Issues discussed in the material:

- What is the technology of hot galvanizing of metal?

- What is the technology of cold galvanizing of metal

- How metal is galvanized using galvanic technology

Galvanizing refers to anodic coatings of metal, when a material having a lower electrode potential is applied to the surface being treated. This method of industrial processing of metal surfaces is a very common method of protecting metal from the negative effects of the environment. The technology of metal galvanizing depends on the parameters of the product being processed and the proposed operating conditions. In our article we will analyze in detail all the varieties and features of this technology.

General requirements

1.1. At the stage of preliminary negotiations, before concluding an additional agreement (or contract) to perform galvanizing work on metal structures, the Customer is obliged to transfer to the Contractor in order for the latter to determine the availability (absence) of the technical feasibility of galvanizing the following documents:

- A drawing or package of drawings in the KMD category, adapted only in Russian with overall dimensions and technical conditions for the implementation of anti-corrosion coating by hot-dip galvanizing in accordance with GOST 9.307 - 89;

- Foreign-made drawings (in English, German, Chinese and other languages are not accepted for approval);

- A certificate or certificates for the metal from which the product or metal structure is made, including a different assortment of metal products (angle, channel, I-beam, pipe, plate or circle).

1.2. The transferred metal structures must be marked in the form of a brand (product brand) corresponding to the brand specified in the shipping document. Metal structures must be transferred in packages (by brand and profile) equipped with tags. The tag must indicate the name of the Customer, the brand of the product (name), the number of pieces in the package, and the total weight of the package.

1.3. Metal structures made of low-carbon steels (ST 3 SP, 09 G2 S, ST 20, etc.) are accepted for galvanizing.

1.4. The overall dimensions of steel structure elements subject to zinc coating should be no more than: length - 12.5 m, width - 1.5 m and height - 3.0 m.

Requirements for the design of products to be galvanized (in accordance with GOST 9.307 - 89)

2.1. There should be no “pockets”, closed cavities or air pockets in metal structures; all cavities must be accessible for the unhindered entry and exit of liquids, molten zinc and gases.

2.2. Welding of elements of steel structures should be done end-to-end, either with double-sided seams, or with a one-sided seam with an underweld.

2.3. Welds must be uniform, tight and continuous along their entire length.

2.4. All parts of metal structures must have technological holes (both to fulfill the requirements of paragraph 2.1. and for hanging the products themselves). Technological holes should have a diameter of 15 to 30 mm and be located at a distance of 10 to 30 mm from the end of the part.

2.5. The location and feasibility of making technological holes in the design documentation provided by the Customer must be agreed upon with the Contractor and approved by the specialists of the Central Center of Design Center of ECM LLC before the parties enter into an additional agreement (or contract).

PAY SPECIAL ATTENTION!

2.6. Sealed containers, drums, pipe coils, units with threaded connections cannot be coated by hot-dip galvanizing.

2.7. To avoid explosion, it is not allowed to apply coating to products that have closed cavities.

2.8. Hollow products and products of complex shape are subjected to trial galvanizing.

2.9. It is not allowed to galvanize products with overlapping welded joints.

Requirements for the surface of the base metal (in accordance with GOST 9.307 – 89)

3.1. The following are not allowed on the surface of the base metal:

- rolled scale;

- hangnails;

- pores;

- inclusions (dirt, residues of abrasive material from mechanical processing);

- welding slags;

- molding mass residues;

- graphite;

- lubricant (silicone);

- metal shavings;

- marking paint;

3.2. Pores, fistulas, cracks and surface joints of welded seams are not allowed (cleaning of seams is mandatory).

3.3. Sharp corners and edges of products, except in technically justified cases, must be rounded with a radius of at least 0.3 mm.

Subject to the above requirements, the Contractor guarantees the application of the coating using the hot-dip galvanizing method in accordance with GOST 9.307 - 89.

This is interesting: Cold metal stamping: technology, types, equipment

How is hot-dip galvanizing performed?

There are two stages of hot-dip galvanizing:

- The surface to be treated is carefully prepared for the procedure.

- The product is immersed in a container with molten zinc, as a result of which it is literally enveloped in this metal.

All the nuances of performing such a technological operation are regulated by GOST 9.307-89.

Technological cycle of galvanizing

Hot-dip galvanizing technology requires a careful approach to the implementation of all its stages. To understand their essence and purpose, each of them is worth considering in more detail.

Preparing a metal product for the procedure

GOST indicates that the surface to be hot-dip galvanized must be carefully prepared. This preparation consists of several procedures:

- mechanical processing;

- degreasing;

- washing;

- etching;

- washing after etching;

- fluxing;

- drying.

