Home / Devices

Back

Reading time: 6 min

0

1512

Corrosion-resistant steel, or stainless steel in everyday life, is the most necessary material in the household.

Household utensils are made from this alloy steel; many car parts are also made from stainless steel.

Alloy steel, which is well used in everyday life, is difficult to heat treat during welding.

Inconveniences are expressed by the existence of an oxide film on the surface of products, which melts at a temperature of at least 2,000° C.

However, there are techniques that allow you to repair or connect stainless steel parts by welding and even at home.

The best way for this operation is considered to be the use of TIG technology - manual welding with a non-consumable rod in an inert controlled atmosphere - argon.

The resulting seams are distinguished by their accuracy and reliability, which is necessary when working with alloyed metal.

- General information

- Apparatus for household work QUATTRO ELEMENT MULTI PRO 2100

- FUBAG IRMIG 200 SYN

- FOXWELD INVERMIG 185

- SVAROG PRO MIG 160 SYNERGY

- AURORA SREEDWAY 175

Difficulty factors for welding stainless steel parts

Welding stainless steel is complicated by the fact that this material belongs to the category of high-alloy alloys, which means that its composition contains elements in fairly large quantities that affect its basic properties. In stainless steel, in particular, this element is chromium. Its content in this alloy can be 12–30%. Chromium, along with elements such as nickel, titanium, manganese and molybdenum, forms the anti-corrosion properties of stainless steel, but at the same time gives it other features that affect weldability.

For those who do not like to read long articles and delve into technical details, we suggest you immediately watch two videos with the most relevant options for welding stainless steel for a home craftsman - with an electrode using an inverter and again with an inverter, but in a shielding gas (argon).

Welding of stainless steel must be carried out taking into account the following specific characteristics of this material.

A fairly high coefficient of linear expansion.

For this reason, welding of stainless steel is always accompanied by significant deformation of the parts being joined. In some cases, when the parts being welded are of significant thickness and there is no gap between them, such deformations can even lead to the appearance of large cracks.

Low thermal conductivity

The thermal conductivity of stainless steel is 1.5–2 times lower than that of low-carbon alloys. This feature of the material leads to the fact that the parts being connected in the welding zone are melted even at lower (15–20%) current strengths than when welding products made of low-carbon steel.

Intergranular corrosion

With strong heating (more than 500 degrees Celsius), so-called intergranular corrosion occurs in stainless steels. This happens because layers consisting of chromium and iron carbide begin to form at the edges of the grains of the metal structure. This phenomenon can be avoided not only by careful selection of the welding mode, but also by forced cooling of the stainless steel parts being welded, for which you can use ordinary water. However, it should be borne in mind that only parts made of chromium-nickel steels that have an austenitic internal structure can be cooled with water.

Overheating of electrodes with chromium-nickel rods

Due to the low thermal conductivity of the materials being joined and their increased electrical resistance, welding of stainless steel parts is accompanied by strong heating of the electrodes, the rods of which have a chromium-nickel composition. To avoid this undesirable phenomenon, use electrodes for welding stainless steel up to 35 cm long.

Welding electrodes Sabaros ME 101 3.2 mm for welding stainless steels

How to cook stainless steel with an inverter at home?

People who first heard about using an inverter for welding often wonder if this method can be used to join stainless steel at home.

They are also interested in what points should be given special attention. Even before starting welding work, it is important to thoroughly process and prepare the surface for joining.

In technological terms, such processing is no different from that carried out with low-carbon steels:

- Contaminants must be removed from the surface of the workpiece;

- A mandatory procedure is the treatment of edges and surfaces, for which solvents are used. Due to this operation, it is possible to remove fat, the negative impact of which is to deteriorate the stability of the arc;

- It is imperative to apply an anti-spatter agent to the surface to be treated.

It should be noted that the welded joint must have a gap, thanks to which it will be possible to create favorable conditions for optimal shrinkage.

To connect stainless steels, reverse polarity current is used . When welding, it is important to ensure that the seam melts as little as possible.

For this work, electrodes with a large diameter are usually not used. They can be used when the task of welding thick surfaces arises.

