A variety of rolled products for welded metal structures are produced from carbon steel of this grade. The standards and parameters of the material are indicated in GOST 27772, which allows the use of steel c235 in the production of channels (GOST 8240), equal and unequal angles (GOST 8509 and GOST 8510), rolled sheets (GOST 19903), I-beams (GOST 8239, 26020), and also various bent profiles and corrugated sheets.

This material can be classified as universal, since it can be purged with argon, vacuumed, modified, and processed with synthetic slags. According to the state standard, marking of shaped rolled products made from steel grade C235 is carried out with brown or yellow paint.

Mechanical properties and weldability of steel grade C235

Steel for building structures grade C235 has excellent mechanical properties, allowing it to be widely used for the production of building and industrial steel structures, including those with welded joints. The yield strength of this material varies between 195-235 MPa, the short-term strength limit is 360 MPa. At the same time, the relative elongation of steel at break is at the level of 20-24%.

This metal boasts excellent weldability, so it can be used to create complex weldable structures with virtually no restrictions. S235 steel does not require heating or heat treatment prior to welding, while other grades of similar material are limitedly weldable (require heating to 100-120 o C) or difficult to weld (200-300 o C plus annealing after welding).

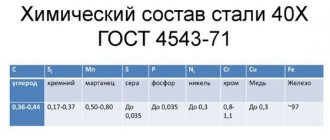

In relation to the chemical composition of the metal, GOST 27772-88 defines the following maximum impurity values (in percent):

- silicon – 0.05

- manganese – 0.6

- nickel – 0.3

- chrome – 0.3

- nitrogen – 0.12

- copper – 0.3

Composition and structure

S235 steel belongs to the low-alloy group. The main component is iron. Additional components:

- Carbon - content up to 0.2%. Due to the low content of this element, the alloy is easily machined and has high ductility. Hardness and strength indicators are reduced.

- Manganese - no more than 0.6%. Increases strength.

- Silicon - no more than 0.06%. Slightly increases strength, ductility, heat resistance.

- Chromium, nickel, copper - the average amount of each component reaches 0.3%. Increases technical characteristics.

- Sulfur, phosphorus - no more than 0.05%. Refers to harmful impurities.

Impurities have virtually no effect on the final characteristics of the metal.

Features of using steel s235

In the standard designation “c235”, the symbol C indicates “construction” steel, and the numbers indicate the approximate yield strength.

Products made from this material are welded with electrodes of type E42, E42a, E46 and E46a, and structural elements that will operate under conditions of strong vibration or dynamic loads, as well as at strong negative temperatures (-40 o C and below), should be welded with electrodes the designation of which contains the letter “a”. Examples of such structures are crane beams, long transport overpasses and other spans. The same welding technology is used to connect high-pressure pipelines and volumetric sheet structures. To produce any products from steel C235, hot rolling technologies are used. Additionally, if necessary, to provide the finished rolled product with a set of required properties, heat treatment can be applied to it. Today it is the most popular metal for creating rolled products, which will subsequently be used in welded structures.

S235

Characteristics of material C235.

Chemical composition in % of material - C235

GOST - 27772 – 88

| Brand: | S235 |

| Substitute: | St3kp2 |

| Classification: | Steel for building structures |

| Application: | production of rolled products intended for building steel structures with welded and other connections |

| C | Si | Mn | Ni | S | P | Cr | N | Cu |

| up to - 0.22 | up to - 0.05 | up to - 0.6 | up to - 0.3 | up to - 0.05 | up to - 0.04 | up to - 0.3 | up to - 0.012 | up to - 0.3 |

Technological properties of material C235.

| - - - - Weldability: | - - no limits. |

Mechanical properties at T=20oC of material C235.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| – | mm | – | MPa | MPa | % | % | kJ/m2 | – |

| Sheet | 2 – 3.9 | - | 360 | 235 | 20 | - | - | - |

Designations:

| Mechanical properties : | |

| sв | – Short-term strength limit, [MPa] |

| sT | – Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | – Elongation at break, [%] |

| y | – Relative narrowing, [%] |

| KCU | – Impact strength, [kJ/m2] |

| HB | – Brinell hardness, [MPa] |

| Weldability: | |

| no limits | – welding is performed without heating and without subsequent heat treatment |

| limited weldability | – welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | – to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

pokovka.biz

steel grade, analogues, explanation, characteristics

In the production of metal structures, C245 steel is a low-carbon grade used for building structures.

