Such a familiar school chalk to everyone, how many funny memories it holds... Only behind its apparent simplicity hides a whole history of the development of the planet. "How can it be?" - you ask. The answer to this question is in this article. You will not only study the physical properties of chalk and its use, but also become familiar with the processes of formation of deposits of limestone sedimentary rocks in the earth's crust that shaped the modern appearance of the Earth.

Minerals and rocks of biogenic origin

Approximately 130–65 million years ago, during the Cretaceous period of the Mesozoic era, the seas of the ancient planet were filled with planktonic and benthic species of foraminifera, as well as mollusks that resembled modern oysters, scallops and nautiluses. In their external skeletons and shells, they accumulated compounds of calcium, phosphorus, magnesium and, dying, formed layers of limestone silt at the bottom of reservoirs. Under the influence of high pressure and as a result of chemical processes, deposits of limestone and chalk were formed from it. The physical properties and composition of these sedimentary rocks are very similar to each other, but they also have differences. The geological processes that occurred on Earth caused the rise of individual sections of the ocean floor and the subsidence of continental zones. What did this lead to?

Distribution of copper in nature

The average copper content in the earth's crust is 4.7 10-3% (by mass), in the lower part of the earth's crust, composed of basic rocks, there is more of it (1 10-2%) than in the upper part (2 10-3% ), where granites and other acidic igneous rocks predominate. Copper migrates vigorously both in the hot waters of the depths and in the cold solutions of the biosphere; Hydrogen sulfide precipitates various Copper sulfides from natural waters, which are of great industrial importance. Among the numerous copper minerals, sulfides, phosphates, sulfates, and chlorides predominate; native copper, carbonates and oxides are also known.

Copper is an important element of life and is involved in many physiological processes. The average copper content in living matter is 2·10-4%; organisms are known to be copper concentrators. In taiga and other humid climate landscapes, copper is relatively easily leached from acidic soils; copper deficiency and associated plant and animal diseases are observed here (especially in sand and peat bogs). In steppes and deserts (with weakly alkaline solutions characteristic of them), copper is inactive; In areas of Copper deposits, there is an excess of it in soils and plants, causing domestic animals to get sick.

There is very little copper in river water, 1·10-7%. Copper brought into the ocean with runoff relatively quickly turns into marine silts. Therefore, clays and shales are somewhat enriched in copper (5.7·10-3%), and sea water is sharply undersaturated with copper (3·10-7%).

In the seas of past geological epochs, in places there was a significant accumulation of copper in silts, leading to the formation of deposits (for example, Mansfeld in Germany). Copper also migrates vigorously in the groundwater of the biosphere; the accumulation of copper ores in sandstones is associated with these processes.

Excursion into geology

The redistribution of the surface of the lithosphere and the water shell of the planet led to the appearance of mountain chains and ridges consisting of sedimentary rocks. These are the Alps, the Caucasus Mountains, the Himalayas, the Pyrenees. And the cliffs of Dover are completely made of pure chalk. They give the English coastline a unique look and have long served as a signal for ships to approach Foggy Albion. In Russia, unique landscapes against the backdrop of chalk rocks can be seen in the village of Storozhevoy near Voronezh. Having become familiar with the geography of the distribution of biogenic rocks, now is the time to study the physical properties of chalk in more detail.

Copper Applications

Due to their valuable qualities, copper and copper alloys are used in the electrical and electrical engineering industries, in radio electronics and instrument making. There are alloys of copper with metals such as zinc, tin, aluminum, nickel, titanium, silver, and gold. Less commonly used are alloys with non-metals: phosphorus, sulfur, oxygen. There are two groups of copper alloys: brass (alloys with zinc) and bronze (alloys with other elements).

Copper is highly environmentally friendly, which allows its use in the construction of residential buildings. For example, a copper roof, due to its anti-corrosion properties, can last more than a hundred years without special care or painting.

Copper in alloys with gold is used in jewelry. This alloy increases the strength of the product, increases resistance to deformation and abrasion.

