- Polymer coatings: types

- Anti-friction coatings as a type of polymer

- Features of polymer coatings

- Application technology

The use of polymer coatings allows you to protect metal surfaces from corrosion, mechanical damage, external, chemical and other influences. They are powdery substances based on various resins and polymers.

Where are polymer metals used?

Areas of application:

- shipbuilding;

- mechanical engineering;

- assembly of various equipment.

Metal structures are made from individual parts that will be installed in water or places with high humidity levels.

Polymer metal in mechanical engineering (Instagram / bazz_linser)

Polyester coatings, application, stability, chemical resistance of polyesters

| Aviation fuel, Gasoline Aviation | Stable | Unstable |

| Automotive gasoline, Gasoline, Auto | Stable | Unstable |

| Nitric acid 0-5%, Nitric Acid 0-5% | Stable | Stable |

| Barium Acetate | Unstable | Unstable |

| Sodium Acetate | Stable | Unstable |

| Lead Acetate | Stable | Max. at t = 160 oF (71.111 oC) |

| White liquor - pulp and paper, White Liquor - Pulp Mill | Stable | Unstable |

| Benzyl alcohol | Unstable | Unstable |

| Benzoic Acid | Stable | Unstable |

| Sodium Benzoate | Stable | Unstable |

| Ammonium Bicarbonate | Stable | Unstable |

| Potassium Bicarbonate, Potassium Bicarbonate | Stable | Unstable |

| Calcium Bisulfate | Stable | Stable |

| Sodium Bisulfate | Stable | Stable |

| Sodium bisulfite, Sodium Bisulfite | Stable | Stable |

| Hydrofluoric acid 10%, Fluoboric Acid 10% | Unstable | Unstable |

| Sodium Bromide | Stable | Stable |

| Hydrobromic acid, Hydrobromic Acid 0-25% | Stable | Unstable |

| Butylene Glycol | Stable | Stable |

| Butyl alcohol, Alcohol - Butyl | Unstable | Unstable |

| Tartaric Acid | Stable | Stable |

| Secondary Butyl Alcohol | Unstable | Unstable |

| Gall oil | Stable | Unstable |

| Hexalene Glycol | Stable | Stable |

| Hexane | Stable | Unstable |

| Heptanes, Heptanes | Stable | Unstable |

| Ammonium Hydroxide 10%, Ammonium Hydroxide 10% | Unstable | Unstable |

| Ammonium Hydroxide 20%, Ammonium Hydroxide 20% | Unstable | Unstable |

| Ammonium Hydroxide 5%, Ammonium Hydroxide 5% | Stable | Unstable |

| Calcium Hydroxide | Stable | Unstable |

| Sodium Hydroxide 0-5%, Sodium Hydroxide 0-5% | Stable | Stable |

| Sodium hydrosulfide | Stable | Unstable |

| Sodium hydrofluoride, Sodium Bifluoride | Stable | Unstable |

| Calcium Hypochlorite | Stable | Unstable |

| Sodium hypochlorite | Stable | Unstable |

| Hypochlorous Acid 0-10%, Hypochlorous Acid 0-10% | Stable | Max. at t = 104 oF (40 oC) |

