What is

Steel is a material that accompanies a person throughout life. This is a car body, a kitchen or hunting knife blade, tools, structural frames, and thousands of other products.

It does not belong to metals - it is an alloy of iron, carbon, manganese and other alloy impurities.

The main metal of steel is iron.

The content of alloy components is iron (45+%), carbon (0.2-2.14%), impurities (the rest). They could create a formula for the substance.

Steamed with cast iron - a product of ferrous metallurgy.

Its shade has become the standard color - steel.

Story

The documented history of rafting begins two millennia BC:

- Samples almost 4 thousand years old have been unearthed in Turkey.

- The material has become available to Europeans since Antiquity.

- The most famous artifacts of the Middle Ages were damask swords. Since that era, it has been the main material for edged weapons.

For centuries, the secret of making Damascus steel and Japanese samurai swords was kept secret.

- The heyday of steel production came in connection with the wars of the 19th century. The 20th century expanded the range with tank armor, aircraft hulls, and helmets.

In the third millennium, the alloy does not lose ground to the materials of the new generation.

Application area

As mentioned above, carbon steel alloys according to their main purpose are divided into two large categories: instrumental and structural. Tool steel alloys containing 0.65–1.32% carbon are used in full accordance with their name - for the production of tools for various purposes. In order to improve the mechanical properties of tools, they turn to such a technological operation as hardening carbon steel, which is performed without any particular difficulties.

Areas of application of carbon tool steels

Structural steel alloys are used very widely in modern industry. They are used to make parts for equipment for various purposes, structural elements for mechanical engineering and construction purposes, fasteners and much more. In particular, such a popular product as carbon wire is made from structural steel.

Carbon wire is used not only for domestic purposes, for the production of fasteners and in the construction industry, but also for the manufacture of such critical parts as springs. After carburization, structural carbon alloys can be successfully used for the production of parts that, during operation, are subject to severe surface wear and experience significant dynamic loads.

Of course, carbon steel alloys do not have many of the properties of alloy steels (in particular, stainless steel), but their characteristics are quite sufficient to ensure the quality and reliability of the parts and structures that are made from them.

Features of the material

The properties of steel are not inherent in nature, they are determined by man.

He decides what composition the material will have, how to obtain it, how to refine it:

- Iron makes the alloy ductile-ductile and easy to process.

- Carbon imparts hardness, but it cannot be more than 3.39% (otherwise the material will become brittle).

- To impart the desired characteristics, the base is enriched with alloying additives. Often these are non-ferrous metals. For example, chromium makes it heat-resistant, nickel makes it tough and resistant to corrosion.

The share of alloying additives is measured in tenths or a couple of percent, but the physical and chemical properties of the final product change dramatically.

Phosphorus, sulfur, free oxygen, nitrogen lower the threshold of ductility and strength. They are removed during the melting process.

The properties of the alloy are also determined by the smelting method - heat treatment (hardening), hot/cold rolling, etc.

Steel is often confused with cast iron. These are truly the closest metal alloys in properties and composition.

The percentage of carbon in the composition allows you to distinguish alloys: up to 2.14 – steel, more – cast iron.

Characteristics of steel

- Density: 7700–7900 kg/m³ (7.7–7.9 g/cm³).

- Specific gravity: 75500–77500 N/m³ (7700–7900 kgf/m³ in the MKGSS system).

- Specific heat at 20 °C: 462 J/(kg °C) (110 cal/(kg °C)).

- Melting point: 1450–1520 °C.

- Specific heat of fusion: 84 kJ/kg (20 kcal/kg, 23 Wh/kg).

- Thermal conductivity coefficient at 100 °C:

| Chrome-nickel-tungsten steel | 15.5 W/(m K) |

| Chrome steel | 22.4 W/(m K) |

| Molybdenum steel | 41.9 W/(mK) |

| Carbon steel (grade 30) | 50.2 W/(mK) |

| Carbon steel (grade 15) | 54.4 W/(m K) |

| Duralumin steel | 56.3 W/(m K) |

- Coefficient of linear thermal expansion at a temperature of about 20 °C:

| steel St3 (grade 20) | {\displaystyle 11{,}9\cdot 10^{-6}} 1/°C |

| stainless steel | {\displaystyle 11{,}0\cdot 10^{-6}} 1/°C |

- Tensile strength of steel:

| steel for structures | 373—412 MPa |

| silicon-chrome-manganese steel | 1.52 GPa |

| machine-building steel (carbon) | 314—785 MPa |

| rail steel | 690—785 MPa |

Examples of problem solving

| Exercise | Find the chemical formula of a substance that contains 10 parts by mass of calcium, 7 parts by mass of nitrogen and 24 parts by mass of oxygen. |

| Solution | In order to find out in what relationships the chemical elements in the molecule are located, it is necessary to find their amount of substance. It is known that to find the amount of a substance one should use the formula: |

Let's find the molar masses of calcium, nitrogen and oxygen (we'll round the values of the relative atomic masses taken from D.I. Mendeleev's Periodic Table to whole numbers). It is known that M = Mr, which means M(Ca) = 40 g/mol, M(N) = 14 g/mol, and M(O) = 16 g/mol.