Chemical composition

Steel consists of approximately:

- 98% iron,

- 0.2% carbon,

- 0.65% manganese,

- from 0.05 to 0.015% silicon,

- up to 0.3% chromium, nickel and copper combined.

The presence of up to 0.05% sulfur, 0.04% phosphorus and 0.08% arsenic is allowed.

Decoding steel C245

In the designation of steel, the letter C means “construction”, the numbers 245 are the yield strength (T) in megapascals (MPa). In more conventional units σT = 24.5 kg/sq. mm.

Among other parameters characterizing the mechanical properties of steel, we note the tensile strength = 370 MPa (37 kg/sq. mm).

Weldability

To assess weldability, use the criterion of carbon equivalent, calculated by the formula

Se=C+G/6+X/5+(N+D)/15, where C, G, X, N, D – the amount of carbon, manganese, chromium, nickel and copper as a percentage in the composition of the steel or alloy.

For C245, the equivalent carbon is below 0.25%, which means good weldability. The weld seam is not prone to the formation of hot and cold cracks. Parts can be welded by any method without additional measures - preheating, forging the heat-affected zone, etc.

Read also: DIY hydraulic wood splitter

Plastic

Plastic qualities, i.e. the ability to deform in a cold state without signs of destruction, are characterized by the relative elongation of the sample at break and the size of the yield area.

Steel C245 has a relative elongation at break, i.e., the elongation of the sample relative to the initial size after fracture, of 25%.

The length of the yield plateau, i.e. the change in relative elongation at which the stress does not change, is at least 2.5%.

This indicates the possibility of bending and stamping thin sheets of steel. For thick ones, local heating should be used to avoid cracks.

To understand the difference in the deformation capacity of thin and thick sheets, you should refer to the course on strength of materials. When bending a sheet, the difference in changes in the dimensions of the outer and inner sides will be greater, the greater the thickness. This means that for a thick sheet, the relative deformation will be greater and the probability of destruction - the appearance of cracks - will be higher.

With increasing temperature, the yield strength of the metal decreases, and the yield area increases. Therefore, to deform a thick steel sheet, it must be heated or the bend radius increased.

Corrosion resistance

Alloying components—silicon, copper, etc.—slightly increase the corrosion resistance of steels.

C245 has moderate oxidation resistance. It is sufficient for inter-operational storage of workpieces, as well as for operation inside dry rooms without additional protection. In other cases, paint and varnish coatings corresponding to the operating conditions of the structure should be applied.

Analogs

According to GOST 27772-88, steel grade C245 corresponds to:

- St3ps5 and St3sp5 according to GOST 380 and GOST 535 (Appendix 1 GOST 27772-88)

- VSt3ps6 according to GOST 380-71 (Table 51b appendix 1 SNiP II-23-81)

- VSt3ps6-1 according to TU 14-1-3023–80 (Table 51b, Appendix 1, SNiP II-23-81)

- 18ps according to GOST 23570–79 (Table 51b appendix 1 SNiP II-23-81)

- E235-B, E235-C, Fe 360-B and Fe 360-C according to ISO 630:1995 (Appendix A GOST 380-2005)

Application

Grade C245 is used for the production of sheet and shaped rolled products - equal and unequal angles, channels, T-beams, I-beams. Rolled steel is used in the production of metal structures for various purposes. Due to their good weldability, welded joints are widely used in their production.

Particularly critical structures operating under conditions of constant increased vibration loads are required to be connected with rivets or other methods that prevent the spread of possible cracks.

As analogues of steel grade C245 we can name steel St.3ps, steel St.3sp, which are similar in mechanical properties and chemical composition. It should be noted that a mandatory requirement is the complete or partial completion of deoxidation of steels before the process of casting into molds. This is indicated by the letters ps and sp in the designation of brands.

