Cold-deformed pipe has found wide application in construction and in many areas of human activity. It is used to manufacture parts for furniture production, lay water, gas and oil pipelines, as well as utility networks, including those intended for pumping aggressive media. The mentioned products are highly durable and have no seams, so their scope of application also extends to the aviation industry, as well as the automotive industry.

Description of the pipe

After reading the state standards, you can understand that a cold-deformed pipe is a hollow rod with no welds or joints. Manufacturing technology can be different, and it can be classified into several types, among them:

- pressing;

- forging;

- rolling;

- drawing.

The most common method is rolling. The blank used is a pipe, which is produced by hot rolling. Steel is rolled using special equipment. The cold-formed pipe is based on carbon or alloy steel. Due to the fact that the described products do not have seams, this allows them to be used in negative conditions and under mechanical stress.

In terms of size, such pipes are much smaller than hot-rolled or welded pipes. However, one important advantage can be highlighted, which is the accuracy of the dimensions. The products have a surface whose quality is much higher in comparison with pipes made using other technologies. Cold deformation produces thin-walled pipes.

Mounting options

The choice of installation is based on the functions of the route being laid. When a tight and durable connection is required, welding is preferred. In household pipelines, the choice is often made to use fittings as pipe fastenings.

The fitting connection of pipes involves a number of stages:

- Applying threads to the previously cleaned edge of the pipe;

- Using special threads as a reinforcer;

- Connection with fitting.

Both hot-deformed and cold-deformed pipelines and mains last more than 50 years. They are reliable, easy to repair and withstand changes in the external environment.

Submit your application

Main features: classification by parameters

Cold-formed pipe can be classified by wall thickness and can be thin-walled or thick-walled. Resistance to negative influences and strength depend on this. The thin-walled seamless pipe is lightweight. This property is in demand when constructing non-standard structures. As for the thickness, it can be from 4 to 6 mm. However, if it is necessary to use a pipe with a wall thickness that differs from the parameters mentioned, products can be produced in production whose walls reach 12 mm in thickness. They are particularly durable.

The diameter acts as one of the main parameters; it can be equal to a value ranging from 5 to 45 cm. A cold-deformed steel pipe can also have a different cross-section, namely:

- oval;

- round;

- rectangular;

- square.

An additional characteristic is the length. Pipes can be measured or unmeasured. The measured length is 4.5 or 5 m. If you need pipes of unmeasured length, then you can choose sections from 1.5 to 11.5 m.

Areas of application

Seamless pipes are in demand in areas where increased demands are placed on the quality and strength of the pipeline.

They are widely used for transporting petrochemical and gas products, supplying fuel in critical components of cars and ships.

They are used in the construction of various external and internal communications both in the housing and communal services sector and in industrial enterprises.

A large selection of standard sizes allows them to be used in furniture designs and room decoration.

State standards

Cold-deformed pipe (GOST 8734-75) can also be classified according to the method of use. Such products may have a special or general purpose. The latter option can have an outer diameter ranging from 5 to 250 mm, while the wall thickness is usually a figure from 0.3 to 24 mm.

Pipes can have different wall thicknesses and are:

- especially thick-walled;

- thin-walled;

- thick-walled;

- especially thin-walled.

For these products there are technical characteristics that are prescribed in state standards 8733-74. The documentation mentions that products can be divided into separate groups, among them those designated by the letters B to E can be distinguished. The first group is the standardization of the chemical composition, group B is the standardization of mechanical properties. Group D determines the standardization of mechanical properties and chemical composition.

If the pipe belongs to group D, then this indicates normalization of hydraulic pressure. Mechanical properties are standardized after heat treatment of pipes that belong to group E. Seamless steel cold-deformed pipes are inspected after manufacturing. The inspection includes sizing, hydraulic pressure testing and mechanical properties testing. Additional products are checked for bending and flattening, using GOST 3728-78 and 8695-77.

Production technology

Blanks for production are the so-called conversion pipes, which are produced by hot deformation from cylindrical blanks - rods. The rod is kept in a furnace to a temperature at which the steel becomes plastic, and turns into a hollow cylinder - a sleeve - on the so-called piercing mill.

To put it simply, its further processing comes down to rolling on a group of successive rollers with gradually decreasing sizes on a stationary or rotating mandrel. The key difference from hot-rolled pipes is that, unlike them, cold-formed pipes undergo main operations at a temperature below the recrystallization mark.

Production cycle diagram.

What do the main stages of production look like?

- Cutting blanks into pieces of measured length.

- A chemical treatment necessary to remove rust and scale from a surface . For carbon steels, solutions of acids (sulfuric and hydrochloric) are used, for alloyed steels - molten sodium hydroxide with an oxidizing agent NaNO3. After etching, the workpieces are successively washed with hot water in a bath, then with a stream of cold water under pressure, after which they are dried for 20-30 minutes at a temperature of 150 - 180C.

- The workpieces are sent to baths with lubricants and technological coatings, which reduce friction losses during further processing.

