During steel processing in production, various types of equipment and chemicals are used. One of the processing processes is steel carburization. This is a chemical-thermal effect, during which the material heats up and its atomic lattice is rearranged. In addition to this, the metal contains the necessary substances to change its properties.

Steel Cementation

The essence of the cementation process

The meaning of any method of chemical-thermal treatment of metals, which includes steel carburization, is that the product is heated to a high temperature in a special medium (liquid, solid or gaseous). This effect leads to a change in the chemical composition of the metal - the surface of the workpiece is saturated with carbon, ultimately becoming harder and more wear-resistant. What is important is that the core of the processed parts remains viscous.

It is possible to achieve the desired effect after such an impact on the metal only if low-carbon steels containing no more than 0.2% carbon are subjected to processing. In order to carry out cementation, the product is heated to a temperature of 850–950 degrees Celsius, and the composition of the medium is selected so that it releases active carbon when heated.

If carburization is carried out skillfully, it is possible not only to change the chemical composition of a metal product, but also to transform its microstructure and even phase composition. As a result, it is possible to significantly strengthen the surface layer of the part, giving it characteristics similar to those of hardened steel. In order to achieve such results, it is necessary to correctly select the parameters of chemical-thermal treatment of the metal - heating temperature and exposure time of the processed product in a special environment.

Equipment for vacuum carburizing of steel

This technological operation is quite time-consuming, since the process of saturating the surface layer of steel with carbon is very slow (0.1 mm in 60 minutes). Considering the fact that the hardened surface layer for most products must be at least 0.8 mm, it can be calculated that it will be necessary to spend at least 8 hours to perform metal carburization. The main types of media for performing metal carburization (or, as they are correctly called, carburizers) are:

- gaseous media;

- electrolyte solutions;

- pasty media;

- fluidized bed;

- solid media.

The most common are gaseous and solid carburizers.

Dependence of the thickness of the cemented layer on time and processing temperature

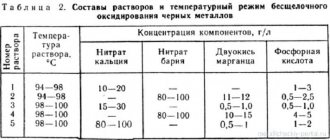

Improving complex nitrogen-carbon saturation - low-temperature carbonitration

The NOC process - low-temperature oxycarbonitriding - was first developed by Russian scientists, and then refined by German researchers and received the name QPQ. Advantages:

- the initial goal is to improve the presentation;

- a sharp decrease in the coefficient of friction;

- the corrosion resistance of grades of pearlitic and austenitic classes processed by the NOK method exceeds that of these materials chromium-plated by galvanic method;

- the cost is 40% lower compared to galvanic coatings.

- carbonitration;

- cooling and holding the oxidation bath in the melt at 350-400°C;

- air cooling;

- washing;

- polishing;

- repeat oxidation;

- flushing

This technology is considered as an effective and economical alternative to galvanic chromium plating for low-alloy pearlitic steels and corrosion-resistant chromium steels.

The carburization process is based on the principle of chemical and thermal treatment of metal . The whole point of the procedure is to saturate the steel surface with the required amount of carbon under certain temperature conditions.

Several years ago, this procedure was almost impossible to implement at home. Today this is possible using graphite media or their analogues. The main thing is desire and some knowledge .

Carrying out carburization of steel in a solid environment

Most often, to carry out carburization of metal in a solid medium, a mixture consisting of sodium carbonate, barium or calcium and birch or oak charcoal (70–90%) is used. Before this, all components of such a mixture are crushed to a fraction of 3–10 mm and sifted, which is necessary to remove too small particles and dust.

After the components of the mixture for chemical-thermal treatment of metal are prepared, they can be mixed in several ways.

- The components of the mixture (salt and coal) are thoroughly mixed in a dry state. If this requirement is neglected, then after the completion of the cementation process, stains may form on the surface of the product.

- The salt is dissolved in water and the resulting solution is poured over the charcoal, after which it is dried until the humidity reaches no more than 7%.

