Profile pipe production technology

Pipes made of 30:30 profile, etc.

The technology for the production of profile pipes is almost the same for various metals; straight-seam or electric-welded pipes are used for the production of profile pipes:

- First, a round pipe is made from a blank (“strip”);

- A profile is made from it using cold or hot deformation - the resulting pipe has a size, shape and wall thickness, depending on the technology and purpose of the product;

- During the process when a pipe is manufactured, the profile can be subjected to heat treatment, which relieves internal mechanical stress.

Dimensions of square profile pipe and weight per linear meter

A square pipe is often used for racks, the supporting frame is assembled from it, and the lintels are made from a rectangular one. It is easier to attach materials (any) to such a frame. And, all other things being equal, the bending strength of a square profile pipe is higher. It is comparable to the performance of an I-beam. But the resistance to torsional loads of a round pipe is much higher. So this must be taken into account.

But to avoid problems, it is necessary to maintain the recommended dimensions of the profile pipes. As already mentioned, all sizes (range) are specified in GOST standards. The possible wall thickness is also indicated there. Small pipes - from 10 to 35 mm in diameter - have a thickness from 0.8 mm to 5 mm. But pipes with sides of 10 mm and 15 mm have walls no thicker than 1.5 mm. Then there is a gradual increase in the minimum size. For example, 40*40 mm has the thinnest wall of 1.4 mm, while 45*45 mm has no wall thinner than 3.0 mm. The same trend continues. The larger the size of the profile pipe, the thicker the walls.

| Size in mm | Weight of one meter, kg | Size in mm | Weight of one meter, kg | Section of the profile pipe in mm | Weight of one meter, kg | Section of the profile pipe in mm | Weight of one meter, kg | Section of the profile pipe in mm | Weight of one meter, kg | Section of the profile pipe in mm | Weight of one meter, kg |

| Square pipe 10x10x0.8 | 0,222 | Square pipe 30x30x0.8 | 0,725 | Profile square pipe 40x40x3.5 | 3,85 | Profile square pipe 60x60x2 | 3,59 | Profile square pipe 90x90x3 | 8,07 | Profile square pipe 150x150x9 | 38,75 |

| 10x10x0.9 | 0,246 | 30x30x0.9 | 0,811 | 40x40x4 | 4,30 | 60x60x2.5 | 4,43 | 90x90x4 | 10,59 | 150x150x10 | 42,61 |

| 10x10x1 | 0,269 | 30x30x,1 | 0,897 | 40x40x5 | 5,16 | 60x60x3 | 5,25 | 90x90x5 | 13,00 | Profile square pipe 180x180x8 | 42,34 |

| 10x10x1.2 | 0,312 | 30x30x1.2 | 1,07 | 40x40x6 | 5,92 | 60x60x3.5 | 6,04 | 90x90x6 | 15,34 | 180x180x9 | 47,23 |

| 10x10x1.4 | 0,352 | 30x30x1.3 | 1,15 | Profile square pipe 42x42x3 | 3,55 | 60x60x4 | 6,82 | 90x90x7 | 17,58 | 180x180x10 | 5,03 |

| Square pipe 15x15x0.8 | 0,348 | 30x30x1.4 | 1,23 | 42x42x3.5 | 4,07 | 60x60x5 | 8,30 | 90x90x8 | 19,73 | 180x180x12 | 61,36 |

| 15x15x0.9 | 0,388 | 30x30x1.5 | 1,31 | 42x42x4 | 4,56 | 60x60x6 | 9,69 | Profile square pipe 100x100x3 | 9,02 | 180x180x14 | 70,33 |

| 15x15x1 | 0,426 | 30x30x2 | 1,70 | 42x42x5 | 5,47 | 60x60x7 | 11,00 | 100x100x4 | 11,84 | Square pipes of special sizes | |

| 15x15x1.2 | 0,501 | 30x30x2.5 | 2,07 | 42x42x6 | 6,3 | 60x60x8 | 12,20 | 100x100x5 | 14,58 | 32x32x4 | 3,30 |

