I was doing some simple woodworking and needed a router. But since I was not sure that this tool would be needed often, I did not buy it and made the router myself from an angle grinder. I thought that this experience would be useful to readers, and then I will tell you how to make a wood router from an angle grinder with your own hands.

Hand tool

So, how to make a milling cutter from a grinder... It is important to use a vice or clamps to securely hold the workpiece. Otherwise the part will not be stable. Using various methods, you can make a milling machine from a grinder. I'll tell you about one of them.

You need to start by developing drawings of the basic base of the tool. The best solution is to make a metal base. It must have sufficient thickness and weight. All this affects how reliable the device will be. Let's move on to creating a plate for fixing - a bracket for attaching an angle grinder. The same material is used as the base. It is also important to make connectors for the back of the instrument. They should be made in the place where the handle is located. Blanks can be made of any shape.

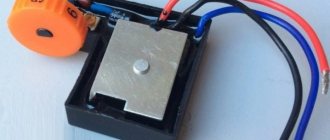

Parts of square pipes are welded to the edges of the fixture. Products that are longer and have a smaller diameter will be guides. They must be welded to the base. In order for the tool to be fixed as securely as possible, you will need to create and weld metal “ears”. To fix the tool at the required height, you need to make a mount. To do this, you will need to weld two nuts and place threaded rods in them. Wing nuts must be attached to them using welding. Thanks to this manipulation it will be easy to fix the tool in the required position.

Source uk-parkovaya.ru

As an adapter, you need to place a drill chuck on the attachment. To install it, you need to cut the thread in advance. It is cut from the inside and must match the angle grinder shaft. After which the drill chuck is screwed onto the shaft and the necessary cutter is installed in it. Next you need to assemble the machine and secure it in the bracket.

Important rules for cutting wood

Cutting and processing wood can be done using a well-known device - an angle grinder. A power saw made from a sanding device will help you handle small wood jobs.

Milling with a grinder will require compliance with the following rules:

use the attachment only for wood products;- work is carried out with gloves;

- the unit must be securely fastened;

- minimum operating speed;

- before use, you should make sure that the material does not contain nails, screws or other metal components;

- the mechanism must be kept in one plane, avoiding distortions;

- The nozzle is replaced when the power supply is turned off.

Stationary tool

The design includes the following elements: a table top with a lined rail, a drive and a solid base.

Source crydee.sai.msu.ru

The following types of such devices are distinguished:

- fixed table top – movable tool;

- movable base – stationary tool.

Design features and device of the milling cutter

A milling cutter is a unit for processing wood or metal. Structurally, the tool consists of several parts:

- housings with a motor and other key elements;

- a protruding holder into which collets are inserted - adapters for nozzles;

- The platform is made of durable and smooth material; it ensures that the router slides along the surface of the workpiece.

There is a power button on the body of the tool; some models also have an accidental start blocking key.

Milling cutters are divided into two types:

- manual;

The hand router must be moved along the surface of the fixed workpiece. - stationary.

Stationary milling cutters remain motionless during operation, but the workpiece itself needs to be moved

Using a router, you can remove the material in a very thin, even layer. In addition, the tool is used to make connections, grooves and cuts, patterns and grooves.

Movable base - stationary tool

It is necessary to make sure that the tabletop is mobile and the grinder is motionless. So that the tabletop can be moved under it, you need to build a structure of guides. It is important that the tabletop is securely fastened. We fix the angle grinder on the vertical bed. It should be strictly to the side of the workbench.

Algorithm of actions:

- make a wooden frame (you can also make it from corners);

- install plywood to the frame;

- to make a good milling cutter from an angle grinder, you need to create connectors specifically for the shaft of this tool;

- using clamps you need to fix the device in the frame itself;

- Make guides on the tabletop so that the part can be moved freely;

- the surface needs to be sanded and painted.

As a result, you will make a device with a vertical attachment..

Source bifai.ru

Self-tapping screws should not be visible above the surface of the countertop. As for the guide rails, it is important that they can be easily rearranged and removed. The best option for fixing them is self-tapping screws.

To use all the capabilities of a homemade milling machine, you will need to buy additional attachments - cutters.

You can clearly see how to make a router from an angle grinder in this video:

A slightly different look at the question - about the advisability of making a router from an angle grinder, see this video:

How to choose the power of wood milling machine equipment for your home workshop

The manual router is designed specifically for work in small workshops or on the road.

It is difficult to process large batches of lumber on it; such a machine simply cannot withstand the volume of work. Bulk workpieces are easier to process on stationary machines. A comment

Andrey Feofanov

Tool selection specialist at VseInstruments.ru

Ask a Question

“To create complex designs on wood, you will have to purchase several types of cutters. Some of them can be made independently, others can be purchased in specialized stores.”

Low-power machines are quite suitable for home and household use. For example, 400 W is enough for small jobs and drilling in soft wood. Machines of this power can be used for cutting grooves. The price of manual wood routers is low, however, the range of functions is very limited.

If you plan to expand the specifics of processing, then it is better to opt for a model with a power of at least 1 kW

With such equipment you can easily work on any type of wood. This is quite enough for household needs. For professional use, it is recommended to choose a machine with a power of at least 1.5 kW. It is not always possible to buy such a wood milling machine, because the price can reach several tens of thousands of rubles. With such a machine it will be possible to process large volumes of wood, as well as plastics, soft alloys, such as aluminum; it will “eat” any type of cutter. Remember that the time it takes to complete a task depends on the power.

