In shape and appearance, the product resembles a small compressed washer. It is used in the industrial and construction fields. A self-tapping screw with a press washer has many advantages compared to other types of fixing structures. It should be used according to the rules.

What is a self-tapping screw with a press washer?

The type of product under consideration is a washer with a large working area. This ensures better fastening of the individual sheet elements. A galvanized self-tapping screw with a press washer is excellent for structures that have a fragile structure. A regular washer may fall into the material during operation. There is a risk that the same problem will arise when screwing in a regular self-tapping screw. The press washer creates a uniform load on the material and prevents the bolt head from sinking into the material.

Characteristics of self-tapping screws with a press washer

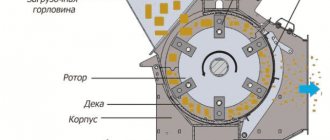

Fixing elements are usually made of steel. They are coated on top with a thin layer of zinc. The roofing self-tapping screw has the shape of a hemisphere, and its press washer is placed on the back side of the tool. It differs from a conventional fastener in its scope of application. Self-tapping screws with a press washer have a tip shaped like a drill and can easily make holes in steel sheets.

Self-tapping screws with a washer not only do not sink into soft materials, but also ensure their better fixation to each other. With their help, the time required to carry out certain types of work is reduced. When working with self-tapping screws, it is not necessary to use a drill, especially if the hole width does not exceed 2 mm. You can also do without additional devices in cases where the recesses are already present in the material.

Features of self-tapping screws with drill

Self-tapping screws with drills are often used as fixing parts for metal structures. They make it more durable and as strong as possible. Thanks to them, the metal sheets are tightly fastened together.

During the manufacturing process, a special protective coating is applied to the screws. Because of this, the process of corrosion formation is prevented. Most often this is a galvanized version.

The quality requirements for these products are set out in GOST 11650-80.

The design of each such self-tapping screw has three main parts:

- Pointed tip;

- Full length thread;

- The cap is a support that prevents the part from going too deep into the material.

Using self-tapping screws with a press washer

Products are often used for fastening thin metal plates. They are especially in demand when installing profile sheets. There are other areas where metal self-tapping screws with a press washer are used:

- internal construction work (installation of metal sheathing);

- fastening of individual elements on sandwich panels;

- construction of window and door slopes;

- installation of ventilation systems;

- installation of load-bearing barriers with metal support elements

All of the above areas occupy a significant share of construction, so the importance of self-tapping screws with press washers in this industry is very great. With their help, you can fasten plates up to 0.9 mm thick. If the sheets are thicker than 0.2 mm, then in addition to the fixing elements, will you also need a screwdriver, screwdriver or electric drill with a suitable attachment to perform fastening?

What types of self-tapping screws with a press washer are there?

Products are divided into 2 types: sharp and with a drill. They differ in the type of tip. The sharp type is used as wood screws and a drill. In terms of technical characteristics, they are not much different from standard fasteners. Their rounded head is suitable for working with a screwdriver and screwdriver. Products with a drill are used for fastening metal sheets with a thickness of more than 0.9 mm.

Sharp self-tapping screw with press washer

The products are highly durable because high-carbon steel is used in their production. They are coated with zinc, which protects the self-tapping screw from destruction and rust. On the head of the element there is a cross-shaped pin. It is necessary so that, if necessary, you can use a screwdriver.

For woodworking, a sharp, painted self-tapping screw with a press washer is often used. It reliably fixes the work surface with sheet materials. The design looks aesthetically pleasing, as the brown self-tapping screws with a press washer look inconspicuous against the background of the wood. Products are sold not individually, but by weight. For 1 kg of sharp screws you need to pay about $2.

Self-tapping screw with press washer and drill

This type differs from the previously discussed mainly in areas of application. A self-tapping screw with a drill is manufactured exclusively for working with metal materials. Instead of a tip, like sharp fasteners, this type has a small drill. Such products are made from stronger layers of steel, because when drilling metal they are subject to a greater load than when working with other types of materials.

The self-tapping screw head with a press washer and drill is the same as for the sharp type of product. It can have not only a cruciform, but also a hexagonal shape, because it bears a large load. Self-tapping screws with a drill can be secured in different ways: manually, with a drill or screwdriver, or with a wrench. They can be used to fasten metal sheets exceeding 2 mm in thickness. The price of products of this type is $3-4 per kg.

Sharp self-tapping screws for metal with a press washer

The main material from which they are made is high-strength carbon steel. Moreover, during the production process, a small layer of zinc is applied to this tool, protecting it from rust and other negative environmental influences. Thus, this self-tapping screw with a press washer is very durable, reliable and resistant to corrosion. The head (that is, the cap) of this tool has a hemispherical shape, under which there is a welded press washer. The pin of such a self-tapping screw is most often cross-shaped.

