical energy disappears. resistance - they go into a superconducting state.

Iron, steel and other metals

Iron and steel are the most important metals. Steel is obtained from iron. It is used to make many items, from oil rigs to paper clips.

Along with 80 pure metals, people know many alloys - mixtures of metals, the qualities of which differ from the qualities of pure metals. Tower cranes, bridges, and other structures are made of steel containing up to 0.2% carbon.

Carbon makes steel stronger while still being malleable. The steel is coated with paint to protect it from corrosion.

Iron and steel

Iron is an element. It is extracted from ore - a compound of iron and oxygen. Most of the mined iron is used to make steel, an alloy of iron and carbon. The most common iron ores are magnetite (top) and hematite (bottom). Iron is extracted from ore in blast furnaces.

This process is called smelting. In the furnace, very hot air is blown through a layer of iron ore, limestone and coke. Coke is almost pure carbon and is produced by heating coal.

The carbon in the coke combines with oxygen to form carbon monoxide, which then "sucks" the oxygen out of the ore, leaving behind pure iron, to form carbon dioxide. This is an example of reduction reactions. Ore, coke and limestone enter the furnace. Limestone reacts with impurities in the ore to form slag.

Inside the furnace, hot air reacts with carbon. Carbon monoxide is formed. In this case, the temperature in the furnace rises to 2000°C. The carbon monoxide then reacts with the oxygen in the ore, reducing it to iron. Molten slag flows out from the bottom of the furnace. It is used in road construction.

At the end, the molten iron is brought out. A blast furnace operates continuously for 10 years until its walls begin to collapse. The height of the blast furnace is 30 meters, the thickness of its walls is 3 meters.

Iron obtained from ore contains carbon (about 4%) and other impurities, in particular sulfur. Impurities make iron brittle, so most of it is processed into steel. This removes impurities from the iron. Steel paper clips contain about 0.08% carbon.

Tools are made from steel containing chromium, vanadium and up to 1% carbon. Steel is produced by exposing molten iron to oxygen. Often a small amount of scrap steel is added to the iron. Oxygen reacts with the carbon contained in the iron to form carbon monoxide, which is used as fuel.

After cleaning, no more than 0.04% carbon remains in the steel;

its quantity depends on the grade of steel. Steel is also produced by melting scrap steel in an electric arc furnace. To make steel, molten iron and scrap steel are poured into a furnace called a converter .

Almost pure oxygen is pumped into the converter under high pressure. When it reacts with carbon, carbon monoxide is obtained (see also the article “Chemical reactions”). Another way to obtain steel is by melting scrap steel in an electric arc furnace. Powerful electric current (see

article “Electricity“) melts scrap. Molten slag flows out from the bottom of the furnace. It is used in road construction.

Alloys

An alloy is a mixture of two or more metals or a metal and another substance. So, brass is an alloy of copper and zinc. Brass is stronger than copper, easy to machine, and does not corrode. In pure metals, atoms are “packed” in close rows (Fig.

left). The rows can slide relative to each other, which makes the metal soft. When there are sudden shifts in the rows, the metal breaks. In the alloy, other atoms strengthen the metal (see figure on the right), because shifting rows is no longer possible. Therefore, alloys are stronger than pure metals.

Many metals themselves are too soft to be used, but their alloys can withstand high pressure and high temperatures (see the article "Heat and Temperature"). Steel is an alloy of iron and carbon, a non-metal.

By adding small amounts of other metals, varieties of steel can be obtained. Knives and forks are made of stainless steel - an alloy of steel, chromium and nickel. Alloys of steel and manganese are extremely strong and are used industrially to make cutting tools.

Aluminum-magnesium alloys are light, strong and non-corrosive. Bicycles and airplanes are made from them (see the article “Flight”).

The most important metals and alloys

Aluminum . A very light silver-white metal that does not corrode. It is obtained from bauxite by electrolysis. Aluminum is used to make electrical wires, airplanes, ships (see the article “Buoyancy”), cars, beverage cans, and foil for cooking. Aluminum beverage cans are very lightweight and durable.

Brass . Malleable alloy of copper and zinc. Jewelry, ornaments, musical instruments, screws, and buttons for clothes are made from brass.

Bronze . A malleable, corrosion-resistant alloy of copper and tin, known since ancient times.

