For decorative finishing, especially in the private sector, material from the group of thin-sheet metal products is increasingly in demand. Let's look at the features of the process of cutting corrugated sheets. Let's get acquainted with controversial issues regarding the use of an angle grinder and a hand-held circular saw. We will also learn about tools with which you can perform straight and curved cuts with minimal harm to the workpiece.

An example of corrugated sheeting for cladding a fence Source domstyle.by

Features of cutting sheets

The corrugated sheet is based on thin sheet steel with a thickness of 0.3-1.2 mm. To prevent the material from rusting and serve for a long time, it is coated on both sides with a thin layer of an alloy containing zinc. For the decorative component, there are layers of special primer and powder paint, which also extend the service life of the canvases.

During installation work, the corrugated sheet is cut. As a result, the protective layers are destroyed. Therefore, the most gentle tool is selected for cutting, and the edges are treated with anti-corrosion agents.

Edge protection against corrosion

There are special paints in cans that are applied by spraying onto the work surface. They are supplied for sale in the same colors as corrugated sheets. Another option is anti-corrosion mastic. In any case, you need to read the instructions to find out whether and what kind of primer should be applied to the damaged edge before finishing.

An example of special paints for protecting rolled metal products Source armadius.com.ua

Is it possible to cut corrugated sheets with a grinder?

An electric grinder is often used in construction because it can process or cut any metal as quickly as possible. The device is also quite easy to use, and the speed of surface processing is its main advantage.

But it is worth noting that when cutting a profile with a grinder, experts highlight many disadvantages from using the tool. The grinder is an abrasive construction device that can quickly damage the sheet.

This happens for several reasons:

- Metal particles heated during operation spoil the coating by burning through it. If the material is not treated with a protective coating after cutting, corrosion will form in these places.

- After processing the corrugated sheeting, uneven edges remain, so you will have to additionally remove burrs from the surface.

To avoid such difficulties, you need to select special discs for cutting corrugated sheets and promptly coat the sheet adjusted to size with protective paints.

Selecting a cutting tool

The main three criteria for choosing the optimal tool for cutting corrugated sheets are the permissibility of working with thin sheet metal, gentle and accurate cutting, and ease of performing the task. These parameters correspond to scissors, hacksaws, their electric analogues and equipment with replaceable discs. Let's take a closer look at the features of working with each option.

Scissors

Hand-held metal shears for cutting corrugated sheets are more convenient to use when cutting a small number of workpieces and forming curved edges. Craftsmen recommend choosing spline samples from this category. Here, the cutting part of the tool is represented by a rectangular plate (also known as the supporting part) and a movable sharpened head that fits into the groove of the plate. The thickness of sheet metal for cutting can reach 2.5 mm.

Using conventional metal scissors Source yandex.net

Another solution is nibblers or notching shears for corrugated sheets in the form of an attachment for a drill or screwdriver. There is a mechanism here that converts the rotation of the cartridge into reciprocating movements of the cutting elements of the device. They can cut both steel blanks and plastic with polycarbonate. The edges are equally neat regardless of the curvature of the intended line.

Example of using a screwdriver attachment Source leguidedelamaison.com

See also: Catalog of companies that specialize in finishing materials and related work

The third option for scissors for cutting corrugated sheets is a power tool. Externally, the technique is similar to an angle grinder. The working part is designed in a similar way to the drill attachment described above. There is also a static part and a moving part. Only there are models that, during cutting, act on the metal from one or both sides (like nibblers or hand scissors, respectively). In the case of the former, there is one drawback - the edges of the prepared sheet are slightly bent.

Option for electric metal shears Source amazon.com

Hacksaw blade

Despite the labor intensity, craftsmen often prefer a hand hacksaw for metal to other tools than can be used to cut profiled sheets. This is justified by accurate and accurate results, the absence of restrictions on the thickness of the blade, and safety compared to electrical analogues. Disadvantages include the difficulty of forming curved edges.

An example of a hand hacksaw for metal Source artem-tools.ru

Alternative powered or battery powered tools for cutting corrugated sheets include a jigsaw or reciprocating saw. Only in the case of the former, the height of the wave on the workpieces should be limited to 20-25 mm in order to prevent the formation of a torn edge. The latter are equipped with a comparatively smaller base plate, so there is no dependence on the topography of the sheet. But in each case, the speed of the saw must be adjusted downward so that the paint along the cut line does not burn.

Electric jigsaw Source ozone.ru

Profile mode for drywall at home

Today, not a single renovation can be done without drywall. This modern material has firmly established its position as a leader in the construction market. If you decide to do your own interior decoration with plasterboard sheets, you should know that you will have to deal not only with this material, but also with metal profiles. The latter are used to create a frame, which is then sheathed with sheets of plasterboard.