Using mechanical treatment, dirt, oxidation products, traces of rust, and slag inclusions are removed from the surface. GOST also prescribes that sharp corners and edges on the product must be rounded, which is also decided at the machining stage. To perform mechanical processing in production conditions, sandblasting units are used.

Degreasing metal products in a solution of orthophosphoric acid

Degreasing, which is performed at a temperature of about 75°, must be performed before hot-dip galvanizing in order to improve the adhesion of the formed protective layer to the galvanized product. The presence of grease and oil stains on the treated surface can cause the zinc coating in such areas to have uneven thickness or even peel off.

Degreasing is carried out using special chemical reagents, the list of which is given by the corresponding GOST. Their residues must subsequently be completely removed from the surface of the product, for which it is washed.

Washing tanks for long items

GOST also indicates that pipes or other products subjected to hot-dip galvanizing should not have oxidized areas, as well as old zinc coating, if it was previously applied. In order to meet these requirements, the surface to be treated is etched. For this purpose, a solution of hydrochloric acid is usually used. This procedure is performed at room temperature (22–24°), and the concentration of the acid solution is selected depending on how heavily the surface is contaminated with oxides and traces of corrosion.

As a rule, solutions containing 140–200 grams of acid per liter are used for etching. When etching, an acid solution can severely damage the surface being treated. To prevent this from happening, and also to minimize the release of hydrogen from the etching solution, special substances called inhibitors are introduced into it. As with degreasing, after etching the product must be thoroughly rinsed to remove any remaining chemicals used.

Products prepared for galvanizing

Fluxing before hot-dip galvanizing, the technology of which involves careful preparation of the workpiece, allows you to solve two important problems at once: prevent the oxidation process and improve the adhesion of the applied coating to the base metal. During the fluxing process, performed at a temperature of 60°, a thin layer of flux contained in a special solution is applied to the surface to be treated. As a rule, ammonium and zinc chlorides are used as flux. They are mixed with water at a ratio of 500 grams per liter to prepare a fluxing solution. When performing fluxing, it is very important to monitor such parameters of the solution used as iron content, density and acidity. If the concentration of iron in the solution is exceeded, hydrogen peroxide is introduced into it, which promotes the formation of iron salts that precipitate.

Any hot-dip galvanizing shop must be equipped with thermal furnaces in which the product being processed is dried after fluxing. This heat treatment allows not only to remove residual liquid, which deteriorates the quality of the finished zinc coating, but also to heat the part to a temperature of 100°, which makes it possible to reduce the costs of the main technological operation.

For what purposes are metal structures galvanized?

The process involves applying a thin layer of zinc; before application, the surface is treated by mechanical and chemical means. The coating provides protection not only barrier, but also electrochemical reaction. Hot-dip galvanizing is used in most cases when working with metals, since it is most susceptible to grading processes. The hot-dip galvanizing method is the most acceptable, as it has a balanced process cost and high results.

Hot galvanizing method in production

The main purpose of galvanizing is to increase the strength of metal structures. A galvanized part does not need to be painted to protect it from corrosion; in total, the process is close to the cost of painting, but has more advantages.

Galvanic galvanizing of metal

Galvanic galvanizing is the process of applying zinc to the surface of a metal in an electrolyte solution. This method is one of the most effective for combating the appearance of corrosion on metal products. The zinc alloy covers the metal with a thin film that has excellent protective properties. It makes it possible, after processing, to use metals in an aggressive environment. It prevents various substances from penetrating the metal structure to change its properties. As a result of the use of zinc and electrolyte, metals become more durable and resistant to environmental conditions.

Zinc is a suitable metal for processing other types of metal materials. After the galvanic galvanizing procedure, a layer of film appears on the surface of the treated metal, which gives it a silvery tint with a bluish tint. Thanks to this, a product made from such material acquires a more aesthetic appearance.

Galvanic galvanizing of metal has advantages and disadvantages.

The advantages of this procedure include:

- high level of productivity. In a short time, a large number of metal products are coated with a solution of zinc alloy and electrolyte.

- Accuracy of the procedure. After processing metal products in this way, a uniform coating is formed that covers the entire product. There are practically no smudges or chips.

- Improving the external qualities of individual metal objects. This method is excellent not only for protecting against corrosion, but also for giving products made from different metals an aesthetic appearance. The surface is covered with a thin layer of silver-colored film. The product becomes shiny.

The main disadvantage of this procedure is the low level of adhesion to different types of metals. As a result, the protective effect against corrosion does not last long. In addition, as a result of anodizing, the metal may become brittle, which leads to structural failure.

Today, galvanizing is used to coat individual components with a zinc alloy to protect them from corrosion and to provide an aesthetically pleasing appearance. Nails, hardware and fastening tools are processed using this method.