| Glycolic Acid 70% | Stable | Unstable |

| Glycol-propylene, Glycol - Propylene | Stable | Stable |

| Glyconic acid, Glyconic, Acid | Stable | Unstable |

| Glycerin | Stable | Stable |

| Glucose | Stable | Stable |

| Deionized water | Stable | Stable |

| Demineralized water | Stable | Stable |

| Di-Ammonium Phosphate | Unstable | Unstable |

| Dibutyl Ether | Unstable | Unstable |

| Diesel Fuel | Stable | Unstable |

| Dimenthyl Phthalate | Unstable | Unstable |

| Carbon dioxide (carbon dioxide), Carbon Dioxide | Stable | Stable |

| Chlorine Dioxide/Air | Stable | Unstable |

| Dioctyl Phthalate | Unstable | Unstable |

| Dipropylene Glycol | Stable | Unstable |

| Distilled water | Stable | Stable |

| Sodium Di-Phosphate | Stable | Stable |

| Mercury dichloride, Mercuric Chloride | Stable | Max. at t = 212 oF (100 oC) |

| Sodium Dichromate | Stable | Stable |

| Diethylene Glycol | Stable | Unstable |

| Tannic acid | Stable | Unstable |

| Sodium iron sulfide, Sodium Ferricyanide | Stable | Stable |

| Fatty Acids | Stable | Stable |

| Isopropyl 100%, Alcohol - Isopropyl 100% | Unstable | Unstable |

| Isopropyl alcohol, Alcohol - Isopropyl | Unstable | Unstable |

| Isopropyl Palmitate | Stable | Max. at t = 180 oF (82.222 oC) |

| Potassium Aluminum Sulfate | Stable | Max. at t = 170 oF (76.667 oC) |

| Caprylic acid | Stable | Unstable |

| Barium Carbonate | Stable | Unstable |

| Potassium Carbonate, Potassium Carbonate | Stable | Unstable |

| Magnesium Carbonate | Stable | Max. at t = 160 oF (71.111 oC) |

| Sodium carbonate, Sodium Carbonate 0-25% | Stable | Unstable |

| Calcium Carbonate | Stable | Unstable |

| Alum flour, Aluminum Potassium Sulfate | Stable | Stable |

| Kerosene, Kerosene | Stable | Max. at t = 120 oF (48.889 oC) |

| Coconut oil | Stable | Unstable |

| Fluorosilicic acid 0-20%, Fluosilicic Acid 0-20% | Unstable | Unstable |

| Sodium Xylene Sulfonate | Stable | Unstable |

| Xylene, Xylene | Unstable | Unstable |

| Corn Starch, Corn Starch-Slurry | Stable | Unstable |

| Corn Sugar | Stable | Unstable |

| Corn oil | Stable | Unstable |

| Sodium Lauryl Sulfate | Stable | Stable |

| Citric acid, Citric Acid | Stable | Stable |

| Butyric acid 0-50%, Butyric Acid 0-50% | Stable | Unstable |

| Butyric acid, Oleic Acid | Stable | Stable |

| Mineral Oils | Stable | Max. at t = 180 oF (82.222 oC) |

| Lactic Acid | Stable | Max. at t = 200 oF (93.333 oC) |

| Carbon monoxide (carbon monoxide), Carbon Monoxide | Stable | Stable |

| Sodium Mono-Phosphate | Stable | Stable |

| Monochlorous acid, Chloroacetic Acid 0-50% | Unstable | Unstable |

| Sea water, Water - Sea | Stable | Stable |

| Urea, Urea | Stable | Unstable |

| Formic acid, Formic Acid 10% | Stable | Unstable |

| Soap, Soaps | Stable | Unstable |

| Naphtha | Stable | Stable |

| Naphthalene | Stable | Unstable |

| Crude Oil, Sweet | Stable | Unstable |

| Crude Oil, Sour | Stable | Unstable |

| Unrefined gasoline, Gasoline, Sour | Stable | Unstable |

| Petroleum fuel, Fuel Oil | Stable | Unstable |

| Ammonium Nitrate | Stable | Stable |

| Ferric Nitrate | Stable | Stable |

| Potassium Nitrate, Potassium Nitrate | Stable | Stable |

| Calcium Nitrate | Stable | Stable |

| Magnesium Nitrate | Stable | Max. at t = 160 oF (71.111 oC) |

| Copper Nitrate, Copper Nitrate | Stable | Stable |

| Sodium Nitrate | Stable | Stable |

| Nickel Nitrate | Stable | Stable |

| Silver Nitrate | Stable | Stable |

| Zinc Nitrate | Stable | Stable |

| Octanoic Acid | Stable | Unstable |

| Olive oil | Stable | Stable |

| Sodium orthophosphate, Trisodium Phosphate | Stable | Unstable |

| Phosphorous Pentoxide | Stable | Stable |

| Hydrogen peroxide, Hydrogen Peroxide 35% | Stable | Max. at t = 120 oF (48.889 oC) |

