Nowadays, to fix two or more riveted elements, it is customary to use blind rivets, which quickly replaced traditional rivets for metal due to ease of installation and excellent performance properties. Today, these devices are widely used in construction, shipbuilding and ship repair, mechanical engineering, in the installation of safety equipment, in the textile industry and many other areas of human activity. The solution allows you to achieve the most durable connection, however, if the task is to fasten heavy-duty parts, then it is customary to use threaded products.

Main types of rivet hardware

All rivets are of two types - threaded and blind, both types of rivets are installed due to deformation that occurs from the pulling force of a special tool - a riveter.

Blind rivets

Blind rivets

consist of a rivet body with a side (flange) and a pull rod, which, when pulled out, deforms the tail part of the rivet body, forming a reverse head that tightens the connected elements. After reaching the maximum traction force, the rod breaks off in a special separation zone, forming a reliable, permanent connection.

Threaded rivets

Threaded rivets

are one-component, and are used to create a strong collapsible connection, while threaded rivets are placed on only one sheet (surface), and the second sheet or material is attracted to the first by screwing a bolt, screw, etc. into the thread.

Threaded rivets are much more commonly used to hold multiple parts together, allowing threads to be created on thin material where threads cannot be cut. At the same time, they do not have any special restrictions in use and provide reliable fixation of all structural elements using a collapsible threaded connection of parts.

Nut samples of a threaded rivet have a thread on the inside, and bolt samples have a thread on the outer (protruding) part.

The rod is an important structural unit

The next, very important structural element of a blind rivet is the rod. It acts as a rivet and can be made of strong steel, which is much stronger than the body. The end of the rod has a special head that acts as a rivet for the inserted end. When performing installation work, the rod is pulled out using a special pneumatic riveter, and if there are too many fasteners, you can get by with ordinary pliers. True, the latter case involves the use of a certain physical force.

The main advantage of the design of blind rivets is the possibility of one-sided installation, when access to the fastening is sufficient only from one side.

A more durable solution (threaded) has a characteristic thread inside the cylinder. In a classic blind rivet there is no such thread .

The threaded cylinder also has a screwed-in rod, which is not pulled out with force, but is carefully unscrewed. To strengthen the connection, a secure screw or bolt is placed inside. As a result, it is possible to create a kind of “closed” fastener, which is often called blind.

After determining the appropriate sizes and materials, as well as choosing the appropriate type of bead, you can begin to search for the specific type of rivet itself.

Types of rivets

Before we figure out what types of rivets there are, let’s define that a rivet is a special fastener created to reduce production costs and make work easier. Special differences in hardware allow you to select the best option for specific fastenings.

Blind rivets open

The basic (standard) rivet is a fastener with a through hole. It is often confused with a hollow rivet, but the main difference is that a hollow rivet is installed with access from both sides, while a blind rivet can be installed on one side, much easier and faster. Speaking about areas of application, we can cite as an example the use of standard blind rivets when installing ventilated facades or assembling house structures made of metal frames. It all depends on the material and diameter of the rivet, but in any case the connection is quite strong and reliable. Installation features allow for minor differences in the diameter of the rivet and holes. The open type of blind rivets is the cheapest in the range.

Blind rivets closed

The main difference between closed blind rivets is the absence of a through hole; with their help, you can create a sealed structure. The body of the fastener makes it possible to “seal” the reverse side, creating a special head. Thanks to the tight fit, it becomes possible to install fasteners that prevent dust, dirt and moisture from entering the structure. The use of additional gaskets allows you to achieve a tight connection.

Closed rivets are suitable for the aviation and mechanical engineering industries.

Reinforced rivets

Reinforced rivets are also called monobolts. Necessary to create a super strong connection. Standard products are significantly inferior in terms of strength, tensile and shear forces. Another name is structural, since the created connection is not subject to vibration and has a wide range of uses. Reinforced models are used in industrial construction and mechanical engineering.