Copper compounds are characterized by high biological activity. In plants, copper takes part in the synthesis of chlorophyll. Therefore, it can be seen in the composition of mineral fertilizers. A lack of copper in the human body can cause deterioration in blood composition. It is found in many food products. For example, this metal is found in milk. However, it is important to remember that excess copper compounds can cause poisoning. This is why you should not cook food in copper cookware. During boiling, large amounts of copper can leach into food. If the dishes inside are covered with a layer of tin, then there is no danger of poisoning.

In medicine, copper is used as an antiseptic and astringent. It is a component of eye drops for conjunctivitis and solutions for burns.

What determine the characteristic features of natural compounds?

The internal spatial arrangement of atoms and molecules of the body - the crystal lattice - completely determines the state of aggregation, melting and boiling points, density, etc. These are parameters that relate to physical properties. The molecular formula CaCO3 corresponds to several crystalline compounds containing charged particles - ions - at lattice sites. These are marble, aragonite, Iceland spar, limestone and chalk. This phenomenon in chemistry is called polymorphism and is explained precisely by the shape of the crystal. Hence the conclusion follows: the physical properties of copper, gold, chalk, acetic acid and any other substance are determined by its state of aggregation, which depends on the internal structure of the compound.

Answers to user questions about copper

We will answer several popular questions from users.

Do old TVs have copper?

From 1 old TV you can get from one and a half to two kilograms of copper. This is mainly the winding of transformers and coils.

What is the electronic and electron graphic formula of copper?

Regarding the electronic configuration of the copper atom: 1s2 2s2 2p6 3s2 3p6 3d10 4s1

Graphic formula of copper:

Types of limestones

Experts can distinguish up to 4 forms of a substance, depending on its structure and physical characteristics. Thus, pure calcium carbonate has a fine granular surface, upon contact with the surface it easily leaves a white mark and contains only up to 5% of impurities, mainly in the form of magnesium or calcium sulfate. Clay sand chalk is beige-white in color, also has a fine-grained structure, but has a higher viscosity and contains up to 10% of foreign compounds, for example, calcium sulfate, silicon or aluminum oxide. Green, yellow or gray chalk marl has even more impurities, and chalk-like limestone is easily recognized by its large yellow or white crystals with dense-cementing properties. It should be noted that in chemistry lessons, when answering the task: “characterize the physical properties of chalk,” you should focus on the first type of substance. Pure, natural calcium carbonate, containing a minimum of ballast impurities, is the substance that is offered to students as a study compound.

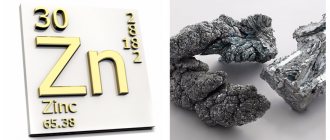

Copper

(Cu from Latin Cuprum) is an element of the eleventh group of the fourth period (a side subgroup of the first group) of the periodic system of chemical elements of D. I. Mendeleev, with atomic number 29. The simple substance copper is a plastic transition metal of golden-pink color (pink color when absence of oxide film). It has been widely used by humans for a long time. Copper coin (photo)

History

Copper is one of the first metals well mastered by man due to its availability from ore and low melting point. This metal is found in nature in native form more often than gold, silver and iron. Some of the most ancient copper products, as well as slag - evidence of its smelting from ores - were found in Turkey, during excavations of the settlement of Çatalhöyük. The Copper Age, when copper objects became widespread, follows the Stone Age in world history. Experimental studies by S. A. Semenov and his colleagues showed that, despite the softness of copper, copper tools, compared to stone ones, provide a significant advantage in the speed of cutting, planing, drilling and sawing wood, and processing bone takes approximately the same time as for stone tools

In ancient times, copper was also used in the form of an alloy with tin - bronze - for the manufacture of weapons, etc., the Bronze Age replaced the Copper Age. An alloy of copper and tin (bronze) was produced for the first time in 3000 BC. e. in the Middle East. Bronze attracted people because of its strength and good malleability, which made it suitable for making labor and hunting tools, dishes, and jewelry. All these items are found in archaeological excavations. The Bronze Age regarding tools was replaced by the Iron Age.

Copper was originally mined from malachite ore rather than sulfide ore, as it does not require pre-roasting. To do this, a mixture of ore and coal was placed in a clay vessel, the vessel was placed in a small pit, and the mixture was set on fire. The released carbon monoxide reduced malachite to free copper:

In Cyprus, already in the 3rd millennium BC there were copper mines and copper smelting was carried out.