Table 1. Galvanic compatibility of metals

| Metal | Steel | Aluminum | Duralumin | Copper | Brass | Bronze | Chromium | Nickel | Zinc | Tin | Solder PIC |

| Steel | + | + | + | — | — | — | + | + | + | + | + |

| Aluminum | + | + | + | — | — | — | + | — | + | P | P |

| Duralumin | + | + | + | — | — | — | + | — | + | P | P |

| Copper | — | — | — | + | + | + | + | + | — | P | P |

| Brass | — | — | — | + | + | + | + | + | — | P | P |

| Bronze | — | — | — | + | + | + | + | + | — | P | P |

| Chromium | + | + | + | + | + | + | + | + | + | P | P |

| Nickel | + | — | — | + | + | + | + | + | + | P | P |

| Zinc | + | + | + | — | — | — | + | + | + | + | + |

| Tin | + | P | P | P | P | P | P | P | + | + | + |

| Solder PIC | + | P | P | P | P | P | P | P | + | + | + |

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the State Construction Committee of the USSR

DEVELOPERS

S.V.Marutyan, Ph.D. tech. Sciences (topic leader), S.A. Klochko, L.N. Pavlova, S.G. Gutnik, L.M. Belousova

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee on Standards dated May 30, 1989 N 1379

3. The standard fully complies with international standards ISO 1461-89*, ST SEV 4663-84 ________________ * Access to international and foreign documents mentioned in the text can be obtained by contacting the User Support Service. — Note from the database manufacturer.

4. INSTEAD GOST 9.307-85

5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Item number |

| GOST 9.302-88 | 4.2.3 |

| GOST 9.402-80 | 1.2.5 |

| GOST 3118-77 | 4.2.3 |

| GOST 6709-72 | 4.2.3 |

| GOST 19251.1-79 — GOST 19251.3-79 | 4.3 |

| GOST 19251.5-79 | 4.3 |

6. REISSUE

This standard establishes general requirements (hereinafter referred to as requirements) for protective coatings applied by hot-dip galvanizing (hereinafter referred to as coatings) on structural steel, including high-strength steel structures, shaped steel products and sheet steel, pipe sets, large-diameter pipes , bent or welded before coating, containers, steel wire products, bulk processed fasteners, steel and iron castings, forgings, stamped steel products, and to base metal and coating quality control methods.

This standard does not apply to coatings applied in a continuous manner.

Pipe galvanizing lines

— Full automatic galvanization of pipes.

— Automatic galvanizing based on “recipes” and controlled by a local and remote computer.

— Extremely limited intervention by operators only for changing the sizes of the internal and external purge rings.

— Just 3 operators can produce up to 1,100 pipes or 25 tons of pipes per hour.

— The equipment is suitable for pipes with a length of 4 to 9.5 meters.

— Semi-automatic lines with operator support for square and rectangular pipes.

Advantages and disadvantages of the method

The main advantages of the method are the cost for long-term use. Maintenance after the hot-dip galvanizing procedure is not required for the part in the absence of mechanical stress. Galvanizing of metal structures has a number of advantages:

- Processing can be carried out on parts of any shape and complexity, as it involves lowering the entire product into a bath of zinc.

- In case of minor mechanical damage, the coating has self-healing properties, in some cases without human intervention.

- Hot-dip galvanizing is carried out when processing containers and pipes, as resistance to corrosion and other influences increases more than 5 times.

- All minor defects of the products are included in the processing process.

- Operation does not require further surface care, as it is protected by a layer of zinc.

Galvanized sheets

Disadvantages exist in absolutely every job; treatment with the zinc layer occurs unevenly. Increased material consumption when performing work, due to the shape of the bath, larger parts cannot be processed. Products treated with a layer of zinc are larger in size; processed products can present difficulties during installation or welding.

Why should you contact us?

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

- non-ferrous metals;

- cast iron;

- stainless steel.

When completing an order, our specialists use all known methods of metal machining. Modern equipment of the latest generation makes it possible to achieve maximum compliance with the original drawings.

In order to bring the workpiece closer to the sketch submitted by the customer, our specialists use universal equipment designed for jewelry sharpening of tools for particularly complex operations. In our production workshops, metal becomes a plastic material from which any workpiece can be made.

The advantage of contacting our specialists is their compliance with GOST and all technological standards. Strict quality control is carried out at every stage of work, so we guarantee our customers a conscientiously completed product.

Thanks to the experience of our craftsmen, the output is an exemplary product that meets the most demanding requirements. At the same time, we start from a strong material base and focus on innovative technological developments.

We work with customers from all regions of Russia. If you want to place an order for metalworking, our managers are ready to listen to all the conditions. If necessary, the client is provided with free specialized consultation.

