Perhaps every person has encountered the appearance of rust on metal parts in their everyday life. And no matter where the corrosion occurred, on parts of the car or an iron fence, it is always unpleasant. But fortunately, the modern chemical industry offers many means that will prevent it from appearing again. We will tell you about the best of them in our review, and the question of how to coat metal to prevent it from rusting will no longer bother you.

A number of compounds can be applied directly to rust Source gidpokraske.ru

The most common methods of combating corrosion

There are several ways to coat metal surfaces to prevent them from rusting. These methods will allow you to extend the life of iron objects and parts for a long time. One of the most effective methods is treatment with chemical-based substances.

This category of compounds includes inhibitors. They are applied to the metal in a barely noticeable thin layer. Thanks to this coating, the product will not rust. Most often, such drugs are used for preventive purposes. The following methods will also help prevent corrosion:

- removing rusty spots on parts mechanically;

- use of chemical-based products;

- use of anti-corrosion compounds;

- folk recipes.

Means for treating metal surfaces against rust Source ad-cd.net

More details about all the methods for preventing the appearance of rust on metal are described below.

Mechanical cleaning

Use a coarse sandpaper or a metal brush to remove corrosion from iron parts. The treatment can be carried out using the wet or dry method. In the latter case, the rust is scraped off by rubbing a brush or sandpaper on the metal.

As for the wet method, it is necessary to first moisten the surface of the parts in kerosene or white spirit. A sandblaster, grinder, grinder or electric drill with a metal brush as an attachment will also come to the rescue.

Cleaning the surface from corrosion can only be used on not very large areas of metal products. The best option is to use a sandblaster. But its high price can be an obstacle for the home craftsman.

Mechanical cleaning is used on small metal surfaces Source kraski-net.ru

Use of chemicals

If the question arises of how to coat metal against rust, then first of all, experts recommend turning to the help of chemical agents. There are two types of such preparations: rust converters and acid compounds. Of the latter, orthophosphorus is considered the most popular. They help clean the surface in minutes. It is not difficult to use acid; to do this, remove dirt from the iron surface with a rag, then remove the moisture and apply a barely noticeable layer of the product to the metal. Use a brush with silicone bristles.

Leave the acid composition on the surface for half an hour. During this time, a reaction will occur with the area damaged by corrosion. Clean the metal with a damp cloth and then a dry one until all traces of rust are removed. Remember safety precautions when working with acid-based anti-corrosion compounds. Use a mask, special glasses and gloves to protect your respiratory tract, eyes and skin on your hands. Cleaners containing phosphoric acid delicately remove traces of corrosion from metal parts and at the same time prevent it from appearing again.

Use gloves to protect your skin from anti-corrosion agents Source foods-ideas.com

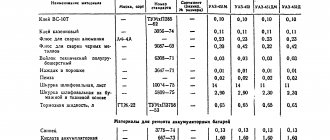

As for rust converters, they cover the entire area of metal parts. This composition creates protection that will prevent corrosion in the future. The most popular converters today are the following:

- " Zinkor ". The composition forms a thin layer on metal objects. In addition, this composition restores the surface of iron objects.

- " VSN-1 ". Serves as a corrosion neutralizer in small areas. After application it turns into a gray film, which can be easily removed with a dry cloth.

- " B-52 ". This corrosion destroyer removes it from any metal surfaces, does not spread during use, and at the same time acts very quickly.

- Berner . This rust modifier is used for nuts, bolts and other small parts that cannot be removed due to corrosion.

- " SF-1 ". Can be used on parts made of aluminum, zinc or cast iron. Removes corrosion and prevents it from appearing again. The manufacturer guarantees that after treatment with this product you can forget about the appearance of rust for 8-10 years.

All of the above drugs are economically consumed.

Rust modifier "Phosphomet" Source prom.st

See also: Catalog of companies that specialize in paints and varnishes and related work

Phosphate coating

Phosphate coating is the result of phosphating. This is the name given to the process of chemical treatment of steel (as well as other metals and alloys) in solutions of phosphate salts of alkali metals or ammonium. As a result of phosphating, a layer of sparingly soluble salts – iron phosphates – appears on the surface of the product. The coating has a dark gray to black color and a rough surface. The usual thickness of the protective layer is 2-5 microns. It is resistant to the effects of kerosene, lubricating oils, atmospheric oxygen, can withstand short-term heating up to 5000C and cooling down to -750C, but is destroyed by acids and alkalis. Often used as a primer - a coating for painting.

