A feature of mechanical testing of welded joints is the mandatory destruction of samples under multidirectional loads. This is the only way to determine important operational indicators, on the basis of which calculations of possible loads are made. Various testing methods are provided. Special control equipment has been developed for them.

For mechanical tests, several serial samples of welded joints are selected. The conclusion is drawn up on the basis of several identical studies of weld ductility and fracture resistance.

The essence of mechanical testing of welded joints

A set of studies of seams produced by various types of welding has been developed and regulated. Among the tests of welded joints, there are groups of testing methods for welded joints with directed stresses:

- The static method involves a gradual increase in the destructive load. The tests are spread out over time so that the tension is constant.

- Dynamic ones act instantly, for a short time interval.

- Fatigue means repeated exposure to the test sample. The number of cycles is a value calculated in tens of millions. The load changes in sign and value.

Mechanical tests are used for serial production of parts.

Static tests include tests of butt welded joints, which determine the physical characteristics of the seams: hardness, creep, elongation, ductility, bending ability and others. The welded joint is compared with a similar specimen made of solid metal. For research, samples with a stripped and uncleaned roller are used.

The conditional yield strength is the stress at which the sample increases in length by 0.2% of the original length. The bending test is necessary to control the ductility of the diffuse layer. The bending load is applied until the first crack appears in the longitudinal and cross sections of the welded joint. Flat and tubular samples are used for experiments.

During dynamic tests of joints, the susceptibility of seams to fatigue deformation and impact bending strength are determined. Tests are carried out under different conditions: normal, low and high temperatures. The results are recorded in the protocol in the form of graphs and examined according to the type of curves. In some cases, other normatively approved studies are used.

Hardness is measured in the area of the diffuse layer and the heat-affected zone, and the structural strength of the metal is assessed in thin sections using metallographic methods.

Three areas are explored:

- diffuse layer of the seam;

- heat affected zone;

- workpiece metal that is not subject to heating during welding.

Factors affecting the quality of weld metal

The quality of the weld metal depends on a number of factors, such as weldability, the degree of exposure of the metal to thermal effects, oxidation, etc. It is important to take into account all such criteria so that the finished welded joints are suitable for certain operating conditions.

The weldability of metals is an indicator on which the ability of metals and alloys, with suitable processing, to form compounds with specified parameters depends. Experts distinguish between physical and technological weldability.

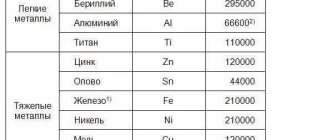

In any case, a significant role here is played by the physical and chemical characteristics of metals, their crystal lattice, the presence of impurities, the degree of alloying, etc., which affects the reliability of the weld metal.

Physical weldability is the ability of a material to form a monolithic compound with a stable chemical bond. This quality is characteristic of most pure metals, as well as their technical alloys and some combinations of metals and non-metals.

Technological weldability is the reaction of a material to welding and the ability to form a seam with the required characteristics.

To determine weldability criteria, the following material properties are taken into account:

:

- sensitivity to thermal effects during welding;

- tendency to grain growth while maintaining unchanged plastic and strength characteristics, structural, phase changes in the heating region;

- chemical activity, which affects the oxidation of the metal during thermal exposure;

- ability to resist pore formation, cracking in cold and hot conditions.

The quality of steels largely depends on their deoxidation ability, which is determined by the proportion of manganese, silicon and a number of other elements in the metal composition. It is also influenced by how evenly these components are distributed. Based on deoxidation, boiling steels are distinguished, marked as “KP”, semi-quiet, with the designation “PS”, and calm, that is, “SP”.

In boiling steel, impurities are distributed unevenly throughout the thickness of the rolled product, which is most clearly manifested in the case of sulfur and phosphorus and is explained by incomplete deoxidation by manganese.

In such steels, aging quickly manifests itself, crystallization cracks form on the metal of the weld and the area adjacent to it. As a result, the material becomes brittle at temperatures below 0°C.

Calm steel is characterized by a uniform distribution of impurities, making it less prone to aging. In addition, it is less affected by the temperature increase during welding.

Semi-quiet steel in its properties is between boiling and calm.

The named characteristics form the basis for the choice of welding method, methods of creating a weld, parameters of thermal effects, etc.

Regulations

The methodology for conducting mechanical tests and calculation formulas are regulated by RD 26-11-08-86 (guidance document of the Ministry of Chemical Industry). Sampling and determination of the type of research are carried out in accordance with GOST 6996-66. For various types of welding, the thickness of the control samples is regulated. The method of preparing welded joints for weld testing and the conditions for conducting research are discussed. Based on the results of the inspection, a protocol is drawn up, which indicates the method of testing the samples.

Quality control of raw materials

The quality of the base metal must meet the requirements of the certificate provided by the manufacturing plants along with the batch of metal.