Low-alloy structural steel C245 has properties that meet the requirements for metal structures for general use.

It can be welded well by all types of welding without additional measures to reduce red and blue brittleness.

The steel has average corrosion resistance. This requires the use of protective paint and varnish coatings for metal structures made from the described steels used outdoors.

Rating: 0/5 – 0 votes

Alloy characteristics

Now that the chemical composition of steel has been studied, the following theses can be put forward regarding the characteristics of C235 steel:

- Plastic. The alloy does not have high hardness due to the low carbon content in the composition, as well as due to some additives that give the metal even greater ductility. Due to this, firstly, facilitation of mechanical processing is achieved: giving a sheet of C235 steel a shape by bending without preheating, straightening with a special tool, cold pressing, etc. Secondly, the risk of defects forming in the part when it is loaded is reduced.

- Weldability. The construction of building structures is difficult to implement without the participation of a welding machine, and therefore the material from which they will be made must have good weldability. And steel grade C235 fits perfectly. After all, it can be welded without preheating in any way and without fear of cracks forming at the seam.

- Corrosion resistance. Steel's resistance to oxidation and rust is very important. After all, this indicator determines how soon this or that structure will become unusable. C235 steel has average resistance to corrosion, which allows it to be worked in conditions of normal humidity without the formation of rust.

Steel s235: characteristics and scope of application

A variety of rolled products for welded metal structures are produced from carbon steel of this grade. The standards and parameters of the material are indicated in GOST 27772, which allows the use of steel c235 in the production of channels (GOST 8240), equal and unequal angles (GOST 8509 and GOST 8510), rolled sheets (GOST 19903), I-beams (GOST 8239, 26020), and also various bent profiles and corrugated sheets.

This material can be classified as universal, since it can be purged with argon, vacuumed, modified, and processed with synthetic slags. According to the state standard, marking of shaped rolled products made from steel grade C235 is carried out with brown or yellow paint.

Mechanical properties and weldability of steel grade C235

Steel for building structures grade C235 has excellent mechanical properties, allowing it to be widely used for the production of building and industrial steel structures, including those with welded joints. The yield strength of this material varies between 195-235 MPa, the short-term strength limit is 360 MPa. At the same time, the relative elongation of steel at break is at the level of 20-24%.

This metal boasts excellent weldability, so it can be used to create complex weldable structures with virtually no restrictions. S235 steel does not require heating or heat treatment prior to welding, while other grades of similar material are limited in weldability (require heating to 100-120°C) or difficult to weld (200-300°C plus annealing after welding).

Read also: Phosphoric acid used for soldering

In relation to the chemical composition of the metal, GOST 27772-88 defines the following maximum impurity values (in percent):

- silicon – 0.05

- manganese – 0.6

- nickel – 0.3

- chrome – 0.3

- nitrogen – 0.12

- copper – 0.3

Features of using steel s235

In the standard designation “c235”, the symbol C indicates “construction” steel, and the numbers indicate the approximate yield strength.

Products made from this material are welded with electrodes of type E42, E42a, E46 and E46a, and structural elements that will operate under conditions of strong vibration or dynamic loads, as well as at strong negative temperatures (-40 ° C and below), should be welded with electrodes indicated in the designation which contain the letter “a”. Examples of such structures are crane beams, long transport overpasses and other spans. The same welding technology is used to connect high-pressure pipelines and volumetric sheet structures. To produce any products from steel C235, hot rolling technologies are used. Additionally, if necessary, to provide the finished rolled product with a set of required properties, heat treatment can be applied to it. Today it is the most popular metal for creating rolled products, which will subsequently be used in welded structures.

All about steel 235

Today, the industrial steel market is very rich. And in this regard, it is very difficult to choose exactly the grade of steel that is suitable for a particular project. You have to delve into the topic, study the characteristics, consider several options at once, hoping to find the right material.

In this article, we will make life a little easier for those who are looking for steel products for their projects. We will talk about steel 235, which is very common and revered in the field of metal structures. We will try to describe as informatively as possible all the most important aspects associated with this grade of steel.