Then, the amount of substance of these elements is equal to:

n(Ca) :n(N): n(O) = 0.25 : 0.5 : 1.5= 1 : 2 : 6,

those. the formula for the compound of calcium, nitrogen and oxygen is CaN2O6 or Ca(NO3)2. This is calcium nitrate.

| Exercise | Calcium phosphide weighing 3.62 g contains 2.4 g of calcium. Determine the formula of this compound. |

| Solution | In order to find out in what relationships the chemical elements in the molecule are located, it is necessary to find their amount of substance. It is known that to find the amount of a substance one should use the formula: |

Let's find the molar masses of calcium and phosphorus (the values of the relative atomic masses taken from D.I. Mendeleev's Periodic Table are rounded to whole numbers). It is known that M = Mr, which means M(Ca) = 40 g/mol, and M(P) = 31 g/mol.

Let us determine the mass of phosphorus in the composition of calcium phosphide:

Then, the amount of substance of these elements is equal to:

n(Ca) :n(P)= 0.06 : 0.04 = 1.5 : 1 = 3 : 2,

those. the formula of calcium phosphide is Ca3P2.

Source

Production technology

The production of the alloy involves the processing of cast iron. In this case, unnecessary components are annealed, replacing them with ligature elements.

The process is carried out at the metallurgical plant using the following technologies:

- Open-hearth method. An open-hearth furnace is loaded with a mixture of cast iron and ore. To anneal excess carbon, melt at 2050°C and introduce alloys. The product (steel) is poured into containers and sent for rolling. The method is considered obsolete.

- Oxygen converter. A flow of air or an air-oxygen mixture is passed through the cast iron mass. The goal is to anneal the contents faster and more completely.

- Electric smelting. The raw material melts at 2210°C. The furnace is closed, so “contamination” of the alloy with gases is excluded. The method is expensive and is used to obtain an elite product.

- Straight. To blow through iron ore pellets, the furnace is heated to 1060°C. An ammonia-oxygen mixture plus carbon monoxide formed during the combustion of natural gas is used.

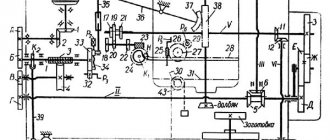

State diagram of iron-carbon alloys, steel region marked in blue

To obtain a material with improved characteristics, heat treatment is continued. The production method involves hardening, carburization, nitriding (accumulation of carbon or nitrogen on the surface to increase wear resistance), cyanidation (“pumping” the outer layer with nitrogen to speed up the process), and other operations.

Location of iron ore

The world's iron ore reserves are not unlimited. Raw materials for iron synthesis are not found on every corner. Territories in which large reserves of ores are located are called deposits. They are classified into types.

- Endogenous deposits are places with a special position in the Earth’s crust. They are often titanomagnetite ores. Outwardly, they resemble lenses and layers.

- Exogenous deposits – location of limonite, etc.

- Metamorphogenic deposits – location of quartzites, etc.

The countries of the former Soviet Union have huge reserves of iron ore. A large percentage of the rocks are found in Ukraine, the Russian Federation and Kazakhstan. Iron ore is also found in Brazil, Canada, Australia, the USA and other countries. But some countries have a shortage of iron in industries, so alloys often have to be imported.

Varieties of some steels

| Steel grades | Heat treatment | Hardness (core-surface) |

| 35 | normalization | 163—192 HB |

| 40 | improvement | 192—228 HB |

| 45 | normalization | 179—207 HB |

| 45 | improvement | 235—262 HB |

| 55 | hardening and high tempering | 212—248 HB |

| 60 | hardening and high tempering | 217—255 HB |

| 70 | hardening and high tempering | 229—269 HB |

| 80 | hardening and high tempering | 269—302 HB |

| U9 | annealing | 192HB |

| U9 | hardening | 50—58 HRC |

| U10 | annealing | 197 HB |

| U10 | hardening | 62—63 HRC |

| 40X | improvement | 235—262 HB |

| 40X | improvement + hardening with high currents. frequencies | 45-50 HRC; 269—302 HB |

| 40ХН | improvement | 235—262 HB |

| 40ХН | improvement + hardening with high currents. frequencies | 48-53 HRC; 269—302 HB |

| 35ХМ | improvement | 235—262 HB |

| 35ХМ | improvement + hardening with high currents. frequencies | 48-53 HRC; 269—302 HB |

| 35L | normalization | 163—207 HB |

| 40L | normalization | 147HB |

| 40GL | improvement | 235—262 HB |

| 45L | improvement | 207—235 HB |

| 65G |

HB - Brinell hardness, HRC - Rockwell hardness.