- Then the pig pipes go to the cold rolling mill (Cold Pipe Rolling), where the rolling process reduces the thickness of their walls . At the same time, calibration rolls slightly increase the length of the workpiece.

- Further processing includes straightening, facing, sizing in reducing rolls or drawing in a ring sizing machine . The pipe is finally formed, turning into a product with ideal geometry and a given diameter.

Calibration by drawing method.

- The last stage before passing quality control is heat treatment . When tempering (heating to a temperature 50 degrees above the recrystallization point) followed by gradual cooling, the accumulated internal stresses of the material are removed, its plasticity and viscosity increase.

Heat treatment is the last stage of production.

Additional properties

Cold-formed pipe is manufactured without welding. Production does not involve preheating, because the products are made from blanks. Deviations are standardized by GOST 8734-75. There is a permissible deviation from the standard, which is 10 mm. According to technical conditions, the thickness difference and ovality should not exceed the limit values.

The curvature of the section is 3 mm, which is true for a segment 1 m long. In this case, we are talking about diameters ranging from 4 to 8 mm. The permissible curvature is reduced to 2 mm when the diameter is between 8 and 10 mm.

Where can I buy

It is not difficult to buy pipes - all large construction hypermarkets and large markets have a large assortment of pipe products. There are also many manufacturers, and each region has its own. You will have to select pipes visually and based on the presence of a certificate. However, even before purchasing, it is worth assessing the future structure or system - in home construction, high strength and tightness are not always required.

For a fence, enclosure, heating system or fencing, you can choose pipes of any quality; when used for a canopy or roofing, you should choose seamless products. If the structures will be loaded or responsible, be sure to request a quality certificate from the seller. But also look with your eyes to see if there is a lot of rust, if the wall thickness corresponds to the declared one, if there is a strong bend or even waviness, or even holes in the walls.

Properties of capillary products

Capillary pipes are manufactured in accordance with GOST 14162-79. Steel grade 12Х18Н10Т is used for production. Such pipes are compared with steel ones. Their difference is:

- corrosion resistance;

- mechanical strength;

- durability.

Such cold-deformed seamless steel pipes, the GOST of which was mentioned above, can be used in aggressive environments. Manufacturing technology allows us to obtain pipes with high technical performance. The production is based on sulfuric acid treatment, which relieves internal stress. This increases safety during operation in the gas, chemical and oil industries.

Such a cold-deformed steel pipe, GOST which must be complied with, has one important disadvantage, expressed in the complexity of the technological process. The consequence is an increase in cost and final price, as well as an extension of production time.

Features of special purpose pipes

Among cold-worked seamless products, it is worth highlighting those made of corrosion-resistant steel, as well as material that can be subjected to high pressure. Another type is a steel capillary pipe with a small diameter. If you are interested in pipes with corrosion-resistant properties, then you should know that they are manufactured in accordance with GOST 9941-81. The documentation specifies technical conditions and assortment.

The wall thickness of such a pipe can be equal to a value from 0.3 to 24 mm. As for the outer diameter, its maximum limit is 250 mm. The smallest value is 5 mm. It is based on high-alloy corrosion-resistant steel. Products are subjected to the same tests as general purpose pipes. With their help, pipelines are laid that are used to transport substances with a high level of aggressiveness. The pumped medium may have a high temperature. Another area of operation is turbojet and jet engines, which are used to supply oxidizer, fuel and oil.

Advantages and disadvantages

Let's consider the pros and cons of cold-deformed seamless bends.

The advantages of the product include:

- Higher quality of workmanship in terms of dimensional accuracy and geometry of products in comparison with hot-rolled products.

- Greater strength, allowing the use of pipes in complex and critical systems.

- The ability to process products with chrome plating and galvanizing, which improves their anti-corrosion properties.

The disadvantage is the high price compared to hot-rolled products.

GOST pressure-resistant pipes

Seamless cold-deformed pipes (GOST 11017-80) can be used at high pressure. Their diameter ranges from 6 to 10 mm. The base is carbon structural steel. Products undergo tests different from those mentioned above. The pipes are tested for hydraulic pressure and tension, the holding time reaches 10 seconds. Area of use: gasoline and diesel engines, which are also called fuel lines.

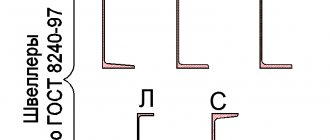

Profile cross-sectional shape

The next parameter we will focus on is the cross-sectional shape of the profile. Typically a seamless round pipe. This kind of rental occurs much more often than others, but there are other solutions. There is such a thing as a profile pipe. This is rolled pipe, in which the profile cross-section differs from round. Profile pipes are also produced seamless. Among the main profile shapes are rectangular and square.

There are also profile seamless pipes:

- teardrop-shaped;

- oval;

- hexagonal;

- flat oval;

- with hollow ribs.

And these are only those profile forms for which there is a corresponding GOST. The range is much wider.