GOST

Absolutely every grade of steel has a document clearly indicating its chemical and physical characteristics, as well as the scope of application and operating requirements. Steel 235 was no exception. GOST 27772 provides a full amount of information about this brand, but first of all we are interested in only some of it.

The composition of any steel, regardless of its purpose, will contain various chemical elements designed to improve the structure of the alloy and endow the resulting steel with some properties, be it strength, ductility, resistance to external influences and much more.

Having familiarized yourself with the composition of the alloying elements of steel 235, you can determine its physical, as well as some chemical characteristics, with a small degree of error.

The 235th is characterized by the following composition:

- 0.2% carbon.

- 0.6% manganese.

- 0.05% silicon.

- 0.3% chromium.

- 0.3% nickel.

- 0.3% copper.

Negative impurities include insignificant sulfur content - 0.05%, phosphorus - 0.04% and arsenic 0.08%.

As you can see, in terms of chemical composition, steel 235 does not have outstanding properties. However, we should assure you that in the field of its application this is not necessary and, on the contrary, more pliable material will be valued higher.

Characteristics of steel 235

The main application of this steel is the construction of metal structures. That is why completely different, specific requirements are placed on it. For such structural steel, what is much more important is not strength, but ductility, resistance to loads and relative softness, which greatly simplifies its processing if necessary. More specifically, steel 235 is characterized by a yield strength ranging from 190 to 230 megapascals with an elongation at break of around 22%.

The next important indicator for any steel directly intended for use in various types of structures is its weldability. The better and easier the welding process is, the better it is, accordingly. And steel 235 is ready to please craftsmen with its unlimited weldability. This means that two parts can be joined together by a weld without preheating and then tempering to relieve stress in the metal. At the same time, the seam itself can be applied by any of the methods available to the master, and the quality of the connection will remain invariably strong.

Analogs

Fortunately for many, the construction steel market is not so poor in steel with similar properties and compositions. Brand 235 also has similar “twin brothers”. The closest analogue is the well-known structural steel St18Kp, VSt3Kp2 or simple St3Kp2.

Rest assured: each of these brands is quite common and is sure to be available in large quantities at any enterprise engaged in the manufacture and sale of steel products.

Epilogue

At the end of this article I would like to summarize all of the above. 235 steel is perhaps one of the best structural steels for welded structures. It is easy to process, simply and reliably welded, and structures can withstand high loads for a long time without breaking.

fb.ru

chemical composition, application. Steel density s245

The C245 brand is a low-carbon steel used for building structures and used in welding without any restrictions. The alloy marking can be presented in the following form - St3ps5 or St3sp5. In fact, we are dealing with steel that is semi-quiet or calm in terms of the degree of oxidation, the proportion of carbon in which does not exceed 0.3%.

Steel s245: chemical composition and GOST standards for products

According to GOST 27772-88, the chemical composition of the C245 alloy is a set of the following elements:

- Fe – about 98%

- C – no more than 0.22%

- Mn – no more than 0.65%

- Ni – no more than 0.3%

- Cr – no more than 0.3%

- Cu – no more than 0.3%

- Si – 0.05-0.15%

- S – no more than 0.05%

- P – no more than 0.04%

- N – no more than 0.012%

S245 steel is used to produce shaped rolled products (including hot rolled):

- GOST 19903 – sheets

- GOST 82 – wide stripes

- GOST 8509 – equal angles

- GOST 8510 – unequal angles

- GOST 8240 – channel

- GOST 8239 and 26020 – I-beams

- GOST 19425 – I-beams and channels

- GOST 8568 – sheets with lentil and rhombic corrugation

- GOST 7511, 8278, 8281, 8282, etc. – bent profiles

Marking of alloys similar to steel grade C245

Low-carbon steel C245, smelted according to GOST 27772-88, can have different markings (according to standards, specifications and regulations):

- St3ps5 or St3sp5 (GOST 380 and 535)

- E235-B, E235-C, Fe 360-B or Fe 360-C (ISO 630:1995 or appendix A GOST 380-2005)

- 18ps (GOST 23570–79)

- VSt3ps6 (GOST 380-71)

- VSt3ps6-1 (TU 14-1-3023–80)

Mechanical properties of alloy c245

Manufacturers do not standardize density for alloy grade C245, however, as reference information, it is most often indicated that the nominal density of steel C245 is 7.85 g/cm3.