Flap rivets

By the name you can easily recognize the principle of operation of this rivet. During installation, the reverse side opens into “petals”, which, by bending, reduce the load at the attachment point, and in the case of very soft material, they can sink into it, strengthening the fixation, while almost not deforming it, but as if piercing it a little. Note that the head is not immersed in the material and remains visible. Flap rivets are needed for the installation of loose, delicate or soft materials. The head does not fall into soft material due to the fairly wide side and the small effort required for installation, which reduces the risk of cracks and deformation. An example is the connection of a smooth surface with a fibrous one, for example, wood, plastic or cellular polycarbonate.

Expansion rivets

Due to its special properties, the expansion rivet is used for the manufacture of furniture and decor; it allows connecting wooden and metal parts. Also suitable for fragile, loose and soft fabrics. The principle of operation is to form the reverse head in such a way that the load is distributed across the petals (partially divided into 3 parts). The main difference from the petal type is that the rivet is deformed and does not open completely.

Rivet nuts

Nut rivets are hardware that first has a flange, then a deformable part, and then a thread; the operating principle is similar to rivets, however, instead of a rod, there is an internal thread on the non-collapsible part.

To install a nut rivet, you need to drill a hole in the part to be fastened, screw the rivet onto the threaded part of the mandrel, which is inserted into the rivet gun and actually acts as a rod for the blind rivet, insert it into the prepared hole and retract the sleeve. The back part is deformed, forming a reliable connection with the inner surface; on the outside, the rivet is held by the side.

Multi-clamp rivets

Also types of blind rivets with an open body with a special design, which, unlike conventional blind rivets, provides multiple compression. This method of wedging the body provides high working loads to pull out.

Terminal rivets

Used for making contact connections, including creating an electrical circuit. How does a rivet work? The answer lies in the material: they are made of metals that conduct electric current (the rivet body is made of brass, and the rod is made of copper-plated steel). There are one- or two-terminal options. Terminal rivets are required to create a ground connection.

Plastic rivets

Rivet material may vary. Plastic hoods are made of polyamide, which means they provide a strong connection. In addition to the raw materials, they have a number of advantages:

- do not conduct electric current;

- not subject to corrosive effects;

- low cost.

Of course, plastic polyamide rivets are not suitable for fastening two metal plates. Used for plastic, fiberglass, cardboard structures associated with metal or other materials.

Cassette rivets

The newest type of rivets is cassette rivets. Today it is considered promising because the operator does not have to insert a single fastener each time. Cassette cartridges are presented in the form of a tape or rod for an entire magazine. A distinctive feature of the installation is that the rod does not break off, but is pulled, which significantly speeds up the installation process. One cassette contains up to 40 pieces. The special tool is not interrupted, but will automatically prepare the next batch. A bonus will be the ability to free up your second hand, which can be used to securely fix the knot.

Thus, it is impossible to single out a specific area of use of rivets in general. Each type is suitable for its own purposes, be it creating a children's playground or the largest business center. The only thing that is not in doubt is that rivets are a unique fastener that allows you to reduce installation time and cost.

Summing up

Blind rivets are indeed a very useful, reliable and high-quality connecting element, with which you can carry out a lot of installation work, achieving the most durable and good connection of all kinds of structures. Modern rivets meet all requirements and standards, so they prevent product deformation even under the most intense impacts. When choosing such a solution, it is important to set priorities correctly and give preference only to proven products. This will allow you to make a smart purchase and avoid mistakes.

Rivets: purpose and materials of manufacture

After we have examined in detail all the types of options on the market, we can confidently highlight several aspects of the purpose of hardware:

- those places where it is impossible to carry out welding work;

- overheating and deformation of the material structure are undesirable;

- increasing vibration resistance properties;

- the need to create a connection of increased strength.

Materials used for manufacturing:

- aluminium-magnesium alloys*;

- bronze;

- copper;

- Monel (an alloy of copper and nickel);

- stainless steel A2 or A4;

- Cink Steel;

- polyamide.

* the difference is only in the magnesium content, the higher the percentage of magnesium, the stronger, the least durable and cheapest Al (Mg1%) and the most durable which is used in blind rivets and then, as a rule, for Al (Mg5%) rods;

In some cases, combinations of these materials are used, for example, the rod may be from one alloy, and the rivet from another. Galvanized steel and aluminum are often combined. In this case, the definition of “combined” rivet is appropriate.