In the absence of a certificate, the metal is put into production only after a thorough check: it is necessary to conduct an external inspection, a weldability test, and establish the mechanical properties and chemical composition of the metal.

During an external inspection of the metal, the absence of scale, rust, cracks, delamination and other defects on the metal is checked. Preliminary inspection of the metal in order to detect surface defects is necessary and mandatory, since it prevents the use of low-quality metal for welding products.

Advantages and disadvantages of the method

First, about the unique capabilities of the technique:

- obtain data on the performance properties of welding;

- study the mechanical characteristics of connections;

- establish design values to determine maximum loads (data necessary for design work);

- the capabilities of the diffuse layer, the thermally affected zone, where internal defects are possible, are checked.

At low costs for studying samples, data are obtained by which the strength characteristics of serially produced parts are judged. Select the optimal welding option for various alloys.

The disadvantages are obvious. The samples are expected to be destroyed and cannot be restored. This control method cannot be used for acceptance of welded joints. Methods are needed for research at the stage of launching series into production.

A feature of mechanical testing of welded joints is the mandatory destruction of samples under multidirectional loads.

Checking the qualifications of welders

The qualifications of welders are checked when the discharge is established, when they are allowed to perform critical welding work, immediately before the manufacture of a critical structure. In each case, both theoretical knowledge and practical skills are tested.

The category is established in accordance with the requirements stipulated in the tariff and qualification reference book. Testing of welders before admission to responsible work is carried out according to the rules for certification of welders.

After satisfactory passing of the tests, welders are issued a certificate for the right to perform responsible welding work.

What properties are determined when testing welded joints?

The developed methods, approved by the standard, indicate several methods for testing welds to determine the mechanical properties of the diffuse layer of samples. Pieces of thermally bonded metal are subjected to multidirectional forces. Determine the force under which deformation occurs along the seam. Taken into account:

- cracks;

- tears;

- changes in the original shape and linear dimensions.

Separately, technologically significant properties affecting the load-bearing capacity and tightness of connections are determined.

Plastic

Static tensile experiments determine the compliance of the diffuse layer and the heat-affected zone to change its original shape under the influence of elongating forces. The ability for stamping with stretching depends on ductility. The elongation index is determined by measuring samples before and after loading. Calculations are made based on the ratio of the elongation to the original dimensions. Each of the strength characteristics is worth considering in detail. The quality of welding depends on each of them.

Tension diagram to test ductility

Strength

For welded supporting structures experiencing multidirectional stresses, the strength indicator is important; the integrity of the structure depends on it. Strength characteristics are determined:

- for bending, forces are applied until the moment of critical deformation of the sample;

- for fatigue, the number of cycles with different loads until failure.

Causes of defects

Defects can appear for objective and subjective reasons. The fact is that any type of rolled metal has a certain level of weldability, which depends on the method of its manufacture and the composition of the alloy. If you plan to work with poorly welded parts, then a significant percentage of defects is initially recorded in the technological maps.

Usually seam welding is associated with problems such as

:

- violation of the integrity of the metal;

- deformation of elements under the influence of internal stresses;

- violation of the shape of the seam bead;

- changing the geometry of the surfacing bead;

- structural changes in the metal, namely, the grain size changes in the phase transition zone of the welded joint.

External defects are less dangerous than internal ones and can be detected using non-destructive inspection methods. However, it is important to understand that it is risky to form critical welds without sufficient knowledge and skills, and it is better to seek help from specialists.

Typically, a violation of the integrity of the metal of welds and the zone exposed to temperature effects occurs for the following reasons:

- the processing of the joints was carried out poorly, for example, the metal of the welded seams was poorly cleaned of scale, rust, oxide film residues, grease and dirt, violations were committed in the process of removing oxygen from the metal of the welded seam;

- surfacing wire and electrodes that are not suitable for the metal of the workpiece were used;

- equipment is faulty;

- the parameters on the welding machine regulators, such as current and voltage, are incorrectly set;

- an error was made when laying out the parts, the coefficient of linear expansion was not taken into account;

- the distance between the electrode and the workpiece is broken, causing the arc to be too long or too short.

Welding operations greatly influence the mechanical properties of low-carbon steel. And the processing of structural steels leads to structural changes in the heat-affected zone, which reduces the mechanical performance of the joint. At the same time, hardening structures and cracks appear in the weld metal.

You need to understand that the weld, the heat-affected zone, and the unexposed workpiece metal have different strengths. This means that during the study it is important to regard the welded joint as an inhomogeneous body. Destructions can occur in any of the three named zones - it all depends on where the lowest strength is observed.

Recommended articles

- Types of welds: differences from joints and descriptions of varieties

- How to cook with electric welding: technology and important rules

- Capacitor welding: process features

Today it is possible to achieve equal strength of welds and the base metal using electrodes with high-quality coatings and other consumables.

