Serebryanka is a heat-resistant paint and varnish material for metal, which is in demand not only in industry, but also in households. You can purchase the material ready-made, but sometimes it has to be prepared from powder at home.

Serebryanka is a heat-resistant paint and varnish material for metal.

Brief description of the material

Silver paint for metal is necessary for painting the material with a silver tint. The substance does not contain this metal. This universal paint and varnish product is able to create a smooth surface and also protect it from the negative effects of the environment. The composition can withstand high temperatures and can also be used not only outside, but also inside. To carry out coloring, the master will need to dilute the dry powder.

Composition and overview of material characteristics

The composition of the coloring agent for metal contains aluminum in different grinds, hence the specific color for the metal composition.

Aluminum powder is often used to paint high-temperature objects. The manufacturer also adds fine aluminum to the metal paint; visual differences are almost impossible to find. In addition, such products contain varnish.

Serebryanka has a rich silver color that can improve the external characteristics of a metal product. The composition lies on the surface in a dense, even layer and thus hides all its defects. You can dilute dry paint at home. The result may be either a heat-resistant or a regular mixture. To simplify the task, you can buy ready-made material.

Why is silverfish so popular?

People have been using this paint for decades. This composition is characterized by a lot of positive characteristics, which is why it is currently in demand among consumers. In industry and the national economy, silver is popular due to its affordable cost, reliability and ease of use.

Application of silverfish

In everyday life, the powdery composition is used for decorative purposes. It is used for painting house fences and interior items. Paint is even used when finishing swimming pools.

Before diluting silverware, the master should find out where it can be used. This point directly affects the method of diluting the powdered substance.

The composition is often used to finish the following items:

- parts in production;

- radiators;

- components from tanks, boilers;

- elements of ship vessels;

- port structures;

- pipeline.

This aluminum-based coloring composition is considered the best for finishing surfaces that suffer from the negative effects of external factors. The characteristic composition of the product allows it to prevent the harmful effects of sunlight and precipitation.

Advantages and disadvantages

Advantageous characteristics of silverfish:

- Convenient to use. The applied layer of paint makes the surface smooth and neat, without streaks.

- Durable. Despite the small thickness of the paint layer, it adheres firmly to the metal and does not peel off.

- Universal in use. Often the composition is used for painting metal, but due to the presence of aluminum in it, painting wood and stone is possible.

- Environmentally safe. There are no toxic ingredients in silver powder.

- It looks aesthetically attractive.

- Durable. According to consumer reviews, after painting the surface does not require updating for 6 years. As for its use inside a building, the coating can last up to 15 years.

- Heat resistant.

The material has few negative properties.

However, it can be noted that the universal composition of the coloring substance is characterized by an explosion hazard and the inability to be applied to a surface that has been treated with an oil, alkyd composition or nitro-enamel.

Benefits of silverfish

Serebryanka is often used for interior work, since after drying it becomes non-toxic and absolutely safe. Even in water, the paint retains its properties for up to three years. Its other advantages include:

- Good adhesion (reliable adhesion to the base), ability to dry quickly. Thanks to this, it is convenient to work with silver even in a residential area.

- High anti-corrosion properties, resistance to ultraviolet radiation.

- Easy to use, no streaks or drips during application.

- Possibility of coloring not only metals, but also other materials.

- Long shelf life of finished paint (up to 6 months in an airtight container). Dry powder can be stored much longer.

- The ability to dilute paint with solvent in different proportions to obtain different shades of the finished product.

In addition, using silver can significantly improve the appearance of the material.

How to make silver coin at home

Before you think about how to dilute paint powder, you should learn about its types. Each of the groups of this substance can be used for certain types of surfaces and with a specific task. The production of paint and varnish composition at home is carried out by dilution.

Common silverfish

Aluminum powder is used to make ordinary silver paint, which can be used to coat not only metal, but also wooden and concrete areas. The composition can also include synthetic drying oil and non-thermal varnish.

Heat resistant

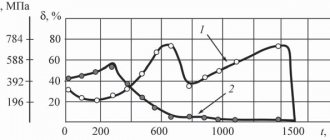

Serebryanka, capable of withstanding temperatures of 300 - 450 degrees above zero, is used for metal processing. It is obtained by diluting aluminum powder composition and bitumen varnish BT - 577. The proportion should be 1 to 5.

Products resistant to high temperatures are used in the following cases:

- painting of cast iron batteries;

- pipeline painting;

- construction of bridges;

- finishing of boiler parts to create a protective heat-resistant layer.