It should be noted that the second method is preferable, as it allows you to obtain a mixture with a more uniform composition.

Charcoal carburizer

Both in industrial and at home conditions, carburization of steel products is carried out in boxes in which a carburizer is poured. To improve the quality of the surface layer of the metal being processed, as well as to reduce the time it takes to warm up the boxes, it is best to manufacture them as close as possible to the dimensions and shapes of the parts.

Optimal conditions for steel carburization can be created by eliminating the leakage of gases formed in the carburizer during the heating process. To do this, the boxes, which must have tight-fitting lids, are carefully coated with refractory clay before being placed in the oven.

Naturally, it is advisable to use specially made boxes only in industrial conditions. For carburizing metal at home, boxes of standard sizes and shapes (square, rectangular, round) are used, selecting them depending on the number of parts to be processed and the internal dimensions of the furnace.

The optimal material for such boxes is heat-resistant steel, but containers made of low-carbon alloys can also be used. The technological process of carburizing metal products is as follows.

Visual representation of the change in structure after cementation

- The parts prepared for processing are placed in boxes, sprinkled with layers of carburizer.

- The filled boxes, coated with refractory clay, are placed in a preheated oven.

- The so-called through heating of the boxes with parts is performed, during which they are heated to a temperature of 700–800 degrees Celsius. The fact that the boxes have warmed up well can be judged by the color of the hearth plate: there should be no dark spots on it in places of contact with the container.

- The temperature in the oven is raised to 900–950 degrees Celsius. It is at these values that steel is carburized.

The high temperature and special environment in which the metal is located contribute to the diffusion of active carbon atoms into the steel crystal lattice. It should be noted that carburizing steel is possible at home, but often does not achieve the desired effect. This is explained by the fact that the carburization process requires long exposure of the part at high temperature. As a rule, this is difficult to achieve at home.

Carbonitration of steel

A popular type of chemical treatment of steel and cast iron of almost any grade is carbonitration, or liquid nitriding. In this case, the surface layer of the workpieces is saturated with carbon and nitrogen in molten salt at a temperature of 560-580°C. Salt compositions are synthesized from ammonocarbon compounds: melamine, melon, dicyandiamide. Carbonitration is similar to cyanidation. But cyanidation is carried out using toxic sodium cyanide at temperatures up to 860°C. Non-toxic compounds are used for carbonitration; it is carried out at temperatures up to 570°.

Read also: Diagram of a gun for polyurethane foam

Advantages of steel carbonitration technology

- Simultaneous saturation with nitrogen and carbon initiates the appearance of carbonitride phases, which are more plastic and less brittle compared to purely nitride phases.

- Carbonitration is the most economical process due to its short duration - 0.5-4 hours.

- Uniformity of heating and diffusion.

- Absence of thermal stresses, ensuring minimal deformations and accuracy of geometric parameters within microns.

- Improving the fatigue strength of products up to 80%, wear resistance, and corrosion resistance.

- Reducing the friction coefficient up to 5 times.

- Lack of fragility of the surface layer saturated with carbonitrides.

- Possibility of processing inexpensive low-carbon steels that cannot be strengthened by traditional nitriding. As a result of carbonitration, they acquire characteristics possessed by more expensive and less easily processed steels.

- This process for ordinary parts is finishing and does not require additional machining. After carbonitration, critical products are subjected to honing - polishing to 1-2 microns.

Combined surface saturation with nitrogen and carbon can be used even for high-alloy and corrosion-resistant steels. On their surface there is a dense film of chromium oxides and other alloying additives, which prevents the process of pure nitriding.

Carbonitration stages

An additional advantage of this technology is the possibility of partially immersing the part in molten salt, which allows strengthening only certain areas.

- Parts with final dimensions arrive for carbonitration. If necessary, leave a minimum allowance on the seating surfaces for polishing.

- Preliminary measures: cleaning, degreasing.

- Furnace heating and carbonitration.

- Cooling in water, oil, air.