Calcium . Soft silver-white metal. It is found in limestone and chalk, as well as animal bones and teeth. Calcium in the human body is found in bones and teeth. It is used in the production of cement and high quality steel.

Chrome . Solid gray metal. Used in the production of stainless steel. Chrome is used to coat metal products for protective purposes and to give them a mirror shine.

Copper . Malleable reddish metal. Copper is used to make electrical wires and hot water tanks. Copper is part of brass, bronze, cupronickel.

Cupronickel . Alloy of copper and nickel. Almost all “silver” coins are made from it.

Gold . A soft, inactive bright yellow metal. Used in electronics and jewelry.

Iron . Malleable silvery-white ferromagnet. It is mined mainly from ore in blast furnaces. Used in engineering structures, as well as in the production of steel and alloys. There is iron in our blood too.

Lead . Heavy malleable poisonous bluish-white metal. It is extracted from the mineral galena. Lead is used to make electric batteries, roofs and screens that protect against X-rays.

Magnesium . Lightweight silver-white metal. Burns with a bright white flame. Used for signal lights and fireworks. Part of light alloys. Holiday rockets contain magnesium and other metals.

Mercury . Heavy silvery-white poisonous liquid metal. Used in thermometers, dental amalgam and explosives.

Platinum . Malleable silver-white inactive metal. Used as a catalyst and also in electronics and jewelry production. Platinum does not react. Jewelry is made from it.

Plutonium . Radioactive metal. It is formed in nuclear reactors during the bombardment of uranium and is used in the production of nuclear weapons (see the article “Nuclear energy and radioactivity”).

Potassium . Light silver metal. Very chemically active. Potassium compounds are included in fertilizers.

Silver . Malleable grayish-white metal. Conducts heat and electricity well. It is used to make jewelry and cutlery. It is part of the photographic emulsion (see the article “Photography and Cameras”).

Solder . An alloy of tin and lead. Melts at a relatively low temperature. Used for soldering wires in electronics.

Sodium . A soft, silvery-white, reactive metal. Included in table salt. Used in the production of sodium lamps and in the chemical industry.

Steel . An alloy of iron and carbon. Widely used in industry. Stainless steel, an alloy of steel and chromium, is not subject to corrosion and is used in the aerospace industry (see the article “Rockets and Spacecraft”).

Tin . A soft malleable silvery-white metal. A layer of tin protects the steel from corrosion. Part of alloys such as bronze and solder.

Titan . Durable white malleable metal that does not corrode. Titanium alloys are used to make spacecraft, airplanes, and bicycles.

Tungsten . Hard greyish-white metal. It is used to make filaments of incandescent lamps and parts of electronic devices. Incandescent cutting tools are made from steel with tungsten filament.

Uranus . Silvery-white radioactive metal, source of nuclear energy. Used in the creation of nuclear weapons.

Vanadium . Hard, poisonous white metal. Gives strength to steel alloys. Used as a catalyst in the production of sulfuric acid.

Zinc . Bluish-white metal. It is extracted from zinc blende. Used for galvanizing iron and producing electric batteries. Contains brass.

Thermal properties

The heat capacity of metal is determined by the ionic core (lattice heat capacity $C_\text p$) and the electron gas (electronic heat capacity $C_\text e$). Although the concentration of conduction electrons in metal is high and does not depend on temperature, $C_\text e$ is observed in most metals only at low temperatures (of the order of several $\text K$), since electron gas in metal. degenerate As the temperature decreases, $C_\text p$ decreases in proportion to $T^3$, and $C_\text e$ decreases in proportion to $T$. Conduction electrons also make a contribution linear in $T$ to the coefficient. thermal expansion of metals.

Conduction electrons take part not only in the transfer of electricity. charge, but also in heat transfer. Due to the high mobility of conduction electrons, the thermal conductivity of M is high. Specific electrical conductivity and the electronic part of thermal conductivity M. are related by a relationship called the Wiedemann-Franz law. The thermal conductivity of alloys is lower than the thermal conductivity of pure metals.

In the presence of a temperature gradient in M. an electric current arises. current or potential difference (thermopower). Due to the degeneracy of the electron gas, the coefficients describing thermopower and other thermoelectric. the effects are small, but their study makes it possible to detect the entrainment of electrons by thermal phonons. Interaction of excited in M. acoustic. waves with conduction electrons leads to the emergence of electricity. current or potential difference proportional to the intensity of the phonon flow (see Acoustoelectric effect).