Where is liquid silver used?

Silver powder is a fairly popular material and is widely used both in everyday life and at industrial facilities. Silver paint is used for painting:

- bridges;

- parts of production workshops;

- radiator systems and central heating batteries;

- parts of ships, floating stations and docks, port and underwater structures;

- various pipes and metal elements;

- parts of systems that need to be protected from overheating;

- sculptures, monuments, grave fences, souvenirs and other items.

How and how to dilute silver powder

Everyone has heard about the existence of silver-colored paint, but not everyone knows how to dilute silver paint for painting metal. If the product was purchased in powder form, then it will need to be prepared before applying to the surface. Dilute the dye with drying oil and varnish. In this process, it is very important to mix the ingredients correctly.

Rules for diluting aluminum powder with varnish

To make non-heat-resistant silver, you should buy varnish. The best option in this case would be BT - 577. The master will need to take 2 units of powder and 5 units of varnish and mix thoroughly. The prepared thick paste will need to be further diluted for ease of application. Craftsmen should give preference to turpentine or solvent as a solvent.

How to dilute silver with drying oil

In addition to varnish, the coloring composition for the metal base is diluted with drying oil.

The synthetic product can be used for dads - 1 and dads - 2. Diluted paint is not resistant to temperature changes.

Correct dilution of the material:

- The proportions for preparing pap - 2 are 1: 3 or 1: 4.

- Pap-2 is prepared with a component ratio of 2:5.

Required thickness

Depending on the painting option, the density of the silver is selected.

In the case of using a spray, both substances are taken in the same quantity. A thicker product is applied to the surface using rollers and brushes. In this case, the solvent used is 2 times less than the powder. To prepare a heat-resistant composition of the required density, toluene is used. If the silver is ordinary, then turpentine and white spirit are more suitable for it.

Surface preparation and painting

Before proceeding with painting, it is necessary to carefully prepare the surface. Rust, remnants of old paint, and scale are removed from metal using abrasive paper or metal brushes (nozzles). Silver has good adhesion to objects being painted, but the effect will be better if you prime them once.

How to paint with silver? It is applied evenly over the entire surface in 2-3 thin layers. The wood is also sanded. It is especially important to remove remnants of other types of paint, otherwise the silver may peel off.

Concrete and brick surfaces are cleaned of lime and chalk. It is recommended to prime once, but if thoroughly cleaned, it can be applied without prior priming. The walls must be dry. Silver paint dries quite quickly (up to 4 hours), but sets faster. Therefore, it is better to correct defects when painting before it is completely dry.

To remove random stains from silverfish, use a solvent. If it is not completely dry yet, you can soak the stain in vegetable oil and then wipe it off.

Paint application technology

For high-quality painting of metal, a brush, spray gun, or roller can be used. In addition, special attention should be paid to surface preparation. For this purpose, the following actions are performed:

- clean the surface with a brush;

- sweep away garbage;

- eliminate rust using special means.

Application technique

Metal finishing with silver should be carried out according to the following principle:

- Preparing the metal surface, degreasing it with a solvent.

- Waiting for the solvent to dry. After this, you can start mixing the paint.

- Applying a layer of primer to previously prepared material.

- Painting the surface after the primer has completely dried.

If it is necessary to create reliable protection of the coating from the negative influence of chemical and physical factors, the paint is applied in three layers. Applying each new layer can begin after the previous one has dried.

Features of silver coating

Surface painting is carried out only on a clean surface, with a substance with a good shelf life. At the same time, the master should remember that applying this paint and varnish material is not possible on any surface. For example, silver is not used over nitro enamel, oil paint, or nbh enamel.

A little silver paint is needed for the primed coating. Another important rule in painting metal is the speed of work, that is, you need to paint the surface with this composition as quickly as possible.

How to wash off paint

During operation, paint may get on interior items. To prevent such a nuisance from happening, it is recommended to cover furniture, windows and doors with film. If the paint and varnish composition gets on the floor, it can be removed using proven methods.

Traditional methods of removing paint

If you need to eliminate silverfish from the surface, you can use sunflower oil, which is available in every home. To do this, apply a small amount of fat to the stain, wait a few minutes and wash it off. The second no less effective method of getting rid of silver is considered to be a liquid for eliminating varnish without acetone in the base. This substance eliminates the problem well if the stains are fresh.