S245: application

C245 steel is widely used in the production of rolled metal, which is subsequently used for the construction of all kinds of welded and non-welded structures. Its strength is sufficient to create heavily loaded elements, and the absence of restrictions in weldability allows you to create structures of complex shapes. Note that this carbon alloy contains silicon, magnesium and manganese. The first two elements prevent the formation of ferrous oxide. Manganese neutralizes the destructive effect of sulfur, which makes the metal brittle.

Analogs and substitute steels

The rolled metal market is truly extensive and therefore for the same operation you can easily find at least a couple of steels with similar composition and characteristics. However, you need to know what exactly to look for. For steel C235, the list of substitute alloys is as follows:

- St18kp;

- St3kp2;

- VSt3kp2.

Knowing the list of these steel grades, any buyer at least triples his chance of purchasing building materials for his needs. Although, with a high degree of probability, a good consultant will be able to point out analogues of a particular alloy free of charge.

Chemical composition

The chemical composition of steel C235 according to heat analysis of a ladle sample must comply with the standards given in table. 1 (Table 1-2 GOST 27772-88).

Chemical composition of steel according to heat analysis of ladle sample

| carbon | manganese | silicon | sulfur | phosphorus | chromium | nickel | copper | arsenic |

| Mass fraction of element, %, no more | ||||||||

| 0,22 | 0,60 | 0,05 | 0,050 | 0,040 | 0,30 | 0,08 | ||

| Maximum deviations by mass fraction of elements, % | ||||||||

| – | +0,050 | – | +0,006 | – | ||||

Read also: Wave channel for dvb t2

Note: When smelting steel from Kerch ores, the mass fraction of arsenic is no more than 0.15%.

It is allowed to treat steel with synthetic slags, vacuum degassing, blowing with argon, modifying steel with calcium and rare earth elements based on the introduction of no more than 0.02% calcium and 0.05% rare earth elements into the metal (clause 2.10 of GOST 27772-88).

It is permissible for the manufacturer not to carry out a chemical analysis of steel for the content of chromium, nickel, copper, arsenic and silicon. The required chemical composition is guaranteed by the manufacturer. In steel smelted from Kerch ores, the determination of arsenic is mandatory (clause 2.13.1 of GOST 27772-88).

The weldability of steel is guaranteed by the manufacturer (clause 2.18 of GOST 27772-88).

S235 in St. Petersburg ✅ – “StalExpress”

This page shows the technical, mechanical and other properties, as well as the characteristics of steel grade C235.

Classification of material and application of grade C235

Brand:

C235

Material classification:

Steel for building structures

Application:

production of rolled products intended for building steel structures with welded and other connections

Chemical composition of C235 material in percentage terms

| C | Si | Mn | Ni | S | P | Cr | N | Cu |

| up to 0.22 | up to 0.05 | up to 0.6 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.012 | up to 0.3 |

Mechanical properties of C235 at a temperature of 20oC

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| – | mm | – | MPa | MPa | % | % | kJ/m2 | – |

| Sheet, GOST 27772-88 | 360 | 195-235 | 20-24 |

Technological properties of C235

| Weldability: | no limits. |

Explanation of symbols, abbreviations, parameters

| Mechanical properties : | |

| sв | – Short-term strength limit, [MPa] |

| sT | – Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | – Elongation at break, [%] |

| y | – Relative narrowing, [%] |

| KCU | – Impact strength, [kJ/m2] |

| HB | – Brinell hardness, [MPa] |

| Weldability: | |

| no limits | – welding is performed without heating and without subsequent heat treatment |

| limited weldability | – welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | – to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Other brands in this category:

metalloconstruction.ru

Mechanical properties

The mechanical properties of shaped and rolled sheets made of steel C235 in tension, impact strength, as well as bending test conditions must meet the requirements of Table 2 (Table 3-4, clause 2.7 of GOST 27772-88).