| 15x15x1.4 | 0,571 | 30x30x3 | 2,42 | Profile square pipe 45x45x2 | 2,65 | Profile square pipe 70x70x3 | 6,19 | 100x100x6 | 17,22 | 36x36x4 | 3,80 |

| 15x15x1.5 | 0,605 | 30x30x3.5 | 2,75 | 45x45x3 | 3,83 | 70x70x3.5 | 7,14 | 100x100x7 | 19,78 | 40x40x2 | 2,33 |

| Square pipe 20x20x0.8 | 0,474 | 30x30x4 | 3,04 | 45x45x3.5 | 4,40 | 70x70x4 | 8,07 | 100x100x8 | 22,25 | 55x55x3 | 4,78 |

| 20x20x0.9 | 0,529 | Square pipe 35x35x0.8 | 0,85 | 45x45x4 | 4,93 | 70x70x4 | 9,89 | 100x100x9 | 24,62 | 65x65x6 | 10,63 |

| 20x20x1 | 0,583 | 35x35x0.9 | 0,953 | 45x45x5 | 5,94 | 70x70x6 | 11,57 | Profile square pipe 110x110x6 | 19,11 | ||

| 20x20x1.2 | 0,689 | 35x35x1.4 | 1,45 | 45x45x6 | 6,86 | 70x70x7 | 13,19 | 110x110x7 | 21,98 | ||

| 20x20x1.4 | 0,791 | 35x35x1.5 | 1,55 | 45x45x7 | 7,69 | 70x70x8 | 14,71 | 110x110x8 | 24,76 | ||

| 20x20x1.5 | 0,841 | 35x35x2 | 2,02 | 45x45x8 | 8,43 | Profile square pipe 80x80x3 | 7,13 | 110x110x9 | 27,45 | ||

| 20x20x2 | 1,075 | 35x35x2.5 | 2,46 | Profile square pipe 50x50x2 | 2,96 | 80x80x3.5 | 8,24 | Profile square pipe 120x120x6 | 20,99 | ||

| Square pipe 25x25x0.8 | 0,599 | 35x35x3 | 2,89 | 50x50x2.5 | 3,64 | 80x80x4 | 9,33 | 120x120x7 | 24,16 | ||

| 25x25x0.9 | 0,670 | 35x35x3.5 | 3,30 | 50x50x3 | 4,31 | 80x80x5 | 11,44 | 120x120x8 | 27,27 | ||

| 25x25x1 | 0,740 | 35x35x4 | 3,67 | 50x50x3.5 | 4,94 | 80x80x6 | 13,46 | 120x120x9 | 30,28 | ||

| 25x25x1.2 | 0878 | 35x35x5 | 4,37 | 50x50x4 | 5,56 | 80x80x7 | 15,38 | Profile square pipe 140x140x6 | 24,76 | ||

| 25x25x1.4 | 1,01 | Profile square pipe 40x40x1.4 | 1,67 | 50x50x4.5 | 6,16 | 80x80x8 | 17,22 | 140x140x7 | 28,57 | ||

| 25x25x1.5 | 1,07 | 40x40x1.5 | 1,78 | 50x50x5 | 6,73 | 80x80x9 | 18,97 | 140x140x8 | 32,29 | ||

| 25x25x2 | 1,39 | 40x40x2 | 2,33 | 50x50x6 | 7,80 | 80x80x10 | 20,63 | 140x140x9 | 35,93 | ||

| 25x25x2.5 | 1,68 | 40x40x2.5 | 2,85 | 50x50x7 | 8,79 | 80x80x11 | 22,20 | Profile square pipe 150x150x7 | 30,77 | ||

| 25x25x3 | 1,95 | 40x40x3 | 3,36 | 50x50x8 | 9,69 | 140x140x8 | 34,81 |

Yandex.RTB RA-1479455-3

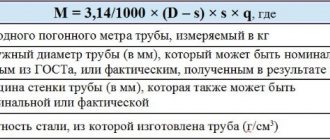

The tables also indicate the weight of a linear meter of profile pipe of each size. It is needed not only to be able to calculate the load on transport. Using this data you can control the wall thickness. You can weigh a piece of pipe, calculate the weight of a linear meter, and then compare it with the standard. If the data is close, everything is fine. If the actual weight is much less, the wall thickness is less than stated. True, the table shows the weight at a steel density of 7.85 g/cm². If the density of the pipe steel is less, this will need to be taken into account.