Flaws

Before diluting “silver” (powder) for painting metal and other surfaces, let’s talk not only about the advantages, but also about the disadvantages of this material. There are few of them:

- Dry powder is quite explosive, so you should store it away from fire in a tightly sealed container. You should also keep silver powder away from children.

- Silver paint cannot be applied to surfaces previously painted with oil, NBC or alkyd paints, as well as nitro enamel. When applying silver to such surfaces, bubbles may appear. The paint does not adhere well or comes off completely.

- Contrary to advertising, acrylic “silver” not only does not have all the wonderful properties of conventional paint, but also shows traces of rust already at the time of painting.

- A solution of silver aluminum powder cannot be used to paint galvanized parts. The contact of these two compounds quickly destroys the zinc coating. If the need to paint galvanized steel is too great, cover it with a couple of layers of a special primer.

Compound

The main component of this paint is aluminum powder, which is obtained by crushing this metal. Thanks to this element in the composition, the painted surface receives a metallic color that resembles silver. It is worth noting that the paint itself does not contain silver.

Aluminum dust in the composition of this coating material comes in two types:

- PAP-1;

- PAP-2.

These powders differ in fractions. The first type consists of large particles, and the second of smaller ones. However, the quality of the surface obtained after painting does not depend on the degree of grinding.

If the paint is sold in an already diluted, ready-made form, then it differs in the type of varnish with which it is diluted. If the paint is intended to be used to protect surfaces exposed to high temperatures, then a special heat-resistant varnish is used to prepare it.

Which paint is best?

As mentioned earlier, the wide variety of paints allows customers to choose from several alternatives. You should take into account operating conditions, environmental properties (humidity, dust levels, etc.), as well as your financial capabilities. It is better to use expensive silicone paint, but for many it is still too expensive.

For iron

Iron furnaces are quite susceptible to degradation and oxidation, since the molecular structure predisposes the material to react with oxygen. High temperature also quite actively accelerates this process, which shortens the service life of the furnace.

If you want the stove to serve for many years, then you should use silicone paint from various manufacturers.

One of the leaders in the domestic market is Elcon, which has modern production. This manufacturer belongs to the “budget” class, but its quality is sufficient for domestic use.

It is important to carefully follow the painting technology, since otherwise the paint will not be able to protect against destructive factors. Remember that painting is not a universal solution that is guaranteed to protect the metal - it is important to follow the painting technology!

For cast iron

Cast iron is a fairly strong metal alloy that can withstand prolonged exposure to extremely high temperatures. Some sources report that you can avoid dyeing altogether, but it’s better to be on the safe side.

An excellent option for a cast iron stove is water-based acrylic or polyurethane paint, which has proven itself to be excellent. Moreover, the cast iron alloy tolerates even violations of the painting technology more favorably, so you don’t have to worry about making quite serious mistakes. to contents

Let's sum it up

If during painting you dropped paint in the wrong place, but it has already dried, then do not worry that you will not be able to wipe it off. Silver can be easily wiped off with the solvent you used to thin the paint. If you purchased ready-made paint and do not have the slightest idea on what basis it was made, then some kind of folk remedies will help you:

- Drop a little sunflower oil onto the painted surface, wait 10 minutes, and then wipe the surface with a dry cloth.

- Apply nail polish remover that does not contain acetone to the stain. This product perfectly removes only fresh traces of paint. After dissolving the paint, the surface should be washed with plenty of water.

When using silverfish, you must follow basic safety precautions and personal protective equipment. Be sure to work with silver paint with gloves, in a ventilated area, and protect from paint getting into the respiratory tract. Apply the paint in several layers, allowing each layer to dry. Primed surfaces can be applied in one layer. When applying silver paint to a coating that does not have a clean surface, remember that you cannot paint nitro enamel, NBC and oil paints with silver paint.

Is it possible to paint a metal stove?

Painting a metal stove is an essential process, but there are a number of additional factors to keep in mind. For this task, only heat-resistant paint for metal stoves is suitable, which can easily withstand exposure to prolonged temperatures. Many furnace owners choose a cheaper option that is not suitable for such tasks.

It is unacceptable to paint a metal stove with ordinary paint, since a number of useful functions of the paint and varnish material are lost, including:

- Heat resistance, which allows the metal to serve for many years without degradation under the influence of high temperatures;

- The absence of materials and additives that evaporate when heated and have a toxic effect on the body of others;

- The presence of protective properties against corrosive changes;

- Moisture resistance.

As you can see, the number of useful properties that paint for an iron stove should have is really many. Try to carefully understand the issue so that the service life of the product is maximum.