Practical application of ZELLER 655 electrodes

The technology for repairing steel structures using welding requires careful selection of electrode materials to restore them to their previous technical parameters. Electrodes of the ZELLER 655 brand significantly increase the efficiency of repairs due to their welding and technical characteristics, especially the ability to weld dissimilar and difficult-to-weld metals.

The material of the ZELLER 655 electrode rod consists of a specially selected composition of elements , the main ones being Fe (iron), Cr (chromium), Ni (nickel). The presence of iron makes it possible to use the consumable in surfacing technology for restoration repairs . Other elements give the weld good corrosion resistance and excellent mechanical wear resistance.

The coating composition of ZELLER 655 electrodes ensures stable arc operation , which should be kept short or medium. Spattering during welding work is reduced to a minimum. The slag is easily separated . The coating ensures easy arc ignition , both initial and repeated, which facilitates repair work, especially in cramped conditions.

The main distinctive feature of the ZELLER 655 electrode is the production of a welding seam with very high strength characteristics . Tensile strength is 880-1280 N/sq. Mm (Newtons per sq.mm.), which is not achieved by practically any other existing similar welding materials. The composition of the material of the rod, in combination with the elements included in its coating, practically eliminates the formation of cracks in the weld seam and ensures very insignificant movements of the seam and the metals being joined.

Where applicable

The above main welding and technical characteristics of the ZELLER 655 brand electrode allow it to be used effectively in repair work, subject to the following technological regulations:

- It is recommended to calcinate the electrodes at a temperature of 350°C for one hour;

- the surfaces to be welded should be cleaned of rust, oil residues, paints and other contaminants;

- perform edge cutting, for example, V-shaped with an angle of 60° - 80°;

- when performing welding work, it is recommended to keep the electrode in a vertical position, apply seams with an overlap of one third of the previous one with the absence of oscillatory movements of the arc;

- heating is required when welding large workpieces, for example, high-carbon steel.

Welding of dissimilar steels

Some structures, due to the operation of their individual parts under different conditions, are made from metals that have different physical and chemical properties. When welding dissimilar steels with conventional electrodes, due to differences, for example, in the values of thermal expansion, cracks form in the weld. Electrodes of the ZELLER 655 brand practically do not change the structure of the metals being welded and have minimal impact on them. The weld is created mainly from filler material, which has minimal forces and is not prone to cracking. The strength characteristics of the structure remain high.

Welding high carbon steels

High-carbon steels include, first of all, tool (U8, U10, U12, R6M5 and others), die (ShKh15, Kh12MF and others) steels. They are used for the manufacture of critical tools and stamping equipment. During operation, cracks form on them, which act as stress concentrators and can cause product failure if they are not welded in time. Since these steels are prone to hardening under thermal influence, which leads to the formation of cracks and other similar defects in the welding zone, the use of electrodes with unique welding characteristics is required. ZELLER 655 grade successfully eliminates defects in high-carbon steels.

Welding spring steel

Spring steels (65G, 50HGA and others) should have increased elastic and plastic properties . If one or more plates from the prefabricated spring structure break, they can be restored by welding with a ZELLER 655 brand electrode. In addition to the high strength of the weld, the alloying elements of the electrode increase the solubility of hydrogen in the melt, which makes the weld plastic and corresponding to the nature of the perceived loads, practically no different from the parameters main spring material.

Welding manganese steels

Manganese steel or Hadfield steel is hardened by heavy impacts . This property also applies to welds made with ZELLER 655 electrode, which achieves high hardness under impact loads. Repair of crusher cheeks, caterpillar tracks, excavator teeth and other structural elements made of manganese steels using welding can be performed with ZELLER 655 consumables. At the same time, the manganese and carbon of the base material practically do not burn out, maintaining its mechanical properties.

Welding unknown steel grades

When carrying out welding repair work on old metal structures for which there is no technical documentation, and it is not possible to determine the steel grade in the laboratory , the use of a ZELLER 655 electrode solves all problems. This universal electrode is capable of providing high-quality welding of almost all existing steel grades. Therefore, you can safely use it for welding repair work using unknown grades of metals.

Restoration of surfaces using surfacing technology

As a surfacing material, ZELLER 655 electrode can act in two forms.

- When restoring a worn surface that has a hardness exceeding the maximum possible when surfacing with the ZELLER 655 consumable, this electrode is effectively used as a buffer layer before surfacing the main hard alloy.

- Structural carbon steels 40X, 40X13 are very often used for the manufacture of shafts, cams, copiers, and gears The surface hardness of these steels after heat treatment is the same in value as the hardness of the surfacing layer of ZELLER 655 electrodes. Therefore, the worn surfaces of parts made of these materials can be surfaced with these consumables without further heat treatment . In case of breakage of a gear tooth made of steel 40Х or 40Х13, the technology of surfacing with ZELLER 655 electrodes allows you to completely restore the entire tooth. The consumable can be used for multi-layer deposition, and no surface defects are formed after each pass. After restoring the contours of the tooth body with an allowance, using mechanical processing (surfacing lends itself well to it), it is brought to the drawing dimensions. With the help of impact loads (this can be done directly during gear operation), the deposited tooth acquires the required hardness of the order of 40...45 HRC (Rockwell hardness).

Story

Hadfield steel, as one might guess from its very name, was obtained by a certain Hadfield. But few people know who this man is and when this steel was offered to him. If you delve into history, you can find out the fact that this material of increased strength was obtained by the English metallurgist Robert Hadfield in 1882 . It became widespread quite quickly, as it turned out to be very interesting material.

Soon after Hadfield steel was released into mass production, the military became interested in it. And not by chance. High strength steel was to become a very important material for the creation of some elements of protective military equipment.