Physical properties

At room temperature and without applying pressure, all substances are solid. But there is gallium, which already at 30 degrees of heat begins to deform and melts in your hands. Characteristics you can note:

- High plasticity. Only manganese, tin and zinc are fragile.

- Can be light or heavy. Compare aluminum with osmium.

- The melting point is very high. There are exceptions, for example, mercury, which is why it is used in classic thermometers.

- Color – gray, silver, bluish. Colored items, such as yellow or red, are rare.

- Increased conductivity of heat and electricity, especially in copper, is why copper wires are popular.

Magnetic properties

Conduction electrons have both paramagnetic (due to the presence of each electron’s own magnetic moment) and diamagnetic (associated with the quantization of electron motion in a plane perpendicular to the magnetic field) properties (see Paramagnetism, Diamagnetism). Ions also contribute to the magnetic susceptibility of M.: in non-transition M., the ions are diamagnetic, in transition ones, as a rule, they are paramagnetic. Due to the degeneracy of the electron gas, the paramagnetic susceptibility $χ$ of the electron gas weakly depends on $T$ (see Pauli paramagnetism). At low temperatures and in strong magnetic fields of strength $H$, the paramagnetic susceptibility $χ$ of a metallic. single crystals oscillate as a function of $1/H$ (de Haas–van Alven effect).

All transition magnets with unfinished $d$- or $f$-electron shells are paramagnetic. Some metals, when the temperature decreases, transform into a magnetically ordered state: ferromagnetic (for example, $\ce{Fe, Co, Ni, Gd}$), antiferromagnetic (for example, $\ce{Ce, Mn}$) or state with a helical magnetic atomic structure (for example, $\ce{Cr}$). In this case, conduction electrons play a significant role in the formation of magnetic structures (see Ferromagnetism, Antiferromagnetism). Most intransition magnets remain paramagnetic or diamagnetic up to $T$=0 K. Magnetic ordering significantly affects all other properties of magnets, in particular electrical properties. properties - in electrical The resistance is contributed by electron scattering on spin waves.

The transition of metal to the superconducting state is accompanied by a change in its magnetic properties: in the superconducting state in weak fields, metal manifests itself as a diamagnetic material in which the magnetic field is zero due to the screening of the external magnetic field by undamped eddy currents (see Meissner effect). In type 1 superconductors ($\ce{Sn, Pb, In}$, etc.) this is true up to fields that destroy superconductivity. In type 2 superconductors ($\ce{Nb_3Sn, NbTi}$, etc.), a magnetic field in a wide range of intensities $H$, without destroying superconductivity, penetrates into the volume of the magnet in the form of vortices, which weakens diamagnetism.

Features of metal casting

Compared to other materials, such as wax or plaster, metal casting differs in several ways. The first of them is the high temperature of transition from solid to liquid state. Wax, plaster and cement harden at room temperature. The melting point of metals is much higher - from 231 °C for tin to 1531 °C for iron. Before you can start casting the metal, it must be melted. And if tin can be melted in a clay bowl on a simple fire made from nearby branches, then to melt copper, not to mention iron, you will need a specially equipped furnace and prepared fuel.

Tin

Lead

Tin and lead - the softest and most fusible metals - can even be cast into wooden dies.

For casting more refractory metals, molds made from a mixture of sand and clay will be required. Some metals, such as titanium, require metal molds for casting.

After pouring, the product needs to cool. Reusable dies are disassembled, disposable molds are destroyed, and the casting is ready for further machining or use.

Galvanomagnetic and thermomagnetic phenomena

If metallic sample through which electricity flows. current is placed in a constant magnetic field, then phenomena arise in it due to the curvature of electron trajectories in a plane perpendicular to ${\bf H}$, which leads to a change in kinetic. coefficients (coefficient of electrical and thermal conductivity, thermoelectric coefficient, etc.) and to a number of new phenomena: Hall effect, magnetoresistance, etc. On the dependence of kinetic. The coefficients of ${\bf H}$ are influenced by the features of the electronic energy. spectrum of M., in particular the topology of the Fermi surface (see Galvanomagnetic phenomena, Thermogalvanomagnetic phenomena). Even a not too strong magnetic field at low temp. pax (about 1 K) can change the kinetics. properties of M., e.g. increase the transverse (relative to the direction of ${\bf H}$) resistance (at $\ce{Bi}$) by tens of thousands of times or almost completely “turn off” the transverse electronic thermal conductivity of the metal.