Articles on topics: Metal products, Metalworking, Welding, Laser cutting, Metal structures, Plasma cutting, Metal bending, Cabinets, Properties of metals, Mechanical processing, Painting

This is interesting: Thermal diffusion galvanizing of metal: technology, equipment, pros and cons

Galvanizing at home

Galvanizing can be done at home. This is a simple procedure, but it requires high precision and great care. You will need a power source, which can be a car battery. But you can also use a 6-12 V and 2-6 A charger.

Theoretically, any salt that can dissolve in water is suitable for preparing an electrolyte. But from a practical point of view, a special zinc solution is required.

You will need the following composition for the electrolyte:

- magnesium or ammonium sulfate – 50 g;

- zinc sulfate – 200 g;

- 1 liter of water;

- sodium acetate – 15 g.

In this case, galvanic galvanizing will be carried out in the best way. But you can use battery electrolyte, which is an aqueous solution with sulfuric acid. Zinc is added to it until the reaction stops. Then the zinc remains, and the acid becomes a salt. A sediment will form at the bottom if you get too concentrated an acid solution. In this case, you need to add water.

Electrolytes are classified as dangerous poisons. Because of this, they should be handled very carefully and only in protective clothing. Carry out the work in a room that can be well ventilated.

When resorting to galvanic galvanization, give preference to glassware or vinyl plastic. If the part is small, you can use a liter jar. When galvanizing, it must be possible to attach the product to the container. The electrolyte is poured into the container after filtering.

The product is pre-degreased so that the zinc covers the surface with an even and durable layer. After this, it is placed in the solution and held for up to 10 seconds. After this, it should be rinsed well in clean water. This process is called chemical activation. Then the anodizing of the steel object begins.

To galvanize parts, it is necessary to use a zinc electrode. It is made from an existing piece of zinc. It is necessary to drill a hole of a suitable size in it. Then a copper wire is threaded into it, on which it is suspended. To do this, the electrode must not only be flat, but also have a shape suitable for convenience. And the surface area should be approximately the same as the area of the product itself.

Use copper wires to connect to the power source. Make sure that the plus is connected to the zinc electrode. In this case, the minus is brought to the product itself. The exposure period ranges from 10 to 40 minutes. This way you will get a zinc coating that will have a high class.

This technology of galvanic galvanizing of metal consists in applying a composition in the form of a coloring composition to the surface. As a result, it is not paint with zinc that is used, but the metal, presented in the form of paint. A large number of materials produced by modern manufacturers are used as galvanizing agents. But the composition of zinc in them changes, which will determine the quality of the finished surface.

If you are planning to galvanize yourself, pay attention to the manufacturer's instructions. Many mixtures have significant pre-treatment requirements.

Galvanizing of metal is carried out with a product that includes two components - zinc powder and a binding liquid mixture. They are sold together but supplied in separate containers. Before using the product, the individual components must be mixed according to the instructions.

The composition is applied at a temperature of 5-40 degrees and at a humidity of 30 to 98%. Carry out work only in a well-ventilated area, using personal protective equipment.

Thus, you can protect steel products from corrosion using simple metal galvanizing equipment. By following simple technology, a high-quality coating is obtained that provides good protection against corrosion processes. And the surface acquires high decorative characteristics.

Do-it-yourself zinc coating of metal (2 videos)

Different galvanizing methods (25 photos)

Factories that do not pollute the environment

- Fully detailed and clear documentation on environmental impact.

- Acid-resistant foundation protection using PVC or propylene coating.

- Oil separation unit for degreasing and pickling solutions.

- Acid regeneration plant using sulfuric acid as a reagent.

- Installation of acid regeneration by concentration of hydrochloric acid.

- Units for computerized automatic measurements of liquids.

- Acid-resistant containers with solution distribution stations.

- Flux regeneration unit.

- Degreaser dosing and diluting device.

- Flux dosing and dilution device.

- Bag filter for white fumes.

Physico-chemical indicators of coating quality

5.1 Physico-chemical indicators of coating quality are given in Table 2.

Table 2 - Coating quality indicators

| Indicator name | Norm | Control method |

| Appearance of the coating | Matte gray finish, uniform, continuous, smooth or rough* | According to 7.4 |

| Minimum thickness of zinc coating, microns | According to table 1 taking into account 5.2 | According to 7.5 |

| Adhesion strength** | There should be no flaking, peeling or flaking of the coating | According to 6.11.2 |

| Residual (hydrogen) embrittlement** | No sample cracking or cracks | According to 7.6 |

| Corrosion resistance*** | No base metal rust | According to 7.7 |

| Protective properties of the coating | According to GOST 9.301 (table 1) | According to 6.11.4.4 |

| * Surface scratches and risks from contact of products with each other, measuring tools and lifting devices without destruction of the coating to the base metal are allowed on the coating. The following are not allowed on the coating: - swellings, cavities, cracks, growths, peelings, inclusions; - lack of coating on critical surfaces, as well as on individual parts (places) of the surface or cavities of products, if this absence is not specified in the RD for the product; — indelible residues of technological mixtures. ** Testing is carried out at the request of the consumer. *** The test is carried out as part of acceptance tests at the request of the consumer and periodic at least once a year. Note - The nomenclature of controlled physical-mechanical (chemical) parameters for coatings with additional processing according to 3.2 is according to the RD for the specific material (composition, coating) used for additional processing. | ||