| Potassium Permanganate | Stable | Unstable |

| Ammonium Persulfate | Unstable | Unstable |

| Potassium Persulfate | Stable | Unstable |

| Beer | Stable | Unstable |

| Picric acid (soda alcohol), Picric Acid, Alcoholic | Stable | Stable |

| Pyridine | Unstable | Unstable |

| Sodium pyroboric acid, Sodium Tetraborate | Stable | Stable |

| Polyvinyl alcohol soda.,Polyvinyl Alcohol | Stable | Unstable |

| Polyvinyl Acetate Latex | Stable | Unstable |

| Natural gas, Gas, Natural | Stable | Unstable |

| Vegetable Oils | Stable | Stable |

| Sugar beet and cane syrup, Sugar, Beet and Cane Liquor | Stable | Unstable |

| Sucrose, Sugar, Sucrose | Stable | Stable |

| Fresh water, Water - Fresh | Stable | Stable |

| Sulfuric acid 0-30%, Sulfuric Acid 0-30% | Stable | Stable |

| Sulfuric acid 30-50%, Sulfuric Acid 30-50% | Unstable | Unstable |

| Sulfuric acid 50-70%, Sulfuric Acid 50-70% | Stable | Max. at t = 150 oF (65.556 oC) |

| Sulfurous Acid 10%, Sulfurous Acid 10% | Unstable | Unstable |

| Sodium silicate | Stable | Unstable |

| Soybean oil, Soya Oil | Stable | Stable |

| Salt water | Stable | Stable |

| Stearic Acid | Stable | Stable |

| Sulfamic acid | Stable | Unstable |

| Aluminum Sulfate | Stable | Stable |

| Ammonium Sulfate | Stable | Stable |

| Barium Sulfate | Stable | Stable |

| Ferric Sulfate | Stable | Stable |

| Potassium Sulfate, Potassium Sulfate | Stable | Stable |

| Calcium Sulfate | Stable | Stable |

| Magnesium Sulfate | Stable | Max. at t = 200 oF (93.333 oC) |

| Copper Sulfate | Stable | Stable |

| Sodium Sulfate | Stable | Stable |

| Nickel Sulfate | Stable | Stable |

| Chromium Sulfate | Stable | Stable |

| Zinc Sulfate | Stable | Stable |

| Sulfated Detergents | Stable | Unstable |

| Barium Sulfide | Unstable | Unstable |

| Hydrogen Sulfide Dry | Stable | Max. at t = 250 oF (121.11 oC) |

| Sodium sulfide | Stable | Unstable |

| Calcium sulfite | Stable | Stable |

| Sodium sulfite | Stable | Unstable |

| Superphosphoric Acid | Stable | Unstable |

| Stannic tetrachloride, Stannic Chloride | Stable | Stable |

| Sodium Thiosulfate | Stable | Unstable |

| Toluene | Unstable | Unstable |

| Brake fluid, Hydraulic Fluid | Stable | Unstable |

| Pickling Acids | Stable | Stable |

| Tridecylbenzene Sulfonate | Stable | Unstable |

| Sodium Tripolyphosphate | Stable | Unstable |

| Trichloroacetic acid 50%, Trichloro Acetic Acid 50% | Stable | Unstable |

| Carbonic acid | Stable | Stable |

| Vinegar, Vinegar | Stable | Stable |

| Acetic acid 0-25%, Acetic Acid 0-25% | Stable | Max. at t = 125 oF (51.667 oC) |

