Abrasion wear” is redirected here

"

A separate article

is needed on this topic .

Abrasive materials

(French

abrasif

- grinding, from Latin

abradere

- scrape) - these are materials with high hardness and are used for surface treatment of various materials: metals, ceramic materials, rocks, minerals, glass, leather, rubber and others. Abrasive materials are used in the processes of grinding, polishing, honing, superfinishing, cutting materials and are widely used in blank production and finishing of various metallic and non-metallic materials.

For a long time, natural abrasive materials (flint, emery, pumice, corundum, diamond) have been used; since the end of the 19th century, artificial ones have been used (electrocorundum, silicon carbide, boron carbide, monocorundum, synthetic diamond and others).

Hardness (Mn/m²) is determined by pressing a diamond pyramid into the surface of the test material (for example, for quartz 11000-11300, electrocorundum 18000-24000, diamond 84250-100000). The abrasive ability is characterized by the mass of material removed during grinding in the following order: diamond, boron nitride, silicon carbide, monocorundum, electrocorundum, emery, flint. Rigid and flexible abrasive tools are made from abrasive materials, which are widely used in all branches of mechanical engineering, especially in the manufacture of bearings.

Types of abrasive processing

The following types of abrasive processing exist:

- circular grinding - processing of cylindrical and conical surfaces of shafts and holes;

- flat grinding - processing of planes and mating flat surfaces;

- centerless grinding - processing in large-scale production of external and internal surfaces (shafts, bearing races, etc.);

- centerless belt grinding - external surfaces, including complex profiles;

- belt grinding of complex profiles - for example, grinding turbine blades;

- cutting and cutting of workpieces - procurement and assembly production, dismantling of structures;

- lapping - abrasive grinding of surfaces (for example, the seat and needle of a diesel injector);

- waterjet processing - jetting and tumbling (castings, forgings, hardware, etc.);

- sandblasting - cleaning substrates from old paint, rust, scale and other contaminants, as well as smoothing surfaces and cleaning castings and forgings;

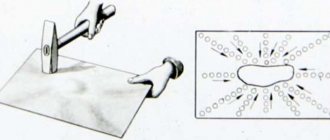

- ultrasonic processing - punching holes in hard alloys, removing broken tools, making dies;

- magnetic abrasive processing - processing with magnetic abrasive powder in a magnetic field;

- honing - processing of holes (engine cylinders, pumps, etc.);

- polishing - giving the surface a low roughness and mirror shine;

- superfinishing - final giving of external, internal and complex profiles the highest precision and surface cleanliness, including diamond superfinishing (precision mechanisms, tools, parts of particularly precise instruments, tools, weapons, etc.).

Literature[ | ]

- Kremen Z.I., Yuryev V.G., Baboshkin A.F.

Grinding technology in mechanical engineering. - Elbor in mechanical engineering / Ed. V. S. Lisanov. - L.: Mechanical Engineering, 1978.

- Blasting: Guide to highly effective abrasive blasting / Kozlov D.Yu. - Ekaterinburg: OOO Publishing House Origami, 2007. - 216 p. — 1000 copies. — ISBN 978-5-9901098-1-0.

- Technical encyclopedia / Ch. ed. Martens L. K. - Moscow: Electronic and Traditional Dictionaries, 2005. - ISBN 5-86460-132-2.

- Guidelines for the training of inspectors for visual and measuring quality control of painting works / Ch. ed. Pirogov V. D. - Ekaterinburg: LLC Publishing House "Origami", 2009. - 202 p. — ISBN 978-5-9901098-1-5.

- GOST R 52381-2005 (ISO 8486-1:1996, ISO 6344-2:1998, ISO 9138:1993, ISO 9284:1992) Abrasive materials. Grain size and grain composition of grinding powders. Control of grain composition.

- GOST 21445-84 (ST SEV 4403-83) Abrasive materials and tools. Terms and Definitions.