Where is the hemispherical self-tapping screw “press washer” used? Its main area of application is the installation of wooden structures and working with various wood materials. Thanks to the presence of a press washer, the device perfectly presses the sheet material to the surface being processed, thereby ensuring a reliable and high-quality connection. The result is a strong and durable structure. And even from an aesthetic point of view, it looks very attractive. That is why a sharp self-tapping screw with a press washer is a leader among its “brothers”.

How to choose a self-tapping screw with a press washer?

Among all the options available on the market, you need to choose a quality one. The strength of the fasteners and the reliability of the entire building structure will depend on this. Criteria that people pay attention to when buying a self-tapping screw with a press washer for metal:

- The color scheme of all elements in the batch. White self-tapping screws with a press washer should not have any other colors. Products of the same color in a batch undergo careful control during production.

- Self-tapping screw size. One element should not differ much from the rest in size.

- Same thread pitch.

- No burrs on the tip of the product. They interfere with its quality screwing.

- The presence of markings in the form of a capital letter. It indicates that the product was manufactured at the factory and meets the required standards.

The advantages of working with such products

A self-tapping screw with a press washer, the price of which varies between 100-200 rubles per kilogram, has a number of undeniable advantages. The use of such devices makes it possible to avoid pre-drilling holes in the surface of the workpiece. This provides significant savings in time spent on installation and protects the material from destruction due to excessive exposure. In addition, connections made using these devices are characterized by increased reliability and durability. This is due to the fact that the self-tapping screw with the press washer is quite resistant to corrosion.

Thanks to the presence of a press washer, a tighter fit of the materials being joined is achieved, and the thread makes it possible to almost completely eliminate spontaneous unscrewing of the self-tapping screw due to shaking or vibration.

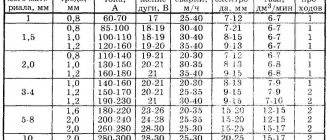

Dimensions of self-tapping screws with press washer

The range of products is presented in a wide range of colors. Thanks to this, you can choose the appropriate option for any type of construction work. Stainless steel self-tapping screws with a press washer are produced in strictly defined sizes. They depend on the type of product and the purpose of its use:

- Fasteners with sharp tips have dimensions from 4.2x13 mm to 4.2x76 mm. The weight of 1000 units with the smallest dimensions is 1.4 kg, and with the maximum – 5.1 kg.

- Self-tapping screws with a drill are available in a standard diameter of 4.2 mm. Their length varies from 13 to 76 mm. The weight of 1000 minimum weight units is 1.75 kg, and the largest ones are 5.7 kg.

Dimensions

The standard sizes of wood screws are different for each variety.

Phosphated, with countersunk heads and cross slots

| Diameter, mm | Length, mm |

| 3,5 | 16 |

| 19 | |

| 25 | |

| 32 | |

| 35 | |

| 41 | |

| 45 | |

| 51 | |

| 55 | |

| 3,8 | 64 |

| 70 | |

| 4,2 | 70 |

| 76 | |

| 89 | |

| 4,8 | 89 |

| 95 | |

| 102 | |

| 127 | |

| 152 |

These products are most in demand during repairs.

Yellow and white with countersunk heads and cross slot

| Diameter, mm | Length, mm |

| 3 | 12 – 40 |

| 3,5 | 12 – 50 |

| 4 | 12 – 70 |

| 4,5 | 16 – 80 |

| 5 | 20 – 120 |

| 6 | 30 – 200 |

With countersunk head and straight slot

Manufacturers indicate the dimensions of these products in a somewhat unusual way: for them, the diameter of the head and the self-tapping screw are given separately.

Diameters can be combined in the following options:

- 16*8;

- 12*6;

- 10*5;

- 9*4,5;

- 8*4;

- 7*3,5;

- 6*3;

- 5*2,5;

- 4*2;

- 3,2*1,6.

Straight slot fastener.

Hex head

The longest wood screws fall into this category. Here is a list of standard sizes of fasteners:

| Diameter, mm | Length, mm |

| 5 | 30 |

| 6 | 30 – 150 |

| 8 | 35 – 200 |

| 10 | 40 – 260 |

| 12 | 100 – 300 |

Wood self-tapping screws 200 mm with a hex head can be used to assemble the rafter system and attach the logs to the beams.

With press washer

The maximum dimensions of self-tapping screws with a press washer for wood are relatively small due to the specifics of their application: they are intended primarily for fastening thin sheet materials to a wooden base.

As a rule, they are produced with a zinc coating.

| Diameter, mm | Length, mm |

| 4,2 | 13 |

| 14 | |

| 16 | |

| 19 | |

| 25 | |

| 32 | |

| 41 | |

| 51 | |

| 75 |