- Washing, drying.

Processed in this way:

- cutting tool;

- Press forms;

- friction pairs;

- gear elements;

- pump parts.

An important advantage of this technology is compliance with environmental standards and worker safety, due to the absence of toxic compounds in saturating environments. Carbonitration is used both in large industrial enterprises and in small workshops and at home.

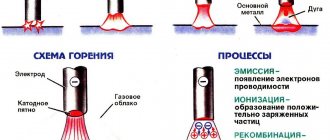

Cementation of parts in a gas environment

The authors of this technology are S. Ilyinsky, N. Minkevich and V. Prosvirin, who, under the leadership of P. Anosov, first used it at the plant in Zlatoust. The essence of this technology is that the metal parts being processed are heated in an environment of carbon-containing gases, which can be of artificial or natural origin. The most commonly used gas is the gas produced during the decomposition of petroleum products. This gas is obtained in the following way:

- a steel container is heated and kerosene is fed into it, which upon evaporation decomposes into a mixture of gases;

- the composition of some part (60%) of the resulting gas is modified (cracking).

The resulting mixture is used to perform chemical-thermal treatment of steel.

Steel carburization process

If steel carburization is carried out using only pyrolysis gas, without adding cracked gas, then the depth of the carburized layer will be insufficient. In addition, in this case, a large layer of soot will settle on the surface of the workpiece, which can take a lot of time and effort to remove.

Furnaces used to perform gas carburization of metal must be hermetically sealed. At modern production enterprises, two main types of such furnaces are used: methodical and stationary. The process of cementation itself in a gas environment is as follows. The parts to be processed are placed in an oven, the temperature of which is adjusted to 950 degrees Celsius. Gas is supplied to the heated furnace and the parts are kept in it for a certain time.

Compared to steel carburization using a solid carburizer, this technology has a number of significant advantages:

- providing better conditions for service personnel;

- high speed of achieving the required effect due to the fact that parts can be kept in a gas environment for a shorter amount of time (in addition, time is not required to prepare a solid carburizer).

Cementing steel at home

Properties of metal after processing

After carburization, the strength of the workpieces used increases. A carburized layer is formed on the surface of the metal. Its hardness in alloy steel does not exceed 58–61 HRC, and in metals with low carbon content – 60–64 HRC. To remove large grains formed after heat treatment, the workpiece is heated again and then tempered.

Additional hardening to correct defects should be carried out at a temperature of 900 degrees. Large grains are crushed due to the formation of perlite and ferrite. When it comes to alloy steel, normalization is carried out as an additional treatment. At the final stage of processing, the workpiece is subjected to low-temperature tempering.

Steel tempering

In what other environments can steel carburization be carried out?

Certain grades of carbon, low-carbon and alloy steels, in particular 15, 20, 20KhGNR, 20Kh, 20Kh2N4A, 18Kh2N4VA, 20G, 12KhN3A, etc., can undergo carburization in other environments.

Electrolytic solution

In such an environment, only small parts can be carburized. This method is based on the anodic effect, due to which the metal surface is saturated with carbon contained in the electrolyte solution. In order for the solution to contain a sufficient amount of active carbon, glycerin, acetone, sucrose and other substances are added to it. Before placing a steel part into the solution, it is heated to a temperature of 450–1050 degrees Celsius (depending on the metal being processed and the size of the part). To heat the solution, an electric current with a voltage of 150–300 V is used.

fluidized bed

Cementation of steel using this technology is carried out in an environment of a hot gas flow formed by the passage of methane and endogas through a layer of heated finely ground (0.05–0.2 mm) corundum.

Paste compositions

To carburize the metal surface using this technology, special pastes are used, consisting of yellow salt, wood dust and soot. Before processing, the part is coated with such a paste and dried, and only then heated to a temperature of 910–1050 degrees Celsius using high-frequency currents.

Regardless of the technology used to carburize the steel, after its completion it is recommended to temper the metal.