Angle grinder (grinder) BOSCH GWS 9-125 S. Photo 220Volt

Due to their simplicity and versatility in use, grinders have gained popularity among both amateurs and professionals . To maintain an angle grinder in working condition during operation, it is necessary to carry out various repair work, often involving the replacement of defective units and parts with new spare parts and components. If the clamping nuts are unscrewed abnormally (using, for example, a chisel, hammer and other similar tools), they may lose not only their appearance, but also their ability to perform their functions. Well-known manufacturers of angle grinders on the market produce various spare parts for them , among which locking devices are not in last place.

What are they?

The clamping nut is part of a threaded connection with the working spindle , which fixes the working tool, providing it with reliable fastening. A distinctive feature is that, regardless of design, the nuts have a sufficiently large supporting surface to create reliable clamping force.

Metabo clamping nut. Photo VseInstruments.ru

Types for small and other angle grinders, pros and cons

The design of clamping devices is largely related to the type of angle grinder on which they are used. Household angle grinders , distinguished by economical price characteristics, use the simplest classic and slightly more complex floating design options for clamping joints for unscrewing/twisting. Such nuts cannot guarantee a quick replacement of a bitten disk; labor-intensive and time-consuming options are possible. The replacement process itself is impossible without additional tools - a pin or spanner (spanner) wrench.

Professional, more powerful modifications of angle grinders with consumable tools of larger diameter are used with specially designed clamping devices. The advantage of this connection is that it can be unscrewed/tightened manually; no additional tool in the form of keys is needed. This ensures efficiency in work; the nuts do not clamp the working tool, which allows you to quickly change it.

More detailed information about the types of clamping devices used on angle grinders is later in the article.

Quick release, quick release, keyless, non-tightening

The main advantage of special quick-release (this name best reflects the characteristics of the design) nuts is to minimize the possibility of the tool jamming during operation. Manufacturers of angle grinders create various options for anti-clamping mechanisms, among which there are devices based on the operation of thrust bearings, spring couplings or conventional ball bearings with an eccentric complementary to the design. An overview of the designs of quick-release fasteners from various manufacturers can be seen in the following video.

Another advantage of such clamping devices is that the use of additional equipment in the form of various keys is minimized . If on quick-release fasteners with a mechanism based on bearings there is no 100% guarantee that you can unscrew them manually, then in the version with a spring coupling such clamping nuts will unscrew easily in any case. Therefore, some modifications of quick-release fasteners have holes for a special pin wrench.

Self-balancing, self-tightening, self-clamping

Expensive top-class professional angle grinders are equipped with clamping nuts with a self-balancing function . A poorly balanced tool for a large diameter angle grinder causes severe vibration during operation. The cavity of such clamping devices is filled with metal balls, which, when rotated, are located in a viscous medium around the perimeter in such a way as to reduce the imbalance to zero. Vibration weakens the threaded connection, so self-balancing nuts have additional devices that ensure self-clamping and self-tightening of the connection. In addition to the absence of vibrations, such a nut increases the operating time of the working tool and increases the service life of the angle grinder itself.

Superflange

The Japanese has simplified the ability to easily unscrew the clamping nut by hand, equipping it with a special rotating washer design. This washer is called a “superflange”. Working in conjunction with a quick-clamping nut, the “superflange” eliminates the use of additional tools other than your own hands.

Non-biting, from biting

The design of the clamping devices, which prevents the working tool from biting, generally consists of two separate parts. The first includes the actual threaded connection that communicates with the working spindle. The second is the pressing surface of the nut, which clamps the tool. Both parts are connected into a single whole without the possibility of exerting any force on each other. As the resistance to rotation of the tool increases, the pressing surface of the nut continues to rotate freely along with the tool, the threaded connection does not interfere with this

Classic, open-end, wrench with rotating washer

The classic nut kit consists of a one-piece clamping washer and a rotating part that serves as a tool support. It is screwed/unscrewed using a pin wrench through the holes in the pressure washer. For users who prefer regular wrenches or socket wrenches, it can be modified to accept a threaded connection with a hex head. The disadvantage of this connection is that the height of the nut increases compared to a conventional one, which reduces the possibility of processing in hard-to-reach places.