The introduction of Hadfield steel into the military industry began with the material being used to create high-strength infantry helmets. At first, such helmets were adopted by the British army, but the American military did not stand aside and also began producing similar helmets. The technology for creating helmets from Hadfield steel remained unchanged until the 80s. The fact is that by that time, steel, which had already become famous, was replaced with organoplastic, since it was lighter, but remained quite durable.

Hadfield steel was also widely used in tank building . It was used to make caterpillar tracks for tanks. Hadfield steel was first used for this purpose from Britain in the late 20s. The use of this steel in the manufacture of tank tracks made it possible to significantly increase the mileage to 4,800 km. By the way, before using the miracle of steel, the mileage was 500 km. What’s most interesting is that this small figure was considered a real record during the First World War. This fact shows how important the use of Hadfield steel was in the field of tank construction.

Subsequently, the use of Hadfield steel was carried out not only in military fields. In the Soviet Union, smelting at this cost was mastered only by 1936.

Processing methods

Cold forming of metals is a well-known method of intentionally creating hardening. Typical technological processes for such metal processing are drawing, cold forging, rolling, pressing (extrusion). If you overdo the processing, the Hadfield steel part can fall apart due to increasing internal stresses that destroy it. Therefore, when processing, for example, a knife blade, which is recommended to be slightly beaten before final sharpening, or when beating a braid (and this is cold forging), you need to apply very light blows and be careful about the recoil from the hammer. As soon as it starts to bounce, it's time to stop hitting, otherwise the blade may crumble.

Due to the high viscosity of Hadfield steel, parts made from it practically cannot be processed with cutting tools. For mass production of products from this steel, only casting is suitable. Casting molds must be made very carefully so that the manufactured parts are not subjected to additional processing. After casting the product and solidifying the metal, the quality of the steel is quite low, since at the boundaries of austenite grains there are small inclusions of carbides, which easily form cracks between the grains and lead to rapid destruction. Turning is possible only with the use of high-speed steels with high heat resistance. That is, the tool, when high temperatures occur at the cutting edge, must maintain high hardness and resist wear.

Changing alloy properties

When a metal is subjected to mechanical stress, microscopic defects are formed in it - dislocations; if such impact continues, these defects begin to shift and interact. They form a new material structure that resists further plastic change in shape. This structure increases the metal's ability to resist applied forces, increases the material's yield strength and reduces its viscosity. This is very important for those metals and alloys that are not strengthened during heat treatment.

At room temperature, Hadfield steel is practically non-magnetic, but after cold deformation, magnetic properties appear. This phenomenon is accompanied by the appearance in the metal structure of dense slip planes of dislocations, which crush the grains into separate blocks. The discovery of Hadfield and Hopkinson was that tensile testing of a steel sample gave it weakly magnetic properties. The appearance of ferromagnetism shows that after this type of load, part of the metal passes into the a-iron state.

What is hardening?

Hardening is an increase in the strength of metals and alloys due to changes in their structure during plastic deformation at a temperature below the recrystallization temperature. That is, the temperature at which, in place of elongated metal grains that have lost their shape, new grains with an undistorted lattice and regular round shape begin to appear and grow. When a metal is hardened, its density decreases; this occurs due to a violation of the order in the arrangement of atoms, distortion of the atomic lattice, the formation of micropores, and an increase in the density of defects. A decrease in density means an increase in the specific volume per unit mass. The outer hardened layer tends to expand, but the inner ones do not allow it to do so. Residual compressive stresses arise in the metal. They can be very useful, as they are able to stop the process of appearance and increase in surface fatigue cracks.

It is impossible to guarantee uniform constancy of specific pressures in the hinge in the range from 80 to 200 kg/cm, at which the ability of steel to work hardening is manifested, and thereby its ability to resist wear is revealed. Below these indicators, hardening of Hadfield steel is not observed, and above this, residual deformation occurs, and accordingly, its abilities cannot be fully used. Numerous observations of the operation of STZ NATI tractors in the field have shown that after about a thousand hours of operation, the wear of the eye holes of the hinge joints is 0.3 - 0.4 cm, and as a result of one and a half to two thousand hours of operation, the eyes are worn out to almost the entire thickness of the wall 0, 8 cm or destroyed earlier.

Alloying

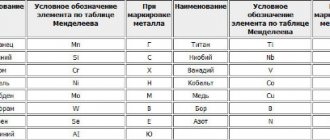

Alloying is a change in the composition of steel using a calculated amount of auxiliary elements, impurities, to give it certain physical qualities. Among the most commonly used alloying components are:

- manganese,

- titanium,

- cobalt,

- tungsten,

- aluminum,

- nickel,

- chromium,

- silicon,

- vanadium,

- niobium.

All these additives have different effects on the final qualities of the resulting alloy. Before purposefully adding alloying components to metal, people became acquainted with natural alloyed alloys that literally fell from the sky in the form of iron meteorites. This iron has been used for a long time. It contains up to 8.5% nickel, an alloying element actively used today.

This type of steel was invented in 1882 by the English metallurgist Robert Hadfield (he was accepted as an honorary member of the USSR Academy of Sciences in 1933). This is a highly ductile steel with a high manganese content. This brand of steel turned out to be so successful that even now, with virtually no changes in the chemical composition, it is widely used in a wide variety of industries. In the USSR, the technology for smelting this steel was mastered by 1936. In Russia and among member countries of the Commonwealth of Independent States, it is known under the brand name 110G13L (or G13L). The letter “L” means that this steel is for casting. The requirements are regulated by GOST 977-88 and its analogues abroad.