Abrasive Tools

Sandpaper with abrasive size FEPA P80.

Abrasive materials for industrial use must be fixed or structurally made in the form of various tools and compositions.

Main types of abrasive tools and compounds:

- Cutting wheels: Various diameters (up to 3500 mm), width, height and shapes (profiles) of the working (abrasive) layer and methods of fixing it to the wheel body.

- Grinding wheels: Various abrasive materials in the form of circles, disks, cones of different profiles and diameters.

- Stones: Abrasive and metal-abrasive stones of various sizes and profiles for honing, lapping, superfinishing.

- Tape: Synthetic or plant-woven tape of different widths with grains of abrasive materials glued to one or two sides.

- Sandpaper: An abrasive material applied to a fabric or paper backing.

- Pastes: Abrasive lapping and polishing abrasives evenly distributed in a binder (paraffin, ceresin, oleic acid, stearin, oils, kerosene, etc.).

- Loose Grain: Dry abrasive grains for waterjet, ultrasonic and sandblasting.

- Tumbling bodies: an abrasive tool in the form of geometrically shaped products (cylinder, prism, cone, cube, etc.) intended for tumbling.

Features of the polishing process

Polishing is considered the final stage of machining parts. With its help you can achieve a mirror metallic shine. Stages of work:

- First of all, the workpiece is processed using grinding machines with coarse abrasives.

- The next step is to reduce the grain size. In this case, it is necessary to take into account the final dimensions of the part so as not to remove the excess layer. Reducing the amount of grit on the sanding surface may leave scratches on the metal surface. Because of this, it is necessary to check abrasive tools.

- To achieve a metallic shine, you need to use GOI paste. It consists of 60% abrasive particles.

When grinding and polishing, it is important to choose a high level of tool resistance to mechanical stress.

When sharpening knives, you can create a high-quality cutting edge using whetstones of different grain sizes and GOI paste. At the same time, the paste has several varieties that differ in the size of the sharp particles.

Abrasive processing of metals is used in various industries. To perform this process, you need to select the right equipment and abrasive material.

Abrasive materials

The abrasive particle size ranges from 2 mm (large fraction) to 40 microns.

Abrasive materials are divided by hardness (superhard, hard, soft), and chemical composition, and by the size of the grinding grain (coarse or coarse, medium, fine, extra fine), the grain size is measured in micrometers or meshes.

An abrasive grain is an individual crystal, intergrowths of crystals or their fragments with a ratio of their largest to smallest size not exceeding 3:1.

The suitability of abrasives depends on physical and crystallographic properties; Particularly important is their ability to break into sharp-angled particles when abraded. Diamond has this property to its maximum. The choice of abrasive material depends on the physical properties of the processed and processed material, as well as on the stage of processing (rough grinding, grinding and polishing), and the hardness of the abrasive material should be higher than the hardness of the processed material (with the exception of diamond, which is processed with diamond).

Abrasive materials are characterized by hardness

,

fragility

,

abrasive ability

,

mechanical

and

chemical resistance

.

Hardness is the ability of a material to resist being pressed into it by another material. The hardness of abrasive materials is characterized according to the Mohs mineral hardness scale by 10 classes, including as standards: 1 - talc, 2 - gypsum, 3 - calcite, 4 - fluorite, 5 - apatite, 6 - feldspar, 7 - quartz, 8 - topaz, 9 - corundum, 10 - diamond.

Abrasive ability is characterized by the amount of material sanded per unit of time.

Mechanical resistance is the ability of an abrasive material to withstand mechanical loads without breaking during cutting, grinding and polishing. It is characterized by compressive strength, which is determined by crushing the grain of the abrasive material, recording the load at the moment of its destruction. The tensile strength of abrasive materials decreases with increasing temperature.

Chemical resistance is the ability of abrasive materials not to change their mechanical properties when interacting with solutions of alkalis, acids, as well as in water and organic solvents.