5.2 In parts and fittings that have blind holes and grooves up to 12 mm wide, as well as through smooth and threaded holes and grooves up to 6 mm wide, the thickness of the coating at a depth of more than one diameter or one width is not standardized, and in these areas it is not allowed lack of coverage. The presence of coating in these places, as well as in threads and blind holes, is controlled by the metallographic method in accordance with GOST 9.302.

Why are metal products galvanized?

Galvanizing involves applying a layer of zinc to the surface of a metal product, the thickness of which can be in the range of 40–65 microns. This coating provides not only barrier, but also electrochemical protection of the metal from corrosion. Galvanizing, which can be performed using different technologies, is used mainly in relation to steel.

Hot galvanizing of metal, when compared with other technologies, is characterized by an optimal combination of the affordable cost of the technological process with the high protective properties of the resulting zinc layer. The coating applied by hot-dip galvanizing, even when the product is used in the most unfavorable conditions, can last at least 65–70 years, fully retaining its protective properties.

Position of zinc in the electrochemical series of metals

How to distinguish galvanized metal from regular metal?

Unfortunately, not all performers are honest with their clients.

Sometimes, when ordering the production of galvanized metal and receiving a batch of finished products, the customer asks himself a seemingly paradoxical question: “Was my metal galvanized at all?” Indeed, the line between galvanized and plain steel is so thin that sometimes only a professional can “feel” it. There are several ways to ensure that your products have indeed been zinc plated:

- visual. The zinc layer forms rainbow stains on the surface of the product and gives it a glossy tint, while untreated steel has a characteristic matte surface;

- use of hydrochloric acid. When even a small amount of it is exposed to the zinc layer, hydrogen will begin to be released into the air;

- using a magnet. Zinc-coated steel has a more powerful magnetic effect than untreated steel.

Spectral analysis will also help to distinguish the conscientious work of a metal galvanizing plant in Moscow from “hack work.” But to carry it out, professional equipment is required, and therefore, this method is not available in everyday conditions.

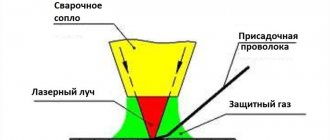

Gas thermal spraying of zinc as a type of galvanizing of metal structures

When listing the main galvanizing technologies, we did not mention one more - the gas-thermal method.

It is used for processing particularly large metal structures with hard-to-reach areas. Powdered rather than liquid zinc is applied to the metal by spraying in a gaseous environment. It is worth noting that in this case, the contact between zinc and metal is quite sharp, and roughness and irregularities may appear on the surface of the workpiece. That is why this technology is not used in its pure form, but for painting.

Galvanizing with phosphating

Our production of galvanized metal is ready to offer you galvanizing with phosphating.

This coating technology is used for copper, aluminum, zinc, cadmium and some alloys such as cast iron and low alloy steel. During the phosphating process, zinc phosphates accumulate on the metal, greatly increasing its resistance to external factors. After this procedure, it can almost completely resist almost all aggressive liquids and gases.

Our metal galvanizing plant in Moscow is equipped with all the necessary equipment to carry out any of the processes described. We will not only select the optimal technology for your rental, but also provide on-site galvanizing services if the parts are too bulky or you need to process a voluminous metal structure.

Features of the procedure

All steel products are subject to corrosion. This becomes especially relevant in humid conditions. If you use galvanizing of metal, the most reliable anti-corrosion protection is provided. This is due to the fact that as a result of this process, a galvanic couple appears on the surface along with the base steel. In it, a high degree of electronegative charge is characteristic of zinc. This level has become significantly lower. That is why it is recommended to cover it with this composition.

In this pair, the main impact of the aggressive environment is on the surface of the zinc coating. In this case, a chemical reaction with the base metal is practically eliminated. As a result, such protection is provided as long as the galvanization retains a sufficient layer. The surface will no longer give the desired effect when the coating is completely destroyed.

Galvanizing steel products provides not only good barrier protection, but also electrochemical protection. This process can be performed in different ways, the choice of which is determined by the availability of special tools and equipment. In some cases, you can apply zinc at home.

Note! Under the influence of moisture and oxygen, the protective coating is destroyed. In its place, zinc hydroxide appears, which provides some protective properties.