Copper mines appeared on the territory of Russia and neighboring countries two millennia BC. e. Their remains are found in the Urals (the most famous deposit is Kargaly), in Transcaucasia, in Siberia, Altai, and in Ukraine.

In the XIII-XIV centuries. mastered industrial copper smelting. In Moscow in the 15th century. The Cannon Yard was founded, where guns of various calibers were cast from bronze. A lot of copper was used to make bells. Such works of casting art as the Tsar Cannon (1586), the Tsar Bell (1735), the Bronze Horseman (1782) were cast from bronze, and a statue of the Big Buddha was cast in Japan (Todai-ji Temple) ( 752).

With the discovery of electricity in the 18th-19th centuries. large volumes of copper began to be used for the production of wires and other related products. And although in the 20th century. wires often began to be made of aluminum; copper has not lost its importance in electrical engineering.

Origin of the name copper

The Latin name for copper Cuprum (ancient Aes cuprium, Aes cyprium) comes from the name of the island of Cyprus, where there was a rich deposit.

Strabo calls copper chalkos, from the name of the city of Chalkis on Euboea. From this word came many ancient Greek names for copper and bronze objects, blacksmithing, blacksmithing and casting. The second Latin name for copper Aes (Sanskrit ayas, Gothic aiz, German erz, English ore) means ore or mine.

The words copper and copper are found in the most ancient Russian literary monuments. Slavic *mědь “copper” does not have a clear etymology, perhaps an original word. V.I. Abaev assumed the origin of the word from the name of the country Media: *Copper from Ir. Māda - through the Greek. Μηδία[8]. According to the etymology of M. Vasmer, the word “copper” is related to ancient German. smid “blacksmith”, smîda “metal”.

Copper was designated by the alchemical symbol “♀” - “mirror of Venus”, and sometimes copper itself was also called “Venus” by alchemists. This is due to the fact that the goddess of beauty, Venus (Aphrodite), was the goddess of Cyprus, and mirrors were made from copper. This symbol of Venus was also depicted on the brand of the Polevsky copper smelter, it was used to brand Polevsky copper from 1735 to 1759, and is depicted on the modern coat of arms of the city of Polevskoy. Polevsky’s Gumeshevsky mine, the largest copper ore deposit of the Russian Empire in the Middle Urals in the 18th-19th centuries, is associated with a famous character in P. P. Bazhov’s fairy tales - the Mistress of the Copper Mountain, the patroness of the mining of malachite and copper. According to one hypothesis, she is the image of the goddess Venus refracted by the popular consciousness.

Copper in nature

The average copper content in the earth's crust (clarke) is (4.7-5.5) 10−3% (by mass). In sea and river water the copper content is much lower: 3·10−7% and 10−7% (by weight), respectively.

Copper occurs in nature both in compounds and in native form. Of industrial importance are chalcopyrite CuFeS2, also known as copper pyrite, chalcocite Cu2S and bornite Cu5FeS4. Together with them, other copper minerals are also found: covellite CuS, cuprite Cu2O, azurite Cu3(CO3)2(OH)2, malachite Cu2CO3(OH)2. Sometimes copper is found in native form; the mass of individual clusters can reach 400 tons. Copper sulfides are formed mainly in medium-temperature hydrothermal veins. Copper deposits are also often found in sedimentary rocks - cuprous sandstones and shales. The most famous deposits of this type are Udokan in the Trans-Baikal Territory, Zhezkazgan in Kazakhstan, the copper belt of Central Africa and Mansfeld in Germany. The other richest copper deposits are in Chile (Escondida and Colhausi) and the USA (Morenci).

Most copper ore is mined by open pit mining. The copper content in the ore ranges from 0.3 to 1.0%.

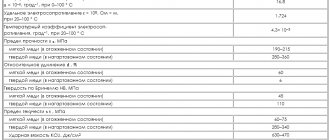

Physical properties of copper

Copper is a golden-pink ductile metal; in air it quickly becomes covered with an oxide film, which gives it a characteristic intense yellowish-red hue. Thin films of copper have a greenish-blue color when exposed to light.