Abrasive materials used for mechanical grinding and polishing of semiconductor materials differ in the size (fineness) of grains, numbered 200, 160, 125, 100, 80, 63, 50, 40, 32, 25,20, 16, 10, 8 , 6, 5, 4, 3, M40, M28, M20, M14, M10, M7 and M5 and are divided into four groups:

- grinding grain (from No. 200 to 15),

- grinding powders (from No. 12 to 3),

- micropowders (from M63 to M14) and

- fine micropowders (from M10 to M5).

Classification of abrasive materials by grain number is carried out by dispersion on special sieves, the number of which characterizes the grain size. The grain size of abrasive materials is characterized by the fraction: marginal, coarse, basic, complex and fine. The percentage of the main fraction is designated by the indices B, P, N and D.

Currently, abrasives are mined and manufactured synthetically, with new synthetic materials generally being more effective than natural ones. Below are lists of known abrasives.

Natural abrasives

- Diamond: A diamond-like cubic allotropic form of elemental carbon, mined from bedrock (kimberlite pipes) and placer deposits. The most valuable material for its abrasive properties. Its black variety, carbonado

(carbonate), mined in Brazil and on the island of Borneo, is considered the best.

The second place goes to the bead

- a radial-radiant variety of diamond. Any diamond unsuitable for cutting is sold on the market under the name of bead. Of the total, 20% is carbonado, 20% is real bead, the rest is diamond powder and fragments. It is used when processing hard stones, as well as for grinding and polishing the diamond itself. - Garnet: Natural mineral, consists of: R2+3 R3+2 [SiO4]3, where R2+ - Mg, Fe, Mn, Ca; R3+ - Al, Fe, Cr.

- Ciliate soil: sedimentary rock consisting primarily of the remains of diatoms. Chemically, diatomaceous earth is 96% hydrous silica (opal). Used in the form of a fine powder for polishing stone and metal.

- Quartz: Crystalline silicon dioxide, one of the cheapest and most widely available abrasives. In dry form it causes silicosis. Use only in conjunction with water supply. Quartz and flint with conchoidal fractures produce sharp-angled particles when broken. They are used in powder for processing soft stones (marble), in sandblasting machines for metal processing, for cleaning stones in the construction industry and for the production of sanding cloths. Balls for ball mills were made from flint nodules.

- Corundum: Crystalline aluminum oxide, like sapphire, mined in placers and sometimes in ores. The mined corundum ore is crushed, enriched and sorted by grain size. It is used in powder and for making artificial circles, bars and skins from it.

- Red ironstone: A common iron mineral Fe2O3. In especially pure varieties it is used for polishing iron and glass.

- Chalk: Calcium carbonate, for fine types of abrasive processing (lapping, polishing).

- Emery: Natural mineral, consists of: corundum and magnetite - black magnetic iron oxide Fe3O4

- Pumice: A bubbly volcanic glass. Pumice with thin glass plates forming partitions between the cells is suitable for grinding. The best pumice comes from the island of Lipari, near Sicily. Used for grinding wood, soft stones and metals.

- Feldspar: a group of rock-forming minerals from the silicate class. Most feldspars are representatives of solid solutions of the ternary system of the isomorphic series K[AlSi3O8] - Na[AlSi3O8] - Ca[Al2Si2O8], the end members of which, respectively, are albite (Ab), orthoclase (Or), anorthite (An). In crushed form, glued to canvas or paper, it is used in cases where soft abrasive material is required.

- Tripolum: loose or weakly cemented, finely porous opalescent sedimentary rock. Used in the form of a fine powder for polishing stone and metal.

Synthetic abrasives

- Mineral slag (coupled slag or nickel slag): used for external cleaning of metal, stone, concrete, brick, and wooden surfaces.

- Steel shot: Used for removing dense scale and processing soft stone.

- Artificial diamond: Synthesis at high pressure, processing of hard alloys, stone, glass, non-ferrous metals.