Advantages and disadvantages

The characteristics of the alloy depend on the composition and manufacturing method. There are also universal properties.

Advantages of steel:

- Strength, hardness.

- Viscosity, elasticity.

- Possibility of mechanical processing. Steel fragments are easy to bend, weld, and cut.

- Wear resistance, durability.

- Prevalence of raw materials.

- Simplicity, cost-effective production.

- Selecting a material with the desired properties. They are provided by a variety of composition and processing methods.

Plus the price availability of products.

Disadvantages of the material:

- Massiveness.

- Vulnerability to corrosion.

- Tendency to accumulate electrical potential.

These flaws are not critical; there are ways to neutralize them.

Structure

Determining the composition of steel would be incomplete without studying its structure. However, this feature is not constant and may depend on a number of factors, such as: heat treatment mode, cooling rate, degree of alloying. According to the rules, the structure of steel should be determined after annealing or normalization. After annealing, the metal is divided into:

- hypoeutectoid structure - with excess ferrite;

- eutectoid, which consists of pearlite;

- hypereutectoid - with secondary carbides;

- ledeburite - with primary carbides;

- austenitic – with a face-centered crystal lattice;

- ferritic - with a cubic body-centered lattice.

Class determination became possible after normalization. It is understood as a type of heat treatment, including heating, holding and subsequent cooling. Here, pearlitic, austenitic and ferritic classes are distinguished.

Classification

The variety of compositions necessitated the need to organize the material. Classification is carried out on several grounds.

By chemical composition

The largest division includes carbon and alloy steels.

Carbon

The characteristics of carbon steels are determined by carbon. Depending on its quantity, three types with different structures are distinguished: low-, medium-, high-carbon - respectively, up to 0.30; 0.30-0.70; 0.70+% carbon.

Carbon steel

The most famous carbon variety is black steel. It can be cold or hot rolled. Types of products: shaped, long, wide, sheet steel, wire rod. This alloy of ordinary standards is valued by mechanical engineers as the number one structural material.

Alloyed

Alloyed - steels with elements added to obtain specified characteristics.

The classification is based on the total volume of alloying additives (except manganese and phosphorus). Depending on this, low-, medium- or high-alloy steels are distinguished, with, respectively, up to 2.5; 2.5-10; 10+% impurities.

Additives include chromium, nickel, molybdenum, and other non-ferrous metals.

The most famous alloy steel is stainless steel. The composition is chromium or chromium-nickel mixture (chromium - up to 26.9%).

By area of application

The properties of steel allow you to choose the material for specific projects:

- Construction. Ordinary low-alloy alloys, the main condition for which is the ability to weld.

- Instrumental. High carbon, high alloy tool material. Heat-resistant, wear-resistant, durable. There are cutting, stamped, and metrological instruments.

- Structural. Material with a low percentage of manganese. Finds application as the basis of units and structures.

Rolled metal from steel

Special steels are considered as a type of structural steel: acid-resistant, heat-resistant, heat-resistant.

Other types of classification: by structure, production method, impurity content.

Quality

The definition of types has become possible in terms of quality in four areas. This:

- Ordinary quality is steel with a carbon content of up to 0.6%, which is smelted in open-hearth furnaces or in converters using oxygen. They are considered the cheapest and have inferior characteristics to metals of other groups. Examples of such steels are St0, St3sp, St5kp.

- High quality. Prominent representatives of this type are steel St08kp, St10ps, St20. They are smelted using the same furnaces, but with higher requirements for the charge and production processes.

- High-quality steels are melted in electric furnaces, which guarantees an increase in the purity of the material in terms of non-metallic inclusions, that is, an improvement in mechanical properties. Such materials include St20A, St15X2MA.

- Particularly high quality - manufactured using special metallurgy. They are subjected to electroslag remelting, which removes sulfides and oxides. Steels of this type include St18KhG-Sh, St20KhGNTR-Sh.

Marking

The composition and production method determined the marking of steels.

The material is divided into three groups:

- Group A includes seven grades of steel - from St 0 to St 6. The higher the number, the better.

- Group B – grades from BSt0 to BSt 6. Increasing the numbering means increasing the level of strength and fluidity.

- Group B is labeled as VSt.

In group A, mechanical characteristics are regulated, in group B the composition is a priority, for segment B both scales are important.

Alloy deoxidation

Determining steel by the degree of deoxidation implies three types: calm, semi-calm and boiling. The concept itself means the removal of oxygen from a liquid alloy.

In mild steel, almost no gases are released during solidification. This happens due to the complete removal of oxygen and the formation of a shrinkage cavity on top of the ingot, which is then cut off.

In semi-calm steel, gases are released partially, that is, more than in calm steel, but less than in boiling steel. There is no shell here, as in the previous case, but bubbles form at the top.

Boiling alloys release large amounts of gas as they solidify, and in cross-section it is easy to notice the difference in chemical composition between the top and bottom layers.