Along with osmium, cesium and gold, copper is one of the four metals that have a distinct coloration that is different from the gray or silver of other metals. This color tint is explained by the presence of electronic transitions between the filled third and half-empty fourth atomic orbitals: the energy difference between them corresponds to the wavelength of orange light. The same mechanism is responsible for the characteristic color of gold.

Copper forms a cubic face-centered lattice, space group F m3m, a = 0.36150 nm, Z = 4.

Copper has high thermal and electrical conductivity (it ranks second in electrical conductivity among metals after silver). Specific electrical conductivity at 20 °C: 55.5-58 MS/m. Copper has a relatively large temperature coefficient of resistance: 0.4%/°C and is weakly dependent on temperature over a wide temperature range. Copper is diamagnetic.

There are a number of copper alloys: brass - with zinc, bronze - with tin and other elements, cupronickel - with nickel and others.

Atomic density of copper (N0) = 8.52 * 10 28 (atom/m³).

Application of copper

in electrical engineering

Due to its low resistivity (second only to silver, resistivity at 20 °C: 0.01724-0.0180 μOhm m/), copper is widely used in electrical engineering for the manufacture of power and other cables, wires or other conductors, for example, in printed circuit wiring. Copper wires, in turn, are also used in the windings of electric drives (household: electric motors) and power transformers. For these purposes, the metal must be very pure: impurities sharply reduce electrical conductivity. For example, the presence of 0.02% aluminum in copper reduces its electrical conductivity by almost 10%.

Heat exchange

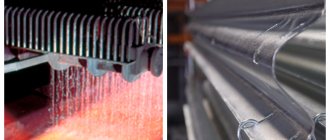

Cooling system made of copper on heat pipes in a laptop Another useful quality of copper is its high thermal conductivity. This allows it to be used in various heat sink devices, heat exchangers, which include well-known cooling, air conditioning and heating radiators, computer coolers, and heat pipes.

For pipe production

Due to their high mechanical strength and suitability for machining, copper seamless round pipes are widely used for transporting liquids and gases: in internal water supply systems, heating systems, gas supply systems, air conditioning systems and refrigeration units. In a number of countries, copper pipes are the main material used for these purposes: in France, Great Britain and Australia for gas supply to buildings, in Great Britain, USA, Sweden and Hong Kong for water supply, in Great Britain and Sweden for heating.

Copper rods (photo)

Copper pipes (photo)

In Russia, the production of water and gas pipes from copper is standardized by the national standard GOST R 52318-2005, and the application in this capacity by the federal Code of Rules SP 40-108-2004. In addition, pipelines made of copper and copper alloys are widely used in the shipbuilding and energy industries to transport liquids and steam.

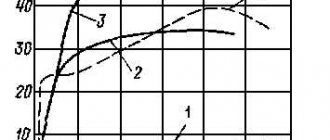

Copper alloys

Alloys using copper are widely used in various fields of technology, the most widespread of which are the above-mentioned bronze and brass. Both alloys are general names for a whole family of materials, which, in addition to tin and zinc, may include nickel, bismuth and other metals. For example, the composition of gun bronze, used for the manufacture of artillery pieces until the 19th century, includes all three main metals - copper, tin, zinc; the recipe changed depending on the time and place of manufacture of the weapon. A large amount of brass is used for the manufacture of artillery ammunition casings and weapon casings, due to its manufacturability and high ductility. For machine parts, alloys of copper with zinc, tin, aluminum, silicon, etc. (rather than pure copper) are used because of their greater strength: 30-40 kgf/mm² for alloys and 25-29 kgf/mm² for technically pure copper. Copper alloys (except beryllium bronze and some aluminum bronzes) do not change their mechanical properties during heat treatment, and their mechanical properties and wear resistance are determined only by the chemical composition and its effect on the structure. Modulus of elasticity of copper alloys (900-12000 kgf/mm², lower than that of steel). The main advantage of copper alloys is their low coefficient of friction (which makes them especially rational for use in sliding pairs), combined for many alloys with high ductility and good resistance to corrosion in a number of aggressive environments (copper-nickel alloys and aluminum bronzes) and good electrical conductivity. The magnitude of the coefficient of friction is almost the same for all copper alloys, while the mechanical properties and wear resistance, as well as behavior under corrosion conditions, depend on the composition of the alloys, and therefore on the structure. Strength is higher in two-phase alloys, and ductility is higher in single-phase alloys. Copper-nickel alloy (cupronickel) is used for minting small change coins. Copper-nickel alloys, including the so-called “Admiralty” alloy, are widely used in shipbuilding (turbine exhaust steam condenser tubes cooled by sea water) and applications related to the possibility of aggressive action of sea water due to their high corrosion resistance. Copper is an important component of hard solders - alloys with a melting point of 590-880 ° C, which have good adhesion to most metals, and are used for durable connections of a variety of metal parts, especially dissimilar metals, from pipeline fittings to liquid rocket engines.