All over the world, galvanizing of metal is widely used for anti-corrosion protection. This is due to the fact that zinc has a low cost. In addition, it provides high protection against environmental influences. And the galvanizing process is characterized by low costs, which makes it accessible for independent use.

When zinc enters the atmosphere, active interaction with oxygen begins. As a result of this process, a thin layer of oxide film appears on the surface, which protects the steel from the aggressive effects of external factors. To obtain a high-quality result, it is necessary to correctly select the thickness of the future coating. It is largely determined by the time of the process and temperature conditions.

If you have used galvanizing of metal at home, such a product cannot be subjected to further mechanical processing. Otherwise, the protective layer will disappear and the work will have to be repeated.

Galvanic galvanizing bath

In the modern world, specialized equipment is required for galvanic processing of metals in a zinc alloy solution. Manufacturing plants use production lines that consist of elements that allow galvanic processing of metal products on an industrial scale.

Equipment for galvanic galvanizing is represented by specialized baths. They are made from materials that are not destroyed under the influence of an aggressive environment.

Galvanic galvanizing baths can be of several types:

- small-sized bath. It is designed for processing small metal products.

- Medium sized bath. It can easily fit one metal object, which consists of metal parts. There is no need to disconnect them to fully process the product.

- Large bathtub. It is used for processing large objects with zinc alloy. It even accommodates short length pipes.

The main disadvantage of electroplating equipment is that it is not suitable for processing non-standard products.

Also included with the equipment for carrying out this process of processing metal products is a device for supplying electric current. Without it, the deposition of zinc particles on the surface of metals is almost impossible. It must have electrodes for connection to metal and zinc alloy.

Advantages of hot dip galvanizing

- The pyrogenic properties of zinc significantly reduce the risk of fires. The coating obtained by hot-dip galvanizing is significantly superior in this regard to special paint or plastic;

- As a result of immersing a metal element in a molten zinc solution, a complex chemical reaction occurs that promotes the formation of an iron-zinc alloy. The newly formed coating penetrates much deeper into hard-to-reach areas and gives the structure resistance to physical influences;

- Minor damage to the zinc coating (for example, scratches) does not reduce its protective properties; the metal will still be protected from corrosive processes even in the damaged area;

- A significant increase, compared to other processing methods, in the service life of the product and its reliability.

offers hot-dip galvanizing services at low prices in Moscow and the Moscow region. The quality of work is conditioned by the mandatory fulfillment of the following conditions.

Firstly, the product is first subjected to sandblasting, degreasing and acid etching.

Secondly, the surface to be treated is coated with flux.

Thirdly, the sequence of technological actions and technical processing requirements from the beginning of the process to the removal of the product from the bath of molten zinc is strictly observed.

Types of devices

To work with a dimensional part, use a bath filled with zinc electrolyte or melt (temperature - 450℃). This is galvanic and thermal treatment, which is carried out mainly in factories. It is impossible to use the first method at home - you need a bath of impressive size and equipment for melting and centrifuging the material.

To carry out the procedure on your own, a cold treatment option using a spray bottle filled with special paint is suitable.

You can also use zinc electrodes, which are supplied with current from a battery. A similar kit, which also includes a special fluid and a wire for connecting to the battery, is available in any car store. Cost - about 1000 rubles.

Quality control of coatings according to GOST 9-307

Important points during the procedure are described by the control of Gosstandart. There are many processing requirements, the main ones are:

- Requirements for metal, this section describes the categories of steel products that can be processed.

- The appearance and quality of the coating, as well as the thickness of the finished product, are determined in accordance with GOST.

- Quality control methods are determined by ways to determine the quality of finished products.

Hot galvanizing process for pipes

Control and its methods involve checking finished products by applying mechanical damage or special marks. Hot galvanizing of metal structures is also determined by the effect of temperature, the product is heated to 200 ⁰C, and visually checked for damage or peeling of the metal.

Hot galvanizing technology

Hot-dip galvanizing technology differs from other metal processing methods in its undoubted advantages:

- This technology allows processing metal parts of very complex geometric shapes. Thus, galvanizing of pipes has become widespread.

- If mechanical damage to the zinc coating occurs, self-healing processes begin. In some cases, outside intervention is not even required.

- The technology of hot galvanizing metal results in the creation of a coating that is particularly resistant to liquid media. If we compare this method with other galvanizing methods, the resistance of the coating will be 6 times higher. Such properties allow the technology to be used for processing pipes and various types of containers.

- Using this technology, you can get rid of various defects of the treated surface (pores, cavities, etc.).

- Hot-dip galvanizing allows you to obtain parts with a reliable coating, the operation of which is much more economically profitable. Such products will not need to be regularly painted or otherwise protected from the harmful effects of the environment. Accordingly, this is the optimal technology for processing elements that will later be located in hard-to-reach places (underground, in walls, etc.).