The principle of selecting rivets is compatibility, or better repetition, of the material, in terms of mechanical and physical properties, from which the elements being connected are made.

Another important selection criterion is susceptibility to galvanic corrosion. It manifests itself at the junction of dissimilar metals under high humidity, for example, during rain. If you are not sure how to choose rivets for a riveter, then you can use a special table of electrochemical potential. The effect of moisture will be on the more electronegative material.

When choosing a material, the following features must be taken into account:

- Ideally, choose an electropositive material for the rivet itself, so that corrosion occurs on an element that can be easily replaced;

- check compatibility using the electrochemical potential table;

- use a dielectric barrier, such as a gasket.

When purchasing rivets, it is also worth considering the operating temperature of the finished product. The fastener material and product must be matched to ensure the same thermal expansion as the temperature rises and falls. Ignoring the selection rules may lead to premature rust or other damage.

In addition to the basic elements, there are coated rivets. Powder paint is used for this, and the shade corresponds to the RAL color chart.

Metal riveting

The process of riveting metals consists of two stages: preparatory and the actual installation of hardware. Preparation - drilling holes, if necessary, countersinking for countersunk heads

Please note that countersunk heads can be on one (either) side or on both

The riveting process itself is as follows:

- insert the rivet;

- tighten the parts to be connected;

- form a closing head using a tool;

- check and clean the connection.

This is how blind rivets are installed

With a good tool, work goes quickly. For private use and one-time work, manual riveters are usually used. And even with them, the process itself (without drilling holes) takes a matter of seconds. If we talk about installing corrugated sheets or metal tiles, it is recommended to coat each hole made with paint to prevent corrosion. It is these processes - drilling and painting - that take a lot of time.

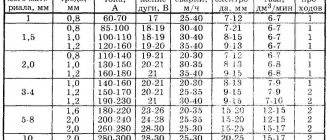

In general, there are two ways to install rivets: cold and hot. When hot, the joint is preheated to a certain temperature (determined by the metal and the thickness of the parts). In practice, it is used when installing rivets of large diameter - 12 mm or more.

The rivets are placed in rows. The minimum distance between adjacent ones is 4 diameters; from the edge of the sheet to the center of the hardware is no less than 1.5 times the diameter of the rivet. When attaching a profiled sheet, place it in a recess, not in a wave.

Advantages and disadvantages

Today, rivets are considered a universal fastener that provides reliable fastening of sheet materials. In addition, hardware has a number of other advantages.

Advantages of metal rivets:

- the connection is resistant to strong mechanical loads, vibration and shock;

- the possibility of durable fastening in places where it is impossible to use threaded options or welding equipment;

- Blind and threaded rivets are easy to install;

- A wide choice of materials reduces the risk of corrosion.

Disadvantages of rivets:

- the need to purchase special equipment for installation - a riveter;

- if the diameter of the hole and the rivet are not matched, the strength of the connection is weakened;

- impossibility of end-to-end connection without the use of additional pads;

- noisy installation of options with a closing head.

At the same time, the disadvantages of metal rivets are not always a contradictory factor. The noise can be tolerated, and overlapping installation is one of many options for assembling the structure.

APPLICATION OF RIVET CONNECTIONS

Riveted joints are used in structures that can withstand large vibration and repeated loads, with small thicknesses of the parts being connected, as well as for connecting parts made of non-weldable materials and those that do not allow welding due to warping or tempering of thermally shaped parts.

This joining method is most effective when applied to sheet and profile products. Moreover, in some cases this type of connection is the only possible one.

In modern industry, permanent connections of parts are usually made by welding, soldering, riveting, and gluing. Each of these processes has its own advantages and disadvantages. The most widely used method is welding. However, it is not always possible to connect dissimilar metals and coated metals by welding; during welding, warping of the parts being connected occurs, welding seams are sensitive to variable loads, and the thermal effect of the weld weakens the strength of the parts. These welding disadvantages are successfully overcome by the newest method of fastening materials - single-sided riveting.