Mechanical properties of rolled steel C235

| Thickness, shelves, mm | Mechanical characteristics | Bending until the sides are parallel (a – sample thickness, d – mandrel diameter) | Impact strength KCU, J/cm² (kgf m/cm²) | |||

| Yield strength σ t, MPa (kgf/mm²) | Tensile strength σв, MPa (kgf/mm²) | Relative elongation δ5, % | at a temperature of −20°C | after mechanical aging | ||

| no less | no less | |||||

| Mechanical properties of shaped steel | ||||||

| From 4 to 20 incl. | 235 (24) | 360 (37) | 26 | d = a | – | |

| From 20 to 40 incl. | 225 (23) | 25 | d=2a | |||

| Mechanical properties of sheet and wide universal rolled products | ||||||

| From 2 to 3.9 incl. | 235 (24) | 360 (37) | 20 | d = a | – | |

| From 4 to 20 incl. | 26 | d = 1.5 a | ||||

| From 20 to 40 incl. | 225 (23) | d=2a | ||||

| From 40 to 100 incl. | 215 (22) | 24 | ||||

| St. 100 | 195 (20) | d = 2.5 a | ||||

For sheet metal with a thickness of 4-8 mm, the rate of relative elongation δ5 = 24% (clause 2.21 of GOST 27772-88).

The calculated resistances in tension, compression and bending of sheet, wide-band universal and shaped rolled products made of steel grade C235 in accordance with GOST 27772–88 for steel structures of buildings and structures should be taken according to table. 3 (Table 51 Appendix 1 SNiP II -23-81)

Calculated resistance of rolled steel C235

| Rolled thickness¹, mm | Design resistance², MPa (kgf/cm²), rolled | |||

| sheet, broadband universal | shaped | |||

| Ry | Ru | Ry | Ru | |

| From 2 to 20 | 230 (2350) | 350 (3600) | 230 (2350) | 350 (3600) |

| St. 20 to 40 | 220 (2250) | 220 (2250) | ||

| St. 40 to 100 | 210 (2150) | – | ||

| St. 100 | 190 (1950) | |||

- The thickness of the shaped steel should be taken as the thickness of the flange (its minimum thickness is 4 mm).

- The values of the calculated resistances were obtained by dividing the standard resistances (yield strength and tensile strength according to GOST 27772–88) by the reliability factor for the material γm = 1.025 (clause 3.2 of SNiP II -23-81), rounded to 5 MPa (50 kgf/cm²) .

Steel for building structures C235 - characteristics, properties, analogues

This page shows the technical, mechanical and other properties, as well as the characteristics of steel grade C235.

Classification of material and application of grade C235

Grade: C235 Material classification: Steel for building structures Application: production of rolled products intended for building steel structures with welded and other connections

Chemical composition of C235 material in percentage terms

| C | Si | Mn | Ni | S | P | Cr | N | Cu |

| up to 0.22 | up to 0.05 | up to 0.6 | up to 0.3 | up to 0.05 | up to 0.04 | up to 0.3 | up to 0.012 | up to 0.3 |

Mechanical properties of C235 at a temperature of 20oC

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| – | mm | – | MPa | MPa | % | % | kJ/m2 | – |

| Sheet, GOST 27772-88 | 360 | 195-235 | 20-24 |

Technological properties of C235

| Weldability: | no limits. |

Explanation of symbols, abbreviations, parameters

| Mechanical properties : | |

| sв | – Short-term strength limit, [MPa] |

| sT | – Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | – Elongation at break, [%] |

| y | – Relative narrowing, [%] |

| KCU | – Impact strength, [kJ/m2] |

| HB | – Brinell hardness, [MPa] |

| Weldability: | |

| no limits | – welding is performed without heating and without subsequent heat treatment |

| limited weldability | – welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | – to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding - annealing |

Other brands in this category:

Please note that this information about the C235 brand is provided for informational purposes. The parameters, properties and composition of the actual C235 grade material may differ from the values given on this page. More detailed information about the C235 grade can be found on the information resource “Brand of Steel and Alloys”. You can check with our managers for information about the availability, delivery times and cost of materials. If you find inaccuracies in the description of materials or errors found, please inform the site administrators using the feedback form. Thanks in advance for your cooperation!

www.c-met.ru