It is easier and cheaper to make a heater based on nichrome. A meter-long piece of self-regulating cable costs 330 rubles and goes on forever. Sellers surprisingly consistently forget to indicate the temperature of the system setting, but provide information about power that directly depends on conditions, and the indicator, by definition, in the described case is not constant. If we were talking about a resistive cable, the above would make sense. For example, a self-regulating one works independently and does not require a thermostat. Has high fault tolerance. This means that the risk of fire is minimal if you happen to make a homemade heater.

Small homemade heater

Progress

First, we separate the cooler grille from the fan, it will also be useful to us. We place the fan with the correct side (so that it blows outward) into the jar, and secure it to the bottom with several screws. It will be needed to drive hot air into the room from the hot wire. Now we roll the wire itself into a spiral - it can be wound on a thick pencil and removed. This is necessary for greater heat transfer when air passes past the spiral. We fix the spiral inside the case, the ends need to be brought out and connected to the wires. Our heating is almost ready. All that remains is to cover the case with the cooler grill for safety. It’s as if it was specially created for this - it turned out to be an excellent device, reminiscent of a hot hair dryer.

Examples of homemade heaters

As already noted, it is easier to make a heater from nichrome. You will need a section with a resistance of 27 - 28 Ohms to get a power of 2 kW. Do not connect such spirals in parallel. In this case, the power is multiplied by the number of heating elements, and the home switchboard in the Khrushchev building draws 5 kW. If you do not take into account modern high-rise buildings. Power is calculated using the formula:

Do-it-yourself heater-wind blower

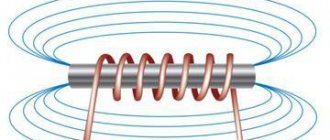

With a resistance of 28 Ohms, the result is 1728 W, if the effective voltage value is 220 V. It is unlikely that you will be able to assemble a tubular water heater at home, and there are as many nichrome spirals as you like. Wind the wire around a ceramic rod, as is done in electric fireplaces, or on plates, as in hair dryers or wind blowers. Where to get heat-resistant material. It costs a penny in the capital market, but it’s expensive to buy online. Disassemble old equipment and borrow what you need. Do not use steel for winding; this action will cause unpredictable consequences. By the way, the soldering iron has a ceramic insulator inside.

If nothing comes to mind, use a special hammer (for bricks) to chop off a thin plate from the brick and use it. The fragment is heavy, but reliable. If you find a fire brick, it is better to use a heat-resistant one. Ceramic tiles will do. Don’t forget to make a recess at the ends of the plate for the wire, wind it in one layer, no more. In this case, the heat exchange conditions are violated, and the nichrome can burn. By the way, make holes in the tiles using special drills (for tiles, with a stone at the end). If forced airflow is expected, for example, with a processor cooler, this will improve heat transfer.

By the way, fans are not used at all to increase power, as it seems. The thermal effect of nichrome depends little on air temperature. The wind just picks up the heat and spreads it around the room faster. The heating is more even. Ceramic tiles can be installed using any method, including heat-resistant adhesive (temperatures of at least 800 degrees). When heated, nichrome glows and works as an infrared heater. If the above is not enough, introduce airflow.

It is better to take 230 V motors. Low power asynchronous motors used in hoods or household fans are suitable. Do not use commutator motors: they are noisy and spark. By the way, you can get asynchronous electric motors in a refrigerator, kitchen hood or air conditioner. Linear compressors should be avoided; there are no rotating parts inside. A homemade heater for an apartment is assembled based on a cassette recorder. There are quiet motors inside; you need to properly adjust the speed for rewinding.

If you need a homemade heater for your summer house, assemble a burner based on an injector. They described a similar design, these are popular in the USA. Do not use gasoline to generate heat; the vapors are explosive. We do not recommend blowing ionized air through the nozzle in the heater, but it is possible to place a perforated tile into the fire. It will serve as a ceramic grille, battery and heat emitter. It’s easier to make a homemade heater using a collet travel cylinder. It is necessary to make the attachment correctly, for example, based on a commercial one for cooking.

Some notes

You can improve the device using additional parts:

- gypsum

- steel wire

- switch

The steel bracket does not have to be adapted in any way inside the case - it is only needed as a convenient stand for the device. The switch allows you to easily operate the device. It can be installed on the side of the jar body by adding a couple of screws. But gypsum will help give strength and durability to the nichrome wire. Pour the dry gypsum into water, dilute it and dip a twisted spiral into the solution, then air-dry it under a layer of gypsum until it hardens. Now the heating will be softer, and the device will be more durable and safe. The main thing is not to forget to leave contacts at the ends for connecting the wires.

Result: We have a simple and effective device for heating a room. If everything is done correctly, it will be safe to use and will consume very little power.

Heaters and cables

Not everyone has ever encountered a self-regulating cable; let’s tell you a little more about these interesting components for defrosting systems for building gutters. The ohmic wire generates heat according to the Joule-Lenz law. The effect is directly proportional to the current, inversely proportional to the resistance, and depends on the operating time of the structure. To obtain useful heat in heaters, people were looking for materials with increased resistance. This seems to reduce the Joule-Lenz effect, but the trivial wire cannot be connected to the 230 V network - the core burns out. There is a short circuit. Try to make a heater with your own hands without danger to others.