Electron emission

When M is heated to high temperatures, the emission (“evaporation”) of electrons from the surface of M is observed (see Thermionic emission). The number of electrons escaping from the M. per unit time is proportional to exp$(–W/kT)$, where $W$ is the work function of the electron from the M., $k$ is the Boltzmann constant. The value of $W$ for decomp. M. (and even on different crystalline faces of the same M.) is different and amounts to 2–5 eV; $W$ depends on the surface condition. Differences in $W$ determine the contact potential difference between the diff. M. The emission of electrons from the surface of M. also occurs in strong electric waves. fields (strength of the order of 107 V/cm) as a result of the tunneling passage of electrons through a potential barrier reduced by the field (see Field emission). Tunneling electrons through a small (less than 1 nm) gap is the basis of scanning tunneling microscopy.

Electron emission also occurs under the influence of electromagnetic radiation in the visible and UV ranges - photoelectron emission; when the surface of a metal is bombarded with electrons - secondary electron emission, or with ions - ion-electron emission; when the surface of a metal interacts with plasma - explosive electron emission.

Industrial production

To obtain lithium by industrial methods, consumable raw materials are first prepared - minerals or salt solutions, which are extracted from salt lakes. Regardless of the method of extraction of consumable raw materials, the output is Li2CO3, which will undergo industrial processing.

Methods for obtaining consumable raw materials:

- electrolysis;

- recovery;

- refining.

The choice of an industrial method for producing alkali metal depends on the availability of equipment, the required result, and the type of consumable raw materials.

Refining

Metals in electromagnetic fields

AC electrical a current of frequency $ω$ flows along the surface of the magnet, penetrating into it to the depth of a skin layer of thickness $δ=c\sqrt{2πσω}$, where $c$ is the speed of light (see High-frequency conductivity); for example, for $\ce{Cu}$ $δ≈$ 6·10–6 m at $ω=$ 6·10–8 Hz. When an electromagnetic wave falls on the surface of M., part of the electromagnetic energy is absorbed in the skin layer, and the other part is re-emitted by electrons and reflected from the surface of M. Coefficient. reflections (for $\ce{Cu}≈$ 2·10–5).

When electromagnetic waves, the frequency of which is equal to or a multiple of the cyclotron frequency of conduction electrons, fall on a magnet placed in a strong constant magnetic field, resonance phenomena are observed in the magnet (see Cyclotron resonance). In some M. (eg alkaline) one can observe electron paramagnetic resonance on conduction electrons and spin waves.

M., placed in a sufficiently strong magnetic field at a low temperature, has many. properties characteristic of plasma: various weakly damped waves (helicons, magnetoplasma waves, dopplerons, etc.) can propagate in it (see Plasma of solids).

Basic methods of metal casting

Casting into the ground

Traditional way. A simple or composite model is made from wood or other modeling materials, then a matrix is made from a sand-clay mixture based on the model. Read more about this method in the corresponding article.

Earth casting technology

The model is removed from the mold, its parts are assembled together, and a gating system is created. The form is pricked with thin sharp needles to ensure gas removal. They make a casting, wait for it to cool,

Metal casting

A split mold, called a mold, is made from metal parts. Matrix parts are produced by casting or, if high surface quality and dimensional accuracy are required, by milling. The molds are lubricated with non-stick compounds and filled.

Metal casting

After cooling, the molds are disassembled, the castings are removed and cleaned. The metal matrix can withstand up to 300 operating cycles.

Casting using gasified models

The model is made not of wood or wax, but of a low-melting and gasifying material, mainly polystyrene. The model remains in the mold and evaporates when the metal is poured.

Casting using gasified models

Advantages of the method:

- the model does not need to be extracted from the matrix;

- you can make models of as complex castings as you like; complex and composite molds are not needed;

- The complexity of modeling and molding has been significantly reduced.

Gasification casting is becoming increasingly popular in modern metallurgical industries.