ADVANTAGES OF SINGLE-SIDED RIVETING

- Low labor intensity.

- Easy to use and install.

- High quality connection.

- Easy maintenance.

- Possibility of installing prepared (painted or coated) parts and assemblies.

- Possibility of installation with access from only one side.

- High degree of automation.

AREAS OF USE

- Automotive industry and car service.

- Transport construction.

- Aircraft manufacturing.

- Climate control and ventilation.

- Furniture industry.

- Construction and installation of various structures and structures.

- Electrical industry and electronics.

- Food industry.

- Mechanical engineering.

- Production of consumer goods, etc.

Rivet material

Depending on the material from which the rivets are made, the strength and reliability of the connection will differ. The most common options:

- aluminum. Such fasteners can reduce installation costs and, moreover, this material is fireproof (therefore, aluminum rivets are used in air ducts; when aluminum is struck by foreign objects or debris, a spark does not occur);

- stainless steel. In addition to reducing the risk of corrosion, they have high strength;

- galvanized hardware. Suitable for attaching sheet materials to other structures, for example, during the installation of gutters or metal fences.

How to choose types of rivets for a riveter

The first aspect is the material of manufacture. Products made from aluminum are used to provide connections between objects with increased protection against corrosion. Such elements are durable.

Brass rivets are used to secure the grounding system in panels and other objects that are used to transmit current. Stainless steel rivets are used in the food and chemical industries. Distinctive features: highest corrosion resistance, enhanced fixation.

The second aspect is length. A rivet that is too short will not provide a proper connection. A rod that is too long will look unflattering and impractical.

Diameter and length

Of course, if we are talking about the independent use of rivets at home, then turning to GOST standards will be unnecessary. It’s another matter if this fastener is used in production. Regulation of the size of blind rivets to create unbreakable connections is indicated in the standards:

- GOST R ISO 15974-2005 and GOST R ISO 15973-2005 - standards for blind rivets;

- GOST R ISO 15979-2017 - blind rivet standard steel/steel side;

- GOST R ISO 15977-2017 - blind rivet standard aluminum/steel flange;

- GOST R ISO 15980-2017 - blind rivet steel/steel;

- GOST R ISO 15981-2017 - blind rivet standard aluminum/aluminum side;

- GOST R ISO 15978-2017 - blind rivet aluminum/steel;

- GOST R ISO 14488-2005 – description of the standard for “blind” rivets.

Purpose

Blind rivets are used to connect sheet material and require access to the working surface from only one side. This is one of their main differences from traditional “hammer” models. The rivets are installed into the drilled hole using a special tool, which can be either manual or pneumoelectric. Connections made using blind rivets are very strong and durable. In addition, the parts are easy to install and are highly resistant to aggressive chemicals, high temperatures and humidity.

Due to their versatility and reliability, the scope of application of blind rivets is quite wide. The parts are actively used in shipbuilding, aircraft and mechanical engineering, textile industry and construction. When working on high-risk objects, rivets act as an alternative to welding joints. In addition, rivets are widely used in the repair of parts and mechanisms in hard-to-reach places and fire-hazardous objects. In addition to connecting elements made of ferrous and non-ferrous metals, blind rivets are capable of connecting plastic and textiles in any combination. This allows them to be widely used in electrical work and actively used in the manufacture of clothing, consumer textiles and tanks.

Installation

Installation of blind rivets is so simple that it does not cause difficulties even for beginners.

The only prerequisite for installation is the presence of a riveting tool and compliance with the sequence of work.

- The first step will be to apply markings on the front side of the upper part to be connected. The distance between two adjacent rivets should not be less than five diameters of their heads.

- Drilling holes should be carried out taking into account a small allowance.

- Deburring is performed on both sides of each part. If access to the closed side is limited, deburring it can be neglected.

- The blind rivet must be installed in such a way that the shank is on the front side.

- Grasping the rod with a riveter and working with a pneumatic gun should be done smoothly and with sufficient force at the same time.

- The remaining part of the rod, if necessary, is cut off or bitten off with pliers. In case of a carelessly broken rod, the head can be processed with a file.