When choosing an electrode for metal of a certain thickness, it is recommended to use special tables that contain all the necessary data. If you make a mistake with the choice of electrode, this will lead to a violation of the tightness of the seam, creating a risk of microcracks, cavities and pores. The reason for their appearance is the boiling of the metal.

To weld stainless steels efficiently, you should use a current value 20% lower than that used for welding low-alloy steels. If you plan to work with an inverter intended for use in domestic conditions and private construction, then you can limit yourself to setting the range 60-160 A. Thanks to the presence of smooth adjustment, you can set the welding current with maximum accuracy, which will have a positive effect on the quality of the seam. Special tables make it easy to determine the recommended values for welding current, which are determined by such a parameter as the thickness of the material being joined.

Having finished creating the seam, it is necessary to allow it to cool, which will allow high-alloy steel to successfully resist the effects of corrosion processes.

The cooling problem is solved using copper gaskets. If you have to deal with austenitic steel, ordinary water can act as such a solution.

The most common methods of welding stainless steel

Welding of stainless steel products characterized by a high chromium content can be performed using several technologies. This includes, in particular, the following types of welding:

- argon arc (using a tungsten electrode and AC/DC TIG modes);

- performed in MMA mode with coated electrodes;

- semi-automatic arc welding in an argon environment, carried out in MIG mode and using stainless steel wire;

- so-called cold welding for stainless steel, performed under high pressure (the name of this technology is due to the fact that it does not involve melting the metal during the process of joining it);

- seam technology and resistance spot welding.

The technology for welding stainless steel parts involves thoroughly degreasing their surfaces using acetone or aviation gasoline. This is done in order to reduce the porosity of the seam being performed, to make the welding arc more stable, and to thoroughly clean the edges of the parts being joined. Only after thorough cleaning can you begin to perform the operation using the chosen method. There are several basic methods for welding stainless steel parts, as well as technologies that are used quite rarely. In any case, the decision on how to weld stainless steel should be based on the specific conditions and requirements for the joint being formed.

Choosing an inverter for home and part-time work

For the last twenty years, inverters have occupied the podium of welding equipment for home craftsmen. Unlike bulky transformer “welders”, inverters can be freely carried on the shoulder and transported anywhere on a construction site. Some models allow you to repair a car by spot welding, others have an argon-arc function for connecting two parts without an electrode wire. There are also semi-automatic machines for serious installation work. Which inverter should I buy? Let's look at the selection criteria "at a glance".

Welding with coated electrodes (MMA)

Welding stainless steel parts using MMA technology, which involves the use of coated electrodes, is the most common technology. This method is quite simple, it can be used at home, but it does not allow you to obtain the highest quality seam.

Conveniently, this kind of stainless steel welding can be done even at home, but for this you will need a special welding machine called an inverter. In order for welding stainless steel with an inverter to produce a highly reliable connection, it is necessary to select the correct electrode for a specific grade of stainless steel. All electrodes used to weld stainless steel products are divided into two main types:

- with a rutile coating based on titanium dioxide (welding with such electrodes, which provide small metal spatter and a stable arc, is performed with direct current and reverse polarity);

- with a coating based on magnesium and calcium carbonate (with such electrodes, stainless steel is welded using direct current of reverse polarity).

To understand which electrodes to use to weld stainless steel, just look at GOST 10052-75, which presents all types of such consumables, and also stipulates which one should be used for working with metal of a specific chemical composition. In order to select stainless steel electrodes that meet the requirements of this GOST, it is enough to know the grade of the metal from which the parts need to be connected.

All requirements for electrodes for welding stainless steel can be found by downloading GOST 10052-75 for free in pdf format from the link below.

GOST 10052-75 Coated metal electrodes for manual arc welding of high-alloy steels with special properties

Welding thin stainless steel

Welding any thin metal, including corrosion-resistant steels, requires the welder to have experience and knowledge. You should choose one of the presented methods for joining thin stainless steel:

1. The simplest option is to use a welding machine and special electrodes for stainless steel . It is important to set the current intensity lower than when welding ordinary steel (about 20%). The advantage of this method is that there is no need for additional tools and preparatory procedures. The main disadvantage is the low quality of the connection. Features of the welding process of thin stainless steel using electrodes are presented here.