Alloys in which copper is significant

A duralumin part of the Hindenburg airship (LZ 129) damaged by fire. Dural (duralumin) is defined as an alloy of aluminum and copper (copper in duralumin is 4.4%).

Jewelry alloys

In jewelry, alloys of copper and gold are often used to increase the resistance of products to deformation and abrasion, since pure gold is a very soft metal and is not resistant to mechanical stress.

Copper connections

Copper oxides are used to produce yttrium-barium-copper oxide (cuprate) YBa2Cu3O7-δ, which is the basis for the production of high-temperature superconductors. Copper is used to produce copper oxide galvanic cells and batteries.

Other Applications

Copper is the most widely used acetylene polymerization catalyst. Due to the fact that copper is a catalyst for the polymerization of acetylene (forms compounds of copper with acetylene), copper pipelines for transporting acetylene can only be used if the copper content in the alloy of the pipe material is no more than 64%.

Copper is widely used in architecture. Roofs and facades made of thin sheet copper, due to the auto-attenuation of the corrosion process of the copper sheet, serve trouble-free for 100-150 years. In Russia, the use of copper sheets for roofs and facades is regulated by the federal Code of Rules SP 31-116-2006.

The predicted new mass use of copper promises to be its use as bactericidal surfaces in medical institutions to reduce intra-hospital bacterial transfer: doors, handles, water stop valves, railings, bed rails, table tops - all surfaces touched by the human hand.

Copper vapor is used as a working fluid in copper vapor lasers at lasing wavelengths of 510 and 578 nm.

Copper production and mining.

World copper production in 2000 was about 15 million tons, and in 2004 - about 14 million tons. World reserves in 2000 were, according to experts, 954 million tons, of which 687 million tons were proven reserves; Russia accounted for 3.2% of total and 3.1% of confirmed world reserves. Thus, at the current rate of consumption, copper reserves will last approximately 60 years.

Production of refined copper in Russia in 2006 amounted to 881.2 thousand tons, consumption - 591.4 thousand tons. The main copper producers in Russia were:

Company thousand tons % Norilsk Nickel 425 45% Uralelectromed 351 37% Russian Copper Company 166 18%

In 2009, Metalloinvest Holding joined these copper producers in Russia, purchasing the rights to develop the new Udokanskoye copper deposit. World copper production in 2007 was 15.4 million tons, and in 2008 - 15.7 million tons.

The leaders in production were:

Chile (5.560 million tons in 2007 and 5.600 million tons in 2008), USA (1.170/1.310), Peru (1.190/1.220), China (0.946/1.000), Australia (0.870/0.850), Russia (0.740 /0.750), Indonesia (0.797/0.650), Canada (0.589/0.590), Zambia (0.520/0.560), Kazakhstan (0.407/0.460), Poland (0.452/0.430), Mexico (0.347/0.270). In terms of global production and consumption, copper ranks third after iron and aluminum.

The world's explored copper reserves at the end of 2008 amounted to 1 billion tons, of which 550 million tons were confirmed. Moreover, it is estimated that the global world reserves on land amount to 3 billion tons, and deep-sea resources are estimated at 700 million tons.

Copper powder (photo)

Modern mining methods

More than 170 minerals containing copper are now known, but only 14-15 of them are of industrial importance. This is chalcopyrite (also known as copper pyrite), malachite, and native copper is also found. Copper ores often contain molybdenum, nickel, lead, cobalt as impurities, and less commonly gold and silver. Typically, copper ores are beneficiated in factories before being sent to copper smelters. Kazakhstan, the USA, Chile, Canada, and African countries are rich in copper - Zaire, Zambia, South Africa. Escondida is the world's largest copper ore quarry (located in Chile). Depending on the depth of occurrence, ore is mined using open or closed methods.