Wrench clamp nut (30.35 mm; M14) for KWB angle grinders. Photo VseInstruments.ru

Floating, scrollable

Unlike the usual solid pressure washer, the design of which is actually one of the reasons for jamming of the working tool of angle grinders, there are modifications with a rotating pressure washer . This design option consists of a hex nut rolled into the surface of a pressure washer. Biting a disc with such a clamping device is extremely rare. Open-end or socket wrenches 19x22 are not so difficult to find. The author of the following video describes the operation of his angle grinder with such a clamping device.

With independent washer

In the following video, the author shows the operation of a nut from the manufacturer AEG , where the pressure washer does not depend on the part of the nut that is connected to the thread. The clamping device equipped with a folding bracket, when it is in the upper position with a reduced load, freely tightens the nut. Once the bracket is lowered, the eccentric clamp is activated, engaging the pressure washer and the top of the clamping device. In this position, the grinder performs working actions. After completing the work, the bracket is raised to the upper position, the eccentric clamp is loosened and manually, holding the bracket, it is unscrewed.

Diameter

Nuts for household angle grinders must have an external size that reliably presses the tool, the diameter of which ranges from 115 mm to 230 mm . , an external dimension of approximately 48 mm satisfies these requirements (maybe a little more or a little less).

The operating characteristics are largely influenced by the thickness of the clamping device. Regular standard nuts have minimum values. They are successfully used when working in hard-to-reach places. Special nuts are large in thickness and do not have the same mobility in operation as household grinders.

What kind of thread

The absolute majority of the domestic angle grinder market is dominated by angle grinders with external threads on the M14 working spindle (normal thread with a pitch of 2 mm). The clamping nuts respectively have an M14 internal thread . In rare cases, if the threads do not match, adapters are used.

Quick-release nut for angle grinder Makita 115\125\150\230 with standard M14 thread. Photo 220Volt

Advantages and Disadvantages of Pressure Fasteners

Floating fastener

In such a nut, the lower segment and the upper are not dependent on each other, they rotate on their own. It is used in angle grinders instead of a standard nut. The advantages of such a fastener are:

- it does not require a specialized wrench to unscrew (a regular open-end wrench or a simple socket wrench will do);

- The circle is not pressed tightly, therefore, the clamping fastener unscrews freely.

There is probably only one drawback - its cost is slightly higher than the standard one.

Regular nut

Practiced in various modifications of the instrument. Included in the package of cheap angle grinders. Advantages of the fastener:

- presses the circle firmly;

- low cost.

Flaws:

- a specially designed key is required for unscrewing;

- often spontaneously sticks to the circle, and special skills or equipment are needed to unscrew it.

Superflange fastening element

A specialized nut with a moving internal element, made by Makita. Advantages:

- makes it possible to freely remove the circle no matter how tightly it is tightened during work;

- increases user efficiency.

The downside is that the cost is significantly higher than that of other fasteners for angle grinders.

Self-locking nut

Replaces conventional clamp fastener. Advantages:

- no special key required for unscrewing;

- can be easily dismantled;

- high wear resistance;

- durable.

Flaws:

- quite expensive;

- may sometimes stick to the circle and in this case it should be turned away as usual.

Fastening element with auto-balancer

The structure contains bearings inside the nut. During operation, the bearings are dispersed internally and balance vibration processes. Advantages:

- the grinding disc works 50% longer;

- no vibration;

- increases the service life of the tool.

The disadvantage is the high cost.

Popular brands of elements for fixing circles

Competition in the angle grinder market dictates to large manufacturers the need to produce spare parts and components , especially those that quickly fail. Each large company strives to create its own original design of clamping devices. The popularity of self-produced nuts among users increases the company’s rating in market conditions.