The reliability of the connections is ensured by the strength of the weld metal, and also depends on the width of the overheated metal in the thermal zone, the total width of the weld material and the overheated metal. Important factors include the nature of the application of external load, the temperature at which the product is operated, etc.

Inspection of workpieces for welding

Before entering the assembly, the cleanliness of the metal surface, the overall dimensions of the workpieces, the quality of edge preparation and their bevel angles are checked.

Defects in workpieces for welding significantly affect the quality and productivity of welding work. For example, an increase in the bevel angle of the edges leads to an increase in the amount of deposited metal, an increase in welding time and unnecessary consumption of electricity and electrodes. In addition, the connection after welding will be more deformed, since the more deposited metal, the greater its shrinkage when cooling. Preventing defects in workpieces will eliminate unnecessary work to correct them.

Welding wire quality control

For welding and surfacing wire, GOST establishes the grade and diameter of the welding wire, chemical composition, acceptance rules and test methods, requirements for packaging, labeling, transportation and storage.

Each coil of welding wire must have a metal tag indicating the name and trademark of the manufacturer, the symbol of the wire according to the standard and the batch number.

The certificate accompanying the batch of wire contains the following data: trademark of the manufacturer, symbol of the wire, heat and batch number, condition of the surface of the wire (copper-plated or non-copper-plated), chemical composition in percent, tensile test results, wire weight (net) in kilograms.

Thus, the presence of a tag attached to the coil of welding wire, as well as a certificate for the wire, is a guarantee that the wire is suitable for welding. The surface of the welding wire should be free of scale, rust, dirt and oil. High-alloy steel wire should not have any residual graphite lubricant.

Welding wire, for which there is no documentation, is subject to careful control. The most important thing is to check the chemical composition of the wire, for which 0.5% of coils are selected from each batch, but not less than two. Chips for chemical analysis are taken from both ends of each controlled coil or from two sections at a distance of at least 5 m from one another. After conducting a chemical analysis, the grade of welding wire is determined and the possibility of its use for welding is determined in accordance with the technological process.

X-ray scanning

X-rays are electromagnetic waves. They have the following properties: the ability to penetrate through opaque bodies; act on photographic film, like light; under the influence of these rays, some substances, for example gray zinc, glow (luminesce); cause ionization of gases, including air, and make it electrically conductive; in large doses causes a harmful physiological effect on a living organism, destroying its tissues.

In industry, X-ray machines of the RUP type were used to examine products. Thus, the RUP-120-5-1 apparatus is used for scanning metal from steel up to 25 mm thick and light alloys up to 100 mm thick.

The transmission diagram of the welded joint is shown in Fig. 9.

Figure 9, Scheme of X-ray transmission

1-X-ray tube 2-cassette 3-film 4-screens

The radiation source (X-ray tube) is placed at a certain distance from the seam, so that the rays are directed perpendicular to its axis. A light-proof cassette is attached to the opposite side, which should fit tightly and evenly to the translucent area of the product. The cassette contains X-ray film and two intensifying screens. When transilluminating, the film is exposed to the rays for a certain time, called exposure. Exposure depends on the thickness of the metal being illuminated, focal length, radiation intensity and film sensitivity. Intensifying screens serve to reduce exposure. After exposure, the film is removed from the cassette and developed. The negative is then washed and fixed to produce a permanent photographic image. The image of the seam section obtained on the negative will be the same in the degree of darkening of individual places. Rays falling on the film through a defect will be absorbed to a lesser extent compared to rays passing through dense metal, and will have a stronger illuminating effect on a certain area of the photosensitive layer of the film.

When scanning, a flaw meter is installed near the seam (parallel to it), on the side of the radiation source, Fig. 10.

Fig. 10, Design of a plate defectometer (dimensions in mm)

which serves to determine the depth and size of the detected defect. A flaw meter is a plate made of the same material as the metal being scanned. The thickness of the plate should be equal to the reinforcement of the seam. The defectometer has grooves of varying depths. At the same intensity, the darkening of the film under one of the grooves with the darkening of the defect, with a known groove depth, determines the size of the defect (in height). In addition to plate defectometers, wire sensitivity standards are used. The quality of a translucent weld is determined by comparing the film with reference photographs established to identify a product or group of products. Transillumination can detect most internal defects: lack of penetration, pores, inclusions, large cracks.

When scanning a butt weld with Y-shaped edge preparation, the cassette with the film is usually reinforced from the bottom of the groove, which makes it possible to reveal lack of penetration at the top. To determine lack of penetration along the edges, the ray source is installed in two different positions (II and III), as shown in Fig. II.

Lack of penetration along the edge is recorded on the film in the form of a dark strip that stands out against the lighter background of the weld. Gas pores and slag inclusions are equally detected with any transmission scheme.