| Acetic acid 25-50%,Acetic Acid 25-50% | Stable | Unstable |

| Formaldehyde | Stable | Unstable |

| Ammonium Phosphate | Unstable | Unstable |

| Phosphoric Acid Fumes | Stable | Stable |

| Phosphoric Acid | Stable | Stable |

| Phthalic Acid | Stable | Stable |

| Hydrogen Fluoride, Vapor | Stable | Max. at t = 95 oF (35 oC) |

| Copper Fluoride | Unstable | Unstable |

| Fluorosilicic acid, Hydrofluosilicic Acid 10% | Unstable | Unstable |

| Cottonseed Oil | Stable | Unstable |

| Calcium Chlorate | Stable | Stable |

| Sodium Chlorate | Stable | Unstable |

| Zinc Chlorate | Stable | Stable |

| Aluminum Chloride | Stable | Max. at t = 120 oF (48.889 oC) |

| Barium Chloride | Stable | Max. at t = 200 oF (93.333 oC) |

| Ferric Chloride | Stable | Stable |

| Cadmium Chloride | Stable | Unstable |

| Potassium Chloride, Potassium Chloride | Stable | Stable |

| Calcium Chloride | Stable | Stable |

| Magnesium Chloride | Stable | Max. at t = 220 oF (104.44 oC) |

| Copper Chloride | Stable | Stable |

| Sodium Chloride | Stable | Unstable |

| Nickel Chloride | Stable | Unstable |

| Stannous Chloride | Stable | Stable |

| Mercury chloride, Mercurous Chloride | Stable | Max. at t = 212 oF (100 oC) |

| Chlorine -Wet Gas | Unstable | Unstable |

| Chlorine - Dry Gas | Stable | Unstable |

| Hydrogen Chloride, Wet Gas | Unstable | Unstable |

| Sodium chlorite, Sodium Chlorite 25% | Stable | Unstable |

| Chlorine Water | Unstable | Unstable |

| Copper Cyanide | Unstable | Unstable |

| Sodium cyanide | Stable | Unstable |

| Hydrocyanic acid | Stable | Unstable |

| Cyclohexane | Stable | Unstable |

| Oxalic acid | Stable | Stable |

| Sodium Electrolyte, Sodium Solutions | Stable | Unstable |

| Ethylene Glycol | Stable | Stable |

| Ethyl gasoline, Gasoline, Ethyl | Stable | Unstable |

lkmprom.ru

Types of polymer layer

Varieties:

- PVDF (polyvinylidene fluoride). Advantages: resistance to fading and mechanical damage, adding shine to surfaces, increasing the service life of metal parts.

- Pural. It is made on the basis of polyurethane. Advantages: Resistance to high heat, ultraviolet radiation and chemicals. Disadvantage: susceptibility to plastic deformation.

- Polyester. Advantages: resistance to ultraviolet radiation, moisture, and chemicals. The composition has high flexibility and can withstand temperature changes.

- Plastisol. After the work, a thick layer is formed. It has the highest resistance to mechanical damage and temperature changes.

Car wheel with polymer coating (Instagram / ilber.aktobe)

Anti-friction coatings as a type of polymer

A special type of polymer coatings is antifriction solid lubricant coatings (ATSC). They are similar to paints, but the dye is replaced by tiny particles of solid lubricants distributed throughout the volume of the binder and solvent.

For the production of polymer ATSP, polytetrafluoroethylene (Teflon, PTFE), molybdenum disulfide, graphite and other solid lubricants are used. Both organic and inorganic materials can act as a binder: titanate, epoxy resin, acrylic, polyamide-imide, phenolic, etc. Components.

In Russia, the company is engaged in the development and production of such materials. The product line includes anti-friction solid lubricant coatings designed to solve various problems, cleaners and special solvents.

MODENGY polymer coatings - MODENGY 1010, MODENGY 1011, MODENGY 1014 and others - have proven themselves in plain bearings, sliding guides, gears, other medium- and heavily loaded sliding friction units, fasteners and threaded connections, vehicle engine parts (valve rods, piston skirts, throttle valves, main bearings, spline joints), pipeline fittings, metal and plastic elements of automotive equipment (staples, springs, hinges, locks, adjustment mechanisms, etc.), as well as other metal-polymer friction pairs, metal -rubber, metal-metal, polymer-polymer.

Advantages of MODENGY polymer coatings:

- Operability in dusty environments, vacuum and radiation

- Low coefficient of friction

- High anti-wear, anti-corrosion and extreme pressure properties

- Wide operating temperature range

- Resistant to acids, organic solvents, alkalis and other chemicals

- The ability to create a thin protective layer on parts that practically does not change their original size

MODENGY polymer coatings make it possible to effectively control friction, increase the service life and efficiency of equipment, and provide the surfaces of parts with the necessary set of protective and tribological properties.

Thanks to the use of MODENGY ATSP, plastic oils and lubricants can be completely eliminated. Solid lubrication technology allows you to create a friction unit that does not require maintenance. Anti-friction coatings are applied once and provide lubrication and protection of various parts throughout their entire service life.