The following manufacturers offer technologies that allow them to create fasteners with excellent performance characteristics.

Super nut from MAKITA

The Japanese company mentioned in this article above has released a super nut from MAKITA on the market. A complex and expensive mechanism ensures 100% easy unscrewing of the nut by hand after work with increased intensity and workload. The author of the following video shows in detail the structure of the super nut and the advantages of operation.

BOSCH

The quick-release nut from the German manufacturer BOSCH under the name SDS-clic is similar in design to the MAKITA super nut. These clamping devices are completely interchangeable and can be used on angle grinders from both manufacturers.

AEG

A less complex mechanism for quick-release fasteners, but also cheaper than that of manufacturers MAKITA and BOSCH. It is based on a conventional thrust bearing. The simplicity of the design does not guarantee 100% unscrewing by hand when the disk is clamped.

METABO

METABO quick-release nuts differ little in design from AEG or DeWalt . However, it will not be possible to install them on many angle grinders. The installation design provides for the presence on the threaded part of the spindle of two oppositely located grooves, such as keyways. It is clear that they do not always take place, which is a serious drawback in expanding the applicability of METABO clamping devices.

Quick-release nut Quick M 14, EWS Metabo. Photo VseInstruments.ru

The device of the grinder

The construction of an angle grinder is not very complicated.

Grinder diagram

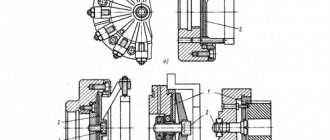

The design of an angle grinder (angle grinder) includes the following main elements and components:

- electric motor – stator and rotor (coils, copper windings, metal casting, bearings);

- electric brushes - elements that supply power to the collector to convert electrical energy into rotational energy;

- gearbox – transmission of rotation from the engine shaft to the working body;

- clutch - a device to prevent a sudden stop of the engine when the working body is braked;

- controls - power button, power blocking devices and power and speed control devices;

- device for installing and replacing the working element - clamping nut (washer), rotation lock button;

- additional handle (handle);

- the housing - metal or plastic - serves to install all parts and protect them.

The replaceable working element is located at an angle of 90 degrees. These are: grinding wheels, whetstone, brushing, alpha disc, Velcro sandpaper. Sharpening stones, like wheels, have a lot of options.

A grinder is needed for mechanical processing of materials - for cutting, stripping, grinding, drilling and developing openings. A large centrifugal load acts in different directions from the disk, which requires a protective casing for safety.

How to replace the nut

The grinder is a very dangerous power tool. Therefore, replacement of parts and components should be approached with special care. If the clamping nut has been lost, do not replace it with a regular M14 hex nut. The pressing surface of such a fastener is insufficient to securely fasten the tool. It is better to contact a service center or buy a standard clamping nut in a specialized store.

If you are far from the benefits of civilization, for example, in the country, you can use a lathe located in the household. If he is not there, perhaps a familiar turner with a machine lives next door. Turning a nut and cutting threads is not a difficult task even for a professional turner.

What solution to the problem is offered by specialists and amateurs + (Video)

- Install a newspaper gasket under the nut;

- Place a gasket from a plastic bottle under the nut;

- Replace the nut with a nut of a different design.

What is a newspaper gasket? This is a paper washer the size of a nut. It is put on the installed disk, and a nut is screwed on top. This piece of paper was a stumbling point, because the safety inspection always spoke about the harmfulness of such a decision.

Representatives of safety authorities treat the installation of gaskets made of any other materials in the same way:

- Cardboard;

- Paronitis;

- Gaskets made of various plastics;

- Rubber gaskets of various thicknesses.

But there is a solution that does not contradict safety requirements and allows you to install and remove the disk normally. This is a special nut that consists of two elements - a nut and a pressure washer. The use of such a nut does not require any shims, because with it the disk does not jam.