Types and sizes of profile pipes

Pipe from profile 10:10

The most traditional and used forms of metal profile pipes are rectangular and square profile pipes.

The variety of standard sizes of metal profile pipes corresponds to the variety of areas of their application:

- The pipe cross-section can range from 10x10 up to 450x350 mm;

- The wall thickness can be 1-12 mm;

- Length in accordance with GOST and TU – from 6 to 12 meters.

In addition, profile pipes are classified according to manufacturing methods:

- Electric welded;

- Cold-deformed electric welded;

- Profile seamless;

- Hot-deformed;

- Cold-worked.

In the manufacture of profile metal pipes, the following grades of steel are used:

- In accordance with GOST 380 - St2ps, St2sp, St2kp, St4ps, St4sp and St4kp;

- In accordance with GOST 1050 - 08kp, 10, 10ps, 20, 35 and 45.

Pipe selection criteria

When choosing steel pipes of any section, you should pay attention to the following parameters:

- preparation method;

- grade of steel from which the products are made;

- dimensions and wall thickness of the profile pipe;

Manufacturing methods

Rectangular or square steel pipes can be manufactured:

- welded method. They are characterized by a smaller wall thickness and a lower strength index;

Electric welded hot rolled pipes

- seamless method.

Seamless pipes can be:

- hot-rolled, that is, made from hot-rolled strip. Such pipes are distinguished by a large cross-sectional size and increased wall thickness and are used primarily for the construction of frames of houses and other structures;

- cold rolled. In this way it is possible to produce pipes with more precise parameters. A square or rectangle in cross-section turns out to be geometrically correct. Pipe sizes may vary. The primary use is the creation of furniture frames and decorative elements.

Seamless pipes have qualities such as ductility, pressure resistance and a smooth surface. A distinctive feature is the increased wall thickness, since it is quite difficult to produce pipes in this way with other parameters.

High-strength profile pipes

The weak point of welded pipes is the seam, which can burst under heavy load. Therefore, to create frames with heavy loads, it is recommended to use seamless pipes. However, it should be borne in mind that the cost of such pipes is higher.

What steel are the pipes made from?

Steel square and rectangular pipes are manufactured in accordance with GOST 13663-86. For the manufacture of pipes (clause 1.4 of the document) the following can be used:

- carbon steel (steel grades are shown in the figure below);

- alloy steel.

Grades according to steel types

For seamless pipes, preference is given to steel grades 08kp, 10ps, 20, 35, 45, and for welded pipes St4kp, St4ps, St4sp, St2kp, St2ps, St2sp.

To increase resistance to corrosion, pipes are coated with zinc, which is designed to reduce susceptibility to rust by 6 to 7 times. Zinc is applied to the pipe by immersing the product in straightened metal. Both the internal and external surfaces of pipes are subject to galvanization.

Assortment of square steel pipes

Pipes in accordance with GOST can have wall dimensions from 10 mm to 150 mm. In this case, the wall thickness can vary from 0.8 to 12 mm.

Characteristics of manufactured types of pipes

For the construction of frames that will be under load, it is recommended to purchase pipes of larger sizes and with increased wall thickness of the product. Small-sized pipes are ideal for making furniture, fence crossbars and decorative crafts.

Advantages and disadvantages of profile pipes

Pipes 25:25

Profiled pipe has the following advantages:

- The production of structures is accompanied by a decrease in metal consumption;

- Angular stiffeners provide good resistance to mechanical loads;

- Optimal execution of logistics operations, including transportation, unloading and loading, warehousing;

- Possibility of using non-standard architectural and design solutions during construction.