90% of primary copper is obtained by pyrometallurgical method, 10% by hydrometallurgical method. The hydrometallurgical method is the production of copper by dissolving it in a weak solution of sulfuric acid and subsequent separation of metallic (blister) copper from the solution. The pyrometallurgical method consists of several stages: enrichment, roasting, smelting for matte, purging in a converter, refining.

To enrich copper ores, the flotation method is used (based on the use of different wettability of copper-containing particles and waste rock), which allows one to obtain copper concentrate containing from 10 to 35% copper.

Copper ores and concentrates with high sulfur content are subjected to oxidative roasting. In the process of heating the concentrate or ore to 700-800 °C in the presence of atmospheric oxygen, sulfides are oxidized and the sulfur content is reduced by almost half of the original. Only poor concentrates (with a copper content of 8 to 25%) are fired, and rich concentrates (from 25 to 35% copper) are melted without firing.

After roasting, the ore and copper concentrate are smelted into matte, which is an alloy containing copper and iron sulfides. Matte contains from 30 to 50% copper, 20-40% iron, 22-25% sulfur, in addition, matte contains impurities of nickel, zinc, lead, gold, and silver. Most often, smelting is carried out in fiery reverberatory furnaces. The temperature in the melting zone is 1450 °C.

In order to oxidize sulfides and iron, the resulting copper matte is subjected to blowing with compressed air in horizontal converters with side blast. The resulting oxides are converted into slag. The temperature in the converter is 1200–1300 °C. Interestingly, heat is released in the converter due to chemical reactions, without fuel supply. Thus, the converter produces blister copper containing 98.4–99.4% copper, 0.01–0.04% iron, 0.02–0.1% sulfur and a small amount of nickel, tin, antimony, silver, gold. This copper is poured into a ladle and poured into steel molds or a casting machine.

Next, to remove harmful impurities, blister copper is refined (fire refining and then electrolytic refining are carried out). The essence of fire refining of blister copper is the oxidation of impurities, removing them with gases and converting them into slag. After fire refining, copper with a purity of 99.0–99.7% is obtained. It is poured into molds and ingots are obtained for further smelting of alloys (bronze and brass) or ingots for electrolytic refining.

Electrolytic refining is carried out to obtain pure copper (99.95%). Electrolysis is carried out in baths where the anode is made of fire-refined copper, and the cathode is made of thin sheets of pure copper. The electrolyte is a solution of sulfuric acid with copper sulfate. During electrolysis, the concentration of sulfuric acid increases. When a direct current is passed, the anode dissolves, the copper goes into solution, and, cleaned of impurities, is deposited on the cathodes. Impurities settle to the bottom of the bath in the form of sludge, which is processed to extract valuable metals. When receiving 1000 tons of electrolytic copper, you can get up to 3 kg of silver and 200 g of gold. The cathodes are unloaded after 5-12 days, when their weight reaches 60 to 90 kg. They are thoroughly washed and then melted in electric furnaces.

Copper granules (photo)

How to introduce children to the properties of chalk

Students first learn about calcium carbonate in introductory chemistry lessons, which introduce the concept of pure substances and mixtures, and also discuss the basic methods of their separation. For example, during laboratory work, the teacher suggests separating metal filings and wood shavings from each other using a magnet. The sugar solution is evaporated to obtain a pure crystalline substance, and the physical properties of chalk and coal are studied after separating the two substances by settling and then filtering a suspension of calcium carbonate in water. The didactic principle of continuity and consistency in the study of new material is used when introducing students to physical phenomena and chemical reactions. The following experiment is carried out: solutions of technical soda and calcium chloride are poured into one test tube. The solution becomes cloudy and then a precipitate forms. This is chalk, it is filtered and chloride acid is added dropwise to the resulting white powder. The reaction proceeds with the rapid release of carbon dioxide bubbles. As you can see, the chemistry program, grade 8, studies the physical properties of chalk along with the main chemical feature of the substance - its ability to react with strong acids, releasing CO2.