Metal carcass

Due to the fact that plasterboard sheets are used to assemble structures of a wide variety of complexity, metal profiles need to be cut, bent and connected. All these manipulations must be done correctly so as not to damage the material and create a durable structure. In this article we will look at everything related to the issue of cutting profiles.

READ How to Cut Skirting Boards for a Ceiling Using a Miter Box

Recommendations from the experts

When working with thin sheet metal, you need to use construction gloves. They can significantly reduce the likelihood of injury from a sharp edge on the cutting line, from burrs and other defects on it. Another important point concerns tools with replaceable disks. They must be equipped with protective covers to prevent sparks from getting into the eyes and face in general. They also reduce the area of distribution of hot metal chips.

As a rule, cutting of corrugated sheets is carried out in a straight line. To make the process of creating a straight edge easier, you can use another sheet as a guide. Simply place it on top of the workpiece. It can also be used at the same time to protect the bottom sheet from damage from sparks.

Another point concerns the flexibility of rolled metal. If you use ordinary metal scissors to cut corrugated sheets, then reliable fixation of the workpiece is not required. In other cases, this must be done.

An example of a working platform using wooden blocks Source stroitelstvo.expert

Otherwise, vibrations and mobility of the blade will contribute to the performance of work in uncomfortable conditions. As a result, the quality of the formed edge will suffer.

Material range

Guide profile

It would seem that what could be difficult in such a process? But as practice shows, even with such a seemingly simple matter, certain difficulties can arise. Metal framing is almost always necessary for drywall. To install it you need to use a profile. It should be noted that the profile for drywall may be different. Today there are the following types of profiles:

These are the two main types of frame elements. But profiles can also be of the following types:

Rack profile

- beacon;

- angular.

HOW to cut a metal profile with an angle grinder or scissors

All of them have to be cut during the assembly of the frame, since it is unlikely that you will need to use the entire length of the rail. Typically, the profile needs to be cut into several pieces to create a frame for the required structure.

Advice from professionals

Now that the issue with the cutting tool has been clarified, it is necessary to add a few words about cut processing. Professionals know that when using “hot” methods (grinder and jigsaw), the coating of the profiled sheet is damaged and the cut itself is charred. Not only is this unsightly, but it also takes extra time to straighten and clean up the cut. Moreover, professionals never use autogen for cutting corrugated sheets.

Of course, it is preferable to cut corrugated sheets using scissors or a hacksaw. In this case, you need to decide what is more important: speed or quality. In any case, after cutting the corrugated sheeting is completed, care should be taken to ensure the durability of its service. The most important advice that is relevant here is: be sure to treat the cut, ideally this should be done with factory paint. Such paint is usually sold in any hardware store, and most manufacturers of profiled sheets include paint complete with corrugated sheets.

Meet the professional sheet!

The full name of the material is profiled sheet. There is one more thing - corrugated sheets. The appearance of the latter is due to its popularity as a roofing material, although it has a very wide range of applications - from fences to load-bearing structures. This is a sheet of galvanized steel that has been profiled (corrugated) to achieve maximum rigidity and strength while maintaining minimum weight. It can vary in thickness and size, profile width, height and shape (trapezoidal, wavy) of the corrugation itself. Often has a polymer or paint coating to protect against corrosion.

Tools for installing corrugated sheets: (1. Screwdriver; 2. Hammer drill; 3. Rubber mallet); 4. Brush with soft bristles;5. Roulette;6. Long rail;7. Marker;8. Level;9. Tool for cutting siding and building profiles.)

After looking at the corrugated sheet that needs to be cut, and evaluating its characteristics and further application, you can determine your cutting requirements by asking the following questions:

- What cutting quality suits you?

- Do you need to cut curved?

- Is it necessary to take care of the safety of the anti-corrosion coating?

- Does speed matter?

- How much money is reasonable to spend on tools, if you don’t have one, and on consumables?

Considering the variety of profiled sheets and the widest range of its applications, we present to your attention tools that allow you to perform cutting - from special to manual.

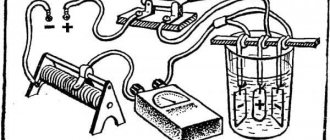

What and how to make a hole in a sheet of metal?

It all depends on the size of the hole. If the diameter is small, a drill will do. If large holes are needed, special drill bits are used. Pay attention to the material from which the horse-drawn horse is made. To process profiled sheets, you should use nozzles with a carbide coating. Processing should be carried out without increasing the temperature.

A jigsaw is used to make a large diameter hole. With this tool, cutting out a circle of large diameter will not be difficult. When working, use a saw with fine teeth