Pipes 40x20

The main disadvantage of profile pipes, like any other metal products, is their susceptibility to corrosion, which leads to disruption or deterioration of the performance characteristics of the pipe.

The solution to this problem can be profiled galvanized pipes. Not so long ago, galvanized profile pipes were used exclusively as water pipes, but modern technologies make it possible to produce them for use in almost any area of human activity.

Important: in addition, galvanizing technology allows you to increase the service life of metal structures made from profiles several times.

Diameters of profile pipes

Pipes 50x50

Due to the variety of areas in which profile pipes are used, the production of a wide variety of sizes and shapes of profile pipes has now been established.

Thus, pipes of different sections (for example, 20x20 and 120x120 mm) are used in the following industries:

- Gas and chemical industry;

- Pharmaceutical companies;

- Energy;

- Housing and communal services, etc.

Useful: one of the most common are pipes with a cross section of 80x80 mm.

Different types of steel are used to produce products of different diameters. In addition, in some cases, a combination of several different types of steel can be used to produce a profile pipe.

Profile pipes are also distinguished by the method of their manufacture. Thus, due to the low loads of such profile pipes, such as 30x30 or 60x60 mm, one weld is sufficient for them.

In the case of large diameter profile pipes (250 mm or more), a double seam can be used, which turns out to be justified when there are significant loads on the structure.

SevZapAgroPromStroy

Prices for profile pipes are indicated in the “price list for rolled steel” section.There are many types of building reinforcement, for example, beams, angles, channels, which are created for specific areas of application, but there is also universal rolled metal, which is cheaper and, most importantly, much easier to install than specialized rolled metal that can replace these parts with such rolled metal is a steel profile pipe.

These profile pipes usually have a rectangular or square cross-section (as opposed to a circle in the pipes we are used to), and are called rectangular and square pipes, respectively. They are rarely used for installation of utilities, since they are mainly used as construction fittings, hence the name - profile pipes.

The main advantages of profile pipes are: - ease of installation in various structures - replacement of many elements of profile fittings and lower cost in comparison with them - convenient shape, facilitating storage, loading, transportation - resistance to severe static loads and high bending strength - saving metal when construction of buildings - resistance to deformation and changes in temperature - the ability to find non-standard architectural solutions Rectangular and square pipes, like ordinary ones, are divided into different types according to the production method - hot-rolled, cold-rolled, seamless, electric-welded. Moreover, hot-rolled or otherwise hot-deformed pipes become a blank for the production of cold-rolled ones.

Seamless profile pipes are especially popular in systems with increased safety requirements. This type of profile pipe has a clear advantage due to the uniform distribution of the load along the entire perimeter. In pipes with seams, the strength of the areas near the seams should not decrease by more than 10-15% (depending on the type of pipe and scope of application), but the ideal option is a seamless pipe. Such elements are used at the most important, most critical facilities, right up to the external circuits of nuclear power plants.

Profile pipes are made from steel grades St2sp, St2ps, St2kp, St4sp, St4ps, St4kp in accordance with GOST 380, as well as steel grades 10, 10ps, 20, 35, 45, 08kp - in accordance with GOST 1050. These types of calm, semi-quiet and boiling steel are the best correspond in a manner to the technological features of the manufacture of profile pipes. As a rule, carbon steel is used in production without special alloying in order to withstand a certain plasticity of the metal, which allows drawing pipes of various shapes. Pipes are made by heat treatment or without heat treatment.

ELECTRIC-WELDED PROFILE PIPES GOST 13663-86. The profile pipe is made from hot-deformed, cold-deformed, electric-welded or electric-welded cold-deformed general-purpose pipes made of carbon steel.

Electric-welded profile pipes are manufactured with external dimensions from 10 to 100 mm, wall thickness from 1.0 to 5 mm, length: unmeasured length - from 1.5 to 9 m; measured length - from 5 to 9 m; multiple measuring length - any multiplicity not exceeding the lower limit established for measuring pipes.