In our range of phosphate coatings you can find:

- on retaining rings

- on self-tapping screws for fastening plasterboard and gypsum fiber boards

Other means

In addition, other products that help fight rust on metal are also popular among home craftsmen. Among them:

- Hi-Gear No-Rust;

- Permatex Rust Treatment;

- Autoprofi.

Below we describe how to coat iron to prevent it from rusting, how to use these preparations and how they differ from each other.

Hi-Gear No-Rust

This aerosol is economical in consumption and helps to increase the adhesive properties of materials due to the formation of a protective film on the metal. Use this anti-corrosion compound at temperatures between 5 and 30 degrees Celsius. The product is suitable for processing parts of building structures, as well as car bodies.

Hi-Gear No-Rust rust converter is suitable for even the oldest stains Source prosmazku.info

The drug has the following regimen of use:

- Before using the spray, clean the surface using any method (eg sandpaper or wire brush).

- Rinse the parts with water and dry with a dry cloth.

- Shake the bottle well. Spray the rust converter evenly over the entire iron area to be treated. Recommended distance is 15-30 cm.

Application

Coatings are in demand in various areas of industry to protect parts and components of equipment from external influences. Depending on the composition, they can be used:

- in medium and heavily loaded sliding friction units - bearings, gears, guides;

- in internal combustion engine parts - plain bearings, throttle valve, piston skirts;

- in threaded connections;

- in pipeline fittings;

- in parts of cars and other equipment with friction pairs: metal-metal, metal-rubber, polymer-polymer, metal-polymer.

In addition, the materials ensure long-term storage and safe transportation of steel products, the formation of dielectric layers in the production of decorative surfaces, and increase the service life and energy efficiency of equipment.

Using anti-corrosion compounds from the Rocket Chemical line

This American company specializes in the production of chemicals used in everyday life. One of its activities is the production of products to prevent rust on iron. The following anti-corrosion compounds have earned the trust of consumers:

- Lithium grease with protective effect . Apply the product to a metal area to prevent and protect against rust. The manufacturer recommends covering rack and pinion mechanisms, cables, chains and door hinges with it. The thin film formed on these parts will not be affected by either snow or rain.

- Long-acting inhibitor . Parts of metal structures treated with this product will not be exposed to rust for 5-7 years. This drug becomes a salvation for those who are thinking about how to coat metal so that it does not rust in water.

Rust inhibitor "Likkor" Source prom.st

Oxide coating

The oxide coating is the result of oxidation. This is the name of the process of obtaining an artificially formed film on the surface of a product, consisting mainly of oxides of the material being coated. In the case of oxidation of steels and cast irons, a dark film is formed on their surface, consisting conventionally of iron oxide Fe3O4 with a thickness of only a few microns. Among others, the most common method is chemical oxidation. When selling it, the product to be coated is immersed in a boiling solution, most often consisting of alkali and oxidizing agents - nitrates and nitrites. The resulting film is tightly adhered to the base metal and has a black color. To increase corrosion resistance, the film is oiled, due to which its pores are filled and become impenetrable to the external aggressive environment. One of the widespread oxidation options is bluing. The name comes from the color of the coating. It is black with a blue tint, like a raven's wing.

In our range of oxide coatings you can find:

- on products made of steel with a strength class greater than 8.8, to prevent hydrogenation during galvanizing;

- on installation screws, where the use of a soft coating is unacceptable;

- on retaining rings DIN 471 and 472

- on a thrust washer, quick-release DIN 6799.

Video description

How to remove rust using Silit, watch this video.

Some home craftsmen use Coca-Cola or Pepsi to get rid of corrosion. These drinks contain phosphoric acid, which easily removes small rust stains. Wipe metal surfaces with liquids or immerse parts in them. Then rinse under running water.

Pepsi can easily cope with rust in small areas Source yandex.net

A mixture based on paraffin and kerosene is also popular. Take these products in equal proportions and mix. Apply to the surface to be treated in several thin layers with a sponge or brush. Leave it for at least a day. After the specified time, remove the mixture along with the rust with a rag, rinse with water and remove moisture with a rag or sponge. It is best to use this method for tools. Do not forget about a mask, gloves and safety glasses when processing with a kerosene-paraffin mixture.