Advantages and disadvantages of polymer metal

Positive sides:

- High level of adhesion. If metal surfaces are properly prepared, a bond is formed between them and the polymer at the molecular level.

- Resistant to moisture. Polymer coatings are applied to metal structures located in water, and they cover the bottoms of boats. Even with active use, the protective layer retains its integrity and does not allow moisture to pass through.

- High wear resistance, mechanical strength. The damaged layer is easy to restore.

- Resistance to ultraviolet radiation. Many metal paints quickly fade in the sun. The polymer layer is not subject to this problem. It can be constantly exposed to sunlight without losing its properties.

- Resistant to temperature changes.

- Durability. Under normal conditions the coating will last about 50 years

- Resistant to chemicals. To test this property, you can coat a metal part with a polymer and immerse it in a solvent. The protective layer will preserve its integrity and properties.

Flaws:

- Due to its high adhesion, the coating is difficult to remove.

- Protective compounds are only suitable for working with metal.

- To apply polymers you need to use special equipment.

Polymer coatings can withstand exposure to open flames. This is due to the application technology.

Car made of polymer metal (Instagram / pokraska_diskov_astana)

Polyester cover

Quite often, Russian manufacturers choose polyester, also called polyester, for coating metal products. It is distinguished by high resistance to ultraviolet rays and the ability to resist metal corrosion. In addition, due to its good flexibility, the material is easy to mold, and equipment with a polyester layer can operate in almost any climatic conditions.

This inexpensive material, in comparison with other types of coatings, does not have very high strength characteristics. Sprinkling polyester with quartz sand improves them, but the price of metal coated with polymers in this case will be slightly higher. At the same time, transportation of such sheets will be complicated by the ability of sand to scratch adjacent surfaces.

Application of a polymer layer

The polymer layer is applied using special equipment in industrial chambers.

Polymer application conditions

Features of the work:

- The humidity level in the treatment area should not exceed 60%.

- Work must be carried out in a sealed chamber.

- It is necessary to clear the work area of foreign objects in advance.

- The part must be secured.

Do not apply a protective coating outdoors, in dirty rooms with a lot of dust and debris.

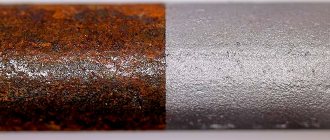

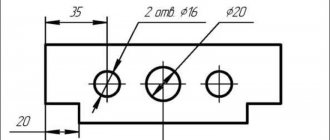

Metal preparation

To increase the adhesion of plastic to metal, surfaces must be properly prepared. They need to be cleaned of dirt and wiped with a solvent to remove grease stains. Treatments to remove plaque can be done chemically, thermally or mechanically. It is important to make the surfaces smooth and remove dirt.

Mixing and applying the polymer composition

The polymer composition can be mixed with callers to change color. Coating:

- The lighting in the sealed chamber is turned on. The master dresses in a chemical protection suit.

- The parts are hung on hooks or clamped in special fasteners.

- A negative cable, called ground, is hung on the workpieces.

- The camera with the master closes, he applies paint.

The application process should be slow. It is important to apply the coating evenly over the surfaces to avoid unevenness.

Application of polymer coating (Instagram / ilber.aktobe)

Thermal stabilization of polymer metal

After applying the paint, the part is slowly heated to change the properties and characteristics of the material. The workpieces are immersed in a special chamber, which is heated to 200°C. The duration of thermal stabilization is 60 minutes. After this, you need to turn off the oven and leave it to cool to 100°C. When it cools down, you can open the chamber. If you try to cool the parts forcibly, the protective layer will crack.

Recommendations for working with polymer metal

Tips for using polymer coatings for metal:

- Before applying the polymer, you need to prepare the working chamber - install effective lighting, remove unnecessary objects.

- When carrying out work, you must use a chemical protective suit, a breathing mask, and safety glasses.

- Coating is repeated 3 times.

You can paint several parts at the same time, but this requires a spacious painting booth and a furnace for thermal stabilization.

The polymer layer on the metal reliably protects the material from the formation of rust, levels the surfaces, and makes them stronger. The effect depends on the correct preparation of the working surfaces and the application of the polymer layer.