Pipes are made from steel grades: St2sp, St2ps, St2kp, St4sp, St4ps, St4kp according to GOST 380; 10, 10ps, 20, 35, 45, 08kp according to GOST 1050. Depending on the purpose, pipes should be manufactured in the following groups: A - with standardized mechanical properties; B - with standardization of mechanical properties and chemical composition of steel grades according to GOST 1050-88 and GOST 380-88..

Profile pipes are manufactured either heat-treated or without heat treatment. The ends of the pipe must be cut at right angles; at the request of the consumer, pipes are manufactured without cutting the ends. Hydraulic testing of the pipe and standards for it are determined by agreement between the manufacturer and the consumer.

STEEL SQUARE PIPES (GOST 8639-82) The range of square pipes is regulated by GOST 8639-82. This standard applies to seamless hot-deformed and cold-deformed electric-welded and electric-welded cold-deformed steel pipes.

Pipes are manufactured:

of unmeasured length: - seamless hot-deformed - from 4 to 12.5 m - seamless cold-deformed and electric welded - from 1.5 to 9 m

measured length: - seamless hot-deformed - from 4 to 12.5 m - seamless cold-deformed - from 4.5 to 9 m - electric welded - from 5 to 9 m

length, a multiple of the measured length: - seamless hot-deformed - from 4 to 12.5 m with an allowance for each cut of 5 mm - seamless cold-deformed - from 1.5 to 9 m with an allowance of 5 mm for each cut - electric welded - any multiplicity, not exceeding the lower limit established for measuring pipes

The total length of multiple pipes must not exceed the upper limit of the gauge pipes. The allowance for each multiple is set to 5 mm (unless another allowance is specified in the order) and is included in each ordered multiple. In the cross section of the pipe, the deviation from the right angle should not exceed ±1.5°. The curvature of the pipes should not exceed 2 mm per 1 m of length.

RECTANGULAR STEEL PIPES (GOST 8645-68)

The range of rectangular pipes is regulated by GOST 8645-68. This standard applies to seamless hot-rolled, cold-drawn and electric-welded rectangular steel pipes.

Application of a profile pipe.

The shape of the profile pipe makes it very popular in construction and in the manufacture of all kinds of metal structures. Using profile steel pipes, fences, shopping and sports complexes, bridges, industrial buildings, communication towers, long-span structures containing heavy loads are erected; they can also be used as supports, columns and ceilings, for example, during repairs to create temporary metal structures or laying electrical networks. One cannot do without such a pipe in agricultural engineering. Profiles with side dimensions of 50×50, 40×80, 50×100 are often used.

Profile pipes play an important role not only in large-scale construction; they are a frequently used material in creating furniture frames, erecting fences and making railings, decorative interior decoration, playgrounds, and window bars. In a word, profile steel pipe is used everywhere.

Advantages of a profile pipe.

The main advantage of steel profile pipes is the reduction in the weight of the metal structure along with ease of installation. There is an obvious gain in the mass of material, and therefore in money, while due to the distribution of the load over the entire profile, a very high resistance to loads is maintained. Moreover, the corrosion resistance of the entire structure increases compared to the use of other types of rolled metal. The possibility of using profile pipes on high-voltage lines is due to the possibility of applying an additional coating to the supporting part, which ensures the safety of conductive elements.

Many designers and architects have practically abandoned the use of traditional types of building metal products in favor of a profile closed pipe due to its practicality and ease of use for modern architectural and design solutions.

Our prices for profile rectangular pipes in St. Petersburg and other rolled metal products will pleasantly surprise you. Thus, our company provides a system of discounts for regular customers.

This directory provides information about all types of steel pipes, in particular about stainless pipes, as well as about rolled products, in particular about fittings and steel circles.

About steel profile pipes

Profile steel pipe

Steel profile pipes can have various types of cross-sections other than round, such as:

- Square;

- Rectangular;

- Flat oval;

- Multifaceted, etc.

Useful: the choice of a specific type of section depends on the specific situation in which it is planned to use this pipe.