2. Welding of thin stainless steel can also be carried out in an argon environment . This method is safer. The gas protects the forming joint from the effects of oxygen, helps to avoid defects and defects, and provides optimal heating of the working area to relieve stress. The high cost makes it difficult to use this method at home.

Manual and semi-automatic welding of stainless steel in argon (AC/DC TIG, MIG)

To perform manual welding of stainless steel in an argon environment, tungsten electrodes are used. This technology, even at home, allows you to obtain high-quality and reliable connections for products that are not very thick. Welding with such electrodes on stainless steel is used mainly for installing communications from pipes through which gases or various liquids will be transported under pressure.

Austenitic stainless steel should be welded with particular care and caution

This technology has certain features.

- To ensure that tungsten, from which stainless steel electrodes are made, does not get into the molten metal in the welding zone, the arc is ignited in a non-contact manner. If it is not possible to do this directly on the part, then the arc is lit on a special coal plate and carefully moved to the workpieces to be joined.

- Welding stainless steel using this method can be performed with both direct and alternating current.

- The modes are selected depending on the thickness of the parts being connected. Such modes, in particular, include the parameters of the cross-section of the tungsten electrode, the diameter of the wire used as an additive, current parameters (strength and polarity), shielding gas consumption, and welding speed.

- It is very important that the alloy level of the filler wire is higher than that of the parts being joined.

- During the welding process, stainless steel electrodes should not make oscillatory movements. If this requirement is neglected, this may lead to disruption of the welding zone and oxidation of the metal in its area.

By using this technology, the consumption of tungsten electrode can be reduced. To do this, you need to keep the argon supply open for some time (10–15 seconds) after the welding process is completed. This procedure helps protect the hot tungsten electrode from active oxidation.

Semi-automatic welding of stainless steel in an argon environment, in fact, has few differences from the conventional manual method. Its main difference is that the wire is fed into the welding zone using special equipment. Thanks to mechanization, the process proceeds much more accurately and at greater speed.

Thanks to the use of semi-automatic equipment, the following welding techniques for stainless steel parts can be implemented:

- jet transfer method, which allows you to effectively weld parts of large thickness;

- short arc welding - for connecting parts of small thickness;

- Pulse welding is a universal technology that allows you to obtain high-quality and reliable connections and is the most profitable option financially.

Tig welding of stainless steel

Which machine is best for welding stainless steel?

Welding stainless steel is somewhat difficult due to its chemical composition. Essentially, stainless steel is an alloy of iron and chromium with the addition of carbon, manganese, magnesium, vanadium and other elements in amounts ranging from a few hundredths to 1-2%. At the same time, the chromium content is in the range of 13-30%.

A welding machine for welding stainless steel can be used of any design - MMA, DC/AC TIG, MIG, but it must have a wider range of adjustments than a machine for welding conventional low-alloy and carbon steel. This is due to the special properties of stainless steel:

- low thermal conductivity;

- high chemical activity in the melt zone;

- significant coefficient of thermal expansion;

- low melting point.

Taking these features into account, a transformer or inverter welding machine for stainless steel must be able to weld at reduced current. In this case, much less heat enters the weld area - the metal does not burn through and its structure is not damaged.

Also, a welding machine for stainless steel must operate in both direct and reverse polarity, switch to alternating current and be able to carry out welding work in a pulsed mode. Not many models of even professional devices combine all these capabilities, so choosing a device to work exclusively with stainless steel is quite difficult.

In addition to electric arc welding, laser welding is also actively used for stainless steel, but mainly in industrial conditions. At the household level or in small workshops, it is quite difficult to find a laser welding machine for stainless steel. This is very complex and expensive equipment, but there are craftsmen who build fully functional laser installations in their own garages.

Features of MMA welding

Both transformer and inverter devices can work with stainless steel. This kind of welding is especially common at the household level and in small workshops where small-scale production of not very critical products from stainless steels is established. As already mentioned, a welding machine for welding stainless steel can be of any design, even an amateur one. In MMA welding, the correct choice of electrodes is important.