Historical reference

Copper is one of the most important elements of antiquity. Copper, gold , silver and tin were the first metals that humanity recognized in its historical development. Because copper is easily processed, it was used by ancient cultures more than 10,000 years ago. The time of widespread use of copper began in the 5th millennium BC. to the 3rd millennium BC

However, in its pure form, copper turned out to be relatively soft for the production of weapons and tools. Therefore, ancient people, through experiments, adding pieces of lead and tin to molten copper, obtained bronze. It is a much harder material than unalloyed copper. Bronze has been used by humanity for over 5,000 years. This alloy gave its name to an entire historical era.

In alchemy, copper was associated with Venus (femininity). Of course, not least because the first mirrors used by women were made of this metal.

Characteristics of calcium carbonate

The substance we are considering belongs to the group of medium salts. It is usually white in color, and, as we said, is a natural semi-rock of biogenic origin. It consists of shell particles, small quartzite crystals, magnesium and calcium carbonates, as well as oxides of these metals. Chalk absorbs and retains water, and its strength decreases. It does not dissolve in water, but forms a cloudy suspension in it. When solving experimental problems in chemistry, the physical properties of chalk, in particular its insolubility in water, are used to detect carbon dioxide. When CO2 is passed through lime water, it becomes cloudy due to the formation of an insoluble precipitate of calcium carbonate. This reaction is qualitative and is used in analytical chemistry.

Physical properties

With a density of 8920 kg/m3, copper is one of the heavy metals with a melting point of 1083.4 C. It crystallizes into the face-centered cubic (FCC) system and has a Mohs hardness of 2.5 to 3. Copper is a very good conductor of electricity. Slightly worse than silver, and much better than gold. In addition, copper is a very good conductor of heat.

However, aluminum is a better electrical conductor per gram of substance than copper. But it is more voluminous, so copper per square centimeter of cable cross-section conducts electricity better than the same cross-section of aluminum wire.

Pure metallic copper has a bright red color with a pink tint. When exposed to air, copper takes on a reddish-brown hue. Due to further oxidation and corrosion, a patina develops very slowly (often over centuries) on the surface of the copper. The metallic luster is lost and the color changes from reddish-brown to bluish-green.

How to increase the viscosity and plasticity of limestone

What does the flooding of Cretaceous rock deposits with underground groundwater lead to? If the moisture content of the rock is insignificant - no more than 2%, then the strength of the crystals decreases. However, when CaCO3 layers are strongly wetted, for example by 25%, the compressive strength of the substance increases almost 3 times. At the same time, the physical properties of chalk, especially plasticity and viscosity, are enhanced. This greatly complicates the technology of its extraction. For this reason, the upper and drier layers of the deposits, although with a low content of pure calcium carbonate, are used to produce it on an industrial scale.

Reserves, production

The world's proven reserves of copper ore amount to billions of tons. Scientists hope that the earth's bowels conceal another 3 billion tons. The richest mines, Chuquicamata and El Teniente, are located in Chile, the largest copper producer (27% of world production in 2022).

Large deposits have been found in the USA, Canada, Iran, Kazakhstan, and southern Africa. Russia contains 3% of the world's reserves. Copper deposits have been found in the Urals, Transbaikalia, and Krasnoyarsk Territory.

It is desirable that the ore contains at least 0.5-1% pure copper. It is mined in mines and by open-pit mining (for deposits located at a depth of 400-500 m). Global production in 2022 amounted to 20.6 million tons, of which a quarter was of Chilean origin.

Where and how to use chalk

The largest amount of the substance is used to produce quicklime, calcium hydroxide and carbon dioxide. To do this, calcium carbonate is burned to form calcium oxide and carbon dioxide. The first substance is also called quicklime or boiling water. It is combined with water, the process releases a large amount of heat, resulting in slaked lime - an important raw material for the construction industry. In combination with sand and water, calcium hydroxide is used for plastering and fastening bricks during the construction of walls. Liming of acidified soils is a well-known and economically cheap method of reclamation work, which increases soil fertility and does not have a negative effect on the species composition of soil organisms.

In this work, the physical properties of chalk were studied and the areas of its application in industry and agriculture were considered.