Optical properties

For electromagnetic waves optical. range M. are usually opaque. The characteristic shine is a consequence of the almost complete reflection of light by the surface of M. When light interacts with conduction electrons, M. plays an important role internally. photoelectric effect, i.e. forced (due to the absorption of photons) transitions of electrons from one energy. zones to another. As a rule, it is internal. The photoelectric effect determines the coefficient. absorption of radiation in the visible and UV ranges and changes in conductivity of M. under the influence of light (see Photoconductivity). The higher the frequency of radiation, the less role conduction electrons play in the interaction of radiation with M.: in the UV and X-ray optical ranges. the properties of M. differ little from the properties of dielectrics.

The reflection of plane-polarized light from the surface of M. is accompanied by a rotation of the plane of polarization and the appearance of an elliptical. polarization. This phenomenon is used for technical purposes. purposes and for determining optical constants M. See also Metal optics.

Mechanical properties

M. is characterized by a combination of high plasticity and viscosity with significant strength, hardness, and elasticity. The ratio of these properties can be adjusted using mechanics. and thermal processing of metals, and in alloys - by changing the concentration of components. Elastic deformation of metals and their alloys is in the range of 0.01–1%, plastic deformation is much higher and at room temperature can reach 10–100%.

Resistance of isotropic polycrystalline. M. influence of external mechanical forces are described depending on the type of deformation (tension, shear, volumetric compression) decomp. elastic moduli (Young's modulus $E$, shear modulus $G$ and volumetric compression modulus $K$, respectively), between which there is a linear relationship through the coefficient. Poisson $ν$: $E=3K(1-2ν)$; $E=G[2(1+ν)]$. For most M. $ν$ is in the range of 0.22-0.46. The elastic moduli of metal are determined by interatomic interactions. In a single crystal, the elastic moduli depend on direction, so they form a tensor. The shear modulus $G$ of metal ranges from 0.39 GPa ($\ce{Cs}$) to 224 GPa ($\ce{Os}$), for iron $G=$ 84.1 GPa. As the temperature increases, the elastic moduli decrease monotonically; the change in elastic modulus in the range from 0 K to the melting temperature is approx. 50% of the original value. In the area of elastic behavior in M., internal manifestations are possible. friction.

Plastic M. deformation is carried out relative. shift (sliding) of parallel atomic planes. Theoretically, the resistance of M. plastic. deformation and fracture is 10–1$G$ (simultaneous rupture of all bonds in the sliding plane). Experimentally plastic. deformation and destruction are observed at stresses of 10–4–10–2$G$. This difference is due to the existence of plastic carriers. deformations – dislocations – lines along which bonds break. The movement of dislocations along certain planes in the crystal ensures a shift of one part of the crystal relative to another. The strength and plasticity of metal are determined by the movement and interaction of dislocations with each other and with other defects, impurities and their accumulations, phase boundaries, and inclusions of other phases.

Mechanical characteristics of M. can be changed within a wide thermal range. and mechanical processing, as well as the introduction of impurities (doping). For example, the tensile strength of $\ce{Fe}$ (technical purity) is 0.35 GPa, while high-strength alloy steels (alloys of $\ce{Fe}$ with other metals and with $\ce{C}$ ) have a tensile strength from 1.5 to 4.5 GPa.

Application of metals

In technology mainly M alloys are used. Thus, for example, due to low strength, pure M. are unsuitable as materials for the manufacture of structures, but many. M. alloys simultaneously have high mechanical strength. strength and high ductility and are widely used as structural materials. M. with low internal level friction, which weakly dissipates vibration energy, is used in the manufacture of acoustic materials. music resonators tools. M. and their alloys are used: in electrical engineering as electrical conductors. current (copper, aluminum), and as materials for resistors and electric heating. elements (nichrome, etc.); in tool technology for the manufacture of the working part of tools (mainly tool steels and hard alloys).

Areas of application

Used in making:

- Thermoelectric converters.

- Highly efficient lasers.

- Pyrotechnics. It is used to color fireworks flames red.

- Soldered.

- Metal halide lamps, alkaline batteries.

- Lubricants.

- Glass, coatings for porcelain products.

Main areas of application:

- nuclear energy;

- metallurgy;

- medicine.

Alkali metal perchlorate is used as an oxidizing agent.

Battery