Electrodes

Two types of electrodes are suitable for working with stainless steel - basic (type SEZ ZIO-8 d4.0) and rutile (Lincoln Electric Omnia 46 D3.0). The first are coated electrodes with an outer layer of magnesium or calcium carbonate. They are designed for direct current of reverse polarity. This means that the “+” of the device is connected to the electrode, and “-” to the part being welded. The diameter of the electrode is selected according to the thickness of the steel being welded and its grade.

Rutile electrodes protected with titanium dioxide (TiO2). You can work with them both with direct current with the same polarity as in the first case, and with alternating current. They hold the arc perfectly and practically do not create metal spatter, which is typical for basic electrodes.

Table 1. Selection of electrodes for stainless steel when welding MMA

It is best to select electrodes, knowing the grade of steel being welded, according to GOST 10052, where a precisely selected electrode is indicated for each metal from the grade of high-alloy steels.

Why is the selection of electrodes so important? Chromium, which is part of steel, interacts very actively with oxygen in the atmosphere and forms a film several atoms thick, which, however, prevents the connection of the melt from different parts of the parts being joined. When the electrode coating burns, it creates a protective atmosphere that prevents oxygen and nitrogen from entering the weld pool. But for stainless steel, a special composition of the protective atmosphere must be selected, so not all types of electrodes are suitable.

Stainless steel welding machines

The choice of which machine to weld stainless steel depends on the skills and qualifications of the welder. But, according to the overwhelming majority of professionals, inverter devices are best suited for RDS of high-alloy steel grades. When purchasing, pay attention to the following basic parameters that greatly influence the result of working with stainless steel:

- Operating temperature range. Some inverters are not able to operate at low temperatures. For a high-quality inverter for stainless steel, the range starts from -10 0C and below.

- The welding current is sufficient in the range of 30-180A;

- Hot Start, Anti-Stick and Arc Force are a must;

- The power of the device must ensure the possibility of using electrodes with a diameter of up to 4 mm.

If we focus on specific models, then for welding stainless steel in domestic and semi-professional conditions, single-phase machines Svarog PRO ARC, PATON VDI-200P, Svarog TECH ARC have excellent characteristics. They are not the best, but their characteristics can be used as guidelines when choosing among models from other manufacturers. WM Pico 162, Lincoln Electric, KEMPPI Minarc are quite suitable for professional work.

In the three-phase family, the best choice would be Svarog ARC 315 Lincoln Electric, EWM Pico, BRIMA ARC.

Argon welding AC/DC TIG

No less common equipment for welding stainless steels in the semi-professional and professional segments are AC/DC TIG machines operating in an argon atmosphere. In this case, the electrode is a tungsten rod; it is necessary to use special grades of filler wire that exceed the level of alloying of the metal being welded, for example, ER 308.

When welding thin metal, you can install a copper plate under the stainless steel to remove heat. After welding is completed, it is necessary to leave the gas supply for a few seconds, the so-called Post flow mode. This allows the metal to cool sufficiently without oxidizing and prevents the tungsten electrode from burning.

AC/DC TIG machines are capable of working with many metals, such as aluminum and its alloys. The most modern ones use Soft Switch technology, which allows you to dramatically reduce the level of heat loss, current balance settings, changing the frequency characteristics when welding on alternating current, and pulsation mode.

A particularly interesting mode is MIX TIG, which is used in semi-professional and professional machines and is a combination of alternate use of welding with direct and alternating currents. In this case, the variable one breaks the oxide film without overheating the metal, and the constant one produces melting and welding. Almost all machines have a Spot Arc mode - spot welding, which allows you to tack metal and accurately perform facial seams.

The best welding machines are TRITON ALUTIG, Aurora PRO INTER, Svarog PRO TIG, Aurora IRONMAN, Fubag INTIG. They are in different price categories, but allow you to weld stainless steel at approximately the same level of quality, differing only in the time of continuous operation and power limitations.

Welding stainless steel MIG/MAG

Semi-automatic welding of stainless steel is available even with not very great professional skills and abilities. But in the hands of professional welders, MIG machines work real miracles, coping with both the thinnest sheets and bulky relief parts.

The MIG/MAG machine must be configurable for short arc (for thin sheets), jet transfer and pulse mode. Gas is used together with monolithic stainless wire; when welding with flux-cored wire, gas is not required. But flux-cored wire can only be used for not very critical work - over time, the seam may become covered with a coating of rust. The ideal case is stainless wire according to GOST 2246-70 in an atmosphere of argon or argon and helium.