Steel profile pipes are widespread on the market and are used everywhere, especially rectangular steel profile pipes, which serve as the basis for most new building structures and architectural objects.

Such profile pipes inherited from steel all its positive characteristics:

- Plastic;

- Reliability;

- Resistance to various influences.

In addition, the presence of a profile additionally increases the fracture and bending strength of pipes, allowing in some cases to quite successfully use them instead of elements such as angles, beams and channels.

It should also be noted that the correct choice of the grade of steel from which the pipe is made makes it possible to reduce the metal consumption of the entire structure, and the magnitude of this reduction can be up to 30% relative to the total mass of the metal used.

Technical characteristics of profile steel pipes are regulated by GOST 13663-86. For the manufacture of such pipes, a profiling method is usually used, which allows for high dimensional accuracy. Manufacturing can be either suture or seamless.

The great popularity of profiled steel pipes has led to their widespread use in rolled steel, accordingly having a positive impact on the cost of this product. At the same time, the market offers the widest range of profile steel pipes, which can be used in both private and industrial construction.

About profile pipes 09G2S

09G2S – profile pipe

Profile pipes made from structural low-alloy steel grade 09g2s are most widely used both in the construction of industrial and civil facilities, and in the domestic sphere of human activity - for example, for installing fences in a country house, in a garden or on a country site, or for the manufacture of display cases and shelving.

Useful: grade 09G2S is deciphered as follows: 09 - 0.09% carbon in steel; G2 – content of no more than 2% manganese; C – silicon content not more than 1%.

For the manufacture of 09G2S profile pipes, low-alloy steel of various profile sections is used, selected in accordance with the purpose and planned operating conditions of the pipe.

The main advantages of profile pipes 09G2S are:

- High technology;

- Minimized number of seams;

- Aesthetic appearance;

- Low aerodynamic resistance to wind and other weather loads, etc.

Metal structures made from profile pipes 09G2S are used in addition to their main purpose - the construction industry in the following areas:

- Signs;

- Billboards;

- Showcases;

- Fences;

- Metal doors and much more.

Profile pipes 09G2S of large standard sizes, such as 200x12 ST09G2S, are most often used in the construction of fairly large civil or industrial facilities. The use of such profile pipes in this case is due to the fact that this material has excellent performance characteristics under conditions of significant loads.

Useful: high bending strength combined with low weight make such profile pipes often the most suitable material for the construction of complex metal structures.

To summarize, we can say that the choice of profile pipes as a material for the construction, installation and reconstruction of buildings, structures and structures, which are based on the need to use metal, is associated with their numerous positive characteristics, which primarily include high manufacturability , saving metal and high reliability of connections.

Did you like the article? Subscribe to our Yandex.Zen channel

Pipe application area

The profile pipe has many advantages compared to standard round pipes:

- low cost. A hollow square-section metal pipe is less expensive than analogues made of wood and can last longer;

- ease of installation. Thanks to its qualities, the pipe can be easily bent. The low weight of the products facilitates the process of transportation and self-installation;

- high resistance to damage. Profile pipes are not susceptible to mechanical stress. Pipes are protected from corrosion by a special coating;

- resistance to temperature changes. The pipe does not deform at both low and high air temperatures;

- reliability. Thanks to the stiffening ribs, the profile pipe can withstand quite heavy loads, and for a long period of time.

The main advantages of pipes determine the scope of their application. Pipes of various sections are used:

- for creating building frames, including as transverse beams, trusses, columns and vertical posts, as they are distinguished by their ability to withstand the load of the cladding and durability;

Frame of a residential building made of profile pipes

- for the construction of frames for gazebos, swings, benches and other small architectural forms;

- for the construction of fences, gates, wickets, both as main pillars and as transverse ribs;

Swing and fence frame made of square pipes

- to create pieces of furniture (tables, chairs, etc.).

Furniture items made from profile pipes

- as protective channels for various communications.

How to make a chair from pipes yourself, watch the video.

In some cases, pipes can be used in the assembly of windows, doors and some elements of the car body.