This technology also has its drawbacks. The most significant of them is that it is possible to process a workpiece of only a certain size, since everything depends on the dimensions of the container where the part is immersed. In production conditions, it is possible to solve this problem through the use of continuous hot-dip galvanizing units (CGG).

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

Hot galvanizing technology involves two stages:

- The product is being prepared for processing.

- The product is dipped into molten zinc, located in a special container, where the metal is coated with zinc.

The technology of galvanizing metal using this method is fully regulated by GOST 9.307-89.

This standard requires that attention be paid to surface preparation prior to hot zinc coating. Preliminary surface preparation should include several stages:

- careful mechanical processing;

- degreasing the surface;

- washing after degreasing;

- etching problem areas;

- washing after etching;

- surface fluxing;

- final drying.

Mechanical processing eliminates all traces of dirt, oxidation, rust and slag. According to GOST, all sharp edges and corners must be removed mechanically. For this purpose, sandblasting units, usually available in the arsenal of large-scale production, can be used.

Special chemical reagents are used for degreasing. The list of means suitable for these purposes is given in the relevant GOST. After degreasing, the remaining product is removed from the surface of the product by washing.

GOST clearly states that the presence of oxidized areas or old zinc coating on the products being processed is unacceptable. If there are any on the metal surface, they must be treated by etching using hydrochloric acid. The process is performed at room temperature. The acid concentration depends on the degree of surface contamination with oxides or corrosion.

After etching, it is also necessary to rinse the product to remove any remaining chemicals used during cleaning.

The technology of hot galvanizing metal allows the use of fluxing of the material among the preparatory work. This operation prevents oxidation processes on the surface and increases the adhesion of the applied coating to the metal itself. To perform fluxing, a temperature of +60 °C is required. Flux is applied in a thin layer to the surface of the part. It usually consists of ammonium chloride and zinc mixed with water in a ratio of 500 g per 1 liter.

Metal galvanizing technology involves the use of special equipment, for example, a hot-dip galvanizing line or a container with molten zinc into which the product being processed is lowered. If a simple method is used and the zinc is in molten form in containers, then a certain temperature must be maintained to maintain the melt. The temperature depends on the dimensions of the workpiece and is on average in the range of +420…+455 °C.

When using such simple equipment for processing workpieces using the submersible method, a number of conditions must be observed at the production site:

- A powerful exhaust hood must be installed to remove the vapors generated during galvanizing.

- The speed of immersion of the product in the melt and the duration of exposure in it must be regulated by special equipment.

- It is important to ensure high-quality cooling of the workpiece after zinc treatment.

If hardware is subjected to hot processing, the operations are performed in the following sequence:

- The workpiece is immersed in zinc melt located in a special container.

- Keep in container for 4–10 minutes.

- The workpiece is removed from the container. The rate of extraction can affect the thickness of the coating formed.

- Then the workpiece is cooled either naturally or by force.

Galvanizing methods

Metalworking specialists distinguish the following methods for applying zinc coatings to metals:

- hot;

- cold;

- electrochemical, or galvanic;

- gas-thermal;

- thermal diffusion.

The application method is selected based on the following criteria:

- conditions for using the part;

- thickness of the protective layer;

- durability;

- special protection requirements.

The thickness of the layer is determined by the time the part is in the working environment and the temperature in the working area. When designing a technological process, it should be borne in mind that mechanical processing after coating the part with zinc will destroy the protective layer.

Hot galvanizing

This method is distinguished by the high quality of the resulting metal coating. However, its distribution is limited by the following disadvantages:

- complex and energy-intensive equipment;

- high temperatures;

- extremely harmful production waste;

- the size of the processed products is limited by the dimensions of the zinc bath.

First, a block of preparatory operations is performed:

- mechanical cleaning;

- degreasing;

- etching in an acidic environment;

- washing and flux treatment;

- drying.

Hot galvanizing

Only after this does the actual galvanizing begin. The prepared parts are lowered into a bath of molten zinc. A thin layer consisting of Fe and Zn compounds appears on their surface. Next, the parts are taken out of the bath and blown with air under high pressure. This allows you to remove excess zinc and at the same time dries the part.

Due to the complexity of the process and harmful working conditions, it is not used at home.

Cold galvanizing

This method is technologically much simpler. It can be reproduced at home. A layer of zinc-containing substance is applied to the workpiece using a brush or roller. To protect workpieces of particularly complex shapes and topography, spray guns are used. Compositions for cold galvanizing of metal are polymer solutions based on fine-grained zinc powder. The most commonly used is zinconol, which creates a corrosion-protecting layer on the surface with a 90% Zn content.

Cold galvanizing is also used in industry to protect already assembled parts and structures - for example, power line supports.