The best devices are Svarog EASY MIG, FEB NORM, BRIMA, TRITON MIG 300, professional ones - EWM Picomig, KEMPPI Minarc MIG EVO 170, Lincoln Electric.

We invite readers to share their own experience of welding with stainless steel. Practical skills, your own findings, non-standard approaches to using equipment - write to us about everything.

wikimetall.ru

Other stainless steel welding technologies

There are several other methods of welding stainless steel that demonstrate themselves better in certain situations, that is, they are not universal. This includes the following methods, which involve the use of special equipment.

Welding stainless steel using a laser beam

This welding method, which even looks very impressive on video, has a number of significant advantages: the metal in the welding zone does not lose its strength due to excessive temperature exposure, cools quickly, cracks do not appear on it, and grains of minimal size are formed in its structure . Equipment for laser welding and the technology itself are widely used in various industries (automobile and tractor manufacturing, installation of pipe communications, etc.).

Cold welding under high pressure

This technology does not involve melting of the material in the welding zone, and metal parts are connected at the level of their crystal lattices. Depending on the resulting connection and the configuration of the parts, pressure can be applied to one or both metal workpieces. It is very interesting to watch a video of such a process: two parts, being in a cold state, seem to be pressed into each other.

Contact welding of stainless steel products

Such welding can be performed using spot or roller technology. As a result, thin stainless steel sheets with a thickness of no more than 2 mm can be joined. The same equipment is used as for other metals.

The video below explains in detail and clearly demonstrates the nuances of feeding a filler rod when welding stainless steel with a non-fusible electrode in an argon environment and other nuances of the work.

Where is the method most often used?

The peculiarity of welding stainless steel using an inverter is that it can be used in any situation, regardless of spatial position. It should be remembered that even experience does not guarantee the creation of high-quality vertical seams. It makes sense to resort to manual arc welding with coated electrodes when it is necessary to create short seams, which is most in demand in small-scale production of parts.

A similar method of connecting products can be used when installing metal structures only if a small amount of work is planned.

In most cases, stainless steel RDS with coated electrodes is used in cases where tack welding is performed during the installation of structures for welding. This option can also be considered in cases where it is necessary to eliminate defects present in small areas of the weld. This method can also be used for surfacing.

In light of this, we can conclude that it can be used in situations where you have to deal with a small amount of work. It is also suitable for welding for personal and household purposes. The elements to be connected can be pipes, metal structures, containers, stainless steel tanks, etc.

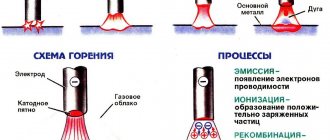

Operating principle and advantages of the inverter device

Such devices are equipped with inverter control circuits that increase the frequency of the current transmitted from the electrical network from 50 Hz (the frequency of the alternating current network) to several thousand hertz. Then the high frequency current is supplied to the winding of the step-down transformer. Thanks to this, the inverter “welder” is superior to the transformer one in the following indicators:

- More stable arc and smooth seam . During operation, the arc does not “jump” even when the voltage drops in the network, and as a result, a more even seam is produced.

- Light weight . Increasing the frequency made it possible to reduce the size of the transformer coils, which significantly reduced the overall weight of the unit. For example, an inverter model can weigh 3 - 4 kg, while a transformer model with the same performance indicators can weigh as much as 20 kg.

What is the maximum current needed?

When you decide which welding inverter is best to choose, pay attention to the maximum output current. In many ways, the choice of device for this indicator depends on how thick the metal you plan to weld and what electrodes you will use. For example, for welding metal products with a thickness of 2 - 3 mm, electrodes (for manual arc) with a thickness of 3 - 4 mm are used. To perform such work, you will need a device with an operating current of at least 120 A. Note that in the household it is rarely necessary to weld very thin parts (less than 1 mm), so 120 A is the working minimum for a home craftsman.

Metal with a thickness of more than 5 mm will take a device with a current load of 200 A. Please note that machines with argon-arc welding have a maximum current of 120 A and higher, and semi-automatic inverters start at 220 A.