Classification of profile pipes by manufacturing method

Although shaped pipes may look similar in appearance, there are four different ways to achieve this configuration. The strength of the product and the cost, as well as the possible maximum dimensions and features of further operation, depend on the production methods.

Seamless hot-formed

Blanks for production by hot deformation are obtained by rolling, continuous casting or forging. To produce seamless profile hot-rolled pipes, a round cross-section pipe that does not have a weld is used. Next, the part is subjected to heating and mechanical stress on a longitudinal press.

A roller system is used to achieve the final shape. This produces a profile of the required size and correct cross-section. In this way, a square or rectangular pipe with thick walls is produced, characterized by increased strength to withstand loads.

Seamless profile pipe.

Seamless cold rolled

To obtain profile products using this method, the same blanks are used without seams as in the method described above. The difference is that the round sleeve does not heat up, but rather cools and only then enters the roller system to form the profile.

In this way, profile pipes with thin walls are produced. The deviation from standard dimensions does not exceed 0.5%, therefore seamless cold-rolled pipes are actively used in shipbuilding, car manufacturing, and various equipment where the accuracy of parameters is important.

Cold-deformed welded pipes

Pipes are produced from steel strips (strips) wound into a roll. Using special equipment, it is unwound and bent longitudinally into a cylinder. The result is a round pipe with a longitudinal side joint. The joint is connected by semi-automatic, resistance or plasma welding.

Strips.

Next, the sleeve is fed to a conveyor with rollers that exert a force of hundreds of tons on it. This gives the product a profile shape. In this case, internal stresses inevitably arise in the metal due to deformations. To “release” them, heat is used. This eliminates possible subsequent physical processes and ensures that the correct, permanent shape of the steel is maintained.

Welded profile pipe.

Welded steel strip pipes

This type of profile pipe production is used to produce products with a small cross-section. Steel sheets are used as the starting material here. First, a strip is made on a guillotine - a pipe blank. Then the strip is subjected to deformation, and the joint is fastened with spot or arc welding.

This method produces profile pipes with thin walls. The product has precise dimensions. When using galvanized steel sheets with an even smaller cross-section, it is possible to produce complex pipe structures of non-standard configurations.

Comparison of methods for producing profile pipes

All profile pipes are inferior in cost to their round counterparts, since they are produced from cylindrical blanks (essentially, ready-made round pipes), and only then become square or rectangular due to processing by rollers.

Round pipes also distribute internal pressure better, because it spreads evenly over the area of the walls. But square and rectangular sections are more convenient when assembling and welding metal structures (easier to join, more convenient to cut, does not roll on a flat surface, etc.), so profile pipes are in great demand.

1. The first two manufacturing methods are considered the most expensive. Because of this, they are rarely used and are justified only for obtaining products intended for places with high loads. These may be support columns and other structural elements on which safety depends.

But where a high-strength profile is applicable, seamless round analogues are also suitable. If you want to save money, you can use non-profiled pipes.

2. The method of producing a profile pipe from strip is the cheapest, due to the low cost of the workpieces. Another advantage of the technology is its unlimited size. A steel strip in a coil can be 10 meters or more in length, so the final profile size has no restrictions.

This makes it possible to produce a single pipe of large longitudinal dimensions, saves time when assembling structures, and eliminates the need to weld additional sections on site.

To summarize: for areas with high loads it is better to use seamless profile pipes, and for normal use profile products made from steel strip are suitable.

3. Be careful when choosing a manufacturer . Note that it is possible to produce a profile pipe from single-seam cylindrical blanks not only at the factory, but also in a garage or small workshop. To do this you will need a machine with rollers. To reduce costs, some entrepreneurs do not waste electricity to inductively heat the metal and relieve residual stress.

This is not critical if the products are used for the manufacture of fences, furniture, and small metal structures. But such pipes are not suitable for construction, since they can subsequently become deformed. In this case, before purchasing, you should clarify the nuances of making the pipe or simply contact a well-known manufacturer with a good reputation.