Spindle rotation speed is a very important characteristic that affects the price of a wood milling machine; you should pay attention to this parameter when choosing equipment. Processing dry or wet wood of varying densities is most effective at certain speeds

The dimensions of the working platform and the distance from the spindle axis to the worktop determine the dimensions of the workpieces being processed. The accuracy and depth of processing of the part, as well as the ability to select the desired cutter, depend on choosing the right spindle for a wood milling machine.

Dust extraction - when processing wood, an exhaust volute is an irreplaceable thing. Sometimes, for such purposes, ordinary vacuum cleaners are used, which are attached at a certain angle to the frame.

Dimensions and weight of the machine - for an amateur, a compact desktop model is suitable, which is installed on a workbench, and after use it is put away in the pantry. If you have a workshop, it is more advisable to assemble a full-fledged wood milling machine on a bed with your own hands. If you plan to work on a construction site, choose a manual router.

A comment

Andrey Feofanov

Tool selection specialist at VseInstruments.ru

Ask a Question

“The manual electric top-type milling cutter can be stationary or submersible. Fixed models are cheaper, however, less functional. In such a tool, the cutter cannot move relative to the device body.”

Much more convenient to use is a plunge router, the drive motor of which is mounted on special guides and can move along them along with the working attachment during processing. The design of plunge-type milling machines also has a special spring, which ensures the lifting of the working attachment after processing has been completed with its help.

If, in the process of purchasing top-type milling cutters, you choose which one is better, then you should definitely pay attention to submersible models, which are perfect for both professionals and beginners

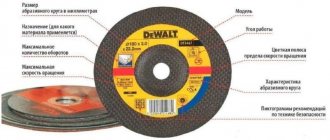

Cutting discs

They are made from tungsten carbide, which is highly durable. Depending on the depth of cut and the number of teeth, there are several types of cutting discs. To choose which drive to purchase, follow these guidelines:

- If you use the wheel infrequently and for a short period of time and cut a variety of wood, you should choose a disk whose teeth have a beveled shape.

- When processing soft wood species, a wheel with straight teeth is used.

- For cutting medium-density wood, particle boards and USB boards, it is best to use wheels with trapezoidal teeth.

How to Rewind a Grinder to 12 Volts

Do-it-yourself grinder from a drill and chainsaw

Quite often in everyday life you need to repurpose working tools. This does not apply to the situation when you need to use an angle grinder, but you don’t have one. There are options to come to the rescue: a drill, a gas-powered one, or an electric saw, what is the duration of the project, what tools are available.

The usual ineffective method of getting an angle grinder from an electric saw

Grinder from a drill ()

For such a transformation, the following tools will be useful at home:

Before starting the transformation, you need to make sure that in the coming days the drill itself will not be useful in the work. In the last article, I told you how to connect and start a 380-volt motor in a single-phase 220-volt power supply. And later it’s enough to follow the step-by-step instructions:

- Choose an attachment for your future grinder.

- Take a small diameter steel rod without grinding off one of its edges. This action is necessary for the best fit into the nozzle. Also, for the best adhesion, you should slightly grind down the places that will come into contact with the petals of the cartridge, not the rod itself.

- Fix all parts.

A frisky, unusual method for creating an angle grinder

There is no second, more difficult method to achieve the desired result.

- The chuck is removed from the drill. For an angle grinder it is not necessary, so there is an option to clean it, lubricate it, or store it.

- Choose an attachment for the upcoming tool. It would be better if it were a part made of strong steel; a lightweight version would be inappropriate here.

- Choosing a rod. It needs to be of such length that its part protrudes outside the drill by 1.8-1.9 cm. Next, one of its ends should be ground off with a rasp so that in the process a rod comes out that completely coincides with the socket in the nozzle itself. Before the joint, it is worth smearing its ends with machine oil for the best passage.

- Installation of the ball bearing is carried out to the output area. A rod will be threaded through it for future fixation at the base. If this step is not necessary, the rod is fixed in its own place.

Do-it-yourself 12-volt cordless grinder

Bulgarian

homemade. Without machines, current was used in production (motor with a Bulgarian disk and almost

Following the instructions, the grinder comes out in 1-2 hours

There is an option to make an angle grinder using this method within a few hours, but you can’t get the necessary tool here.

Grinder made from chainsaw and electric saw ()

A more common method of making a grinder with your own hands is to convert it from a gas-powered or otherwise electric saw. Because of the ready-made fixture

Working of a disc for an angle grinder

will have a number of advantages:

- Possibility of autonomous operation.

- Highest power.

- Cost of operation.

To transform your chainsaw into a different electronic form into an angle grinder, buy special attachments at any hardware store. They will help to accomplish these transformations in a matter of actions.

For an angle grinder, you need to reduce the risk of disc failure. For these purposes, the saw is equipped with a special protective casing. It is also worth reducing the number of revolutions using a speed reducer.

Bulgarian 12 volt ()

For the client to be able to use an electronic instrument, its 12-volt power needs to be converted to 220.

You will learn how to correctly connect single-phase 220 volt electric motors using the example of motors from a washing machine.

Thus, it is natural to power it from a car in which a constant current flows with a voltage of 12 Volts, by installing a special invector.

Low-power invectors should be connected to the cigarette lighter; there are no special requirements. The only aspects are:

- Use at temperatures ranging from 15 to 50 0 C and average humidity.

- Do not allow devices to operate in direct sunlight.

- Do not use the space under the seats for storage, as the invector will heat up during operation. To cool it, you need unobstructed air flow.

It is recommended to connect a more powerful invector to the battery terminals. However, it is prohibited to turn on the ignition or engine if the invector produced is connected to a non-removable battery.

It’s natural to make an angle grinder from different tools that everyone has nearby. Thanks to the instructions, the work can be done with your own hands in just 2-3 hours.