Cold galvanizing

The method is also used to restore partially damaged anti-corrosion coatings, for example, as a result of wear or repair work.

The disadvantage of this method of coating metal with zinc is the low mechanical strength of the coating.

Galvanic method

The electrochemical method allows you to obtain a durable and smooth layer. During the process, you can control the thickness of the applied metal layer. The quality very much depends on the degree of degreasing of the workpiece.

Galvanization of parts occurs as follows. Protected workpieces and zinc plates - donors are lowered into a bath of electrolyte, and voltage is applied to them. The current flowing in the resulting circuit, using the phenomenon of electrochemical metal transfer, pulls zinc atoms from the plates and deposits them on the workpieces.

Galvanic galvanizing

The disadvantages of the method are the high cost, which consists of the cost of plates, electrolyte and electricity. In addition, you will have to incur high costs for decontamination of the spent electrolyte.

Thermal diffusion galvanizing

The technology was developed in the early 19th century, but only recently gained widespread popularity. The workpieces to be protected are placed in a sealed container, into which dry powder containing zinc is added. Next, the container is heated to high temperatures (400-900 °C). The zinc evaporates and its vapors are deposited on the surface of the product. Preparation of workpieces is carried out in the same way as in the case of hot-dip galvanizing.

The advantages of this method are as follows:

- low environmental hazard;

- low porosity;

- high mechanical and anti-corrosion resistance (several times higher than with the galvanic method);

- there is no need for waste disposal.

Thermal diffusion galvanizing

The disadvantages include:

- the coating turns out dull, gray and does not decorate the product;

- low productivity;

- harmful working conditions.

The uniformity of the thickness of the zinc coating layer also leaves much to be desired.

Gas thermal spraying of zinc

The method is used for processing large-sized products, steel sheets, etc. Zinc is transferred to the prepared surface of the workpiece by a jet of burning gas. A zinc wire is placed in the flame of a gas burner, it melts and droplets of metal fall on the workpiece, forming a scale-like layer on it.

Gas thermal galvanizing

The method is used in combination with the application of anti-corrosion paints and varnishes and is very effective for protecting the hulls of sea vessels and coastal structures.

Advantages of the method

Hot galvanizing of metal structures, when compared with other technologies, has a number of significant advantages.

- Even parts with highly complex geometric shapes can be processed using this technology. In particular, this technology is actively used for pipe processing.

- Areas of zinc coating damaged as a result of mechanical impact can self-heal, and this can happen without outside intervention.

- Compared to other galvanizing methods, the hot-dip galvanizing method allows you to form a coating whose resistance when interacting with liquid media is 6 times higher. It is for this reason that this technology is used for processing pipes and various containers.

- Hot-dip galvanizing allows you to effectively eliminate many defects of the surface being treated, such as holes, pores, etc.

- The operation of pipes and other hardware that are coated with zinc using this technology requires minimal financial costs. Their surfaces, in particular, do not require regular painting, since they are already reliably protected from the effects of negative environmental factors. This is very important for pipes that are used in hard-to-reach places (in walls, underground, etc.).

Comparison of cost and performance of hot-dip galvanized steel with other protection methods

Stages of the production process

When hot galvanizing a metal, the bond of zinc with the metal surface occurs at the molecular level. As a result of placing the element being processed in a galvanizing bath, the strongest possible molecular bonds are formed, ensuring the reliability of the coating during long-term operation of the product under conditions of varying complexity.

Processing technology involves several stages, including:

- Surface preparation. The processes of degreasing, washing, pickling and fluxing are carried out.

- Drying metal. Excess moisture is simultaneously removed from the metal surface and the material is heated to a temperature of about 100°C.

- Application of zinc. Occurs in a melt bath. Processing time depends on the specific production task, and takes from 3 to 10 minutes.

At the final stage of work, the galvanized metal is dried and undergoes strict control, confirming the quality of processing and compliance of the result with state standards. The fundamental criteria for the effectiveness of the method are the qualitative characteristics of zinc, melt temperature and the level of preliminary surface preparation. The technology requires strict adherence to the cooling regime, the speed of immersion and lifting of the product, which significantly influence the crystallization of the melt and the thickness of the formed zinc layer.

Which device is better to choose?

It all depends on the size of the part that needs to be galvanized:

- if at home there is a large bathtub for filling with electrolyte and supplying current, then it is advisable to treat the body parts using the galvanic method;

- hard-to-reach machine elements can be protected without disassembly using a cold method - you need a sprayer or roller to apply the solution;

- You can remove small “saffron milk caps” with a special set of electrodes.

At home, the most reliable method will be the first one - galvanic; therefore, the preferred device for galvanizing a car body is a bath with a solution.

Galvanized car frame

This option will be easier for the owner, but will provide a good result.