- Cubic boron nitride borazone (In Russia, cubic boron nitride is known as CBN): Synthesis at high pressure, used for grinding parts made of various steels and alloys.

- Boron-carbon-silicon alloy: Fusion of boron with carbon and silicon in an arc furnace, processing of ferrous and non-ferrous metals, stone, glass, etc.

- Boron carbide (B4C): a refractory compound, second only to diamond in hardness. Used for processing hard alloys, glass, ferrous metals.

- Silicon Carbide (SiC) or Carborundum: A chemical compound of silicon and carbon. First produced in an electric furnace in 1891. The best is considered to be American - Carborundum С°, Norton; German is worse due to impurities. The smaller the grain size, the greater their strength. It is used in powder for the production of artificial wheels and skins for processing hard alloys, non-ferrous metals and titanium.

- Silicon nitride: processing of ferrous and non-ferrous metals.

- Aluminum nitride: metal processing.

- Electrocorundum (Al2O3): crystalline aluminum oxide. It is used when processing ferrous metals, occasionally stone and glass.

- Zirconium oxide (cubic zirconia): processing of ferrous and non-ferrous metals.

- Cerium dioxide: glass processing (polyrite).

- Tin dioxide: glass processing, metal polishing.

- Titanium dioxide: polishing non-ferrous metals.

- Red (iron) crocus is obtained by calcining iron oxalate; polishing powder for metal and glass.

- Crocus green (chrome oxide): for polishing hard stones (quartz, agate, jade), ferrous and non-ferrous metals.

New promising abrasive materials are being developed:

- Carbon nitride C3N4

- Alloy of titanium carbide (TiC) and scandium carbide (Sc4C3)

Separately, the method of magnetic abrasive processing and the materials for its implementation should be highlighted. The essence of the method is to use materials with high abrasive and magnetic properties, which allows for so-called soft processing

and perform polishing at a higher level.

Comparison table of abrasive materials used in abrasive blasting

| Material | Sieve size | Form | Density lb/ft3 | Mohs hardness | Fragility | Origin | Application |

| Sand | 6-270 | * | 100 | 5.0-6.0 | high | natural material | External cleaning |

| Mineral slag, cooper slag/nickel slag | 8-80 | * | 85-112 | 7.0-7.5 | high | waste | External cleaning |

| Shot | 10-325 | * | 230 | 8.0 | low | production | Removing dense scale |

| Steel shot | 8-200 | ° | 280 | 8.0 | low | production | Cleaning, hardening |

| Aluminium oxide | 12-325 | * | 125 | 8.0-9.0+ | average | production | Cleaning, finishing, deburring, engraving |

| Glass balls | 10-400 | ° | 85-90 | 5.5 | average | production | Cleaning, finishing |

| Plastic | 12-80 | * | 45-60 | 3.0-4.0 | low/medium | production | Paint removal, deburring, cleaning |

| Wheat starch | 12-50 | * | 90 | 2.8-3.0 | high | waste | Removing paint, cleaning |

| Corn cobs | 8-40 | * | 35-45 | 2.0-4.5 | average | waste | Removing paint from delicate surfaces |

° - round; * - acute-angled

Based on Wikipedia materials

Geography of supplies of abrasive materials and abrasive blasting chambers for cleaning metal structures: St. Petersburg, Moscow, Tula, Bugulma, Izhevsk, Samara, Yekaterinburg, Chelyabinsk, Omsk and many other cities of Russia.

Equipment for shot blasting at the best prices - Aoks company.

Tweet

Share

Share

Plus

Cool

Similar articles

Shot blasting chamber: why Aox?

Budget solution for camera boxes

Job description for shot blasting machine operator

Automation of shot blasting. Specialized installations

Operation of an overhead conveyor as part of shot blasting and shot blasting installations

How to increase the throughput of a shot blasting chamber?

Economics of Sandblasting and Shot Blasting