For example, to get a 2 kW heater, take a wire with a resistance of 28 Ohms. Try making something out of copper wire. Nichrome is endowed with significant resistivity; 3-5 meters of material will allow you to wind a spiral. If you reduce the cut length, the power will increase, but the situation is unfavorable. The conductor is characterized by a certain maximum power per linear meter that it dissipates. If the value is too high, the coil will burn out. The process will take place quickly in the air.

First tip on how to make a heater:

Research the market for similar factory-made designs. What is the power and internal structure of the heater, what materials is the product made of.

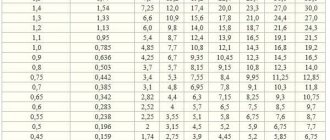

Next we copy the technical specifications. Look in the reference book to see what linear power nichrome dissipates. By the way, the technique uses fechral from Norway, the composition of the material is a secret and cannot be obtained in stores.

What to make from nichrome. Metal factories produce:

Everywhere the ability to provide heat in doses is used (unlike copper, where the released linear power is small, the chance of burning plugs is high). The difference between tubular electric heaters is that the spiral is protected by pressed powder from water and air. The outer copper shell is used to maintain the shape of the dielectric. This will allow electrical isolation of the device. Don't forget, nichrome is metal, it's easy to get an electric shock if you don't take precautions.

The self-regulating cable independently monitors the temperature. We would like to inform the readers that the resistive cable is made of an ohmic conductor. Not nichrome or copper.

The composition of the resistive cable is not important, the main thing is that it generates heat while the supply voltage is applied. New technologies have led to the emergence of a dielectric matrix interspersed with graphite. The concept is the basis for cables that self-regulate and expand as the temperature rises. As a result, graphite inclusions gradually cease to contact each other.

Due to this, the resistance of the area increases. The voltage is constant - 220 V - which means the current drops. Consequently, the Joule-Lenz effect is reduced. When the area cools, the reverse process occurs. The self-regulating matrix contracts, there are more graphite bridges, the resistance drops, the current increases, and the thermal effect increases. To make a cable, two parallel copper wires are taken to supply potential. A self-regulating matrix with graphite inclusions is laid between them along the length. The beauty of the design is that the fragments will be heated independently. Temperature plays a decisive role in the magnitude of the thermal effect.

The matrix is configured at the factory. More often we see products with heating temperatures in the region of low positive temperatures, just above zero. The vast majority of cables are used in defrosting branches of structural elements of buildings, so the properties are selected accordingly. It felt a little icy, the temperature dropped to zero, the matrix shrank, and the cable began to heat up. The advantage of the design is that there is no need to monitor the device. At the same time, a resistive cable gives a fixed thermal effect.

Production

A nichrome spiral is wound from cold-drawn wire without heating.

If the material of the future heater is fechral wire, then the winding is carried out with heating, which is carried out by passing an electric current through the workpiece. In this case, a transformer with voltage steps of 5-10 V is used. The voltage is supplied to the lathe bed and to the tool holder through a guide in which a hole is made for the wire. The guide is insulated from the frame with textolite gaskets. The spiral winding speed is selected so as to heat a given section of the wire to a temperature of 200-300 °C (in the zone of 400-500 °C alloys are brittle). The workpiece is heated only in the area from the guide on the tool holder to the spiral mandrel. The bending of the jumpers must be carried out in a special device without sharp impacts or bends in order to avoid breakages.

Stamps

Spirals are made from nichrome of the two most common grades in industry: X20N80 and X15N60.

These are alloys of nickel and chromium (hence the name “nichrome”). The first of these contains ~80% Ni and ~20% Cr, the second - ~60% Ni and ~15% Cr. The difference in the mass fraction of nickel has a significant impact on the performance and economic characteristics of the alloys. X20N80 has a higher maximum operating temperature and higher cost compared to X15N60. The chemical composition of the materials in question also includes iron (Fe) and manganese (Mn). The chemical composition of precision alloys, including nichromes X20N80 and X15N60, is determined by the GOST 10994-74 standard.

Troubleshooting Settings

The highest probability of failure of electric heaters is due to oxidation of the surface of the heating resistance.

Factors that influence the rate of heater destruction:

- working temperature;

- environmental conditions in which the heater operates;

- switching frequency.

Due to the fact that electric heating installations operate in excess of the permissible values of these parameters, the most frequent breakdowns occur: burning of contacts, violation of the mechanical strength of nichrome wire.

Repair of a nichrome heating element is carried out by soldering or twisting.

What is nichrome

It is an alloy formed by two base metals - nickel and chromium. Moreover, the first sometimes accounts for up to 80% of the alloy structure. Also, other metals are introduced into the composition of nichrome, including iron, aluminum, silicon, etc. The operational features of the material include high electrical resistance, heat resistance, and ductility. Separately, these qualities are not something special for traditional metals, but nichrome thread benefits precisely due to their combination in one structure. For example, the same plasticity makes it possible to produce alloy filament fibers, then using them in furnaces, where the working environment can be about 1,200 ˚C in temperature. In addition, depending on the purpose, the alloy can be additionally alloyed, which gives it new properties or improves its basic characteristics. Thus, to increase the working life, nichrome is diluted with rare earth metal components.